-

Posts

110 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MD11pilot

-

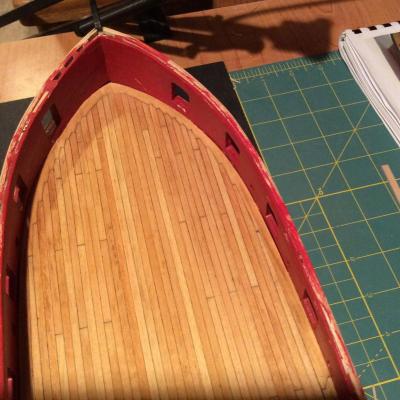

My first attempts at "joggling" or "nibbling". Followed the instructions and it worked out OK. The planking is all laid in, and you can see the results of the joggling fore…. And aft….. To finish the deck, I scraped it with the blade from my hand plane and a utility knife blade. After some sanding I finished the deck with pre-stain conditioner and a 50-50 mix of Minwax Natural and Golden Oak stain.

-

I chose to do my deck in a "3 butt shift" pattern keeping all my joints on top of bulkheads. For me, this adds enough artistic appeal, while keeping the difficulty to a minimum. The idea of joggling into the margin plank was intimidating, but I have to keep reminding myself that this project is supposed to teach me all the all the skills I will need on other projects. I used full width planks from bow to stern instead of tapering. I do like the tapered deck planks others have used, but at my skill level I opted to joggle full-width planks fore and aft. As Sal suggested in his log, i laid in the first 3 planks on either side of the center line with no butts. Most of these planks will be covered in deck furnishings so the effort would be wasted. Also, applying these planks as full length pieces gave nice straight lines to work out from. I used the #2 pencil method of simulating the caulking. The first, full length planks go in….

-

Like a few other Syren builders, I decided to delay the installation of the cap rail. I'm not careful enough, and just know I would beat the heck out of the rail while planking the deck. So, my next step will be the deck. The laser cut margin plank didn't come close to matching the curve of my ship so I had to cut my own. I placed the scarph joint one bulkhead farther aft than in the plans so that the "straight" piece wouldn't have to bend much.

-

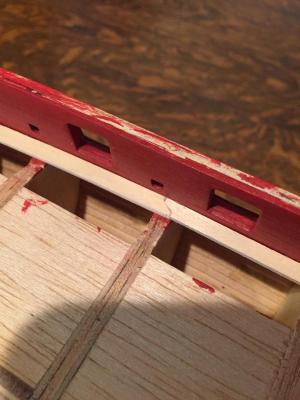

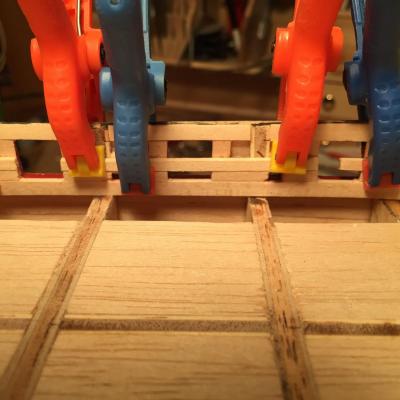

Preparing for the interior bulwark planking. I couldn't stand the thought of thinning down the bulwarks with a sanding block, so I used my electric detail sander. To keep the edge of the sander from chewing up the deck framing too much, i laid down a layer of duct tape. Then the planking is laid in. Since the interior planking is flush with ports, I elected to overlay the planking over the ports, then cut flush with the hobby knife and sand to match.

-

I wanted to add beading to the moulding strips, as pictured in Chuck's instructions. I tried to create the bead on the strips freehand, but just couldn't get a straight line. My stylus would follow the grain and drift off the centerline ruining the piece. So I made a very simple jig out of scrap material. It's nothing more than a couple pieces of planking glued on top of plywood creating a channel just wide enough for the the moulding strip. I predrilled a hole to tightly hold a T-pin just poking thru the center of the channel. By pulling the strips thru this jig I was able to get a decent beading effect. Adding the moulding to the transom...

-

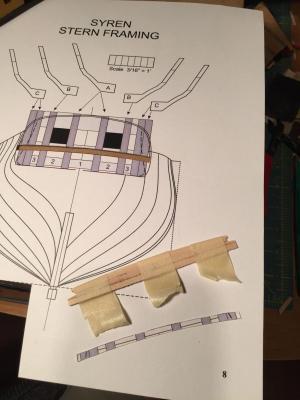

Next I worked on the moulding strips for the transom. I wanted to prebend the strips to ease the process of attaching them to the transom. So I made a simple jig, using the plans to create the correct curve. After soaking the strips, I attached them to the jig and let them dry. As you can see in the picture, even after drying completely, the strips did not hold the curve completely. So if you use this technique for your ship, exaggerate the curve a little bit on your jig.

-

Okay, I admit it - I'm really lousy at keeping my log up to date. So here's some catching up... After completing the exterior planking, I paused for a couple days just looking at the ship and taking stock. Unfortunately, I didn't like what I saw. Specifically, the treenailing was garish. Too big, and too dark. So I made the decision to paint the planking yellow ochre, thereby covering up my mistake. I actually like it painted, even though that was not my original intent. The treenailing faintly shows thru the paint giving a nice effect in my opinion.

-

I love building logs that show the actual techniques and tools used to perform difficult operations instead of just the final outcome. Thanks for the great ideas and nicely done!

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Model paint data base

MD11pilot replied to jbelwood's topic in Painting, finishing and weathering products and techniques

This is a really nice resource John! Thanks. I'm trying to find a color match to the tannish-yellow I've seen on photos of the Brig Niagra and this is helping a lot. -

Hey Augie, after returning from my sabbatical, I spent a pleasurable hour this morning catching up on your new (at least new to me) project. You've been a busy boy!! As always, nicely done. I look forward to following along for the rest of the project and gaining inspiration and knowledge from your comprehensive building log.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

I painted above the waterline, actually going about 1/8" below the line to make sure there were no uncovered areas when the coppering reached this area. I was cheap and used regular masking tape. I tried my best to get good adherence with the tape but still had some bleeding under the tape. That's not a big deal on the hull where it will be covered with copper, but it's a really big deal when it bleeds on to the planking around the gun ports. That ended up costing me extra time doing extra sanding. I've read about good results using Tamiya masking tape on other building logs. Probably a good investment. And that brings me up to date.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.