gkharrin

Members-

Posts

93 -

Joined

-

Last visited

About gkharrin

- Birthday 09/17/1967

Contact Methods

-

Website URL

https://www.hrsms.org/Content/models/?type=model&filter_rel_modeler=233

Profile Information

-

Gender

Male

-

Location

Newport News, Virginia, USA

-

Interests

Traditional working boats, steam tugs, early 20th century coasters, late 19th century warships

-

FreekS reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

FreekS reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

FreekS reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

FreekS reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

ccoyle reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

ccoyle reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

KeithAug reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

KeithAug reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

KeithAug reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

KeithAug reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

KeithAug reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

KeithAug reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

yvesvidal reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

yvesvidal reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

MAGIC's Craig reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

MAGIC's Craig reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

Siggi52 reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

Siggi52 reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

Dr PR reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

Dr PR reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

Since the last update, only 4 strakes added to port and 3 to starboard. That makes me 75% done with the hull, minus some touchups that will be needed at the end. Not much to show for 10 months, but I did have a really good summer, including 3 trips to Europe (the first since before COVID). The first of these was back to Denmark, which I think I last visited in 2008. I saw Christian Nielsen's model of this same boat (Christian Nielsen is the grandson of the builder, also named Christian Nielsen), revisted her sistership Viktoria in Roskilde, and even traveled to the small island of Fejø to see the workshop in which she was built. 100% done with the hull by New Year's Day?

- 24 replies

-

- De 13 Søskende

- sail

-

(and 5 more)

Tagged with:

-

It has been almost 2-1/2 years since I showed any progress. The model was set aside while I designed and built a new shop for my larger tools. The old shop was far too crowded, had poor light, and no heating or cooling. I did 99% of the work myself. A lot of things I did for the first time (including bending aluminum trim) and it took a lot of research to ensure I was doing it correctly and to code. I'm glad to say that project is finally finished. When the model was set aside, 5 of the 6 planks forming the 4th strake were in place. Since finishing the workshop about 3 months ago, I've only managed finish the 4th strake and add the 5th. As there are 10 strakes, this is a small milestone - half way through the planking. Most of these rivet heads shown here wiIl be covered by the deck, which is at the top of the 5th strake amidships and about the top of the 3rd at the stern post and forward end of the cabin. I included them as practice and also for the sake of construction photos such as these. I stopped adding the butt blocks. Some where never added because they interfered with the building jig. For the others, clamping the next plank in place sometime drove the faux rivet heads into the block. I'll add the rest when all the planking is complete. I know people for whom the hull is only a chore and the rigging is their true love. I am the opposite. I truly love a nicely formed hull, so I've spent a great deal of time to do the best job I can. I've fallen short of my own expectations (which did NOT include perfection), but I am not entirely displeased with the results so far. I don't mind learning from mistakes, but the bad part is that I repeat them too many times. My new favorite saying is "I never make the same mistake twice. I make it 4, 5,6 times, just to be certain." Worse than repeating mistakes is when I cannot figure out how the mistake occurred. The most painful mistake has been asymmetry of the planks at the ends. I measured and re-measured so many times I am flummoxed how this is occurring. I thought the problem might be cutting the gain too wide and later using it to line up the next plank, instead of using the next mark on the stem or stern post. You don't want the gain on the plank underneath exposed! But I know I did not cut them wide enough to account for the errors I have encountered. I was unwilling to replace the planks due to the risk of causing more harm than good, and the time it takes to shape a plank and add all the faux rivets. Some bad planks were not discovered until one or two more had been added. I resorted to scoring a curve along a spline clamped to the hull. The spline is aligned with the point it needs to be at the stem/stern and lies right along the plank edge starting a few scale feet away. This picture is exagerated - I never had to trim off quite that much. In a few cases where the offending plank had already been covered by others (no exposed edge), this effort resulted in a hole in the hull where it meets the stem or stern post. I repaired these with a putty made of wood glue and sawdust. I will use the same to fill in the gap left you can see above where the garboard strake meets the stern post - another dissappointment. I used dust from the same wood as the planks and it blends in rather well. It is still noticeable - I would say it detracts from rather than ruins the appeal. If I were leaving it natural, if not happy, I'd be at least satisfied with the results. It matters even less given the exterior will be painted and the repair will be covered up on the inside. So, not executed as hoped or planned, but acceptable. Those in my model club are chiding me for being too picky, but I feel I could do better and I think it is OK to strive for it. Onward we go.....

- 24 replies

-

- De 13 Søskende

- sail

-

(and 5 more)

Tagged with:

-

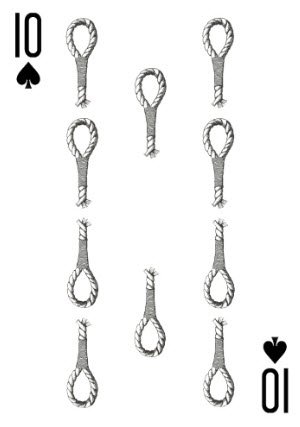

I see my post was moved to "Non-ship/categorised builds". I get that, because it closer to scrimshaw than a boat model. But when I looked at the rest of the posts in the category, I was dismayed my ship-themed item buried among dozens of plane and tank models. Why are those even on this site at all? At least mine is a ship. It was also changed to "finished", which isn't quite true. Not a problem. But as noted earlier, there are still a few details to add. This is the first of the belaying pin counting pegs.

-

I was certain I had compared them before, but as my memory is highly suspect, I double-checked. The dimensions of the web file and CD ROM files are the same. For example, 8415 x 6139 for the construction drawing of De 13 Søskende. More than adequate for building a model - you can see the grain of the paper.

- 24 replies

-

- De 13 Søskende

- sail

-

(and 5 more)

Tagged with:

-

gkharrin reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

gkharrin reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

gkharrin reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

gkharrin reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

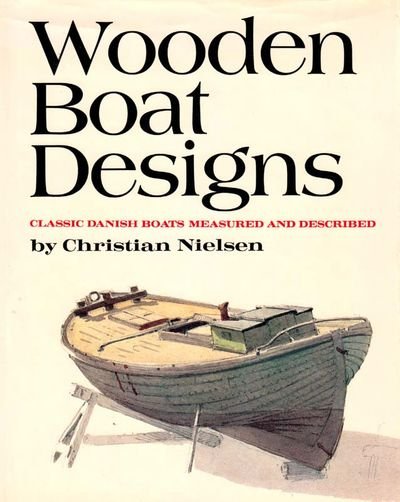

The sad thing is, I bought the book and decided to build the eel drifter. Years went by and a CD with high-res scans was made available. So I bought that too. More years went by, and now all of the drawings in that book can be downloaded for free from the Maritime Museum of Denmark. This includes the German drifter: Lines Sail plan Construction Maybe you already have these in your research. I'll search out your build log also.

- 24 replies

-

- De 13 Søskende

- sail

-

(and 5 more)

Tagged with:

-

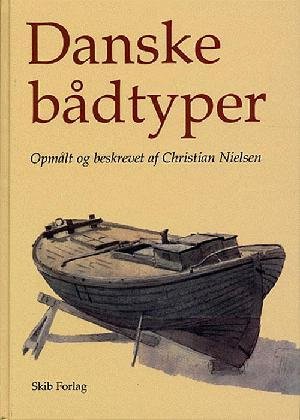

It most definitely is. I first learned of eel drifters from this book: All the boats are Danish, with one exception: it includes a German eel drifter for comparison to the Danish one. It specifically states the German boat design was adapted by the Danes. This article (same author) has the same information in somewhat greater detail. However, I'm sorry to say I think the Danish design is the more handsome one 😉

- 24 replies

-

- De 13 Søskende

- sail

-

(and 5 more)

Tagged with:

-

gkharrin reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

gkharrin reacted to a post in a topic:

De 13 Søskende 1911 (The 13 Siblings) by gkharrin - Scale 1:24 - Danish fishing smack

-

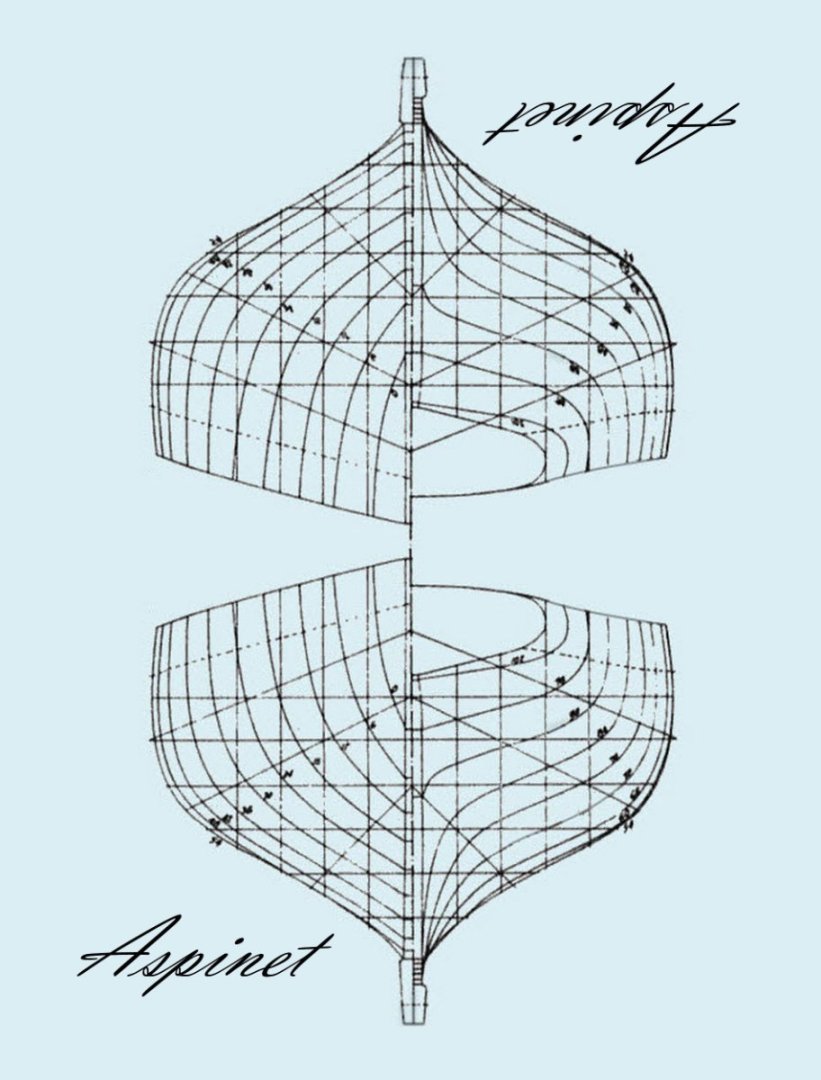

Yet to be done: Turn belaying pins to use as the counters, one set from brass and other of some white metal (aluminum, stainless?) Inlay some belaying pins or other decoration on the sides? Inlay the name "Aspinet" or add a brass plaque? If I inlay the name, I would carve it out and fill it with colored epoxy (after several trial runs). No way I could inlay script letters and I would not want blocky ones. The plaque would be safer.

-

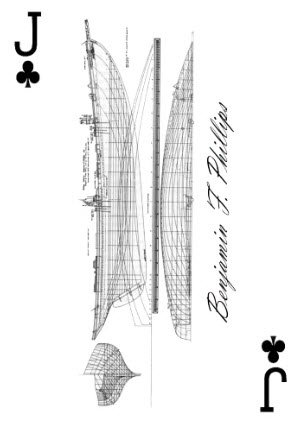

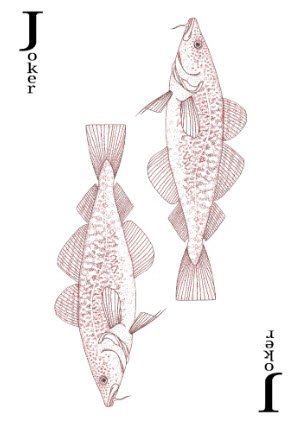

I had custom cards printed by youreondeck.com Backs are the body plan for Aspinet Spade pips are replaced by eye splices Diamond pips are replaced by rigging blocks Heart pips are replaced by .... hearts Club pips are are replaced by deadeyes Each face card is a different fishing schooner from Chapelle's book Though not used in cribbage, the jokers delivered with the poker deck may as well be custom. Since it fished the Grand Banks (or so I presume), I made them cod.

-

I am pretty disappointed with myself for over-sanding and over-estimating how far I was driving the holly into the grooves (as opposed to just crushing the top that got scraped and sanded away). The pieces that were driven in well are still nice and white. Those that were not got sanded too far, and the glue is making it look gray. However, most people said they like the effect (maybe just being kind), and I'm afraid that if I try to fix it at this point the cure will be worse than the disease.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.