-

Posts

200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by jarero

-

-

Great looking build and those stairs look amazing! Nice work.

-

Jeff,

First rate work there. I really like the rails you made and the stain on everything looks great. From the picture it appears "aged". Very cool!

-

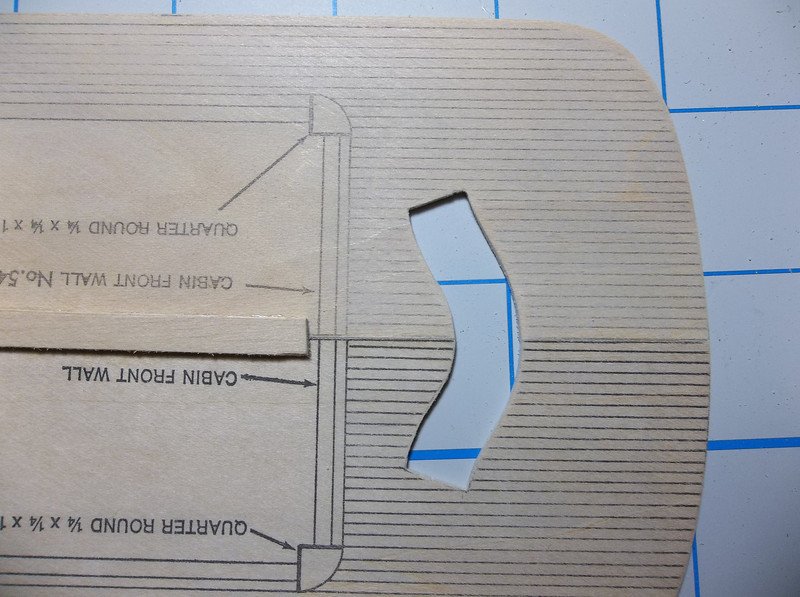

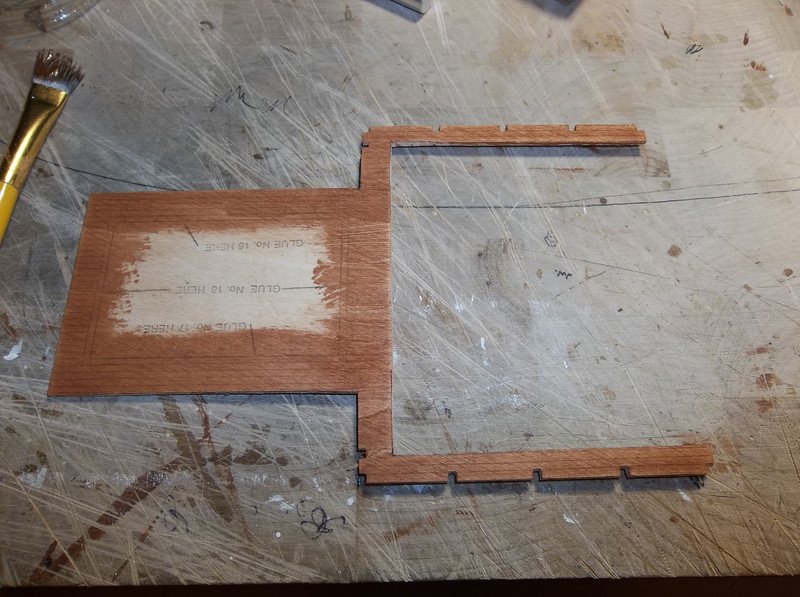

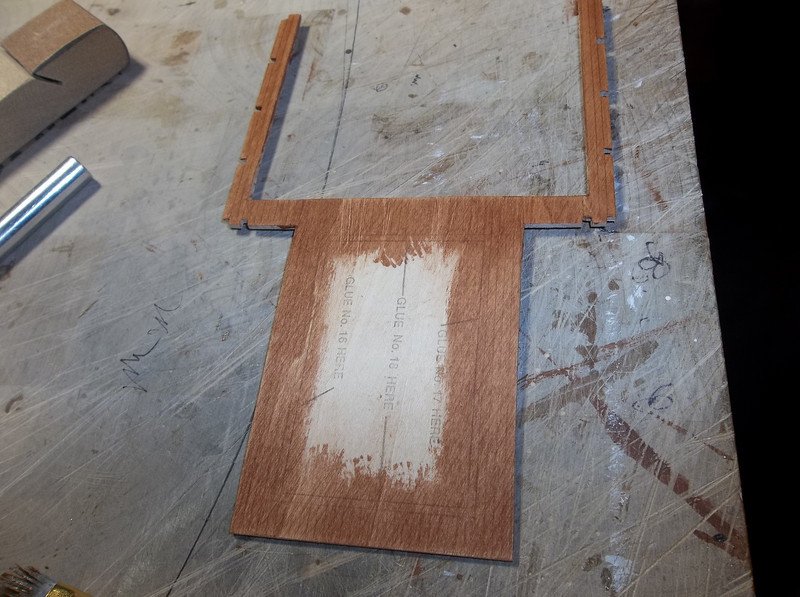

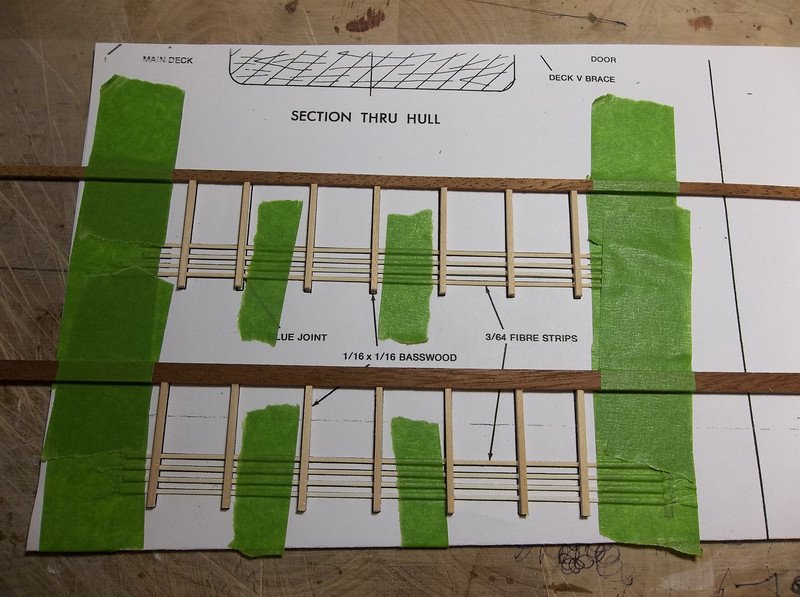

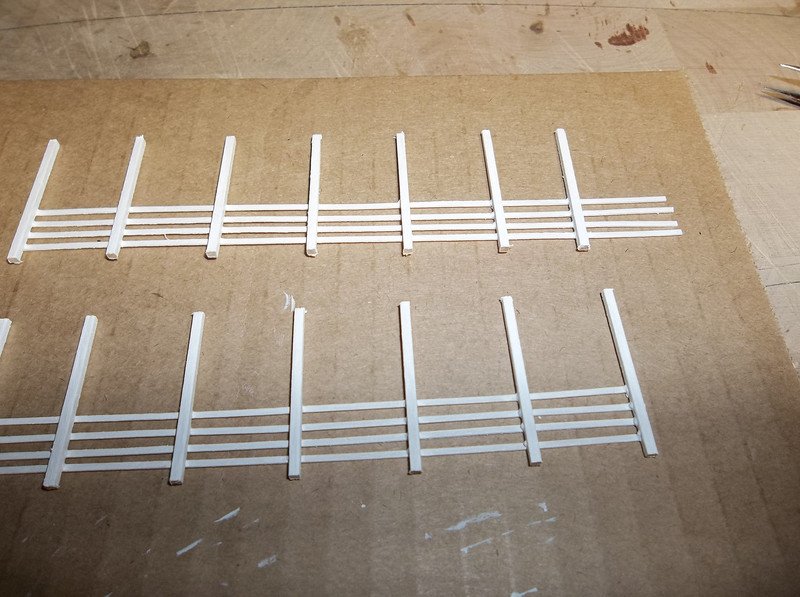

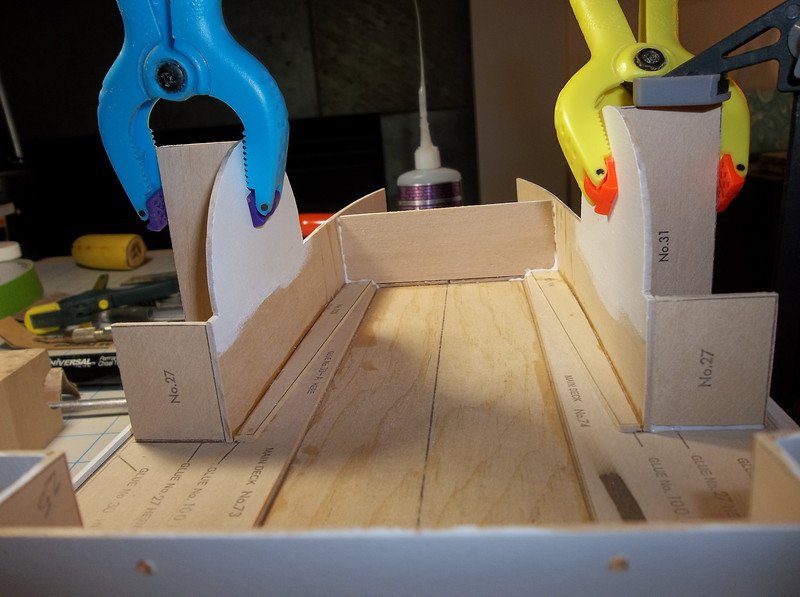

The work continues on cutting out deck pieces, sanding gluing, painting and staining:

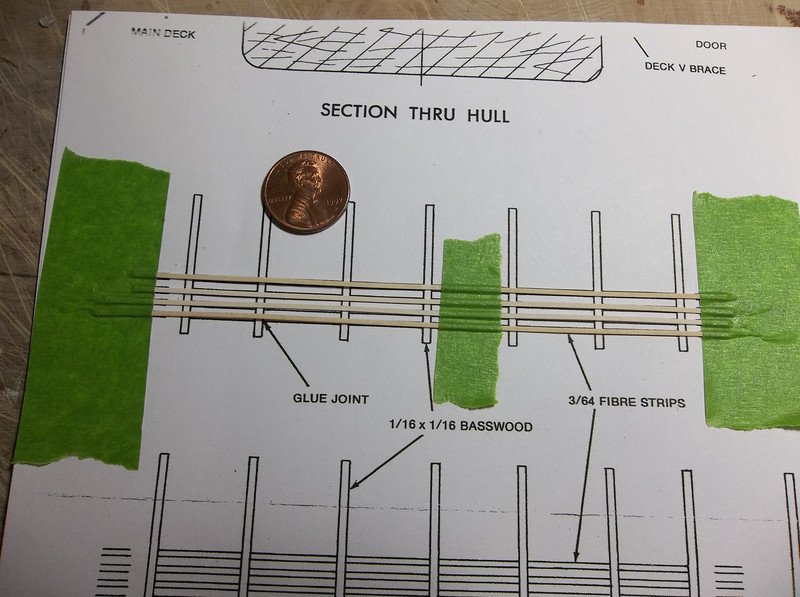

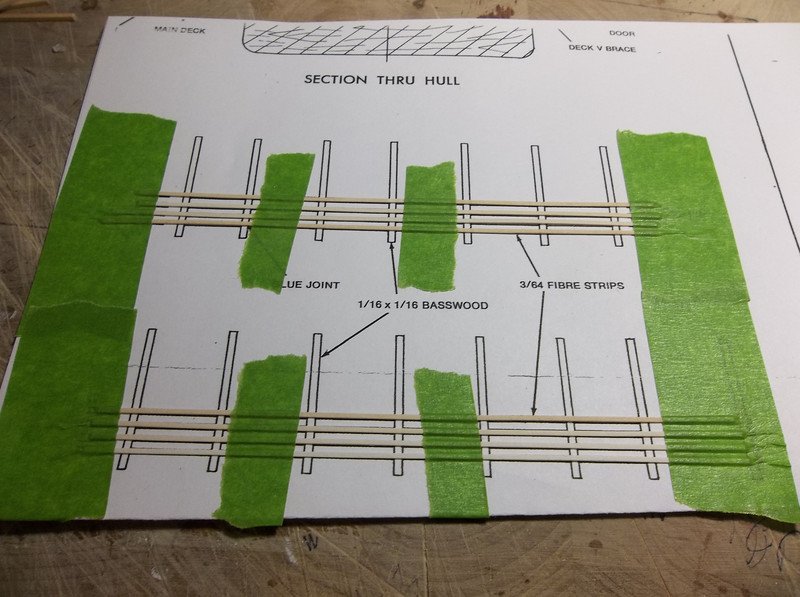

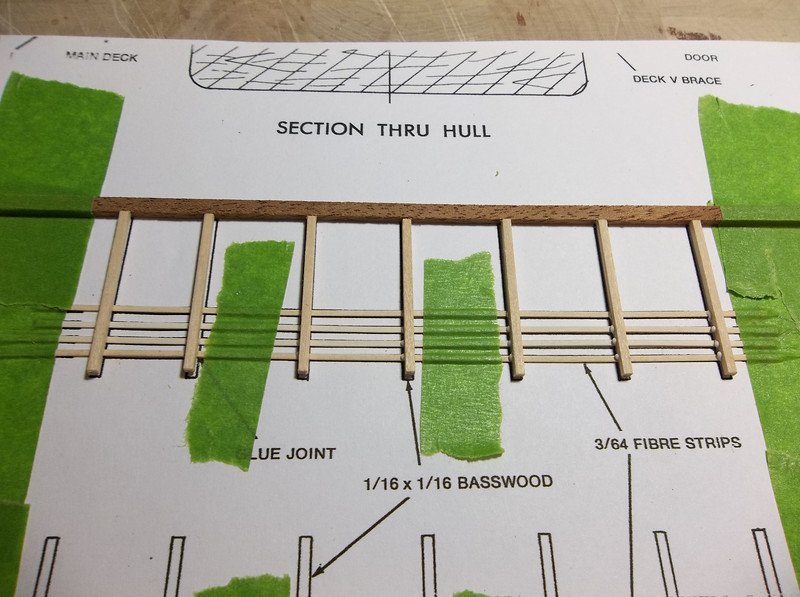

All of the deck pieces rely on a butt glue joint to hold them together so I added a reinforcement strip of wood to help stabilize the joint. This will be covered up by the saloon deck when it is installed.

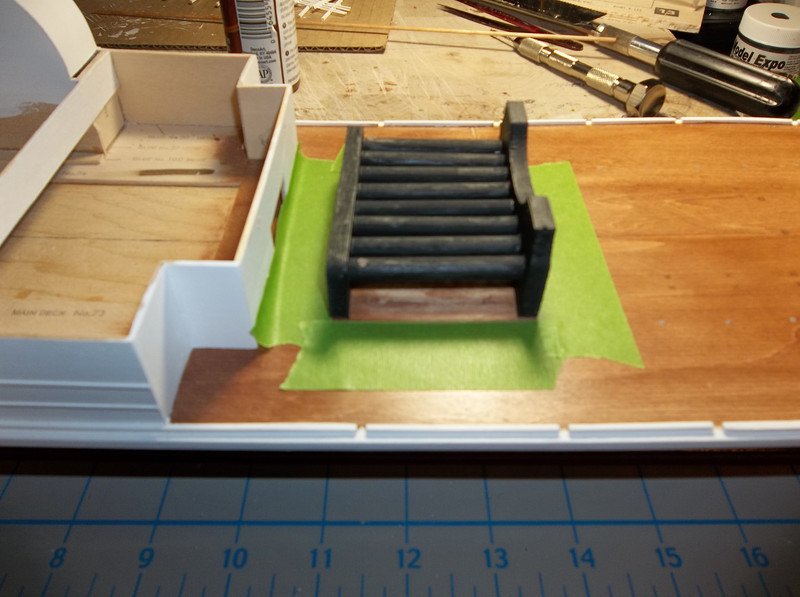

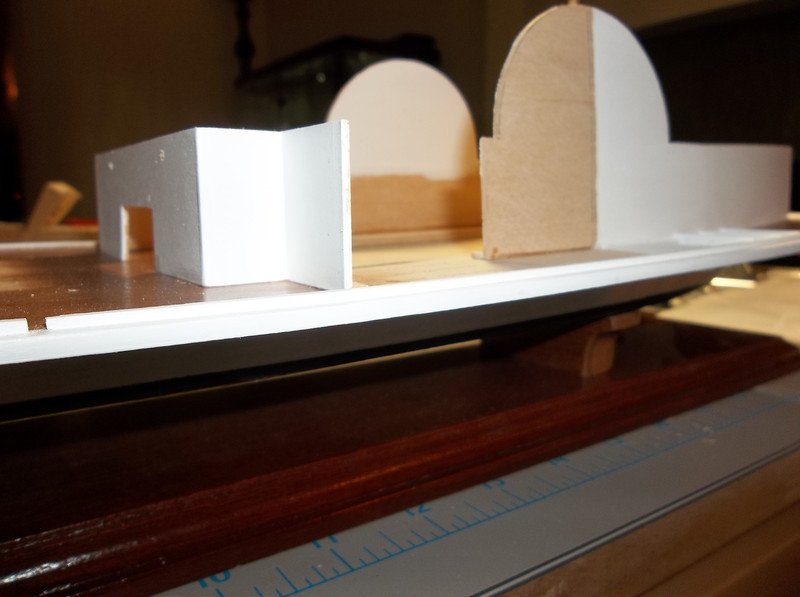

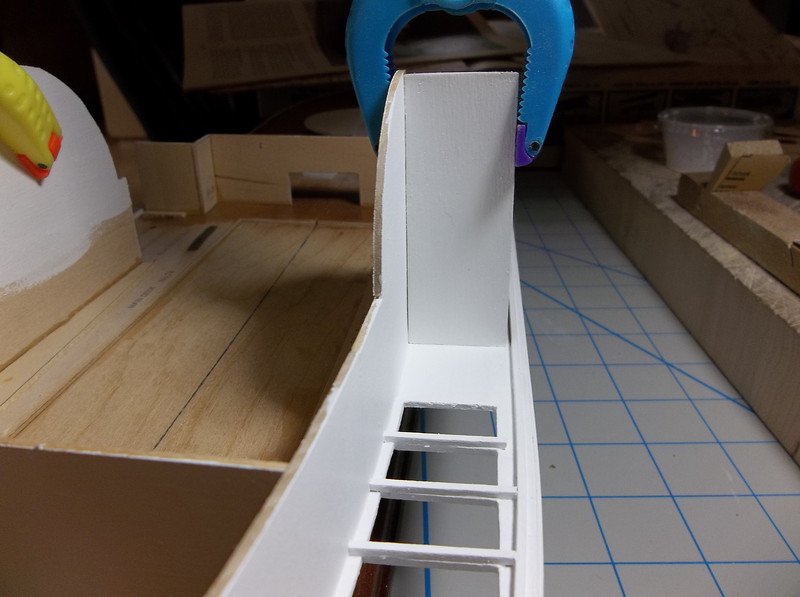

You can see in the above picture that there is a cutout for the grand staircase. He is a close up:

-

Hi Jared,

The hinges are made form 2 pieces of 0.75mm brass wire and the door knob is the round head of a brass nail.

Sorry the door is not fuctional

Thanks for dropping in and for your comments

Jeff,

Thanks for the info about the door knob and hinges. No need to appologize that the door isn't functional. I was just curious.

The build is looking great! Thanks for sharing the updates.

-

-

Jeff,

Nice looking work. I was curious what the hinges and door knob are made from? Is the door functional? Thanks for the update, I look forward to more.

-

Hello jared, As I said before,nice neat workmanship,Q,what type and brand of white did you use,and did you use a spray gun,Thanks Edwin

Edwin,

The compliments are much appreciated. I am using the Model Expo acrylic paints watered down slightly and brushed on. I have an airbrush setup but have yet to try it out yet. I am not sure that I would recommend the paint though. When you are working with it it is hard to get even coverage. It is possible however that the paint is just fine and I lack the skill or knowledge to use it properly. Regardless I will look into different paints in the future and compare results.

PS, good job on the base,love the color,did you make it.Edwin

As much as I would like to take credit that base was supplied with the kit and I agree that it is a nice color!

-

Jared,

Great progress!

I am amazed at the difference in the model from my Amati version. The scale difference may have had a bit of impact but it appears that your 'Bob' will be significantly more detailed than mine. In lieu of a boiler there were eight boiler 'doors' on an empty wall.

By the way, where did you get the dinner plate that looks like a penny???

:P

:P  :P

:PGoing to be interesting to observe.

Cheers,

Jim

Thanks for the compliments Jim. I have a complete matching set of Penny dinerware (custom order)

!

!It is surprising just how much detail there is in some areas and then a lack of detail in others. Some of the parts that use paper instead of wood/metal/plastic baffles me. I looked long and hard for better fittings but just couldn't justify the $100 price tag. I still think it is turning out okish but I would do things a lot different if I started over today. All part of being a newbie I suppose.

Jared

-

-

Count me in for watching this one as well. I have been fascinated lately with admiralty, cutaway and cross section models that show life below deck.

Jared

-

I guess I never thought about it before but you are right it does look large. I have to assume that's the size they made them back then. The unfortunate part is that almost all of it gets covered up eventually and you can barely see it at all.

-

Greetings, I just found your log and read through all of it. Since I started with a Swift as well I can certainly appreciate the large leap you made to this complexity of a build. All I have to say is that you are braver than I am but it seems you are up to the task! Nice work so far and I will enjoy watching.

Jared

-

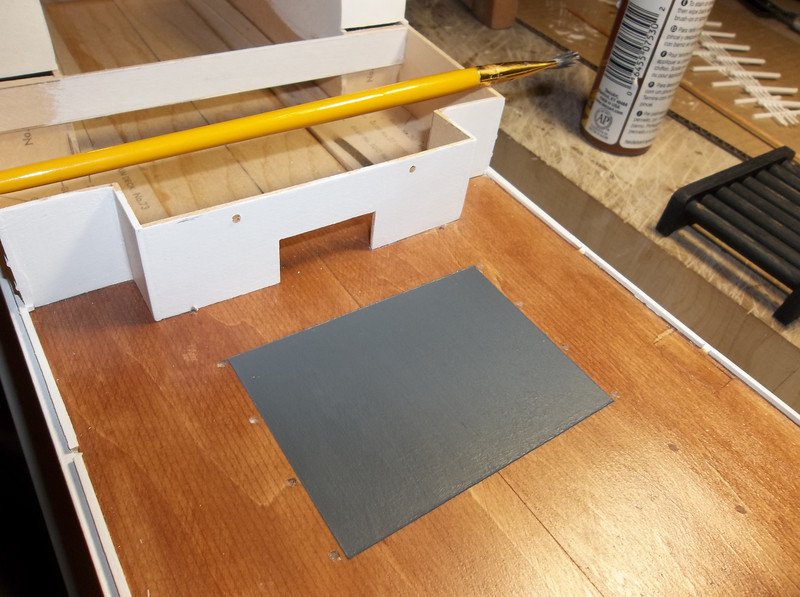

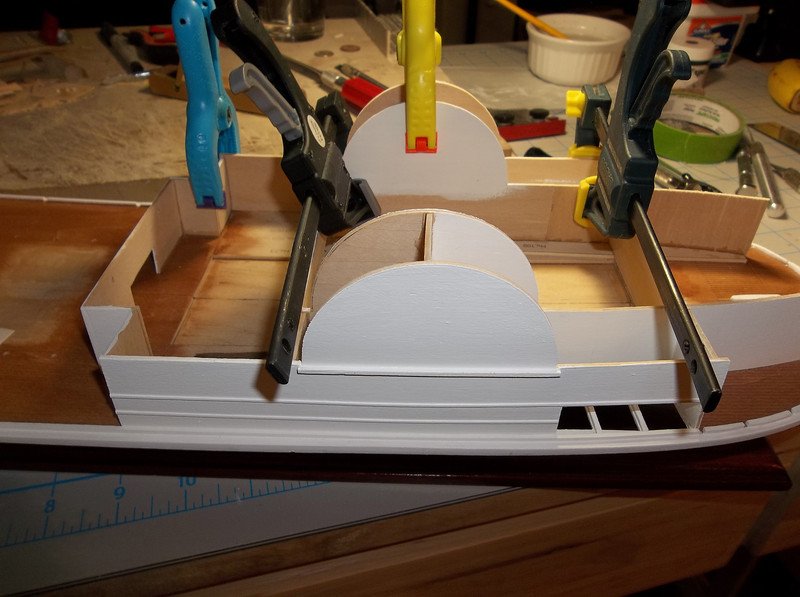

Here is the location on the deck for the boiler:

If you notice in the bulkhead at the front of the engine room there are two small holes. Those are to plum the boiler into the rest of the system. The tape is there for masking off the are to be painted for the boiler room floor.

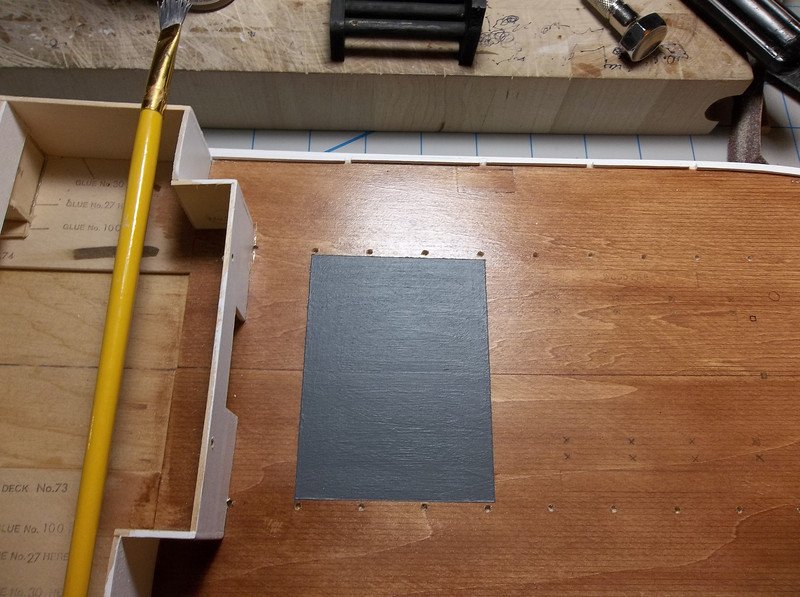

A test fit of the boiler:

Looks good to me but I should check with the boss:

She doesn't look convinced. Maybe she can be bribed with a treat?

-

Time for another update.....

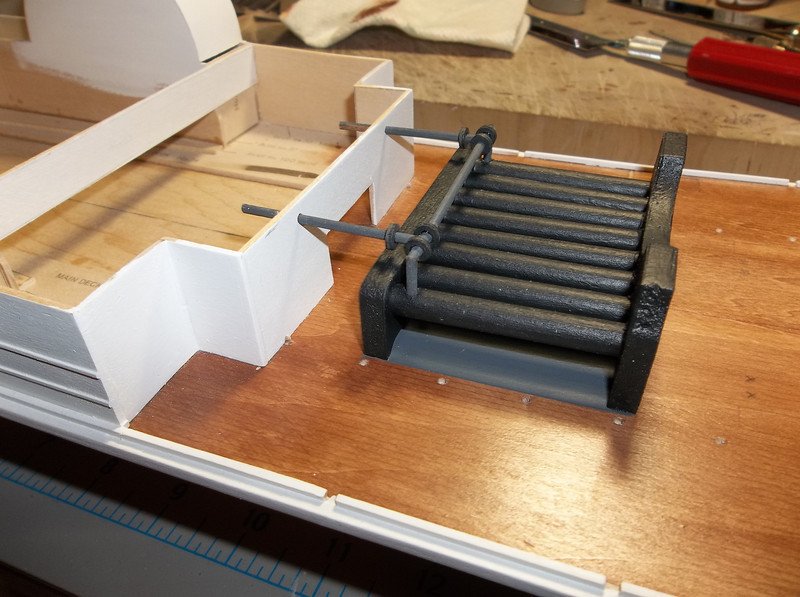

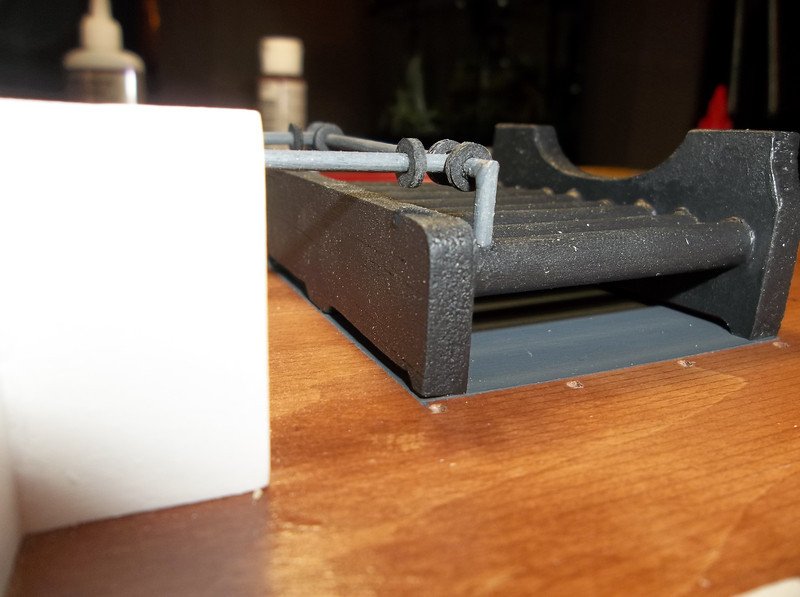

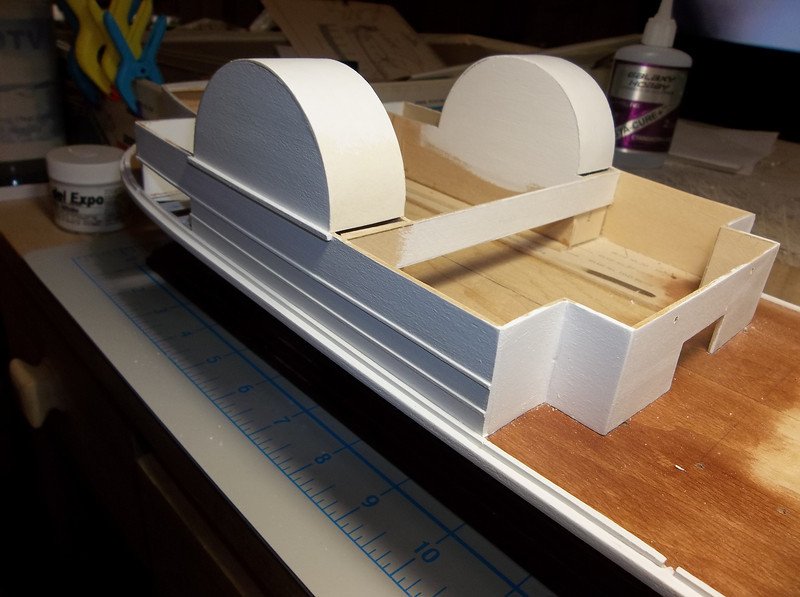

In an attempt to be more efficient I decided to only take pictures of completed steps and avoid all of the in progress messy work so here is the completed boiler:

Ok, well the truth is I forgot to take any pictures until I was finished. You didn't actually think efficiency every enters my mind with this hobby?

I should note that the paint looks spotty because it hadn't fully dried when I took the pictures. It looks much better now.

More boiler pics:

-

Thanks Sjors, and yes I am back in business and hopefully will not take such a long sabbatical next time. It's really tough though when the weather gets nice out because I love being outside in my yard.

-

Sjors, I feel a little guilty that I haven't commented on your build until now but better late than never I suppose. She is truly a masterpiece. Very impressive work!

-

-

-

-

Looking very nice. I was just in Gettysburg last week, speaking of RE Lee. River boats are fascinating in both design and structure. Very nice indeed.

Thanks John, I appreciate you stopping by!

Well what started out as just a two week vacation and then a move to a new house turned into an unexpected 4 month break from modeling. I stopped in from time to time to check on other peoples projects but didn't feel I had much to contribute since I wasn't actively working on my model. I almost felt guilty at times that I wasn't making any progress or wasn't more involved on the site. So at this point I am moved and have finally had time to setup my workspace and have officially dug back into this project. I should have some nice updates soon with pictures and recent progress. Thanks everyone for saving me a seat while I was gone.

Jared

-

Nice start to your build! I will watch this one with interest.

Jared

-

Thanks for the compliments everyone!

Jim, unfortunately I am back from vacation (had a great trip) but now I am in the middle of moving so I don't have a workspace set up as of yet and I have a huge "to do" list ahead of me. No worries though as I will return to this build as soon as I can get setup and have time.

Jared

-

Done with the second planking already? You work fast! Do you have any more pictures of the finished planking?

I am happy to hear that you found a solution to the problem and that you were able to keep the planks in place that you already installed. Keep up the good work.

Jared

-

I need some advice on how to avoid "puckering" or "buckling" of the finish planks.

As you can tell from the photos above, I clamped the fool out of the final wood, but still got puckers. I suspect I can use a hypdermic to inject glue into each buckle and clamp them individually, but I must be doing something wrong for them to show up in the first place.

Advise would really be appreciated.

BTW, the need for filling in the hull is obvious- I will be doing that before I do any planking lower on.

Good to see that you are moving along!

I might have said it before that I am far from an expert but I suspect that you might be forcing too much longitudinal curvature to the planks thus causing the buckling. If that is the case then if you fix the ones you put on already then you will have to force the additional planks to fit which will likely continue the buckling issue. You might have to remove them and start again (fortunately you don't have many to remove). I hope someone with more experience can chime in and validate my suspicion or help you with another suggestion.

Jared

USRC Ranger by trippwj - Corel - 1:64 scale

in - Kit build logs for subjects built from 1751 - 1800

Posted

Wayne, does this mean that you are back to building the Ranger again? Looking forward to the progress if so. Oh and remember that I'm waiting for you to get far enough ahead so I can start mine and copy you!