norseman

Members-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by norseman

-

Have finished installing all the strips across the frames or bulkheads. Today I am working at laying a strip of veneer across the top of the frames or bulkheads to cover the plywood ends. Finding that soaking the strips in hot water for 5 to 10 minutes and using my wifes old hair curling iron I can bend the strips quite easily. The curling iron seems to have the correct radius for this job. Will take a while to get all the frames done but again I have lots of time staying in the house during the virus epidemic.

-

Got my openings done on my forward and aft bulkheads or frames. I will probably widen the opening on the rear bulkhead to more accurately match the original Oseberg. Think I will now put the strips and veneer on top of the frame edges to make them appear to be solid wood instead of plywood. Will also veneer around the openings I made in the forward and aft frames. Not the best pictures shown here as the holes are actually better than they appear.

-

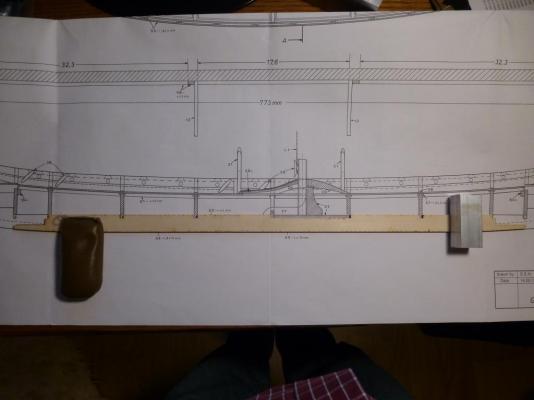

Just by clamping them in place and taking a look at them. The notches on the frames give you a rough placing for the frames. What I found was the curvature in the planks from the kit do not line up well with the notches. Have to move the planks up or down so there will not be a gap where they over lap. Hopefully that answers your question.

-

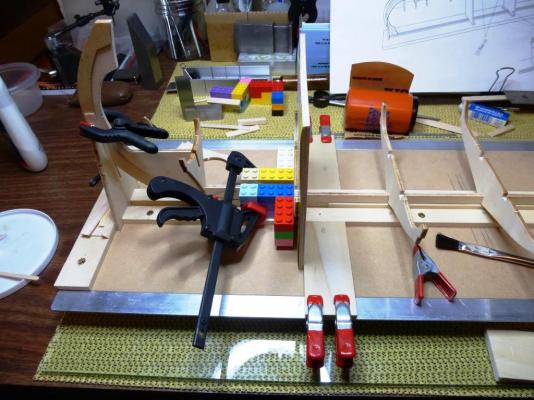

Started to glue my frames into the ship structure. Hoping that when I go to put the 2 side planks onto the frames everything lines up. It is real hard to determine that at this point. Did some rough fittings with the planks and I know I may have some problems. Both Jack P and Von Kossa ran into the same problem. The curves on the planks (plywood pieces) do not have a perfect curve to them to fit nicely around the ships curvature if that makes sense. I don't think putting them into my steamer will help.

-

After a few tries came up with first making a template out of cardboard first and fitting it to the ships planks and beams. Lots of fitting. I then traced that template on to a piece basswood and cut the frames out with my scroll saw. Still had lots of fitting and sanding to get them to fit good but it is slowly coming. Not much else to do with this virus scare.

-

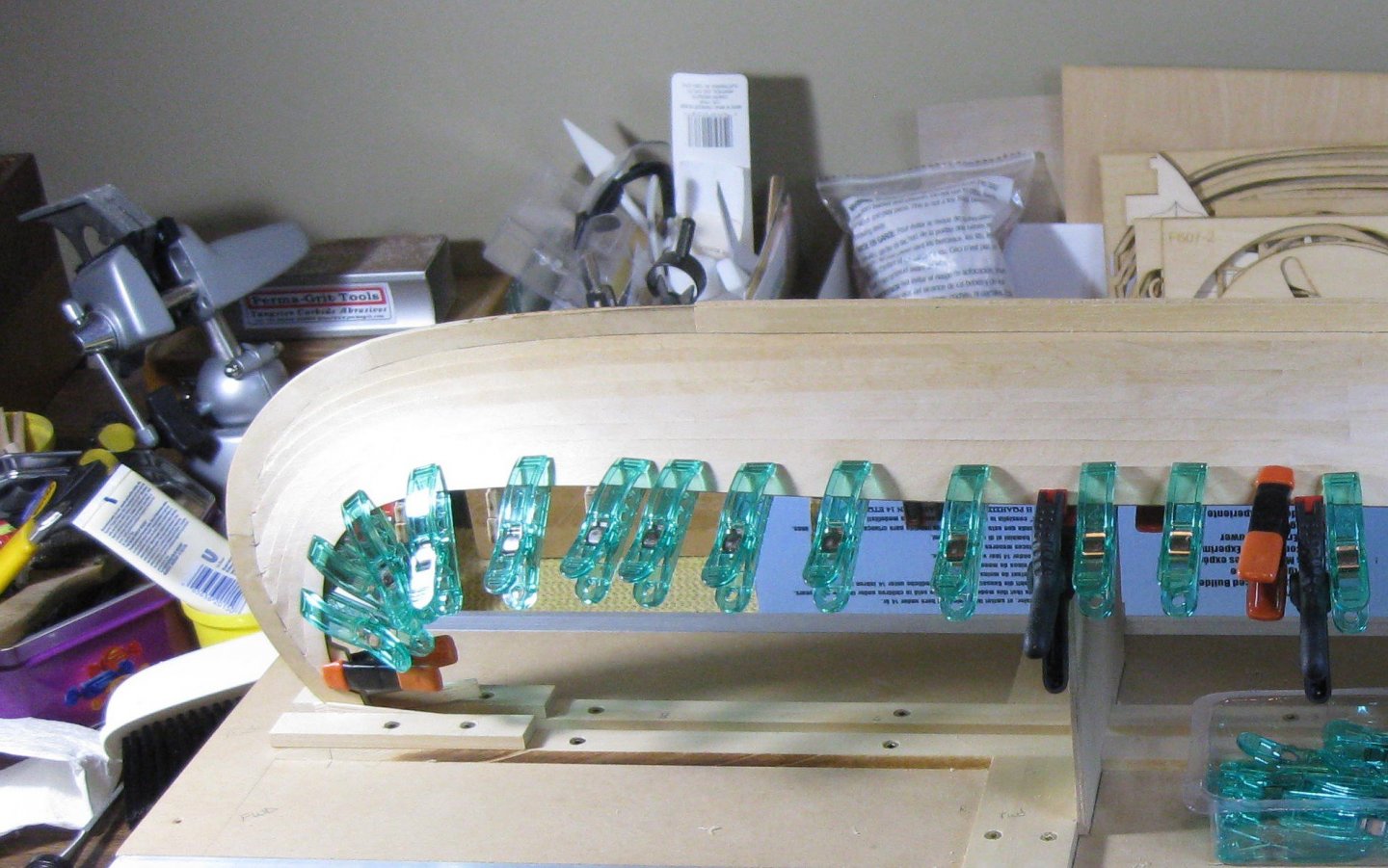

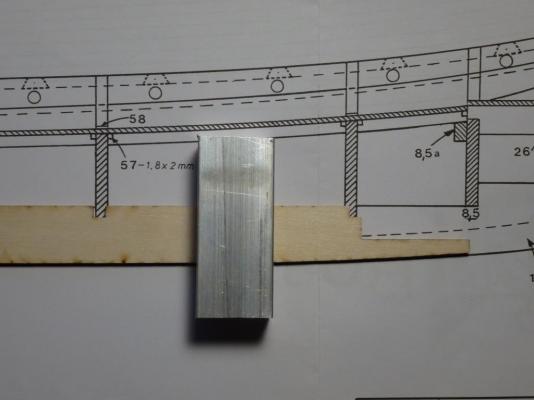

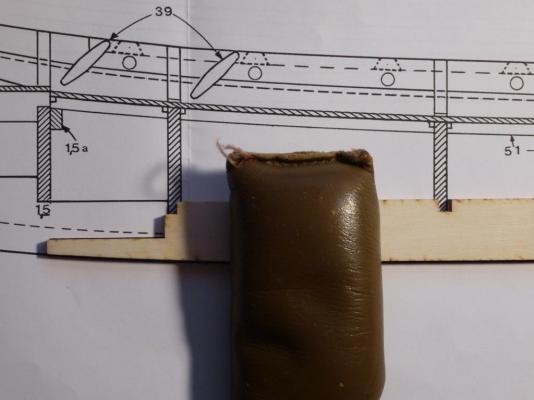

I built the mastfoot using the pieces that Billing Boats supply with the kit. The pieces are made out of plywood. Didn't care for the look of the ends looking like plywood so I used some thin birch veneer to cover the ends over. The mastfoot looks more like a solid piece of wood now and the birch veneer matches the wood color fairly close. Hope it matches up close when I finally stain the boat. I have been still following the build logs of Jack p and Von Kossa to build my ship. They added 6 more frames that the planks attach to so it looks more like the original Oseberg ship in Oslo. I think I will do the same but it adds a lot work as I will have to manufacture the frames. Bought some basswood at the hobby shop to try with.

-

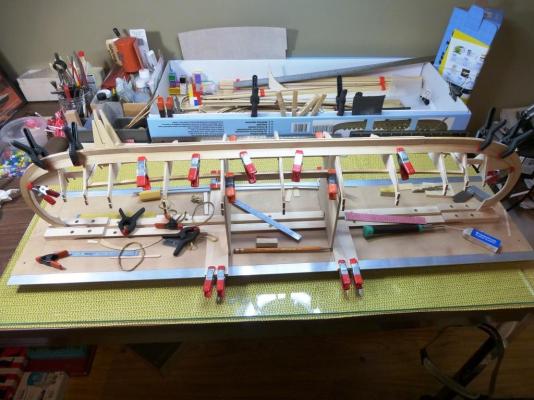

Steam box worked good for helping to curve the strips that the bottom side planks use as a filler to the keel planks. Just like Jack P and Von Kossa with their build I had a hard time to get those strips in the correct position to actually be fillers. I am hoping when I put the top 2 side planks on everything fits okay.

-

Finished gluing the rear scrollwork pieces on. Will have to go back and do some sanding to make everything look good a little later. From what I can gather from the scant instructions and what Jack and Von Kossa did was put a strip (part 56) along the top plank on the keel for the bottom side plank to fair up against. As I fitted the strip along the plank and set the side plank against it I see I have a lot of sanding and fitting to get everything to look good. The notches on the frames aren't exactly cut perfect. They need to be faired and the notches are too deep in places. Gives me a lot of respect for the Vikings who actually built the full size ships.

-

I am building my first wooden ship. It is the Oseberg 720 by Billing boats. I was wondering how important it is for the keelstrip laser cutouts to match up with the drawing dimensions. When I lay the keelstrip on the drawings sheet the cutouts don't line up. Some do, some don't. Is it critical or do you have to adjust the cutouts to line up perfect with the drawing dimensions. I may be over thinking this. Jim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.