-

Posts

620 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captgino

-

- 73 replies

-

- mayflower

- model shipways

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- mayflower

- model shipways

-

(and 1 more)

Tagged with:

-

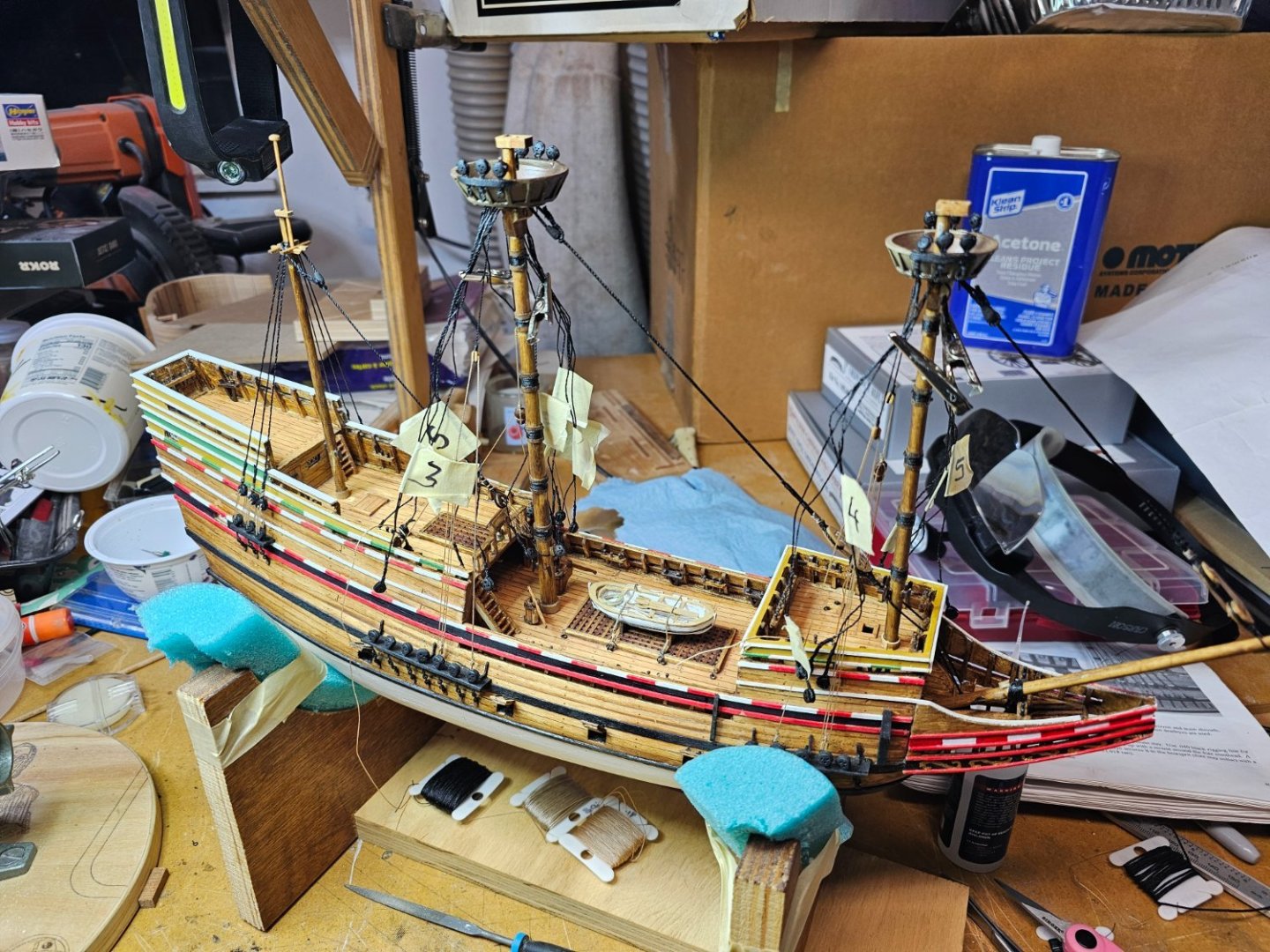

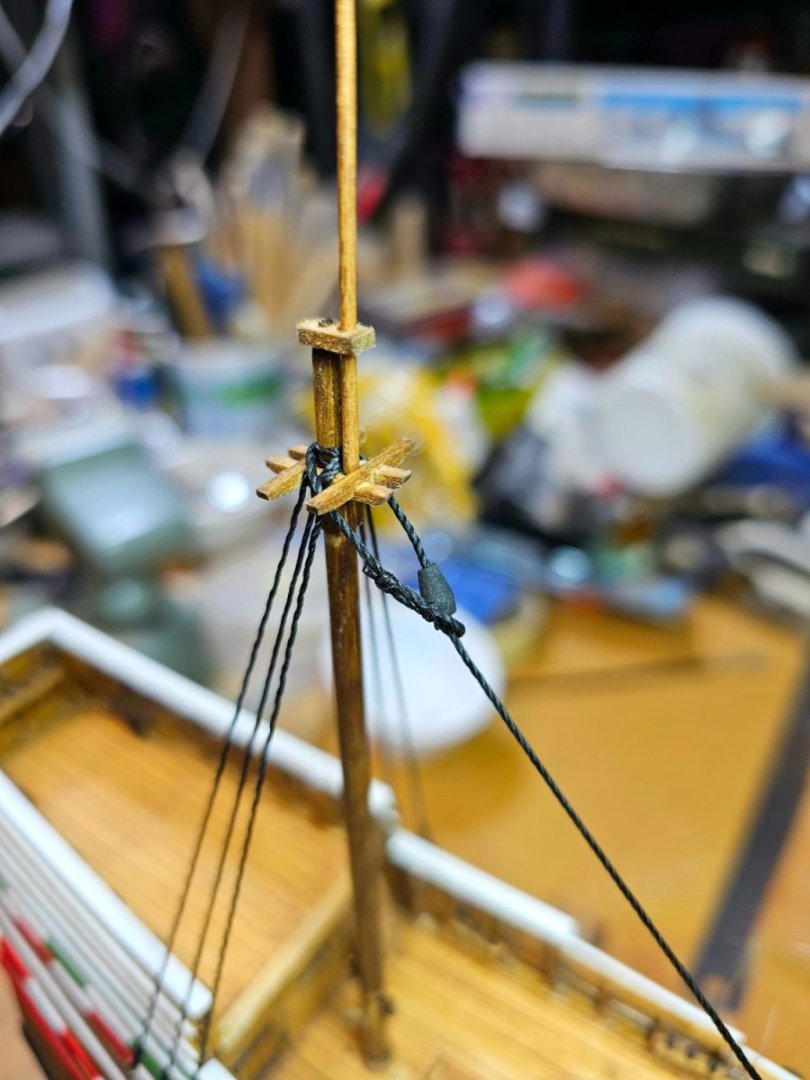

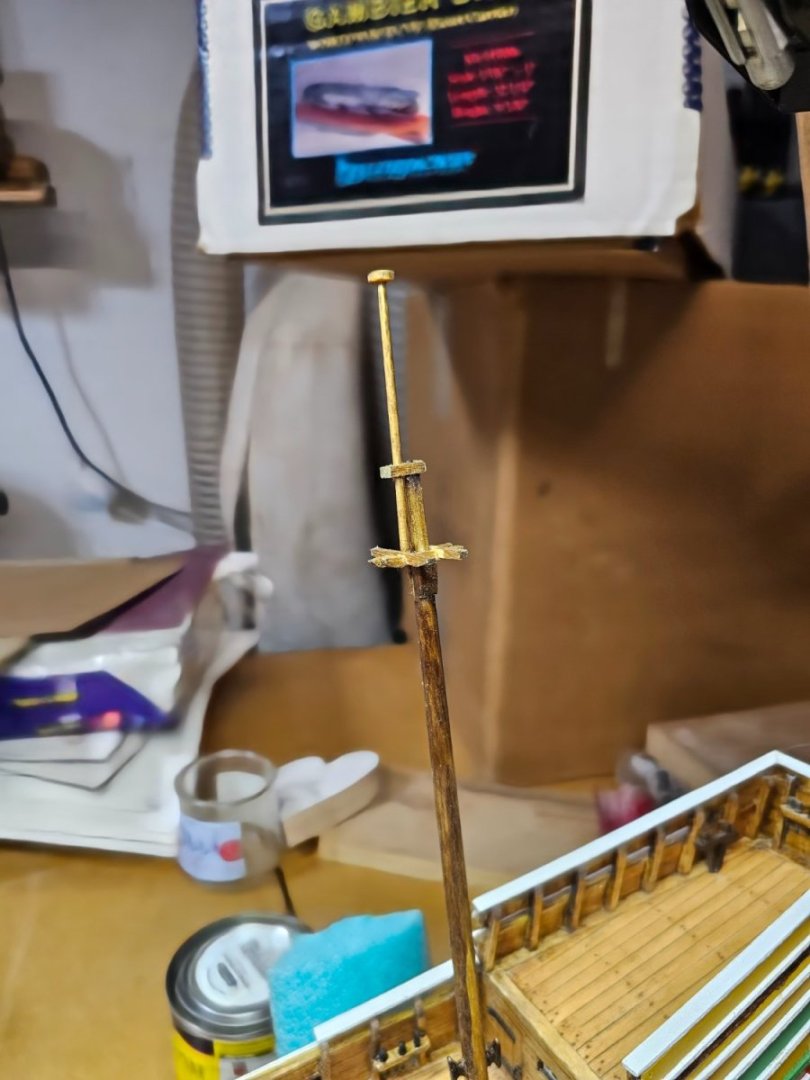

Sorry forgot to take pictures of the masts creation. This is all I have 😢 Jumping into the rigging already 😊

- 73 replies

-

- mayflower

- model shipways

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- mayflower

- model shipways

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- mayflower

- model shipways

-

(and 1 more)

Tagged with:

-

I have failed to finish it yet. I worked on a lot of other projects like a caronade, the Syren and a few models repair and upgrade for families of fellow Ship Modelers that could not finish their ships. But updates are coming.

- 73 replies

-

- mayflower

- model shipways

-

(and 1 more)

Tagged with:

-

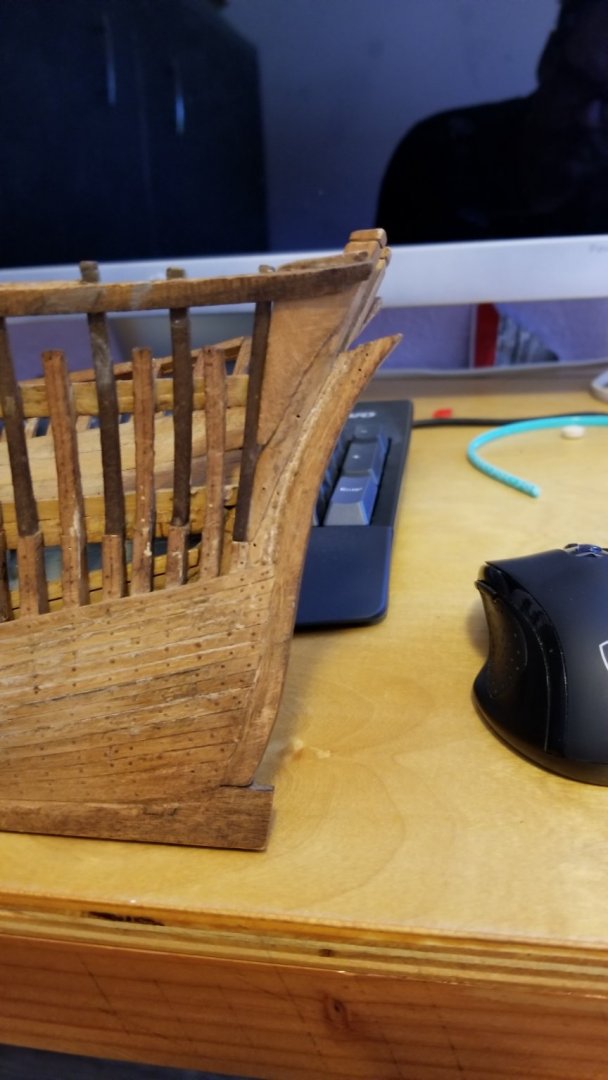

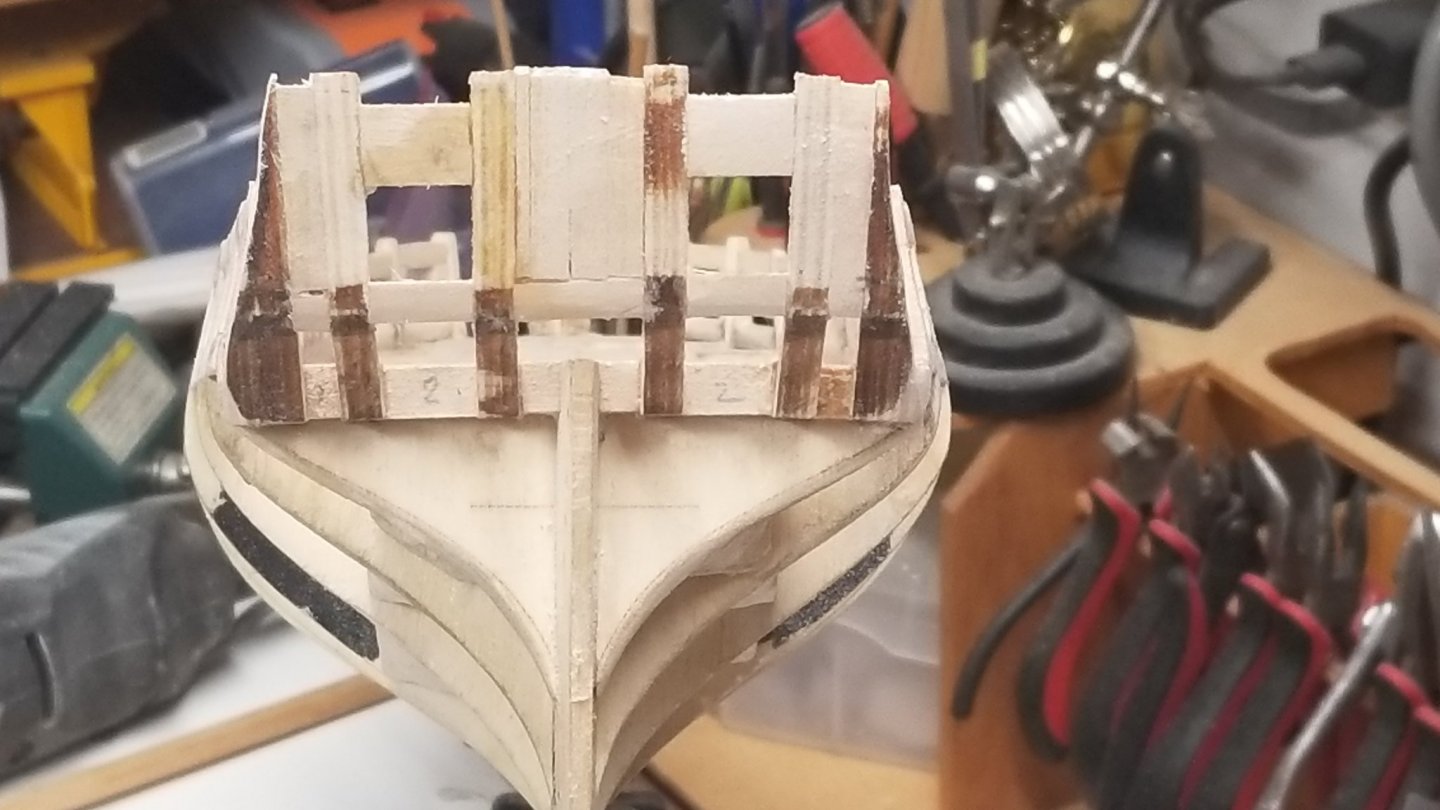

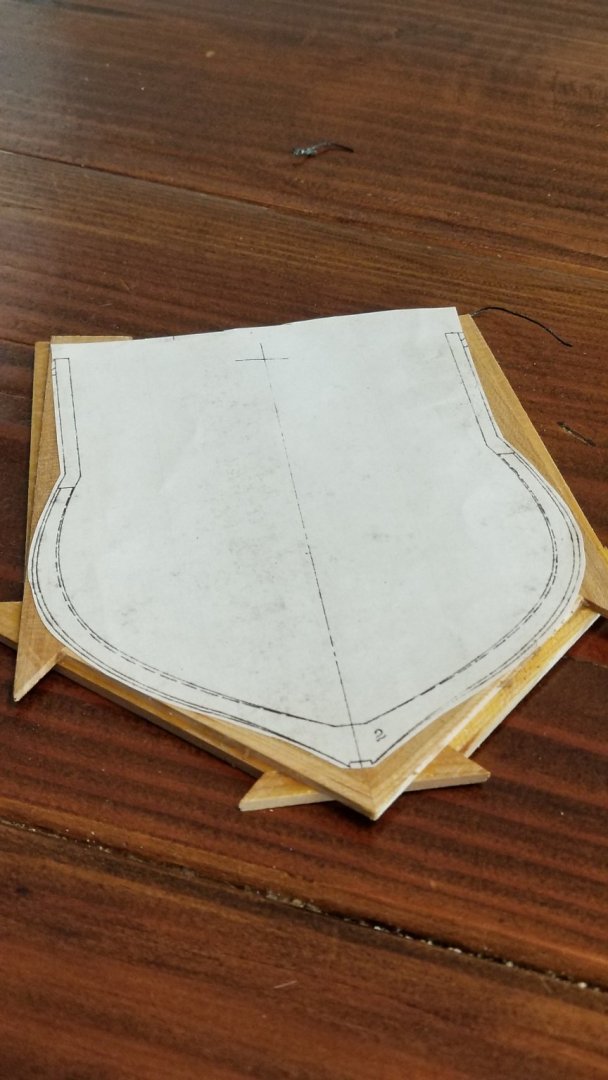

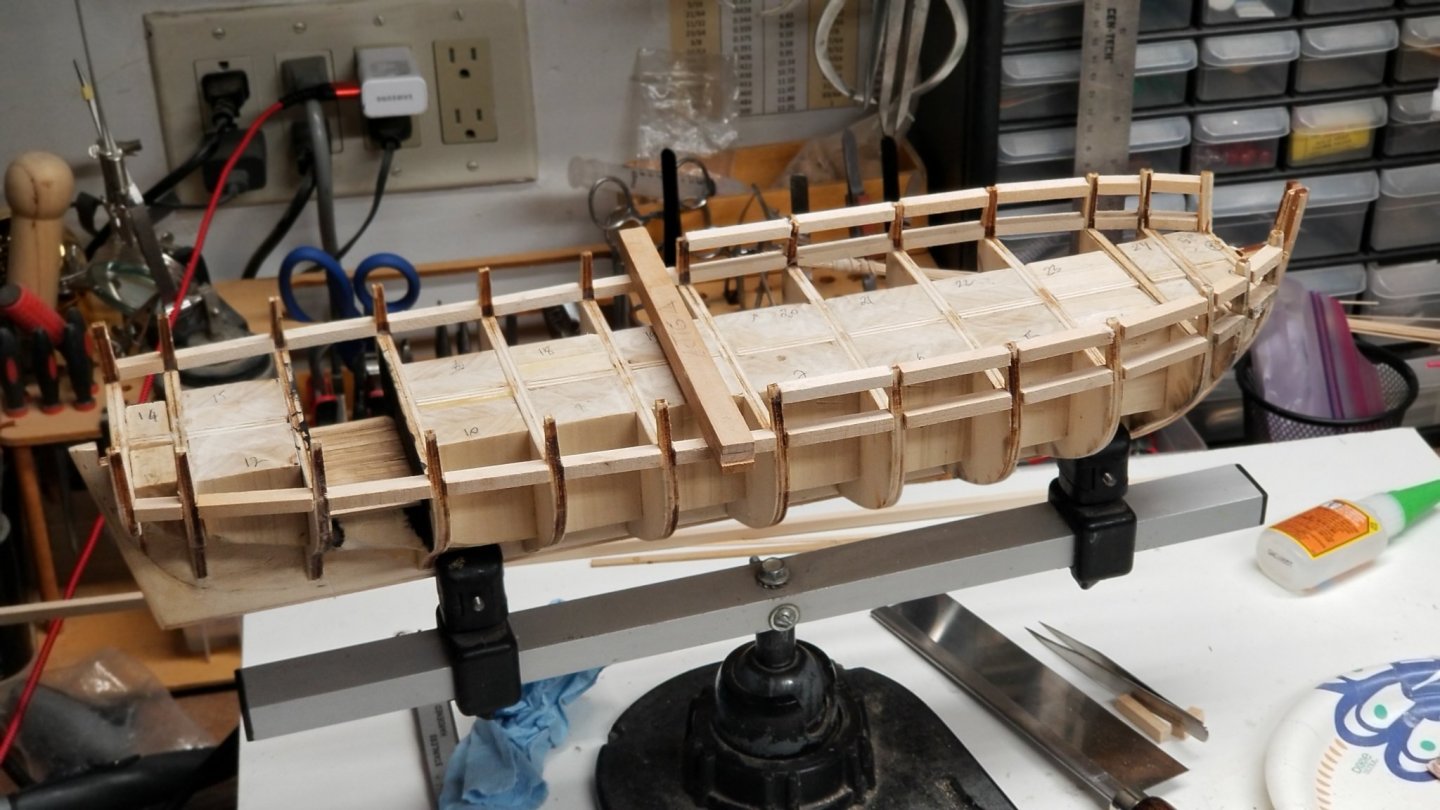

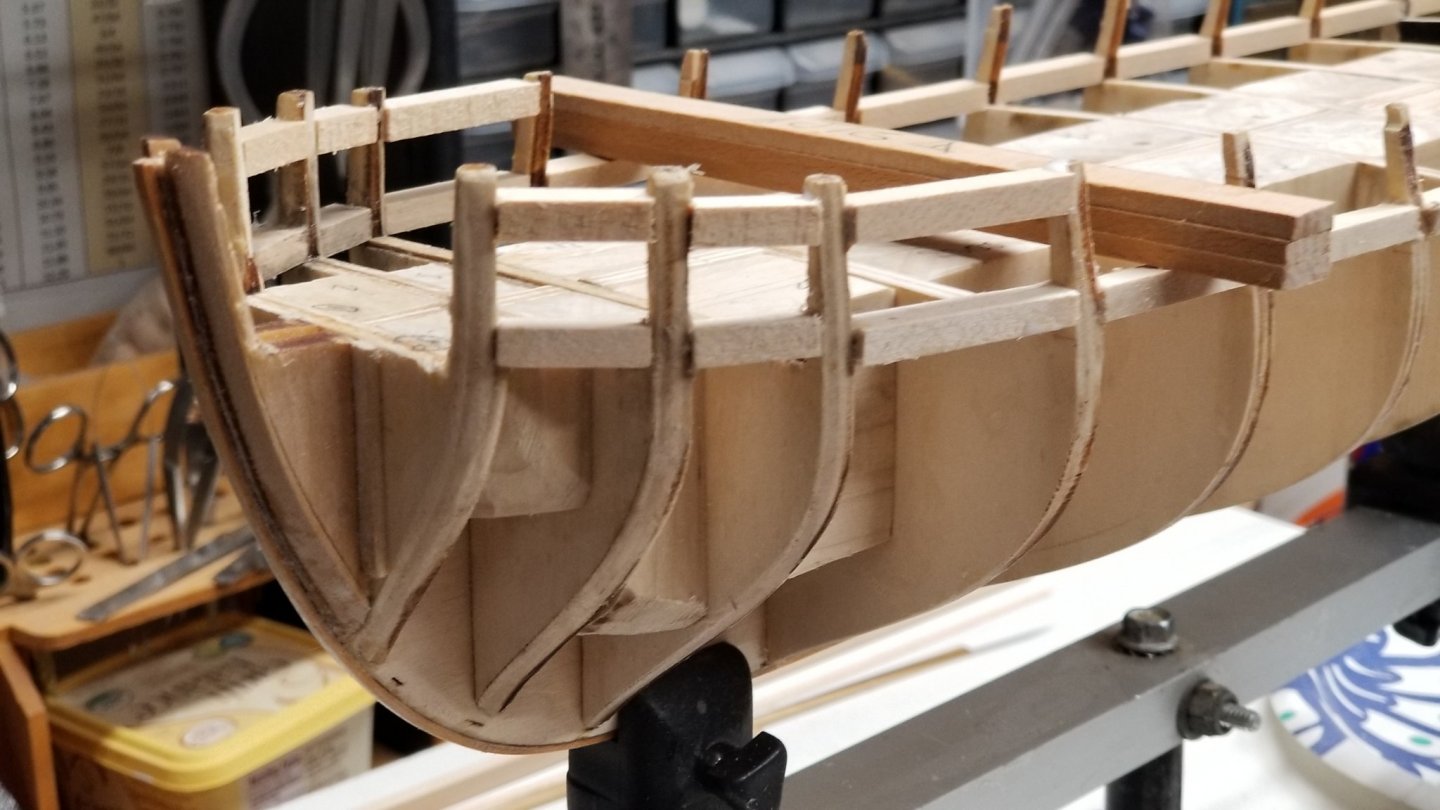

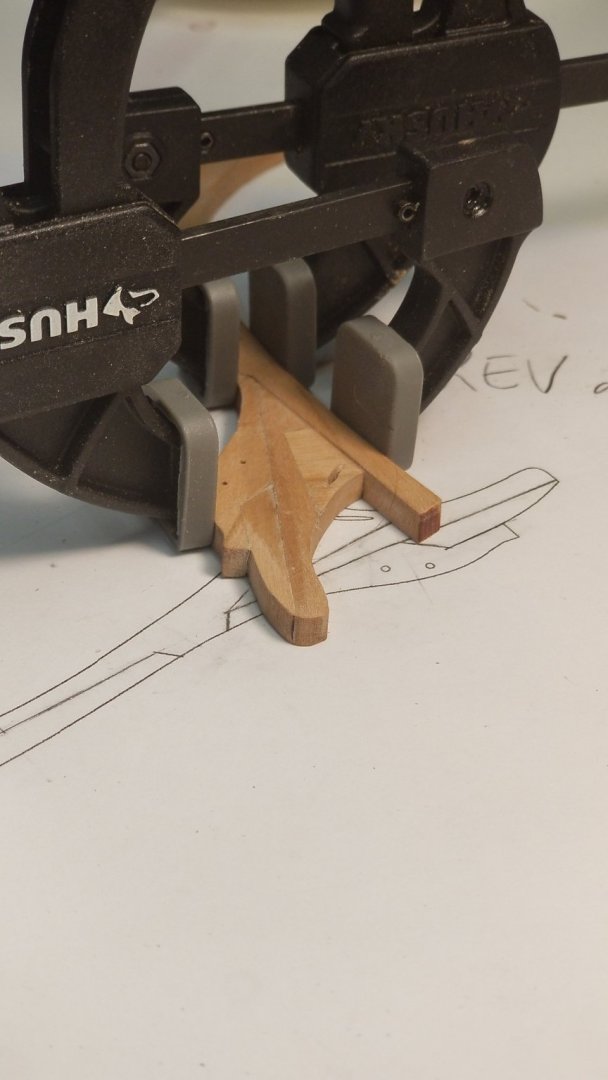

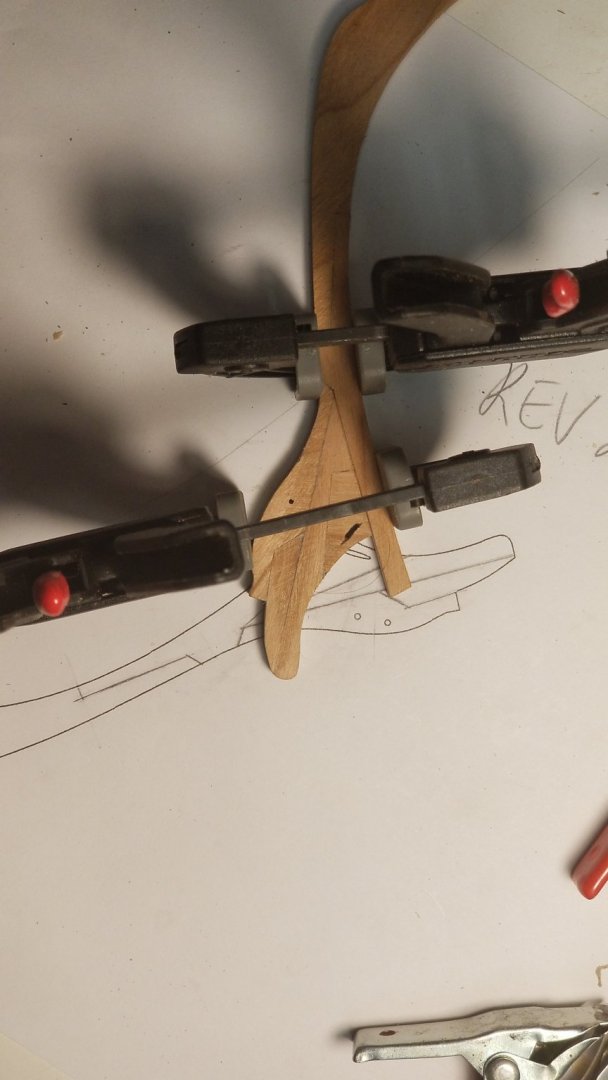

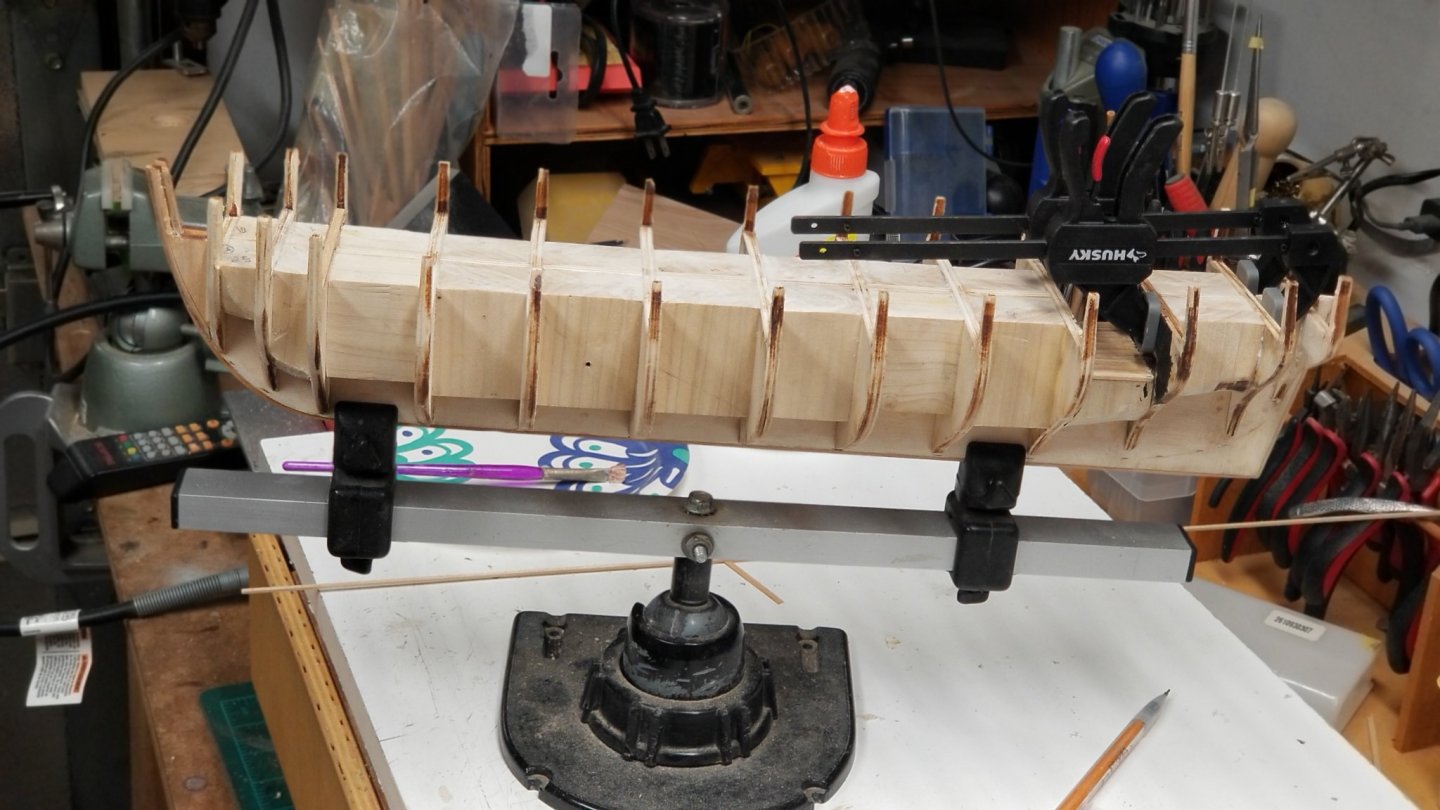

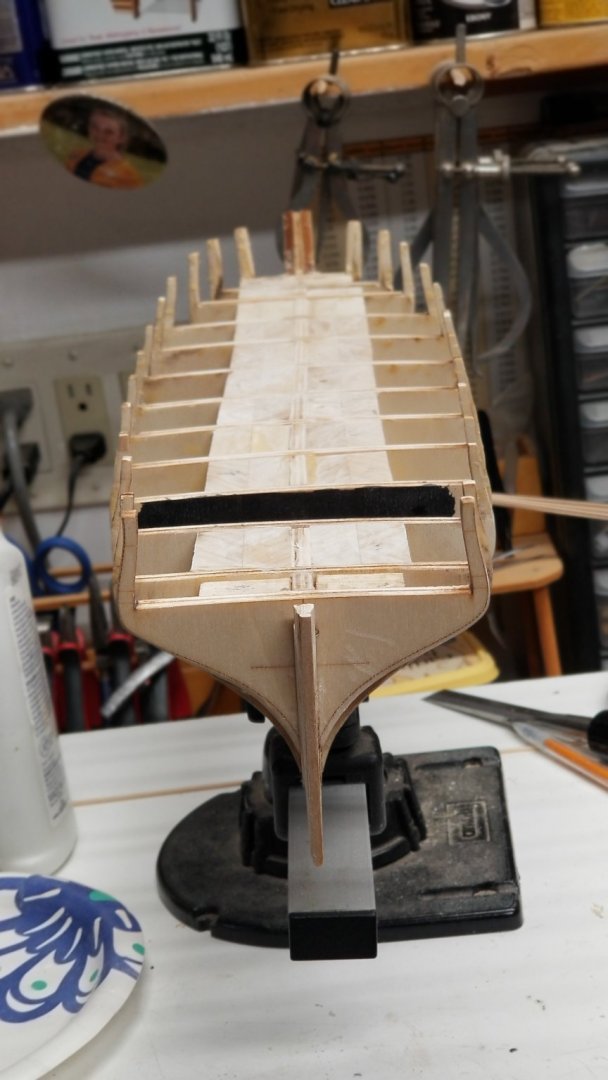

Thank you for the recommendation. I am done with 80% with the sanding of the frames. It still need to get the bevel and various angles figured out. I am assuming that you first put together the stem and deadwood with the keel, right?

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

Hi All, I was given this ship and trying to identify what could be its name. it looks like a Cutty Sack or a Flying Cloud but either the bow or the stern varies. Thoughts?

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

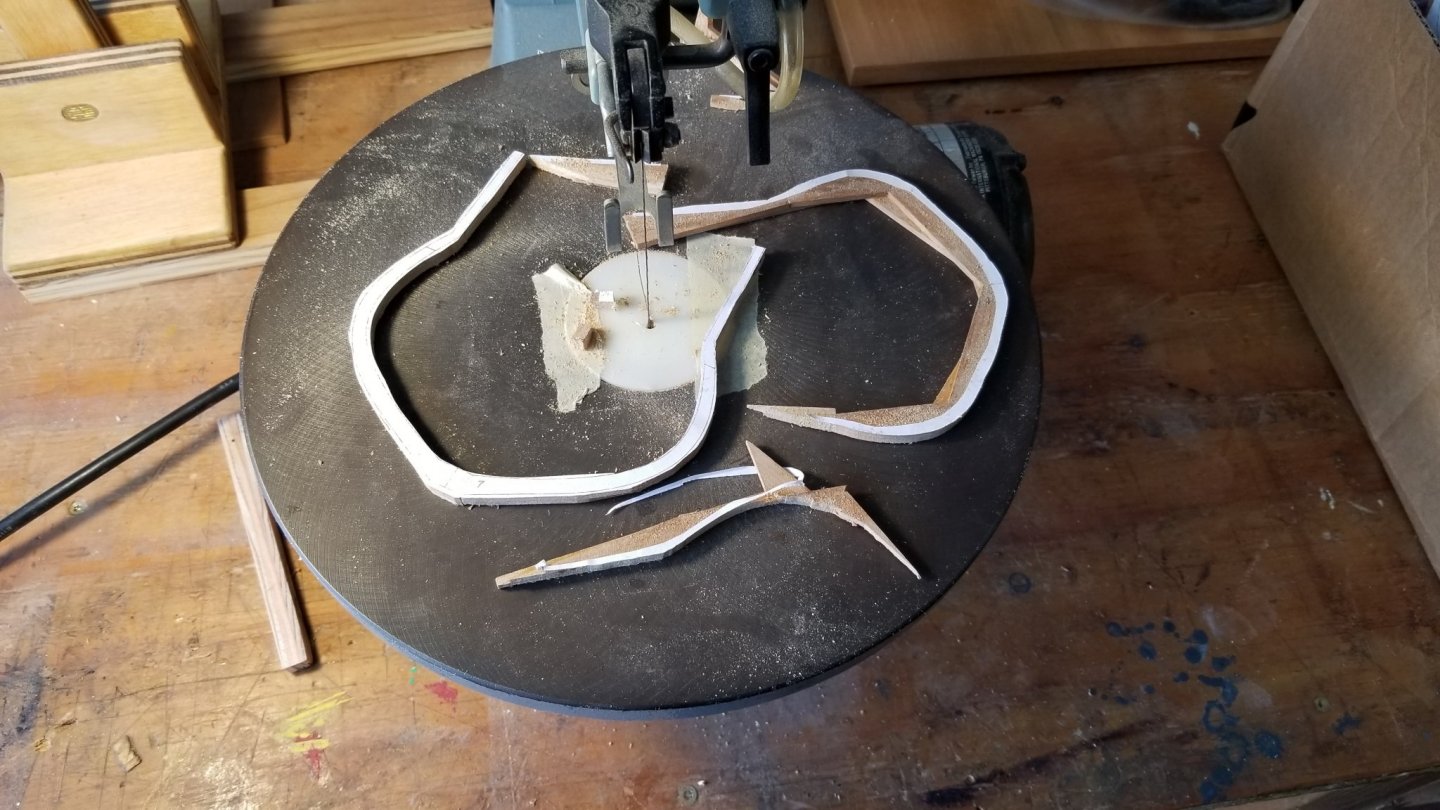

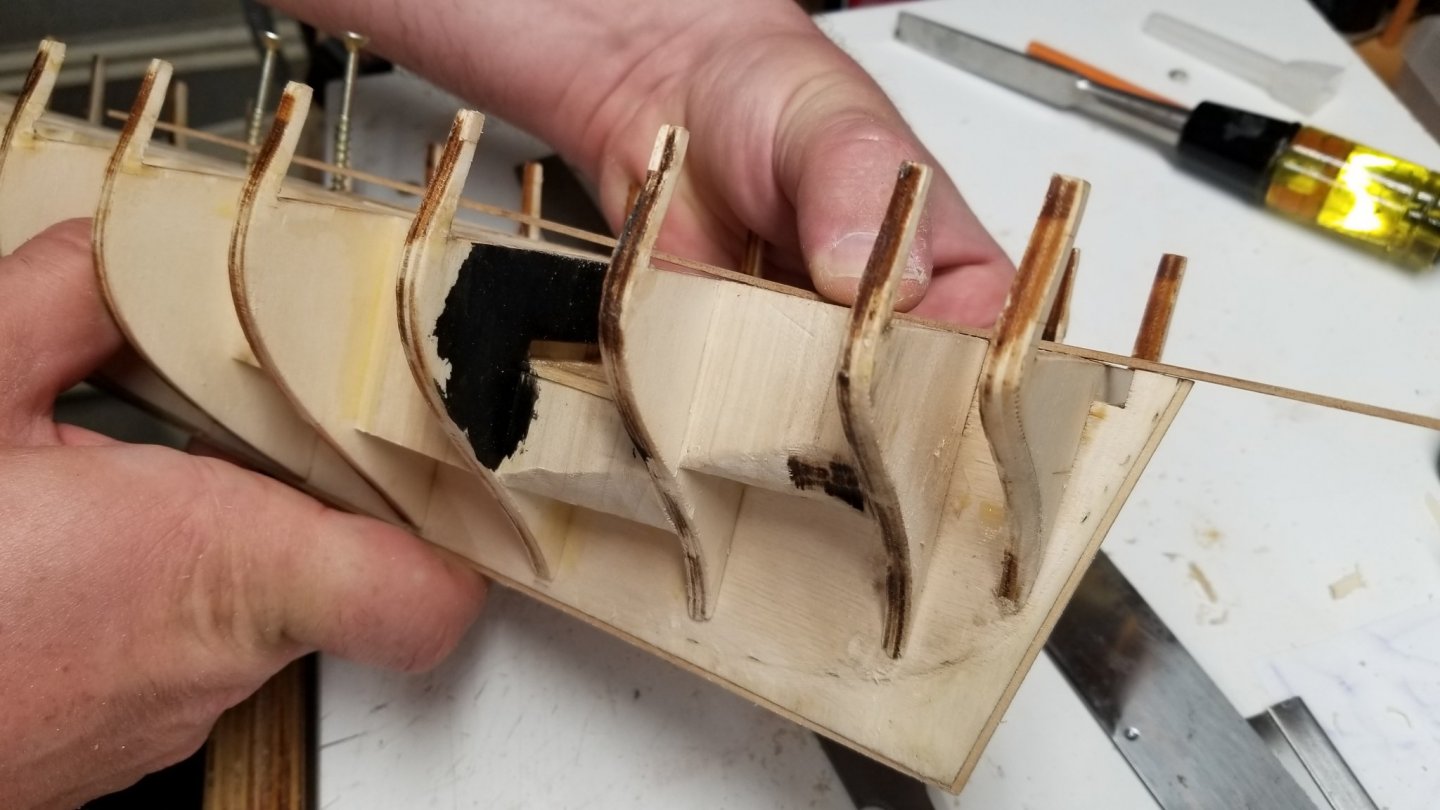

Starting to cut the frames. Stopped after 4 and ordered some new blades which will provided smoother cuts.

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

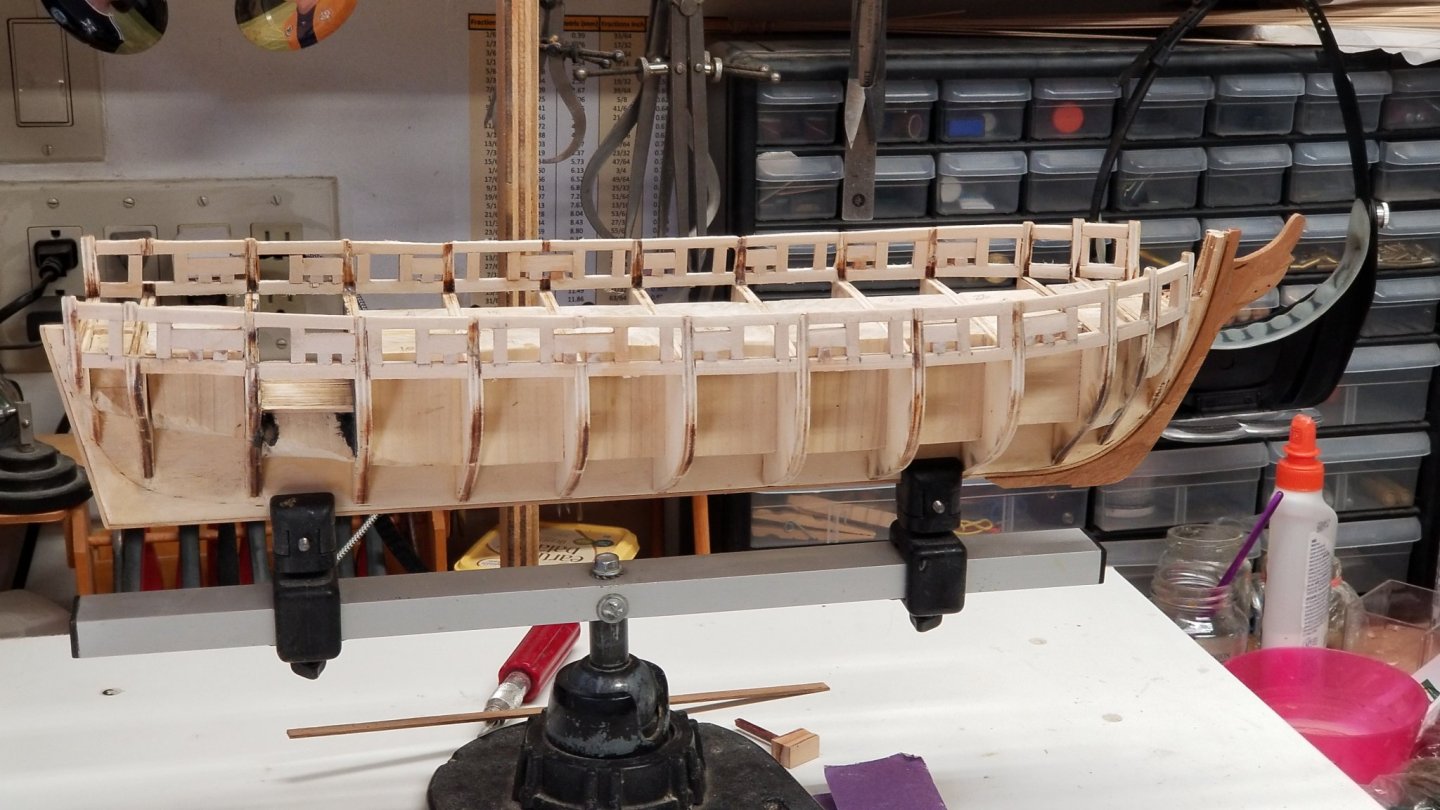

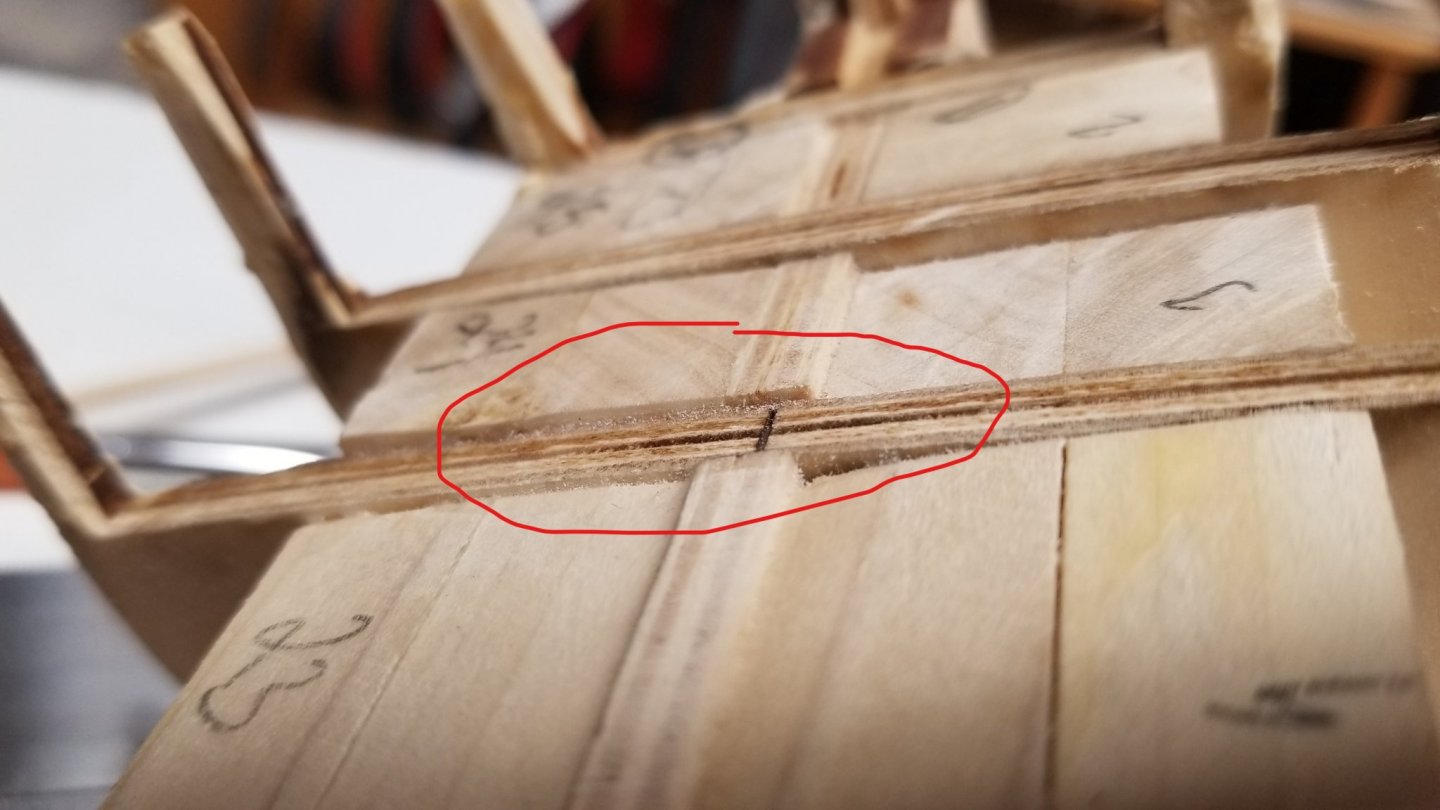

The deconstruction continues on my Syren. I noticed a few issues with frame adjustments. Here is what my survey outlined. The second and third frames from the stern were too high, resulting into a 1/16 gap between the top of the frame and the center 'spine'. See the red marks below. The solution was to remove them and the blocks surrounding them and push them down. I had a similar situation in the bow (see below). I was able to use a thin strip to provide a smooth transition across all frames for the deck planking. Deconstruction madness in pictures. Since the frames were glued with white glue, I used Acetone to soften the glue and a few tools to remove them. Time for your shot! Removal frame 2. Dry fitting frame 2. Drama with frame 3. The doctor is busy. LOL.... Dry fitting line with frame 2 and 3. MUCH BETTER !!! Gluing and rehabilitation.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.