-

Posts

620 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captgino

-

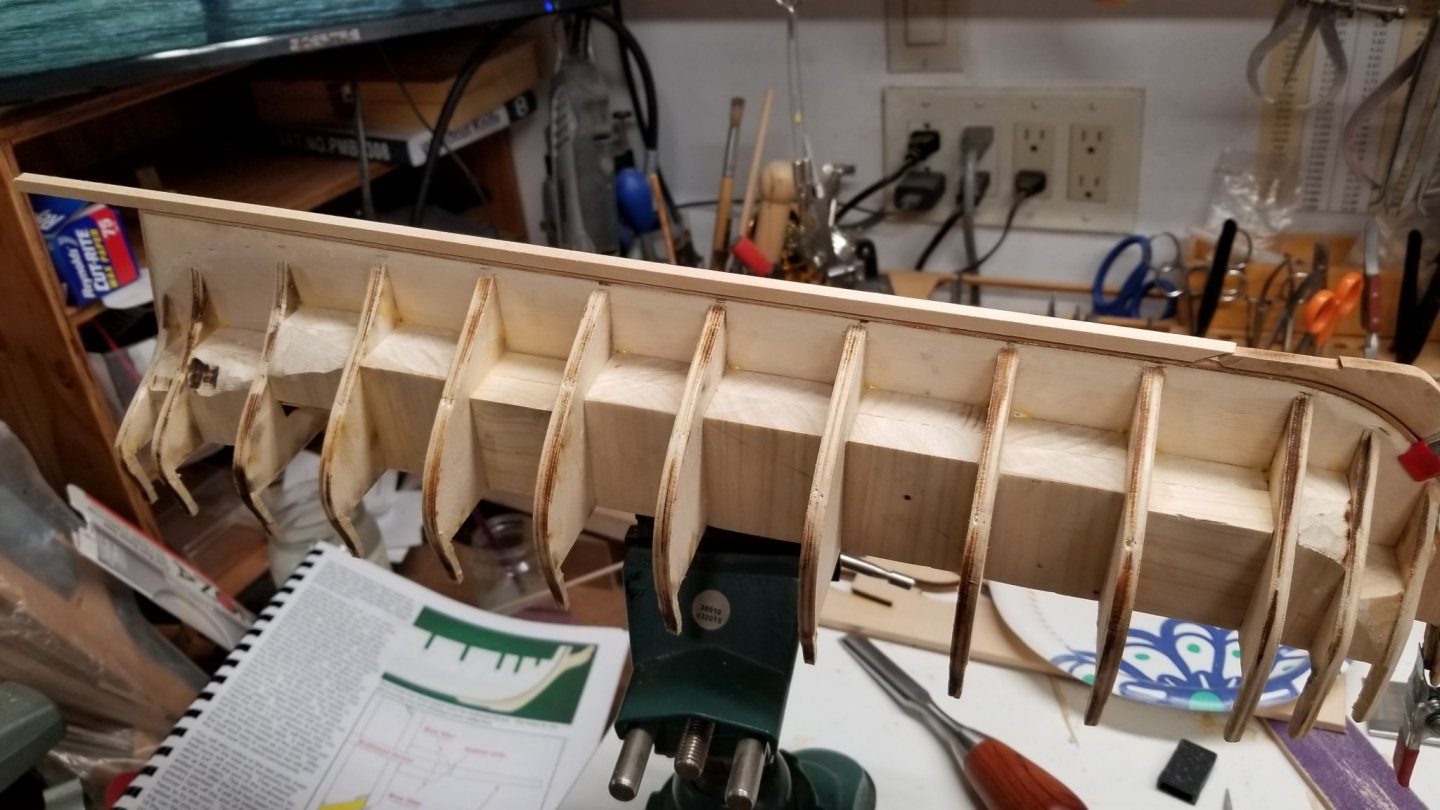

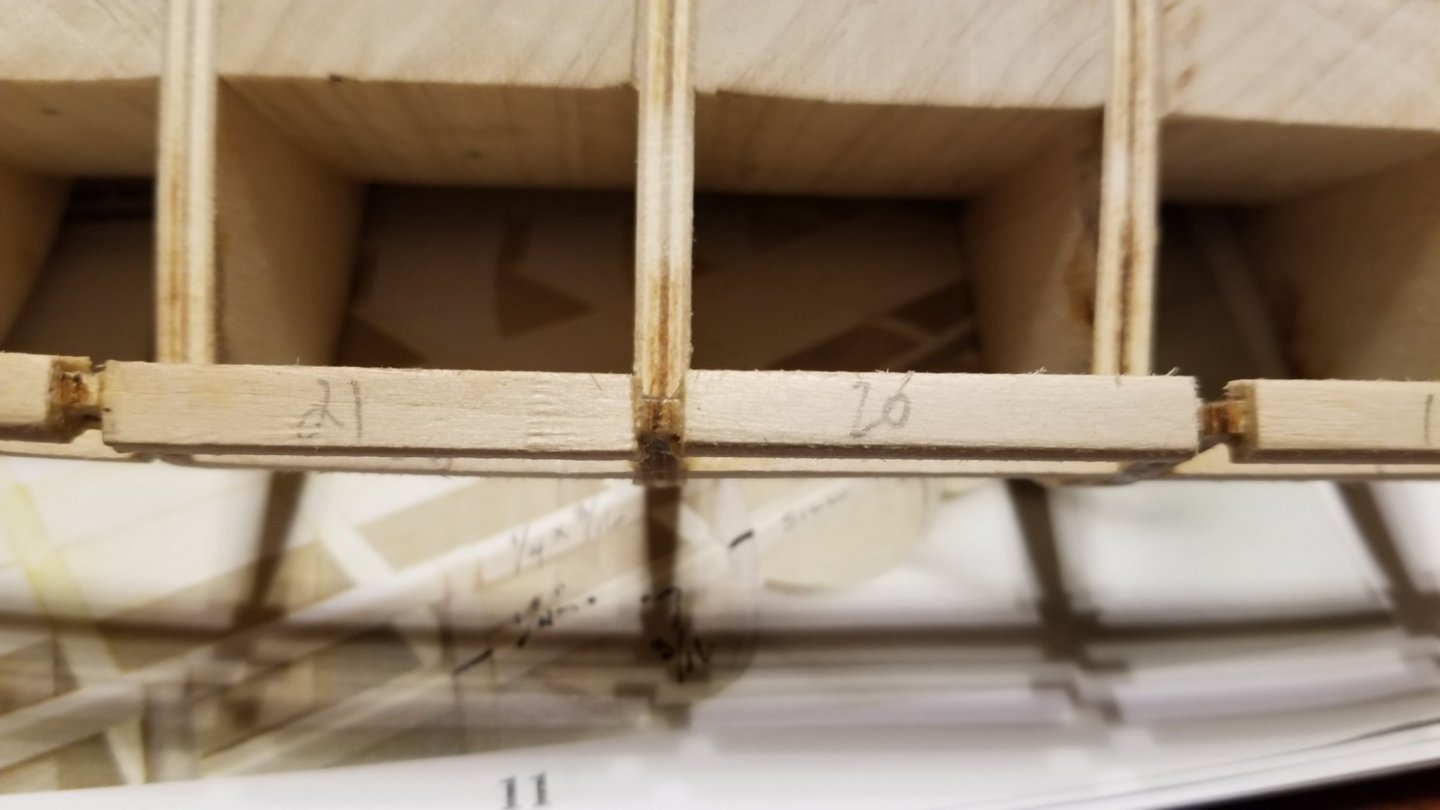

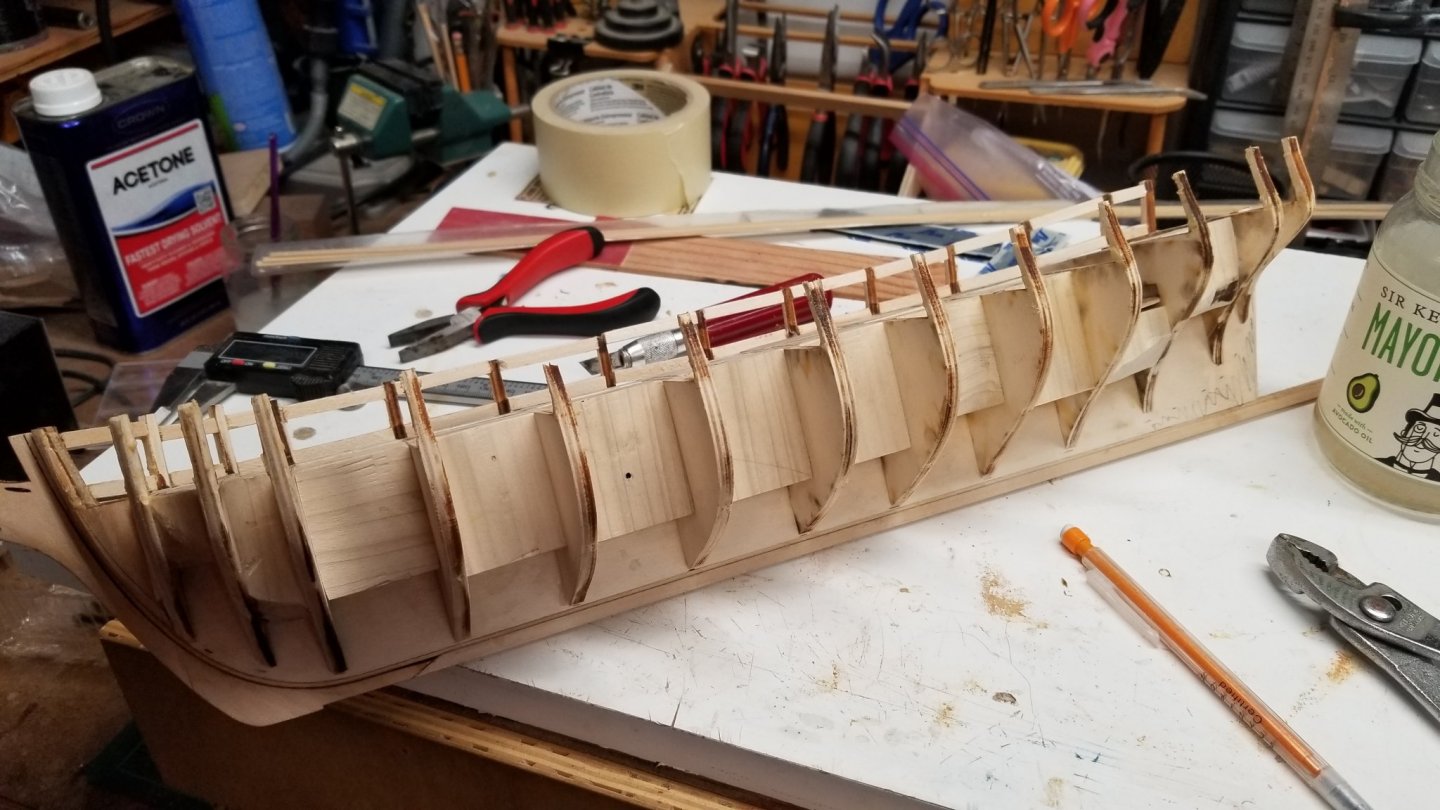

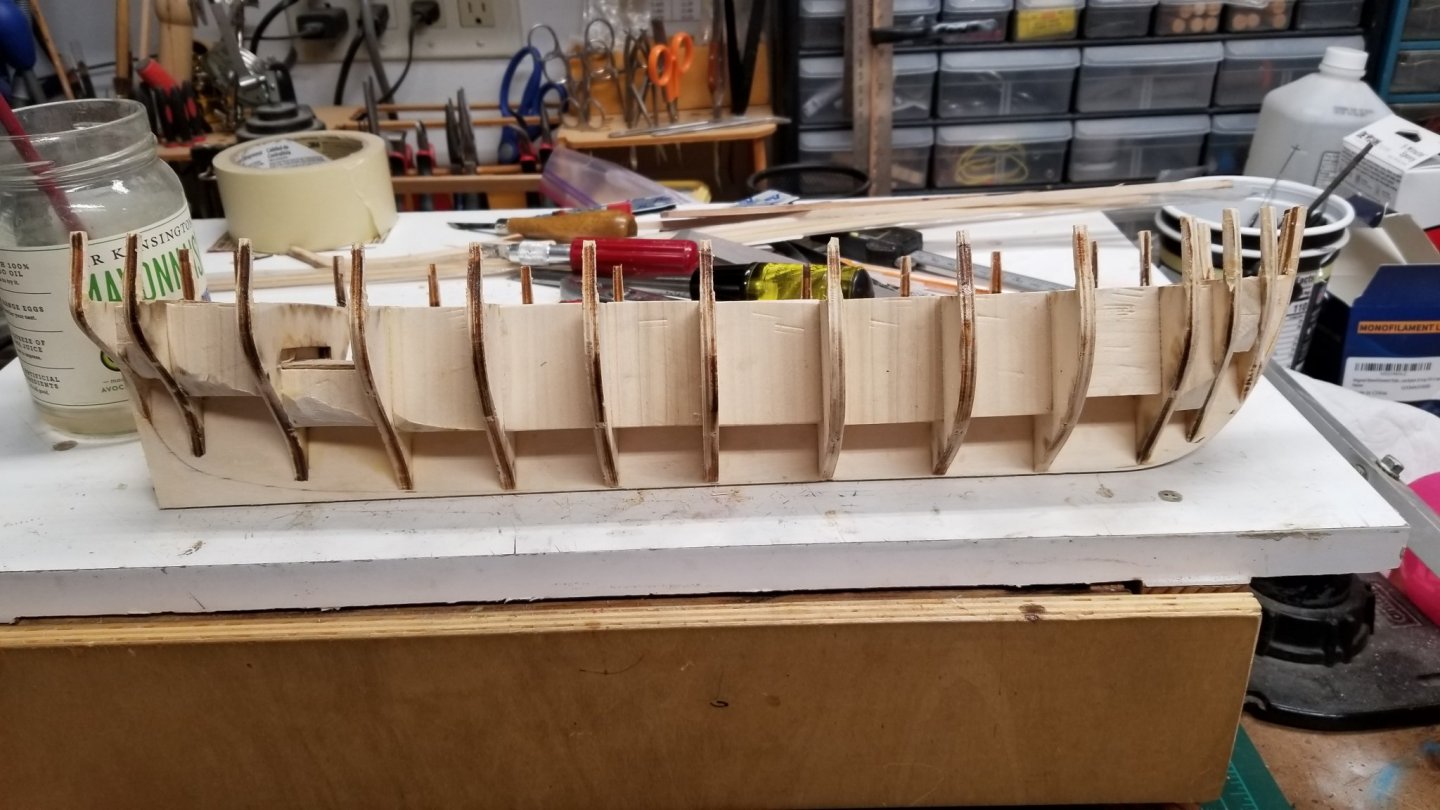

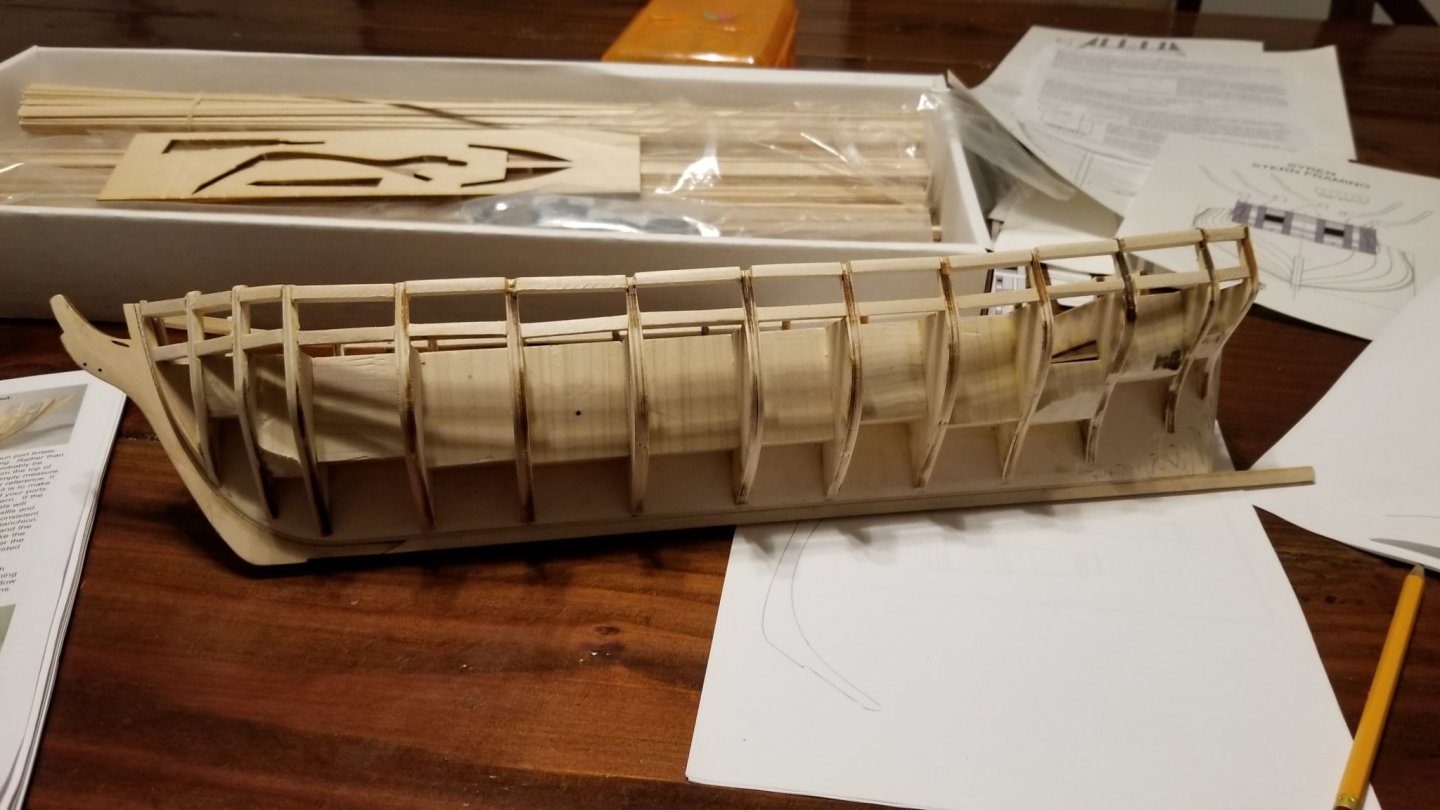

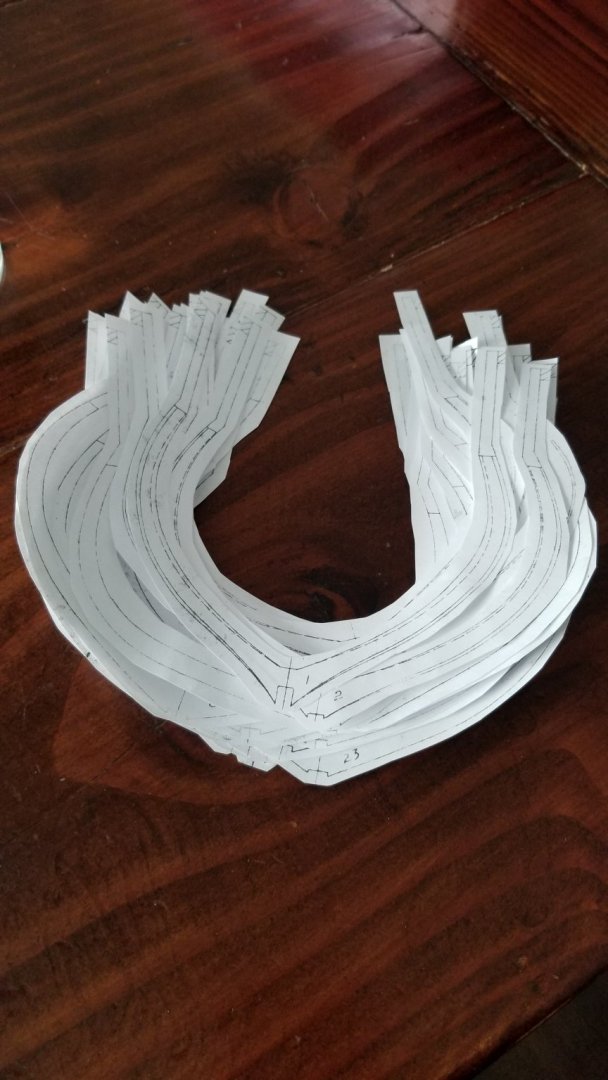

Thank you all for your comments and recommendations. I have started to glue some of the patterns. No distortion on the ones I did so far. You guys are right. It has a tendency to distort easily if you are not careful. I am being very careful and slow when gluing the pattern to minimize impact. It took me about 4 hours to glue 18 frames. I am going to make some additional photocopies to support the frames with a wider pattern. I also unfortunately discovered that I have a few frames in the middle of the ship that will need to be remade, as the pattern is too close to the edge or on it. I think it's a situation where small mistakes in the angles added up and end up distorting the frames. 🤬 Beginner stupidity!!!! I am in the process of surveying the damage. 😢

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

Thank you for this detailed information. I am sorry I completely missed it and did not respond sooner. I agree with you. I think it would be better to put the glue on the wood to avoid having The Paper distorting. I bought some rubber cement from Elmer, and I am trying it how to see how it holds the patterns. I am redoing the stem on my siren and I'm using it there I will see if it works out better. Are the dotted lines representing the front or the back of the frame? Did you tilt at all your bandsaw to get closer to the final shape?

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

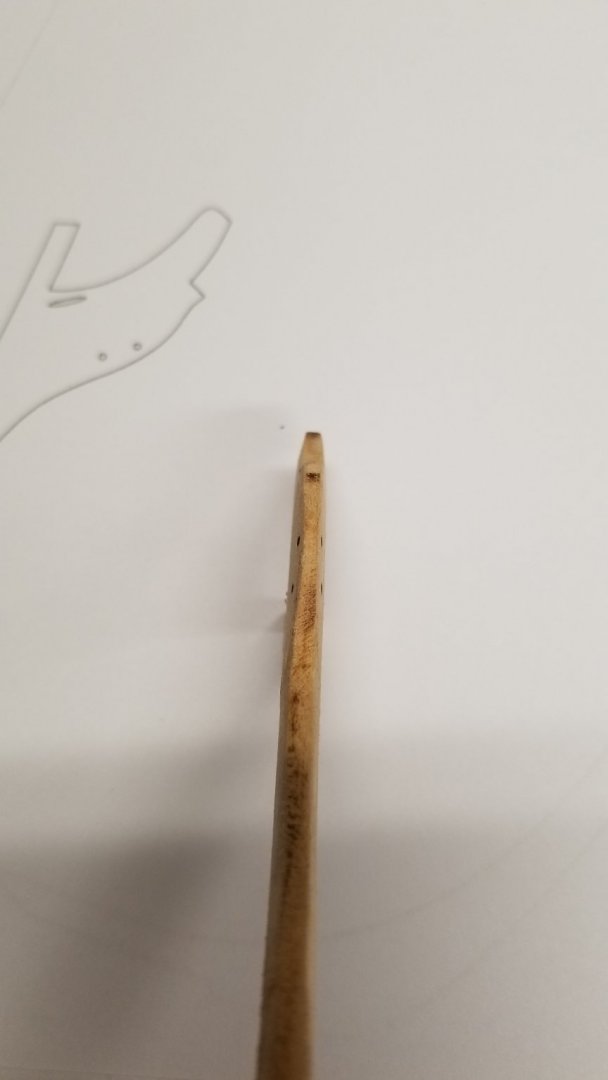

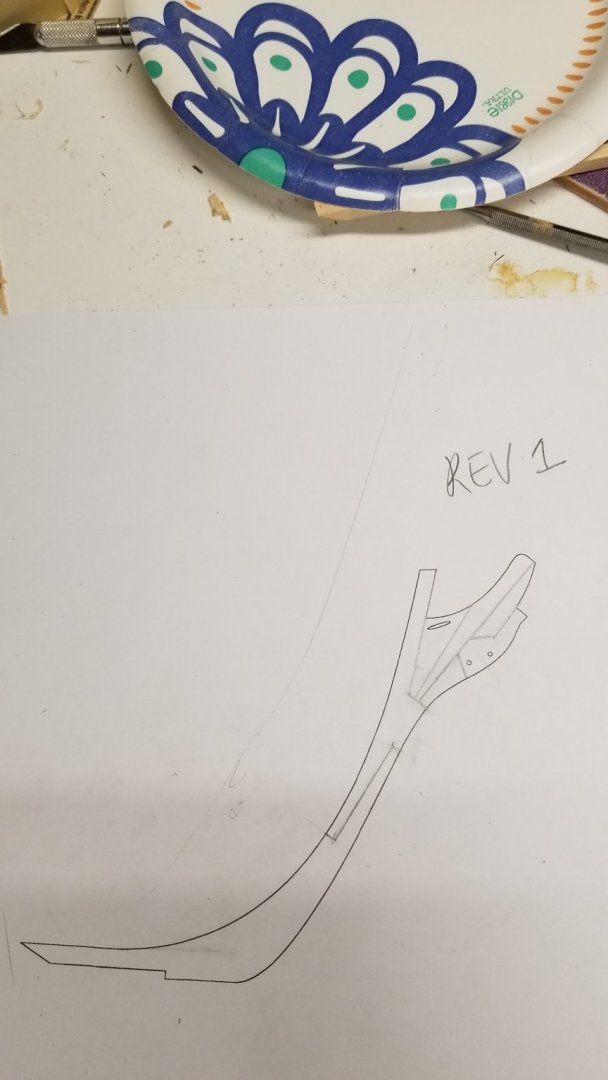

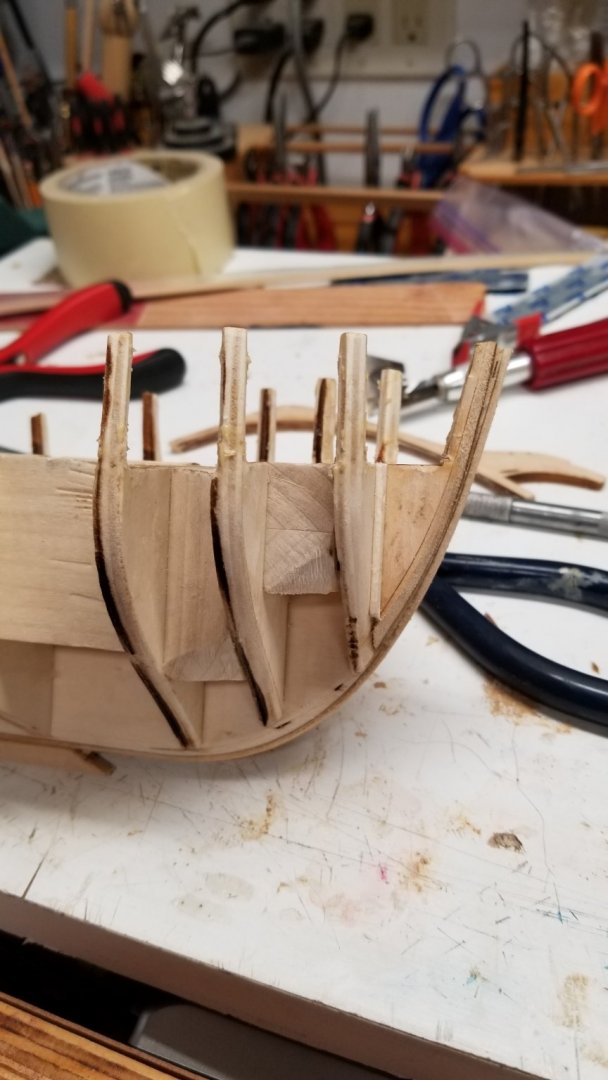

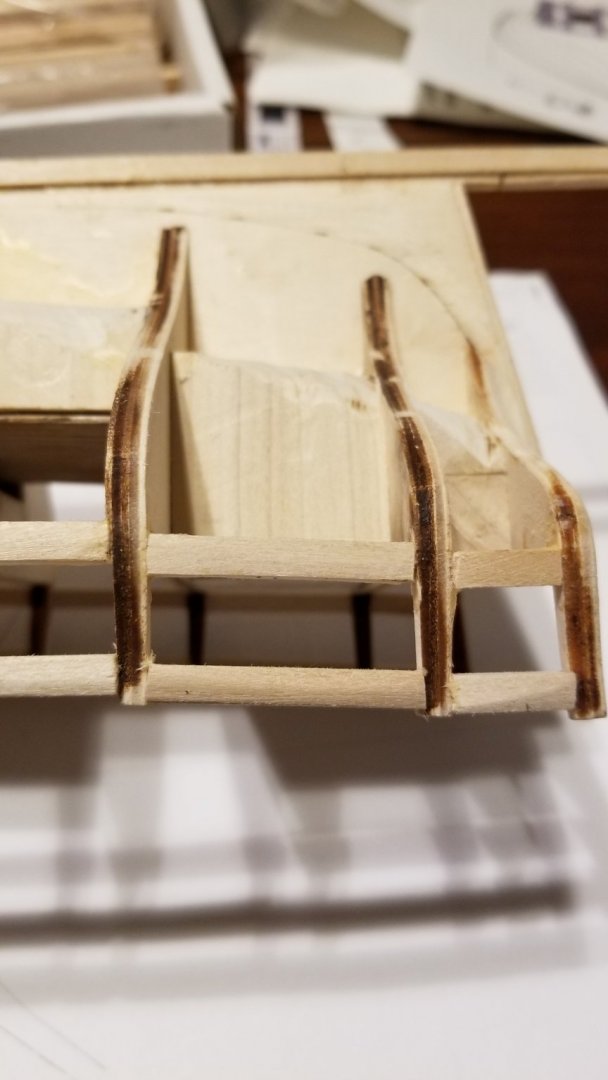

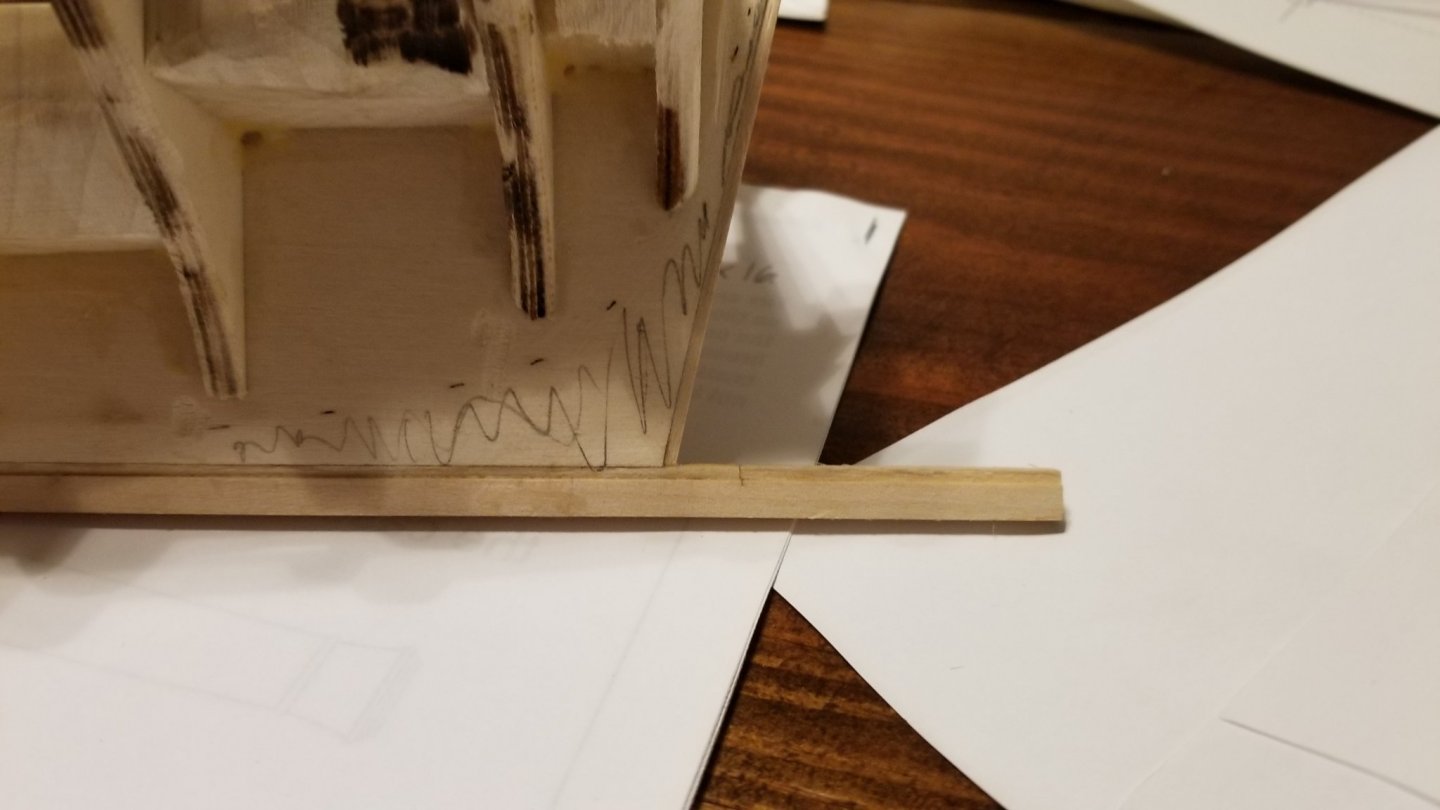

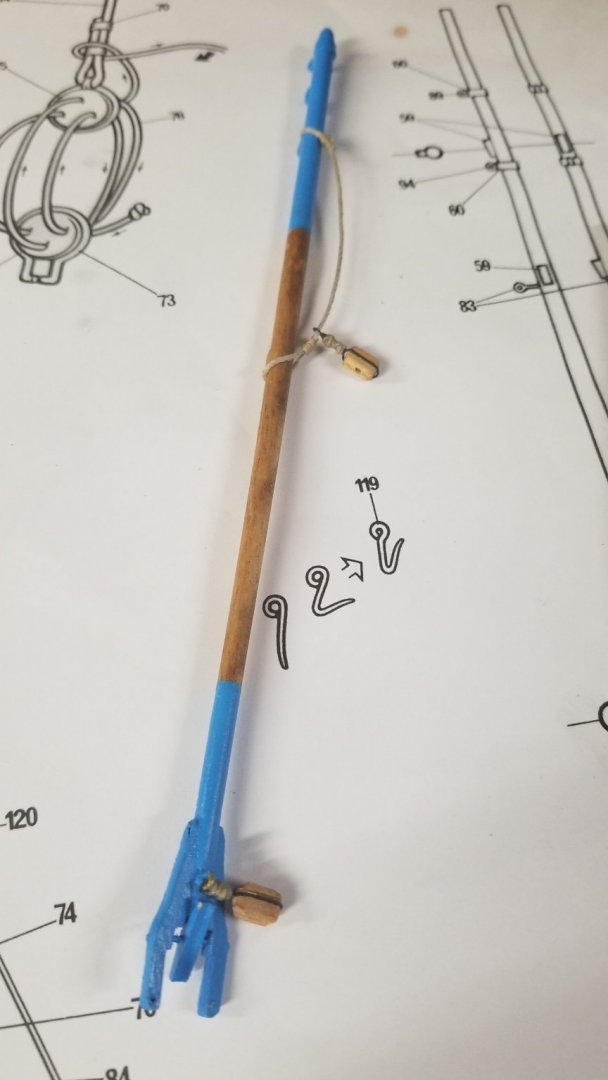

Getting crafty to hold the ship reversed. Worked on the Bearding line quite a bit last night to be able to meet with the 3/32 rabbet strip. The previous one was 1/8 so a lot to catch up to. And... Disaster the strip broke as I was putting rubber bands. To be expected when passing the bulkheads... Grrr. Here the result after fitting the strip on the stern. It will cover by copper so it will not be seen. Dry fitting the new keel and the old stem Stem needs to be redone from scratch. It was faired too much and unevenly. Draft stem design. Thoughts ?

-

Reviewed the documentation and plan. I have a few items to correct. Bearding line missing on one side. Small adjustments for the deck, some of the blocks are a bit too. high. Sills and Lintels all over the place. Stem was over sanded on one side or miss aligned. I am getting to take it appart and correct as much as possible these issues.

-

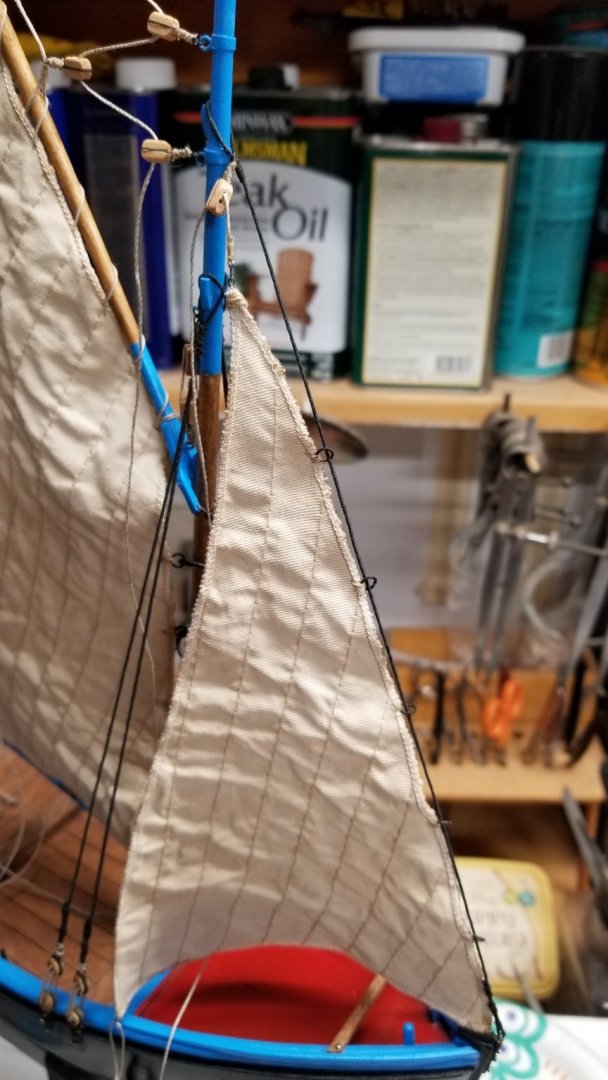

I think it is a wrap! I might spray paint my daughter's name as immatriculation AC2015 when I get my compressor back. I lend it to a friend 😊

-

Darn, a few hours wasted... The bigger problem is getting new copies in this lock-down world we live in 🤔 I will see out bad it is.

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

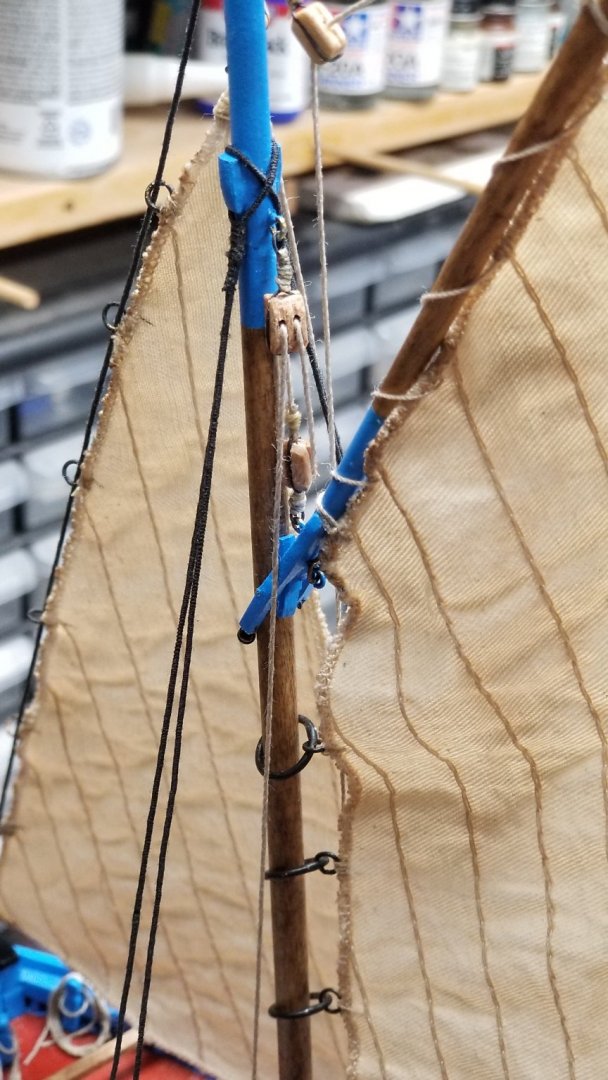

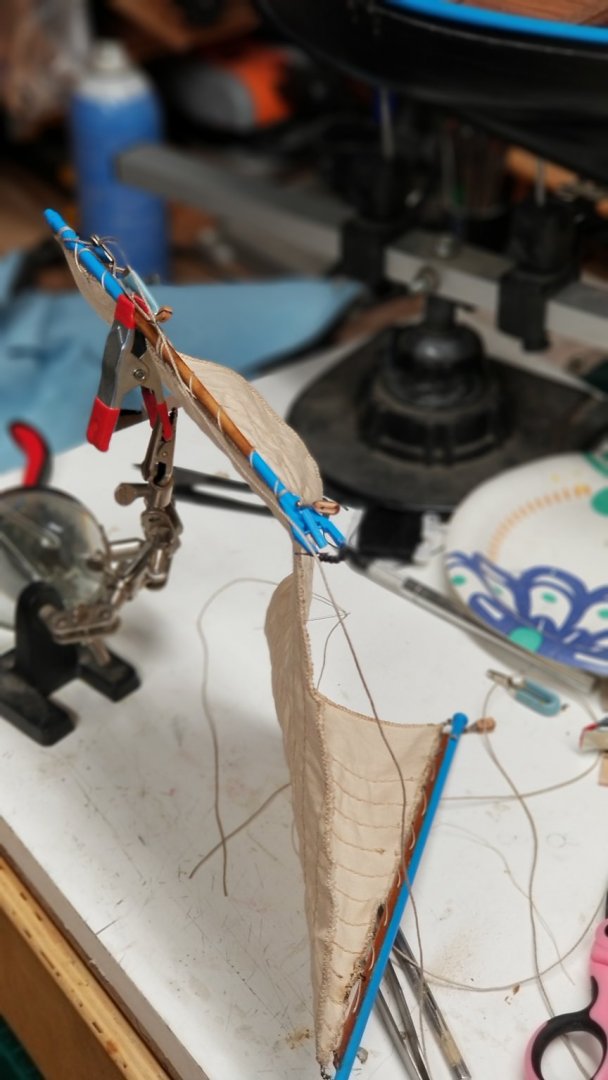

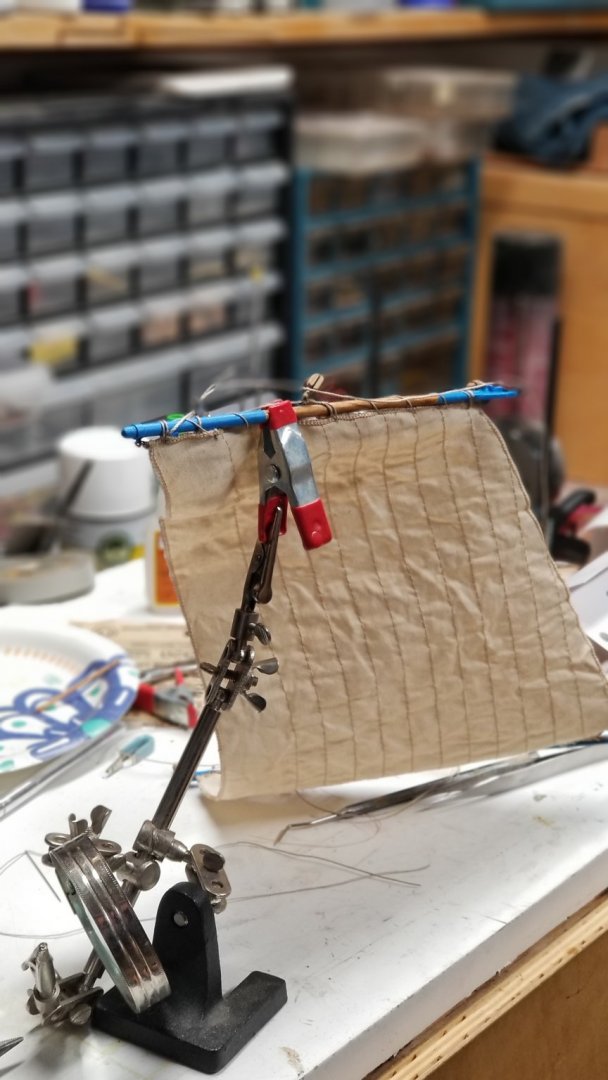

Working on the sails. Mounting one of them. Next is attaching the mast rings. Here is how I am going to hold them before sewing them up.

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

Attached the second shroud. Working on the mainstay. I served a rope and attached the first block on this build.. 😊

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

Time to start the rigging. Attached the mast. Worked on the shrouds by serving them, long and tedious process 🤪 then fasten the deadeyes. Finalized attaching on side.

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

Great recommendation. There are also a lot of French sites with a lot of pictures.

- 9 replies

-

- artesania latina

- marie jeanne

-

(and 1 more)

Tagged with:

-

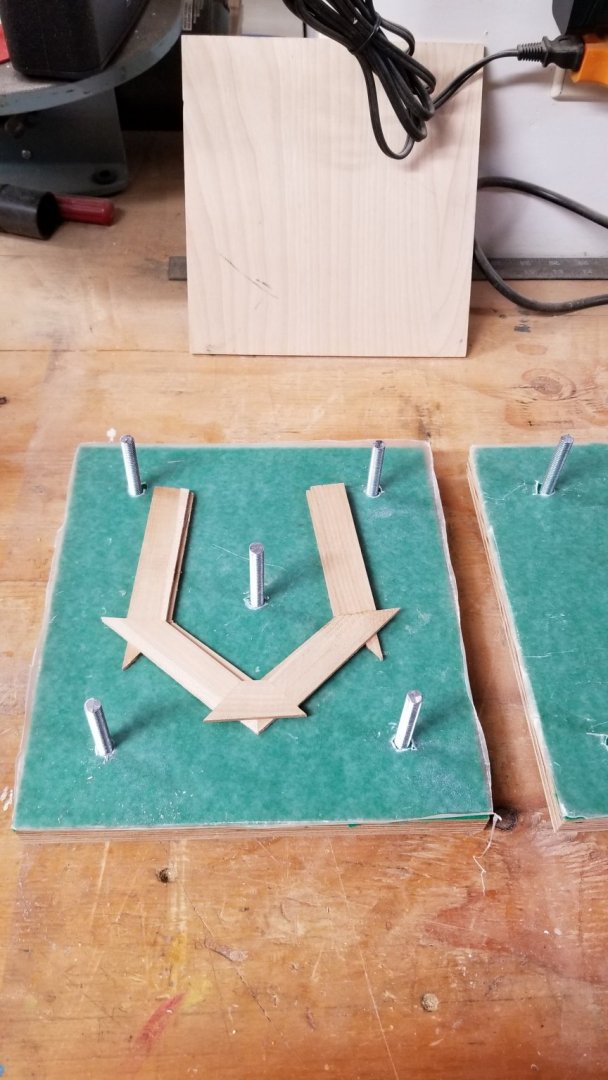

Fairly straightforward process. It just takes forever as I need to wait at least 30 minutes to let the wood glue to set. Made a key to help with the wing nuts. 😊 Here is the result after a few hours. In between glue sessions, I will be working on rigging my other projects.

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.