-

Posts

843 -

Joined

-

Last visited

About pirozzi

- Birthday 01/01/1943

Contact Methods

-

MSN

pirozzi143@msn.com

Profile Information

-

Gender

Male

-

Location

Carson City, Nevada USA

-

Interests

Wood Ship Modelling. Tall Ships

Recent Profile Visitors

-

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

-

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

-

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

-

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

catopower reacted to a post in a topic:

HMS PRINCE by AMATI

-

catopower reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

catopower reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

AgesOfSail reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

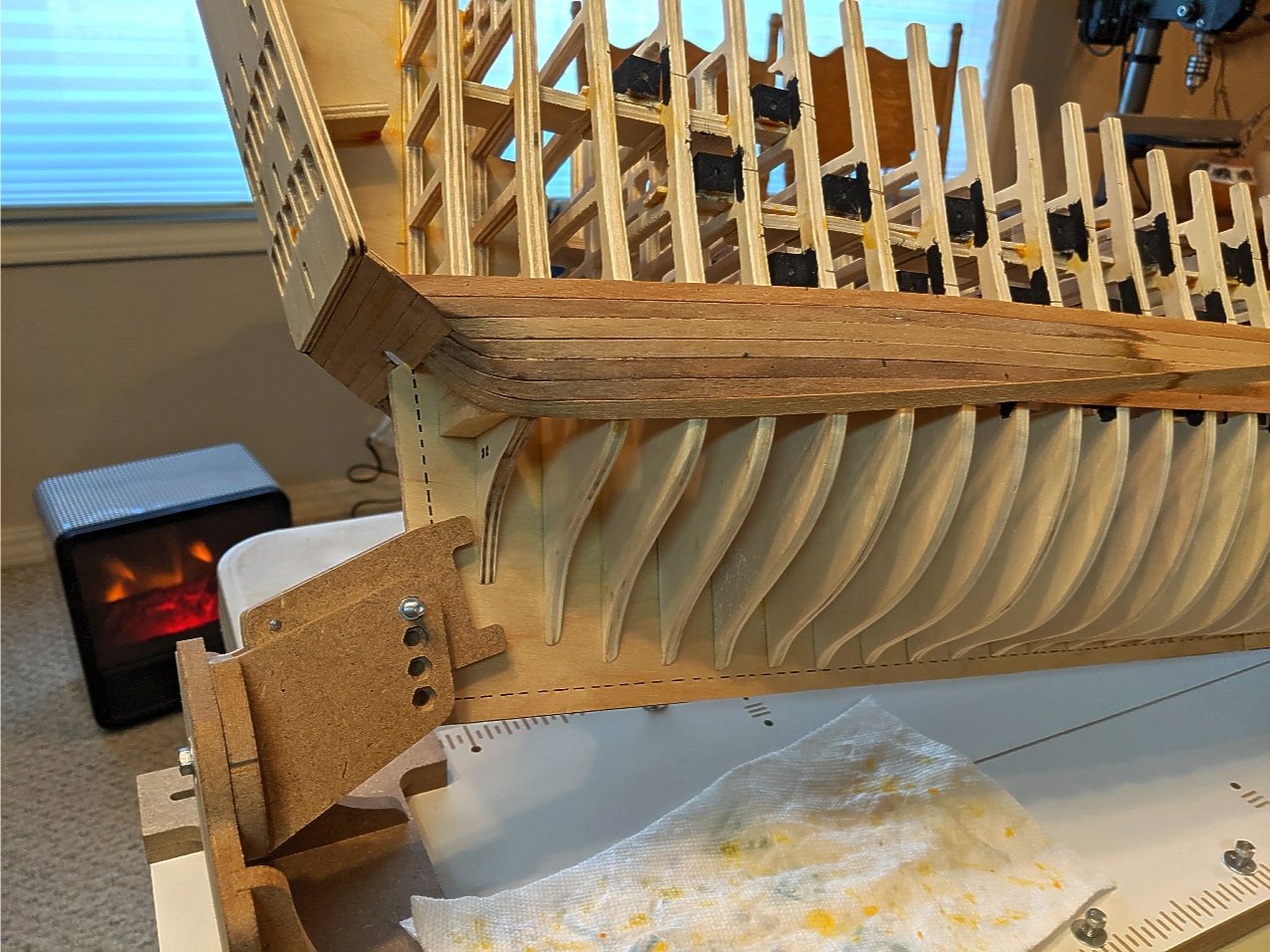

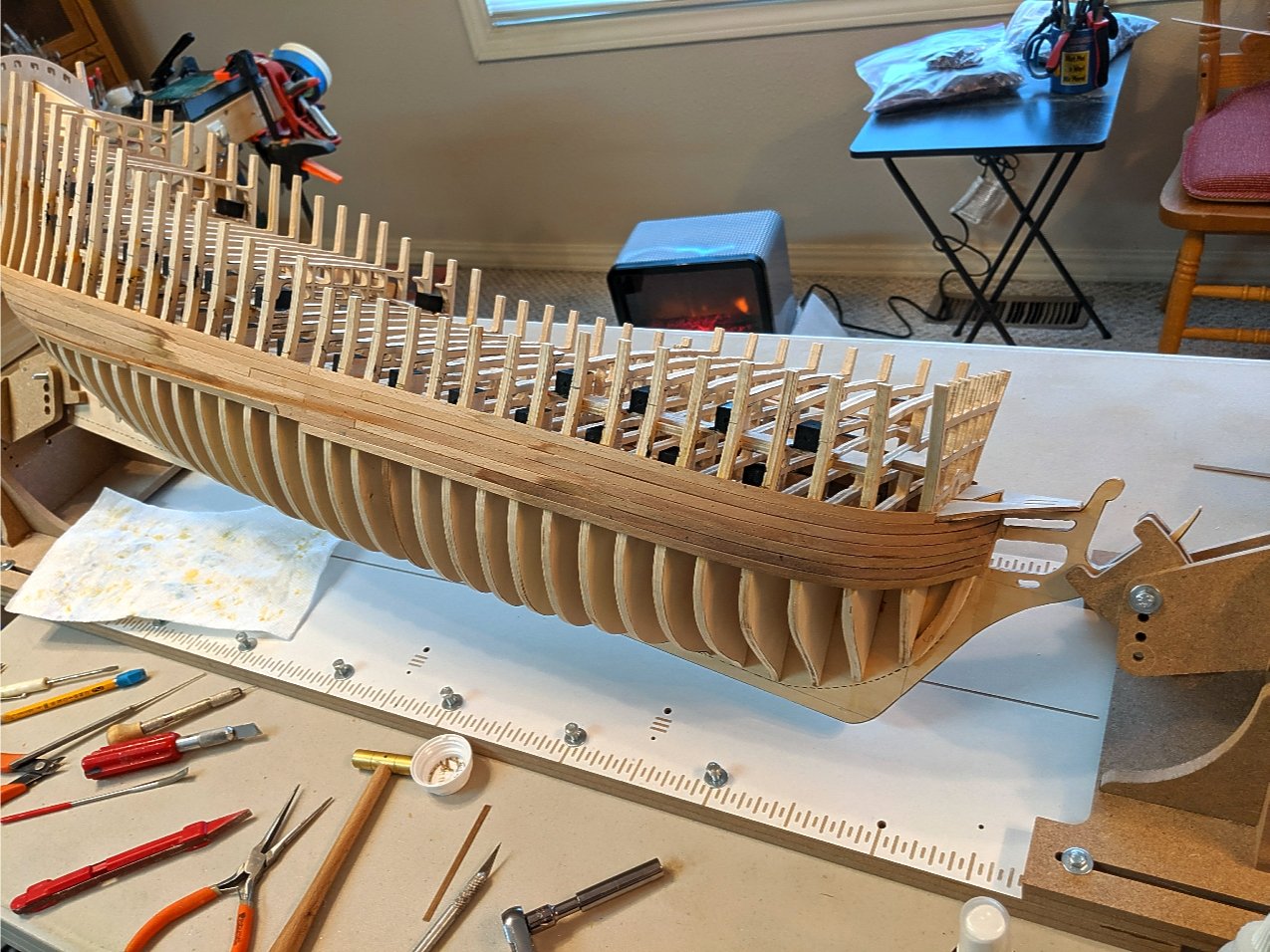

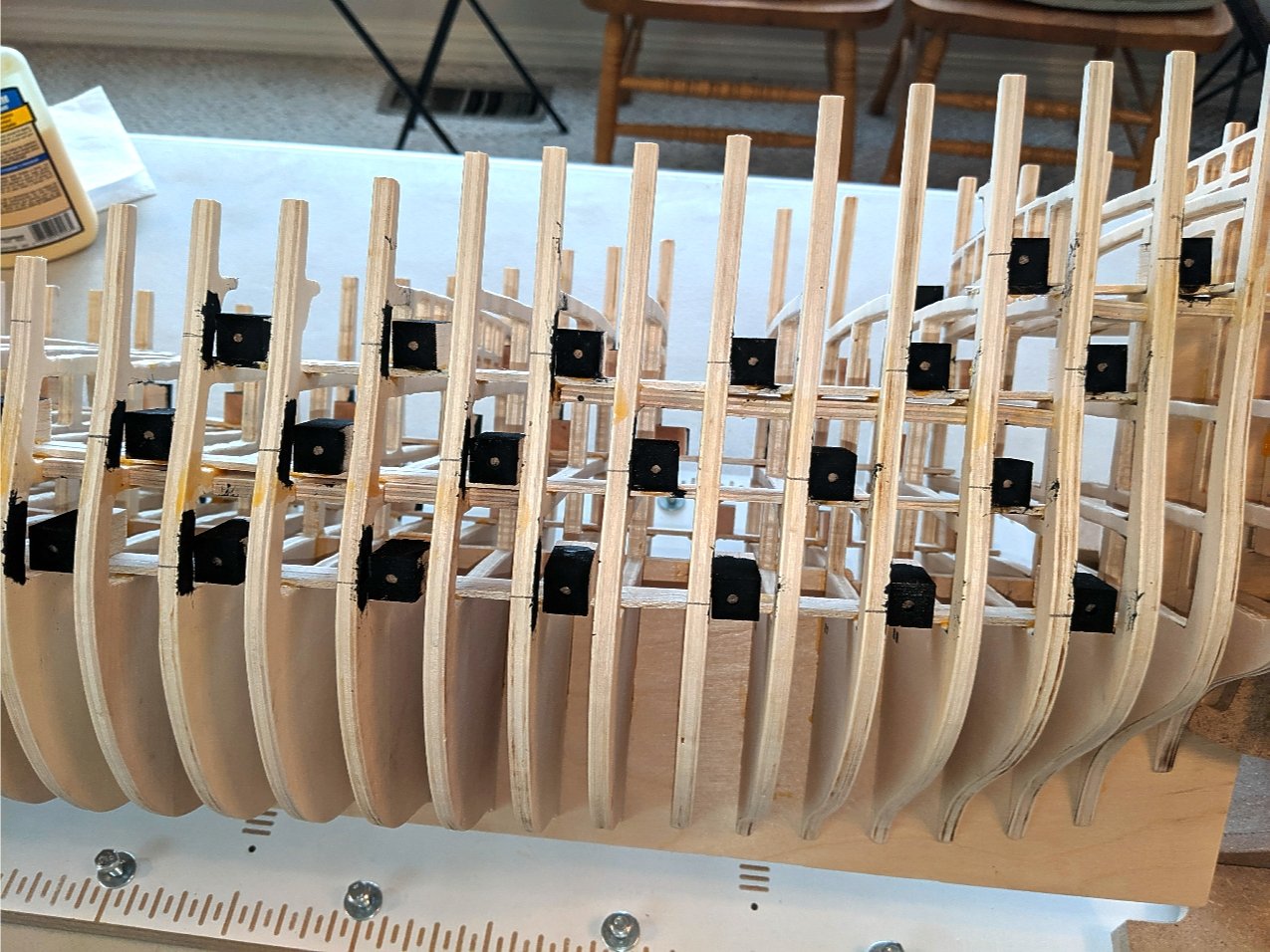

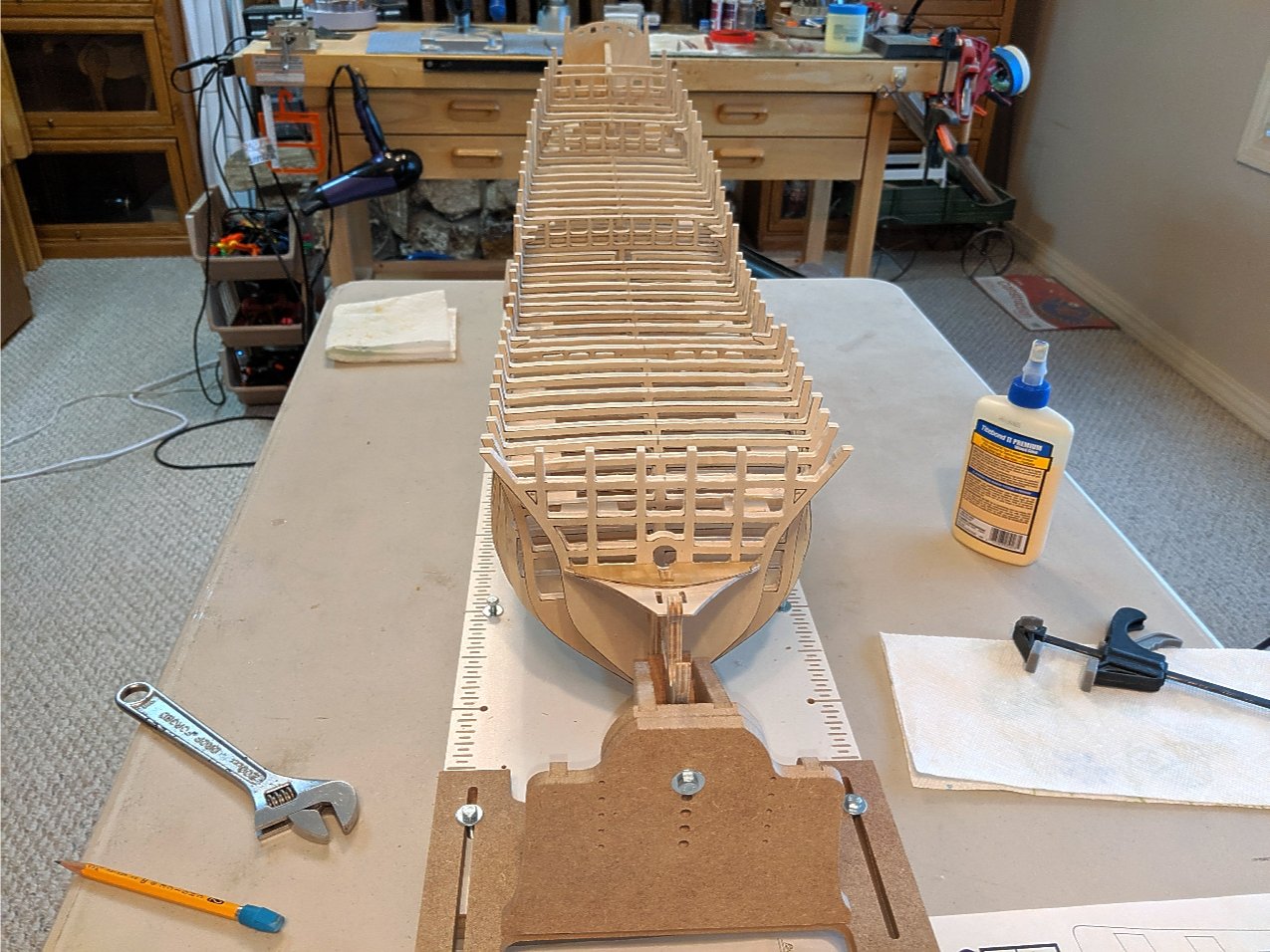

Hi Mates, Long time no see. Now that I am pretty much confined to the house because of this Corona virus epidemic, I have been putting more time into my build. I have finally finished the starboard side of the first planking layer. It was a monstrous job. Besides being a very large hull, the enormous amount of bulkheads requires constant adjustments of just about every bulkhead to get a fairly even and smooth run of the strakes. Even so, there are a few rough spots that will have to be smoothed out when placing the second finish layer of planking. I used little nails throughout to hold the planks until the glue dried and then pulled them out. For the second layer I will not have to use them because there will be a solid layer underneath to glue them to. I used PVA glue for most of the planking, except where the curves in the hull required holding. In those places I used medium thick CA glue and fast drying spray. I did not cut off the ends of the planks that hang over because I might need some extra when placing the decorations and strips to the bow and stern. Although you can't them, I did mark the locations of the gunports with little holes for cutting them out later. Hopefully I will post more quickly now. Vince P.

-

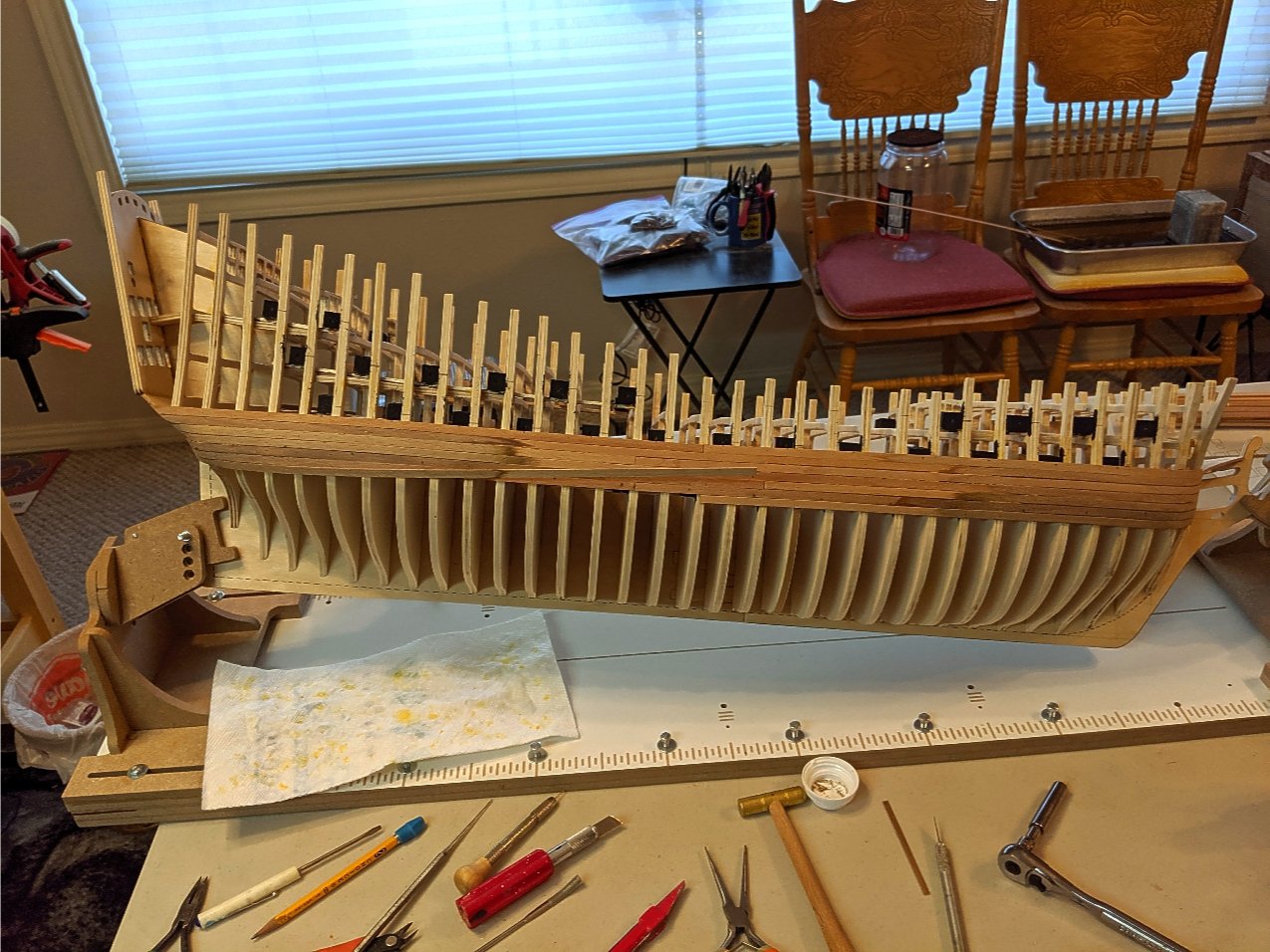

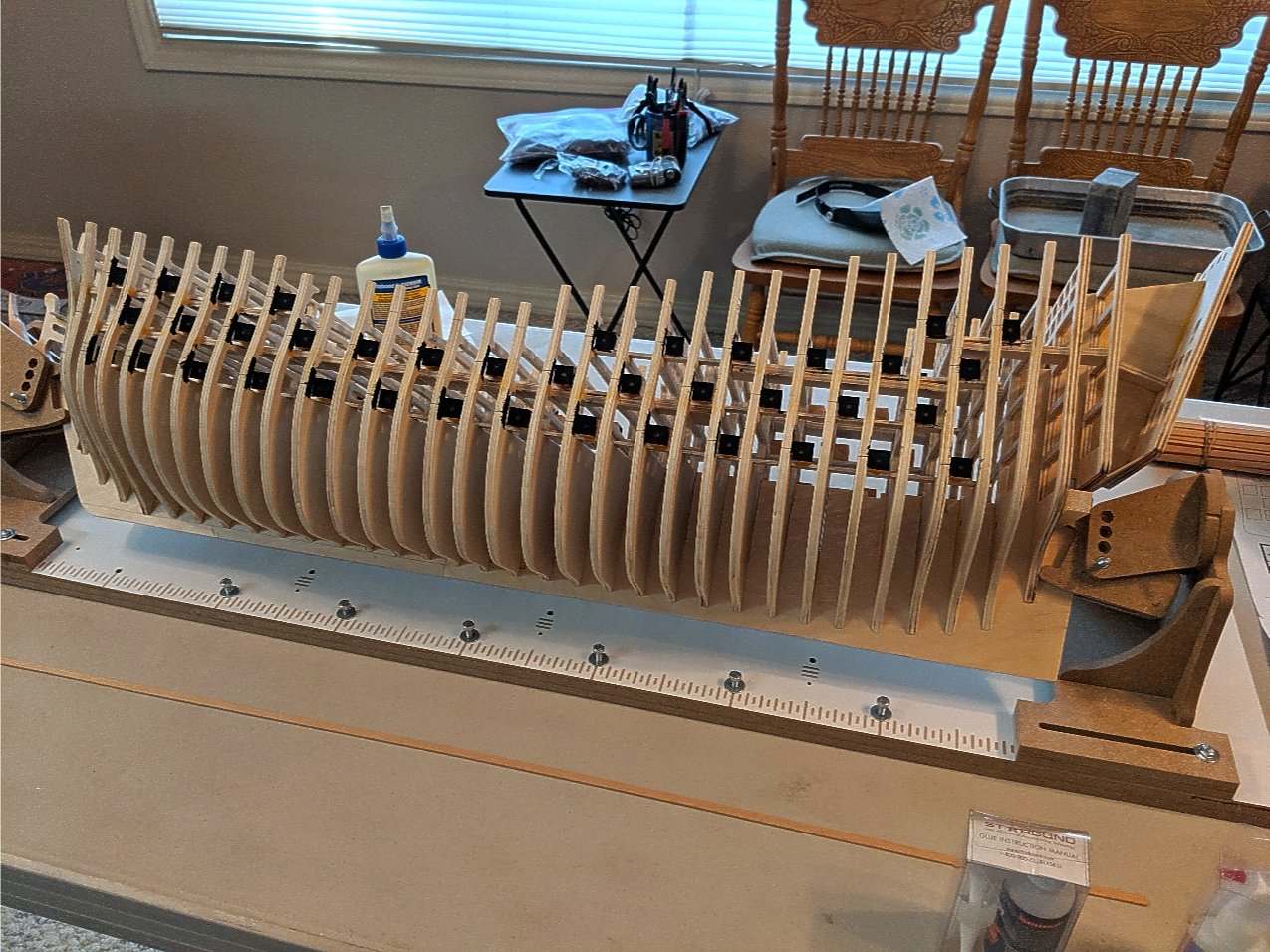

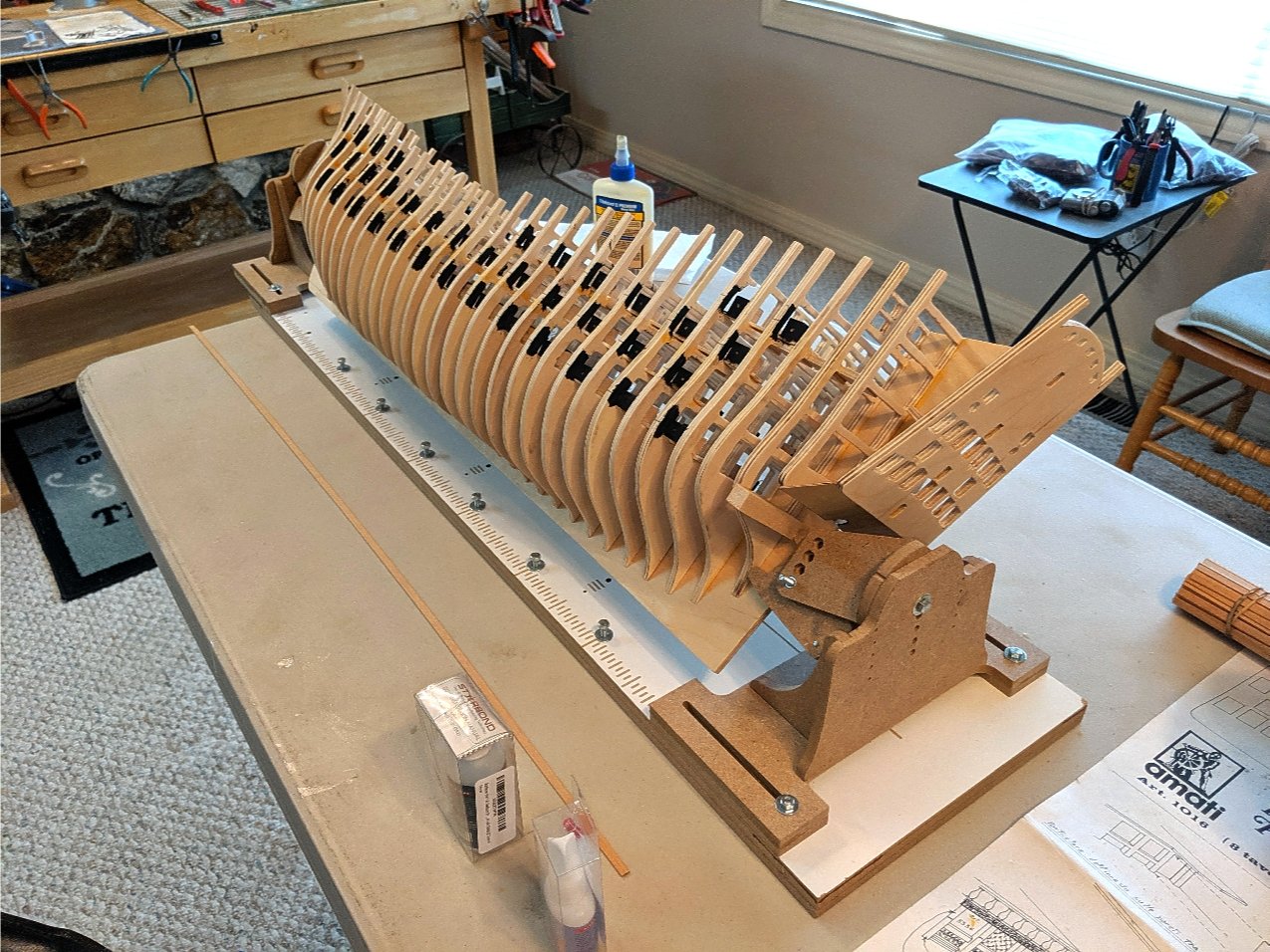

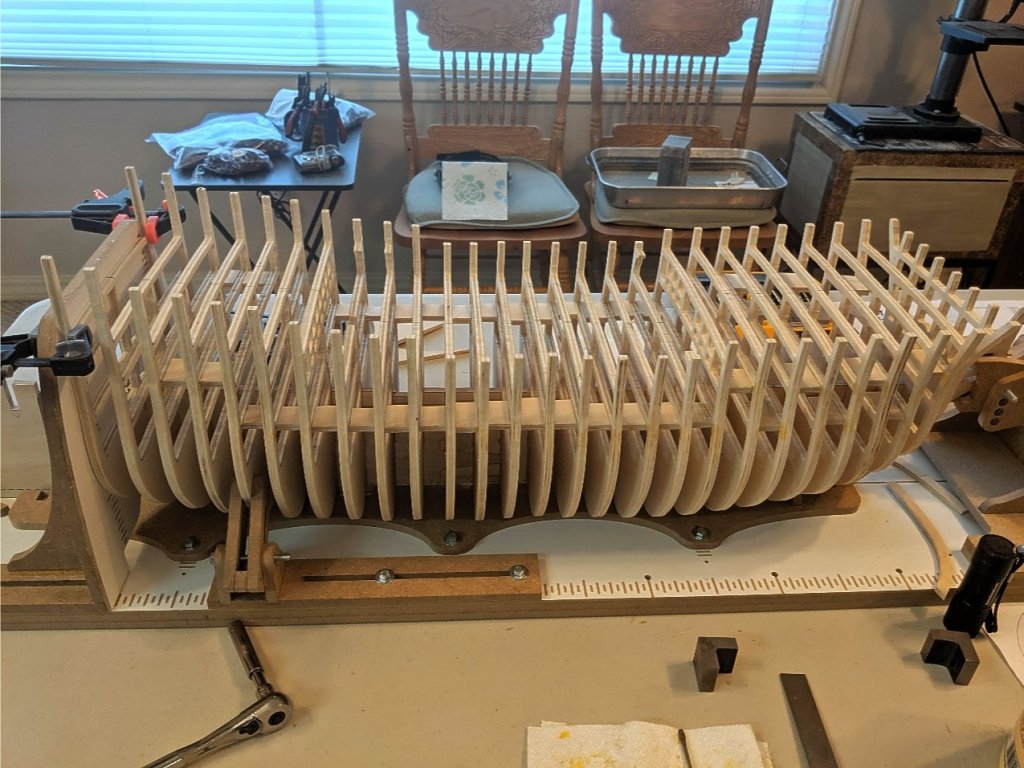

Started the first layer of planking. It is very slow going. Because of the large number of bulkheads, many have to be adjusted along the way to keep the flow of the planking as smooth as possible. There are still ripples that show and those will have to be corrected after the entire hull is planked and before the second layer is applied. Vince P.

-

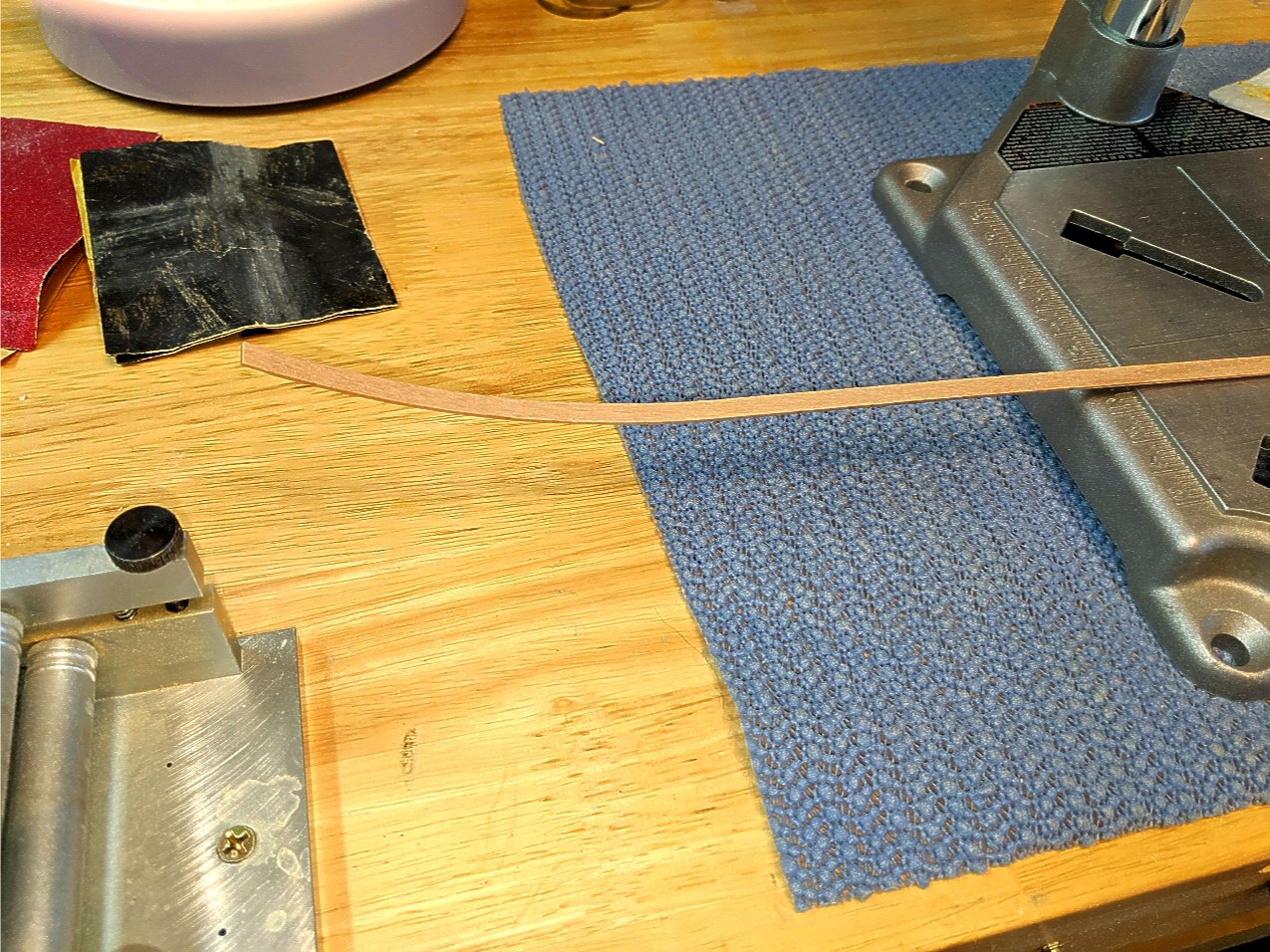

This little plank bender I bought years ago from MicroMark is one of the best tools ever. You can bend wood up to 3mm thick. The wood can be dry and cold. You just adjust the rollers to accommodate the thickness and the amount of arc you need. Just crank the handle. I have planked an entire ship with this. Vince P.

-

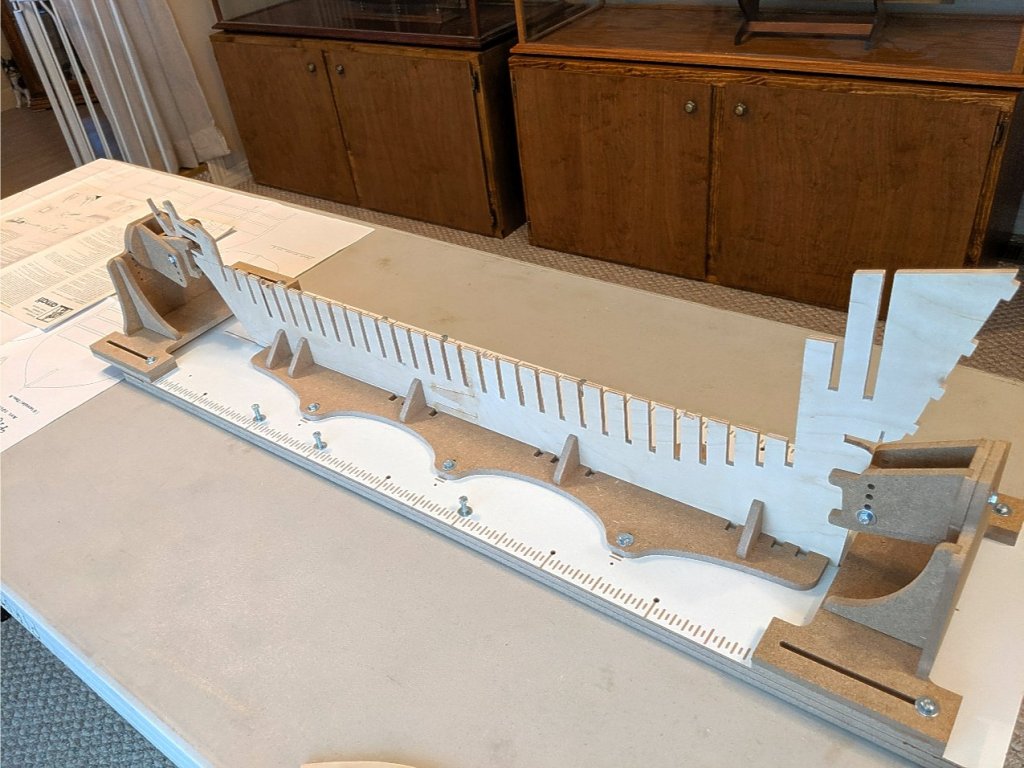

All of the gunports are located and the dummy gun blocks are placed. Locating the ports was fairly easy since they all butt up against a bulkhead. I added planks that follow the deck lines to mount the blocks to. I also noticed that if I want to keep most of the ports open with protruding gun barrels, there are not enough guns supplied. They figure on only having about half of them open. I do have a good supply of gun barrels that are similar in my stash. I will use those. Next up is to bevel the fore and aft bulkhead ends and begin the first layer of hull planking. A hull this size that also has a complex curved stern and a bluff bow will take a considerable time to plank. Vince P.

-

pirozzi reacted to a post in a topic:

USS Constitution by usedtosail - FINISHED - Model Shipways - scale 1/76

pirozzi reacted to a post in a topic:

USS Constitution by usedtosail - FINISHED - Model Shipways - scale 1/76

-

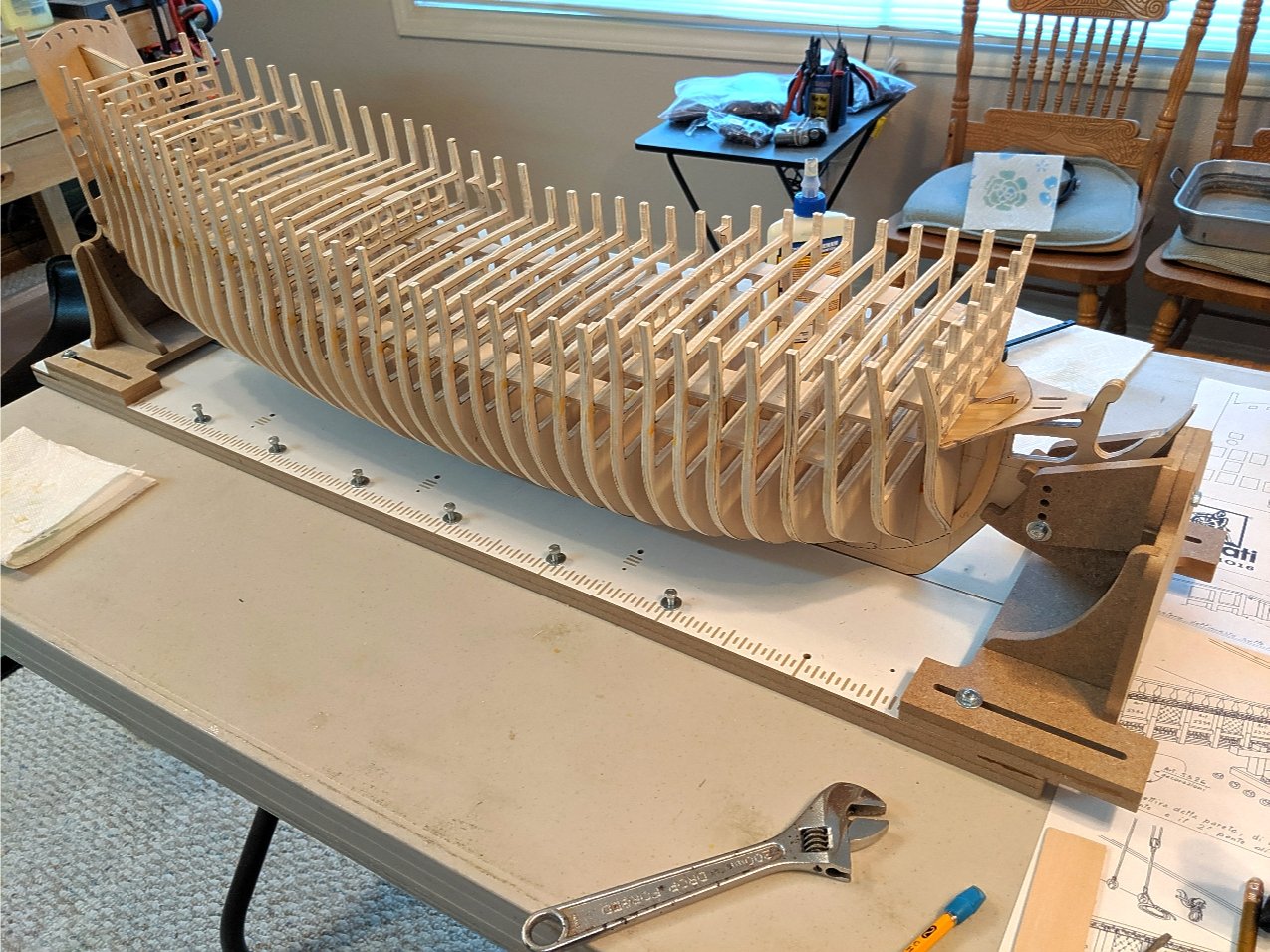

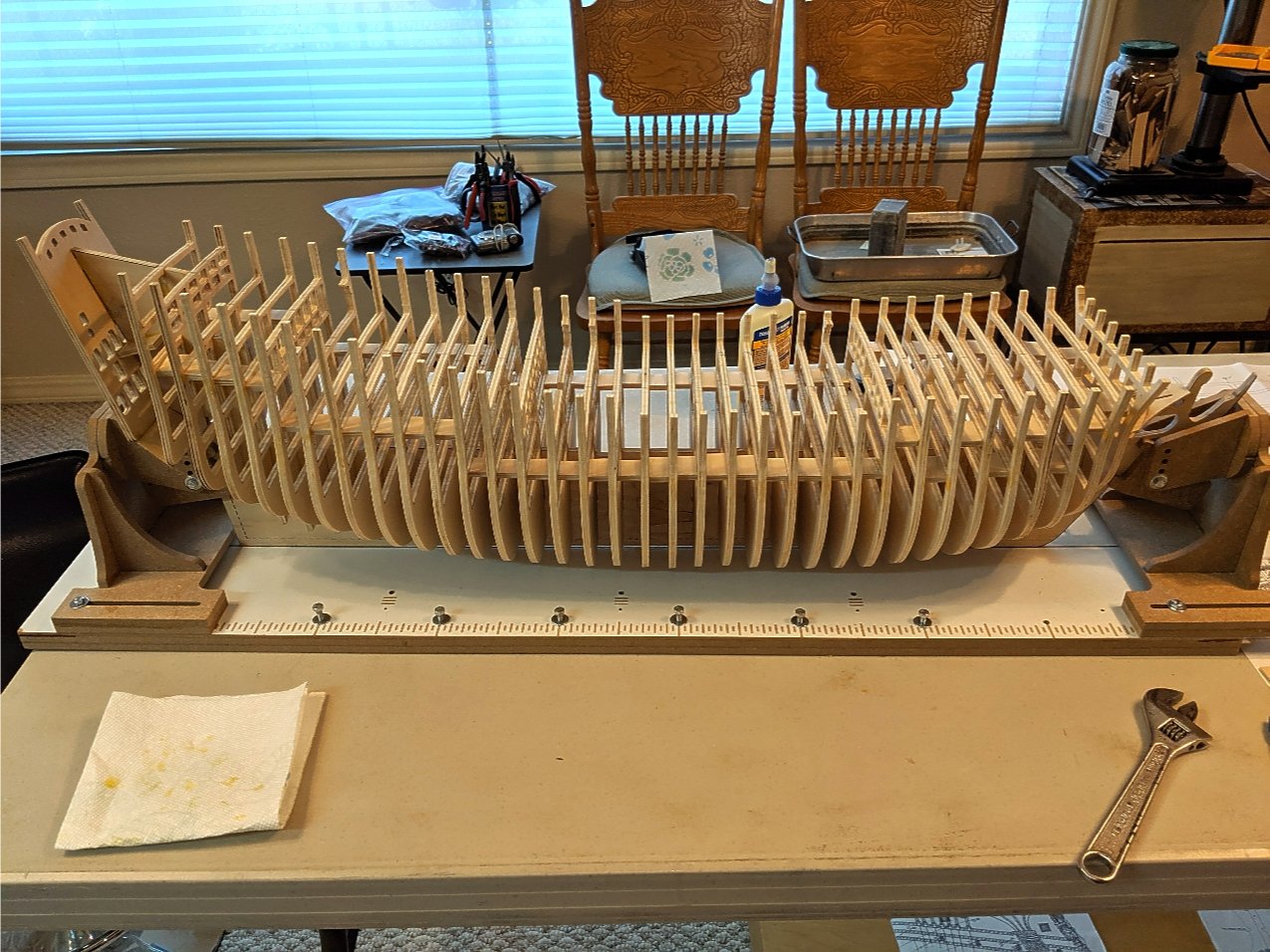

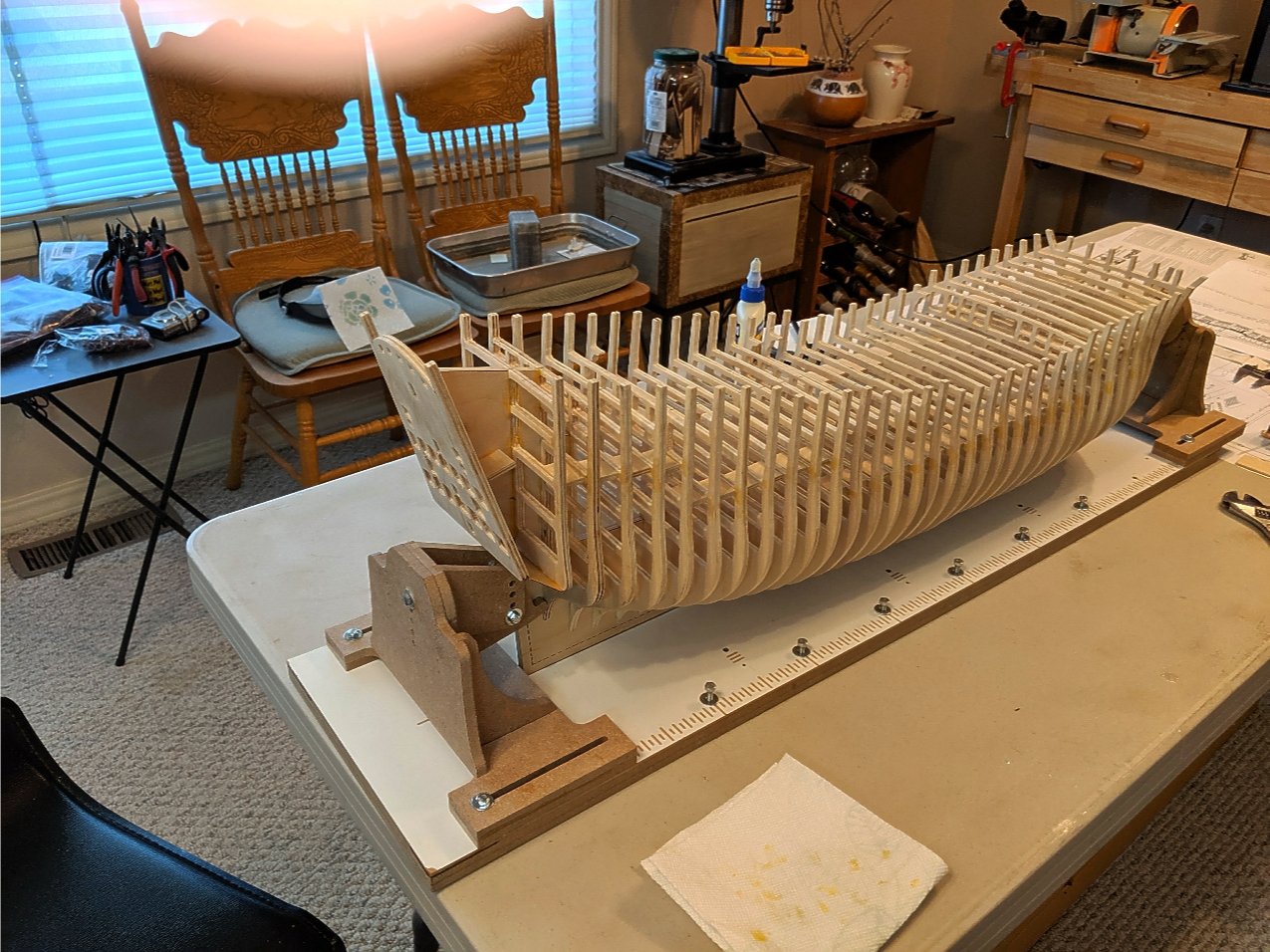

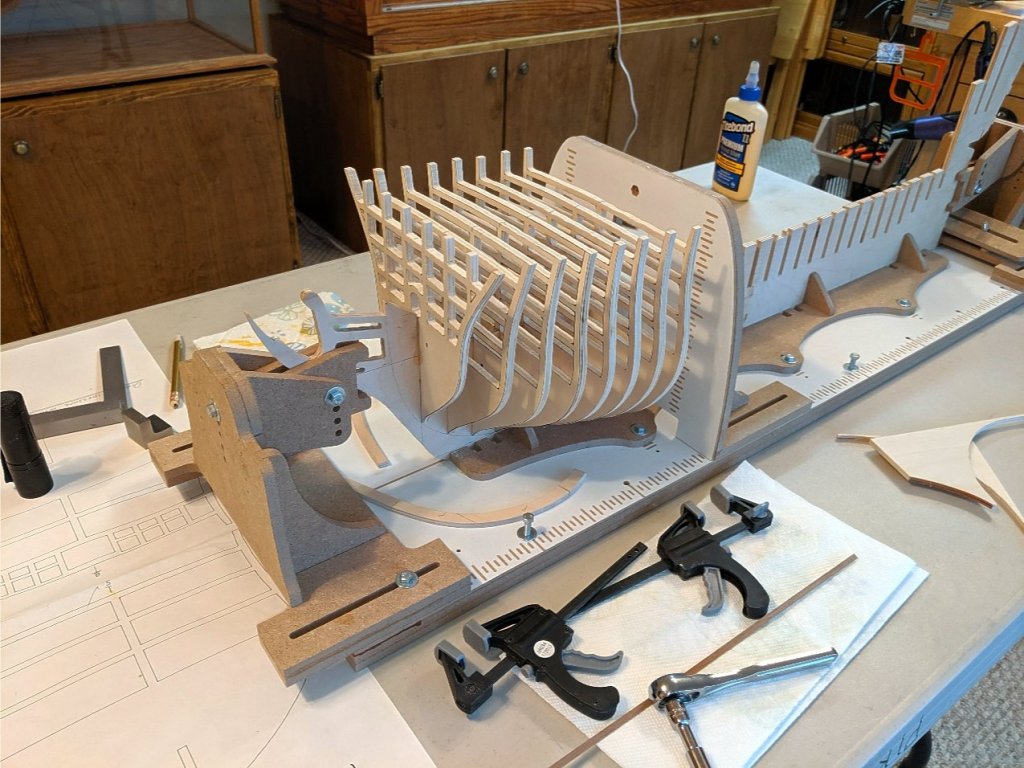

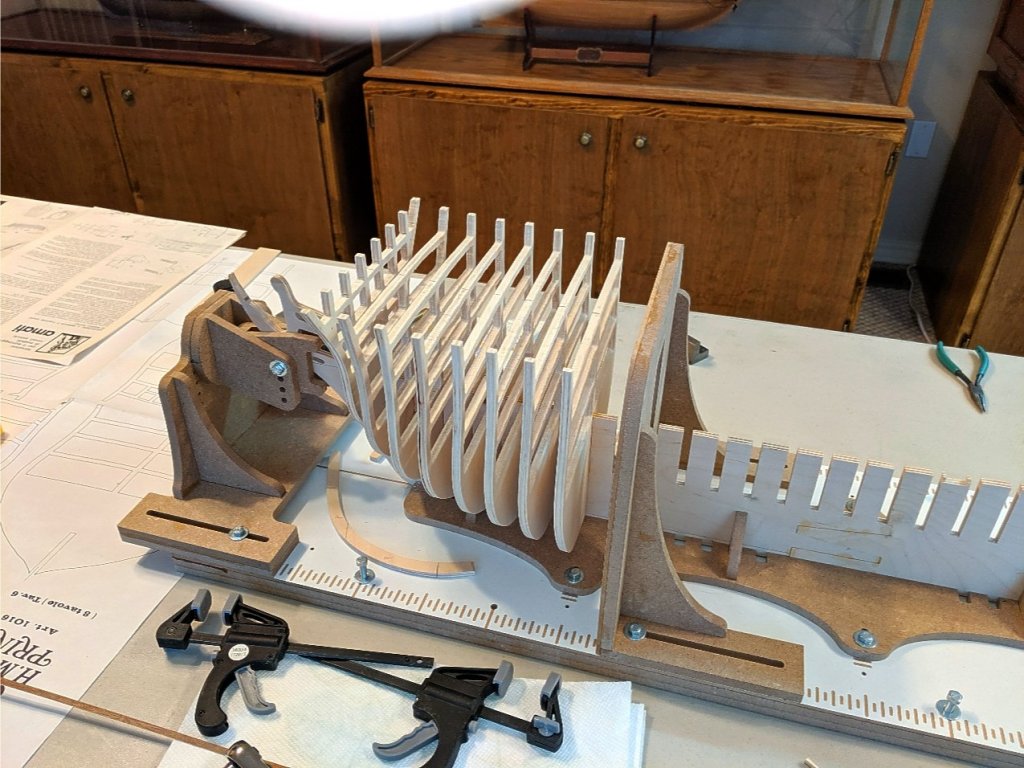

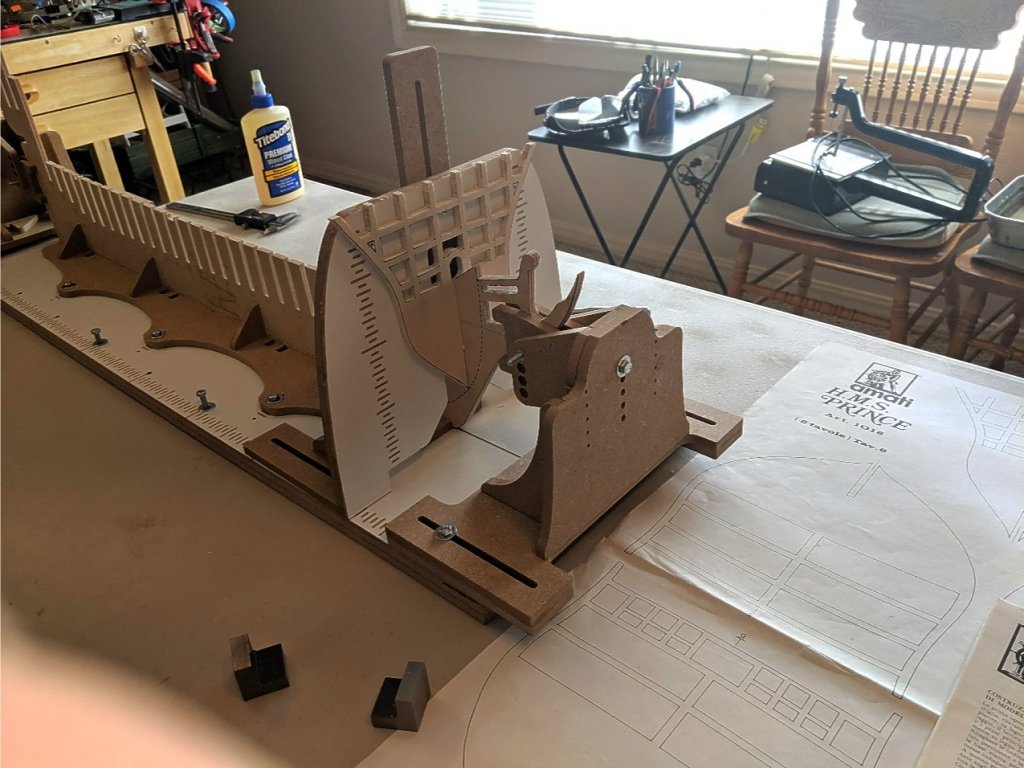

The framing is completed. The Birch plywood is pretty tough stuff. In making all of those cutouts I dulled 6 router blades and wore out a couple of collets. This building slip I am using is fantastic. The last photo shows that the whole hull can be rotated to facilitate planking and all of the hull construction without removing it from the slip. It appears that the entire model can be constructed while in the slip. I am contemplating on what is next. I think that the lower deck gun blocks must be created and inserted after marking the location of the gun ports. Since this model does not have actual lower decks, it would be impossible to place these blocks once the hull was planked. I am only guessing here, but I think this is the way to go. Vince P.

-

I am still working on the bulkheads. I have about 6 more to go. I found out the reason this kit has so many bulkheads which is about double of most kits. Since this kit will not have the lower decks installed even as false decks. The lower deck gun ports are located to butt up against each pair of bulkheads. This make locating them much easier and you don't have the problem of gunports locating right in the middle of a bulkhead. This problem was frequent in building the Royal William and resulted in closing those ports in order to not have to cut away some bulkheads. I am also placing some stabilizing boards between each pair of bulkheads both port and starboard to make the frame more rigid. It is so long and heavy that it flexes way too much. Once the upper decks are placed and the planking is done, that will also help. Vince P.

-

pirozzi reacted to a post in a topic:

HMS Prince 1670 by Captainhash - Constructo - Scale 1:61 - First wooden ship build

pirozzi reacted to a post in a topic:

HMS Prince 1670 by Captainhash - Constructo - Scale 1:61 - First wooden ship build

-

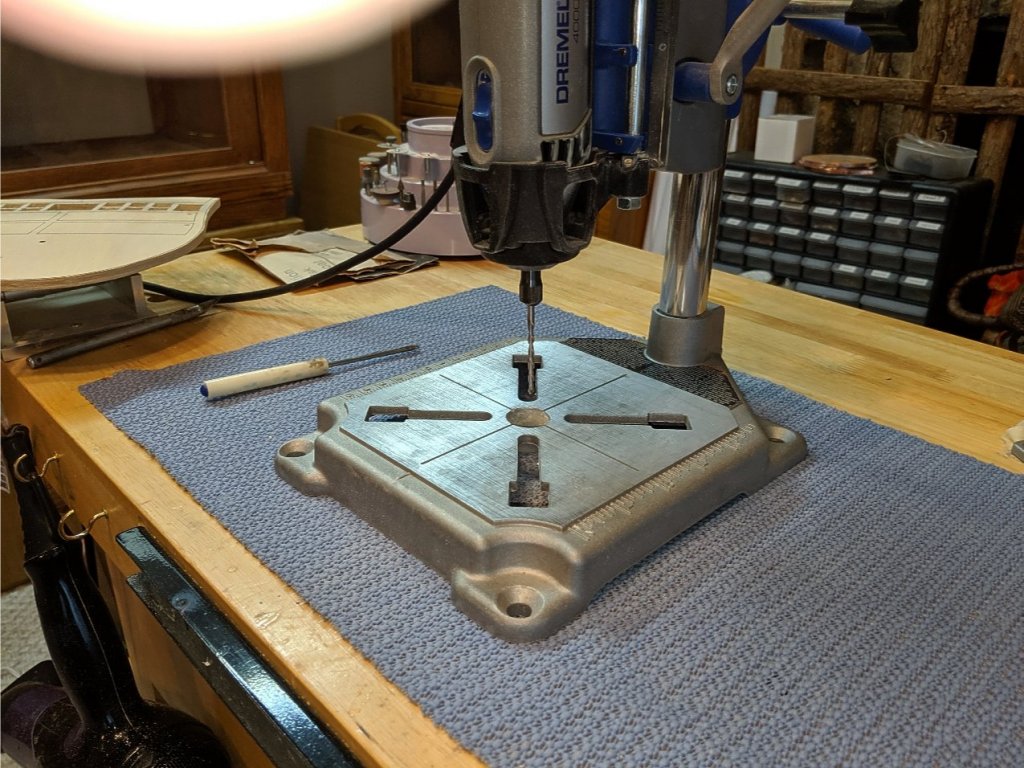

Working on the framing. I decided to make all of the little cutouts in each of the bulkheads even though they are not really needed for the build. It will reduce the weight of the finished model. With all of the metal decorations, this model will be quite heavy. Making all of these cutouts will take considerable time. I made a little milling machine for making the cutouts. I mounted my Dremel Tool in the stand and am using a milling bit. It makes the cuts clean and accurate. My Dremel Tool died after the first 8 bulkheads though. I have had it for about 8 years and used it heavily while working on my models. I just bought the same model as I like the feel of it and it does a good job. Vince P.

-

Started construction. False keel is placed on the slip and first of 34 bulkheads in place. On the first bulkhead I cut out all of the marked spaces because some of the decorative panels might need to be placed there. Since there are no actual decks below the main deck, it is really not necessary to cut out all of the spaces. I may decide not to do that which will save a large amount of cutting and routing. Vince P.

-

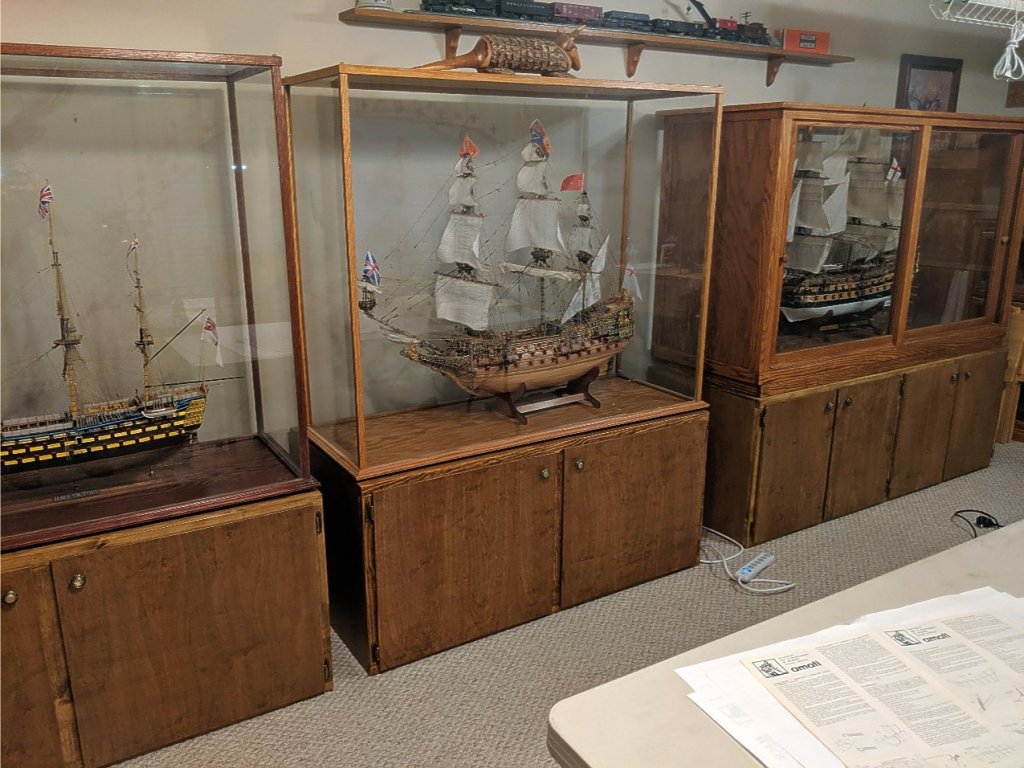

So, I completely re-arranged my workshop to prepare for building the Prince. I had my friend who is a carpenter, build cabinets to place my ship cases on and get them off the floor. Everything came out perfect and looks great. Now on to building the Prince. First up will be to cut out the false keel and all of the 34 bulkheads. Vince P.

-

pirozzi reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

pirozzi reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

-

pirozzi reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

pirozzi reacted to a post in a topic:

HMS Prince by pirozzi - Amati - 1:64 - Original 1978 Kit by Vince P.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)