-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dewalt57

-

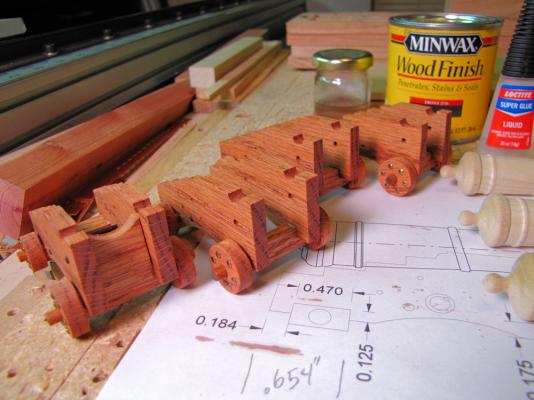

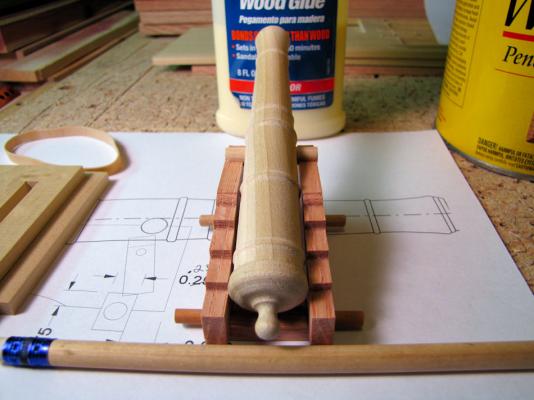

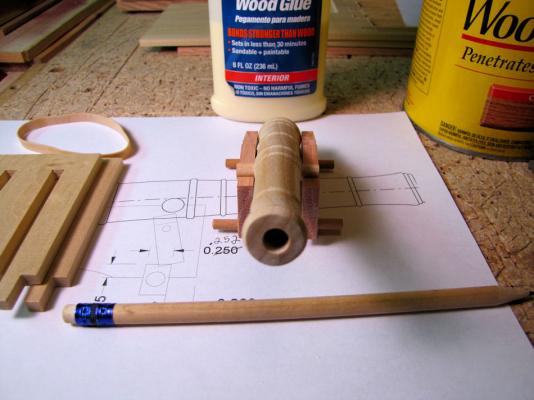

Thanks Ray!!! Still got a few more things to do to the cannons, just finished getting the touch hole plate added and skewers made to hold the cannons while painting them. Getting ready to do some thick primer paint brush work around the touch hole plate and rear of each cannon before I use spray can primer to the whole body. I used 1/8" bamboo skewers glued inside 1/4" poplar dowel so I would have clearance around the cannon's end so the paint doesn't glue the skewer to the barrel. AL

-

LOL.... some times I think I'm dragging 50 lb. cannon balls behind me .... LOL Anyway....I was in Walmart the other day and cruising thru the craft dept. area and ran across these paint pen markers for $1.97, thinking they might be useful to us in our hobby, worth a try I guess. They come in many colors, I got a black one to try out on some scrap, which I did on some red oak, no bleeding and seemed to cover pretty good. I'll try more test on some planking later on. Thought I'd share this with you. Just in case the ink in the Sharpie pen bleeds in the wood on you, there is something else to try. AL

-

Thanks Tim!...... Yes, small mill for sure, vice is only a 4", biggest that will work on a HF Mini-Mill. The X-axis has about a 10" working area, The Y-axis has just a tad less then 4", the Z-axis is not much better and the bigger the chuck the less head space you have..... I use short (screw machine ) drill bits when I can. AL

-

Thanks guys!! Just wish the "mill room" as I call it.... was bigger...... LOL That HF Mini-Mill has been a real little work horse in there over the years, along with the HF Mini-Lathe, been able to pull off some really neat projects with em but had to push em to the limit and then a tad more to get there due to their small working limits!! AL

-

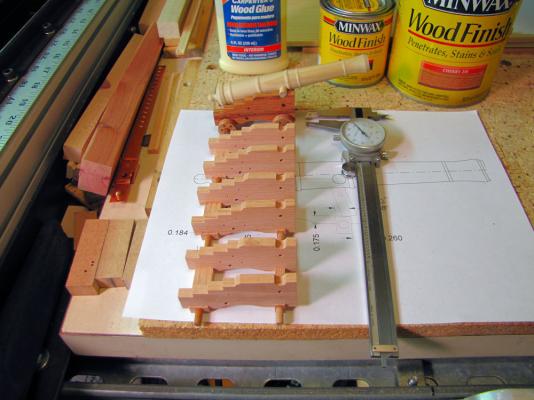

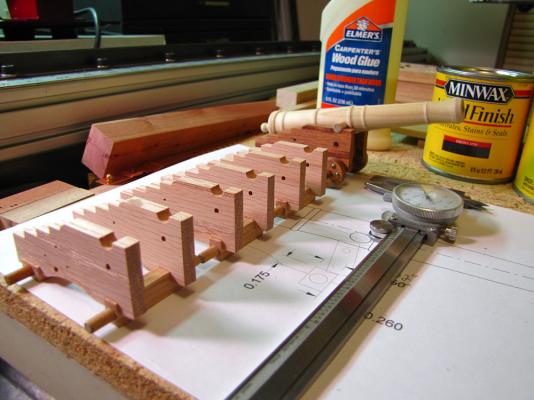

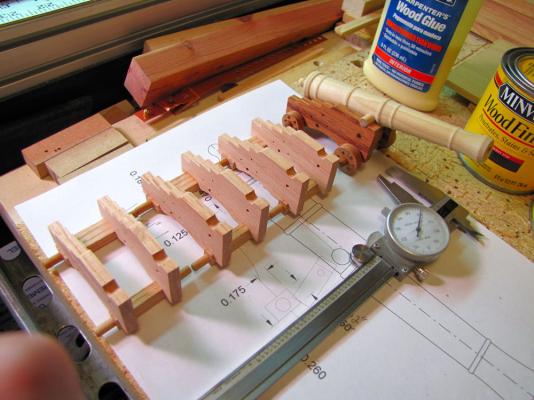

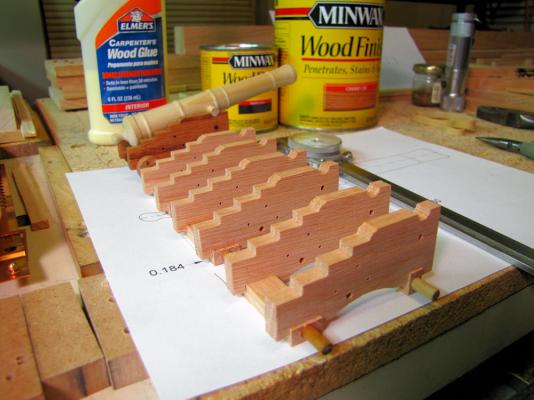

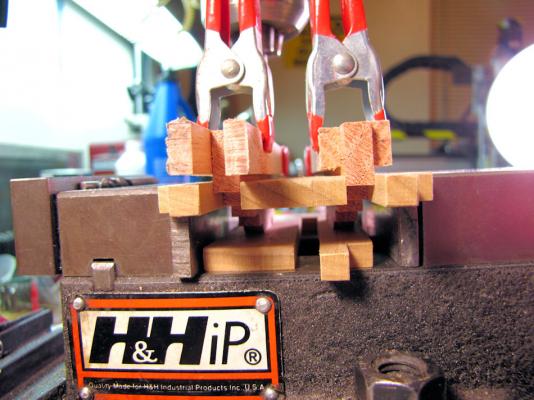

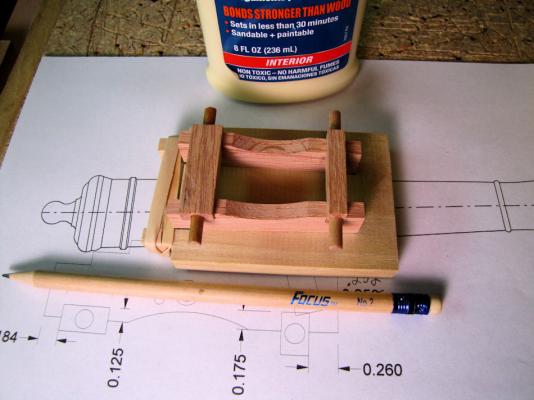

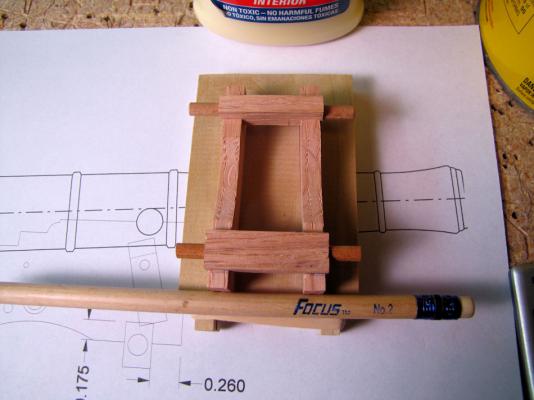

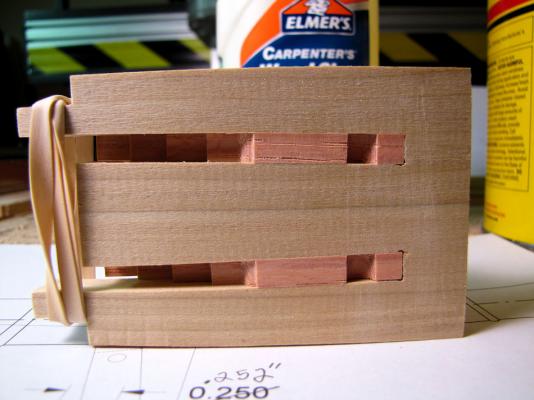

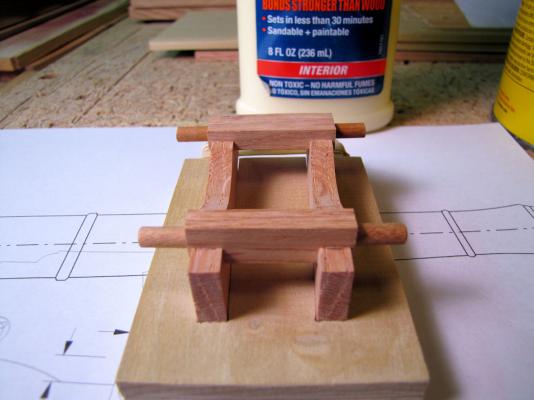

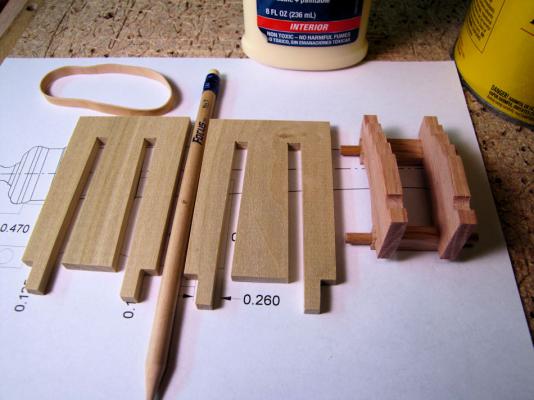

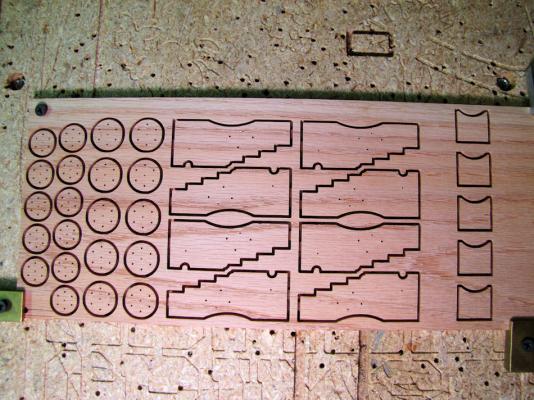

This is how I set up the carriage jig to cut the axiltree slots in the carriage side parts. Done using the manual controlled HF Mini-mill. The clamps hold scrap red oak so I don't have "tear outs" in my good parts as the 1/4" cutting bit chews thru the wood to make the slot.... And YES!!..... thats a home made 24VDC motor drive unit with speed & direction control on the left side of the X axis on the HF Mini-mill! Home made engage/dis-engage shifter lever on the front side, power control box mounted over head on top of Z axis. With that I can power the X-axis left or right from 0 to 20 IPM and NOT have to do any hand cranking of the X-axis!!! Really sweet setup when you need to get raw stock down to size and not wear out your arm cranking the table back and forth... LOL AL

-

Piet........ Thank you!! I thoroughly enjoyed your post of the 019 submarine build, I need to finish reading it all. We share the same addictions it seems, machinery, planes, ships, subs!! I'm a self taught manual machinist, learned it over the years out of necessity to make a living with it plus I like doing it!!. Wasn't till about 8 years ago that I started learning the CNC side of things, still teaching myself and learning how to do it..... LOL I guess I like the challenges of it all and the feeling of creating with it as a hobby. But really, its just another tool to use in the shop, just got a few more buttons to push!! Stop by the shipyard any time for a visit I'll be here making wood chips and saw dust... LOL AL

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.