-

Posts

962 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Moonbug

-

-

Really enjoyed being able to re-locate and catch up on your build, and then to start following it again Danny!

- Bug

-

-

Good stuff! Can I see a wider shot of your makeshift guide and drill?

- Bug

-

-

Cool, thanks. I'm still contemplating exactly how I'll illustrate my mainsail.

- Bug

-

-

I've just stopped by to nudge you a bit like everyone else. :-)

- Bug

-

Thanks very much Eamonn!

- Bug

-

-

Hey Shawn,

There always seem to be more bumps and valleys that you realize once you get started on the sanding.

Be wary of using the CA glue, especially on the second layer of planking. Sometimes it has a tendency to seep through the more porous nature of the thinner wood and cause all sorts of problems and discoloration. This is particularly true if you're using the pure liquid kind (as opposed to the gel). I use CA for the very small parts, but tend to stick with PVA wood glue types for the rest. I've had much fewer problems with the longevity of the hold.

- Bug

-

Nice work. Very interesting treatment of the cabin, very cool.

- Bug

-

-

Can't wait to see photos of the repair. I snapped the top off the mizzen of my San Juan during that build. It's remarkable how many of us have snapped a mast or yanked rigging out of whack despite how careful and precise we all are! Only takes that half second of inattenion...

... often followed by a flurry of colorful vocabulary, a period of slow methodical breathing (and maybe a tear), then finally a plan for reconstruction. Hey... at least you didn't have to pull it off at sea.

- Bug

-

Thanks for the comments everyone!

No problem Sjors! Must be for the Aggy right, I'm sure you've already got the indoor plumbing all laid out for Ildefonso Right? ;-)

Marktime - Thanks for the comments and the information, that's fantastic. I only had a little information and made guesses from there based on some of the famous Russian models. I had not heard of that book, I'm definitely going to go out and try to track it down.

- Bug

-

Nice work. Was the red design already on the sail in your kit, or did you add that?

- Bug

-

Nice patient work. Let the sanding begin!

- Bug

-

There are a few different methods to planking, that's for sure. Personally, I don't think I'm particularly good at it, so I always refer to other folks'.

- Bug

-

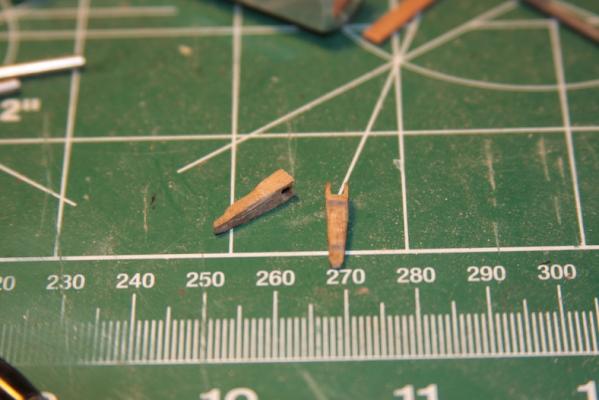

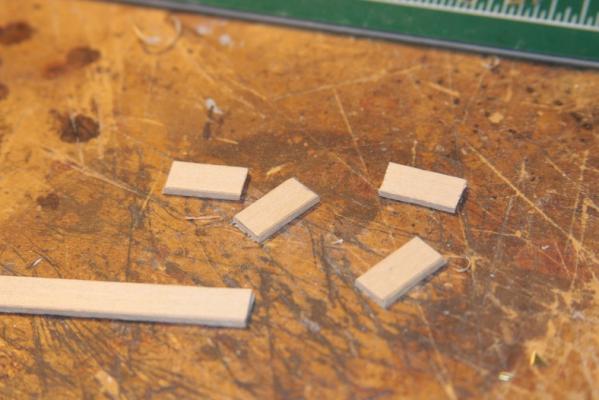

The handle of the pump is created from two strips of 2mm x 2mm square walnut sanded and etched out. They are based in 3mm x 3mm square walnut strips sanded to fit the side of the pump.

The pieces all put together initially and then stained.

The pump mechanism and the strips around the pump are made from a scrap brass dowel and scrap brass flattened pieces. I flatten the end of the brass dowel out by putting it between the flat areas of a pair of pliers and striking it with a hammer.

All of the strips, the handle, and the pump mechanism are attached using a touch of glue, and then firmly attached using pins with the heads sanded down. Finally the pumps are re-stained, and the brass pieces are given a layer of patina.

- CaptCraig, gjdale, zoly99sask and 8 others

-

11

11

-

Although the Xavier Pastor book I have been continually referencing lists the Santa Maria as most likely having a single turn-crank water pump, every other reference I've seen has shown a more traditional pump-handle style water pump. Often times there are two, as in later ships. When it comes down to it - I think the pump-style handle looks better, so I went with that.

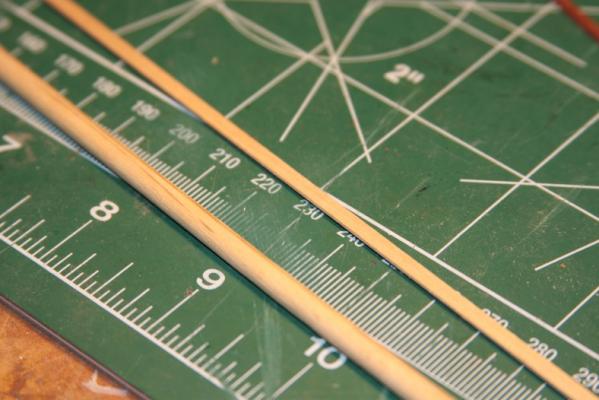

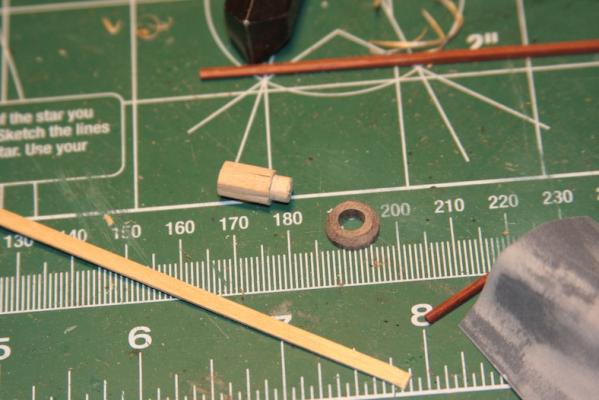

To build my water pump I started with a 5mm diameter dowel and thin basswood strips.

I trimmed the sides of the basswood strips at a 45 degree angle so they would fit together mitre'd nice and snug. I then cut them at 15mm lengths and glued them around the dowel to create the base of the pump. I went with this idea to create a solid base that wouldn't collapse when I started working on it.

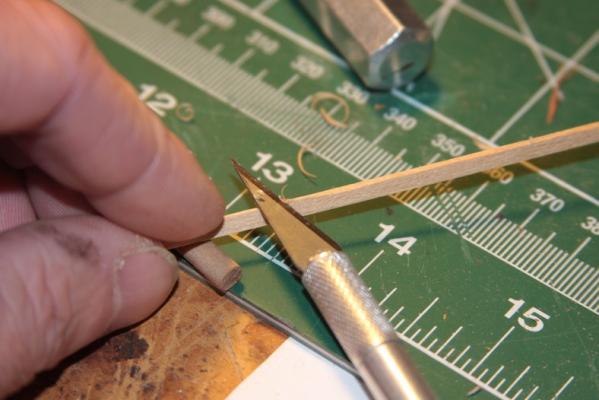

I then hollow out the base of the pump with a drill. The base is made from a 10mm dowel of walnut with the center drilled out at 5mm to accept the base of the water pump. Of course the sides of the base are sanded and beveled.

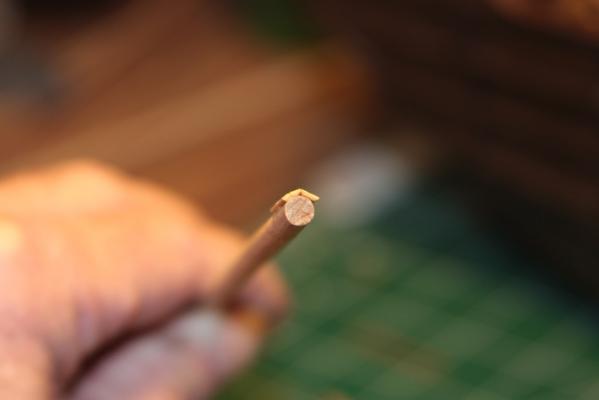

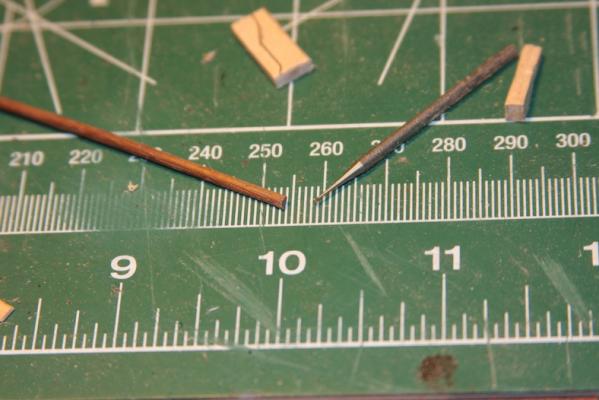

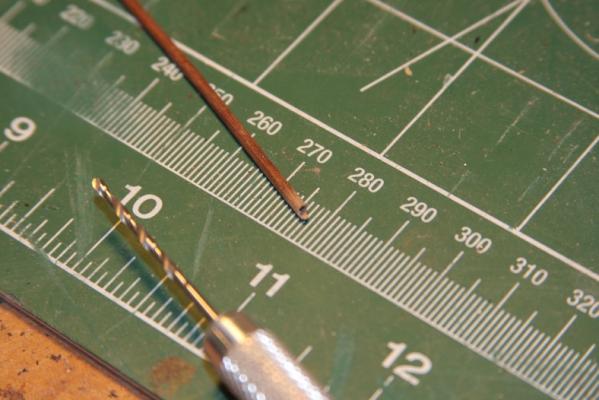

The spout of the pump is a 2mm dowel of walnut with the end drilled out hollow first with a 1mm hand bit, then with a 1mm etching bit for a dremel at low speed.

-

I'll echo what Keith said about the instructions. Sometimes I refer back to them to make sure there isn't some little cleat or something that I've missed, but for the most part research, MSW and other builds here end up being my instructions.

I also ended up cutting a new rudder and stern post. Oh - and to echo Keith (again) - planking the inside of the bulwarks after they are fitted does make a huge difference.

- Bug

-

Thanks Peter and Eamonn for checking out my build.

I very much appreciate the comments!

- Bug

-

Hehe... You guys said "time line".... ;-)

Don't think I've ever had a time line pan out as planned! Good thing it's all about the process and not the finish line.

Nice smooth work Adrieke!

-Bug

-

I wish I had better advice, but I had a very difficult time matching the hull to the keel. What I ended up doing was notching out the hull and thinning out the keel. That wasn't a correct answer though, more of a compromise fix at the time.

I would just recommended dry fitting it and trying to line it up as cleanly as possibly. You probably won't start thinning until area two. Just remember you can always take away easier than filling.

Bug

-

Nice work Russ. Good to catch up on your build(s) again.

- Bug

Santa Maria by Moonbug - FINISHED - Artesania Latina - Bashed

in - Kit subjects built Up to and including 1500 AD

Posted

Today has become a research day in between "real" work. I've secure delivery of the "Vanguard of a Empire" book to which maritime referred to my local library. Now I'm trying to nail down what the cleats and belaying rails would have looked like. I can't imagine they would have been rails with pins, but it's a tough go finding reference that specific.

-Bug