-

Posts

106 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Aleksei Domanov

-

Put through and make knot Put through and serve over. To fix last bight- make overlapping like knot.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

no , I do not use glue. 1. make a knot 2. start to serve over this end let me know if you need pic, photo or vid of this.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

several ways, for example, put it through using needle.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

sorry, misunderstood you :-) what the chemical do you use for copper?

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

solder is different material so needs different chemicals for blackening

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I used it on San Juan - outstanding results.... top marks

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I use gutermann scala360, scala 240, scala200 – two-threaded. I wind two threads in one rope. And resulting rope is used to serve. 2-threaded serve is textured and looks excellent.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Domanoff Rope Serving Machine

Aleksei Domanov replied to Ensign's topic in Modeling tools and Workshop Equipment

I've made prototype like pre-release and now looking how to make it cheaper. Too many acrylic - costs money. Hope to solve it within few weeks. -

Domanoff Rope Serving Machine

Aleksei Domanov replied to Ensign's topic in Modeling tools and Workshop Equipment

now I can make little announce - I'm on the way to make set of marking tools: main tool is laser vertical lines marker and as bonuses - WL marker and centre finder. :-) -

Domanoff Rope Serving Machine

Aleksei Domanov replied to Ensign's topic in Modeling tools and Workshop Equipment

Opps... Sorry, I missed this post The problem was with our site (you couldn't use some symbols in both address and name fields), now we fixed it. Thank you for your help to solve this. Your parcel is shipped out from our country on 3.09 and maybe still on the way as I can't obtain any data from Australian post. Sometimes it takes 7-10days, sometimes 30... Post is unpredictable... Have you received PSU? BR, Alexey -

Dear Michael, I share my experience as well :-) And I proud if I can help such great Master as You. I mean to take care about even wound of thread on spool. If it's "soft" on one spool and "hard" on another - you definitely get "jammed" final rope. Another "cure" - lower the speed of head and takeup block. Alexey

-

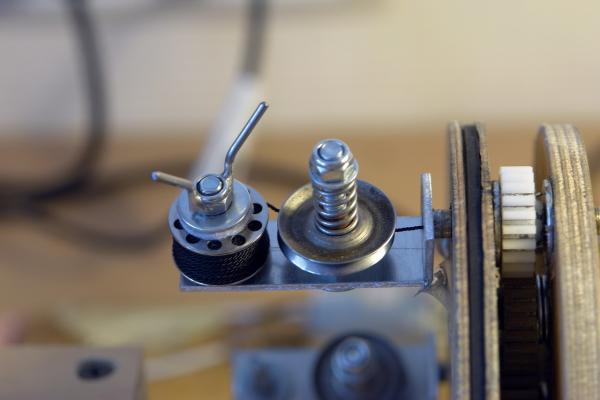

And I see you have problem with quality of "twist". item 4 - It depends on how even strands leave spools. My experience on this matter says - you do not need to brake spools. I made a lot of experiments and lot of versions of spool holders... even in such way :-)) and you need to give attention how thread is lay on spool. any questions - you're welcome! you see, I sell version 2.5 and spent several years to make it...

-

BTW, item1 - this is the main idea we use in ropewalk Prosak. 1 step - you make big "unwind" tension in strands 2 step - leave strands and let then rotate freely to wind in rope how much you make "unwind" tension - so tight you'll get rope

- 26 replies

-

- Ropewalk

- Linen Thread

-

(and 1 more)

Tagged with:

-

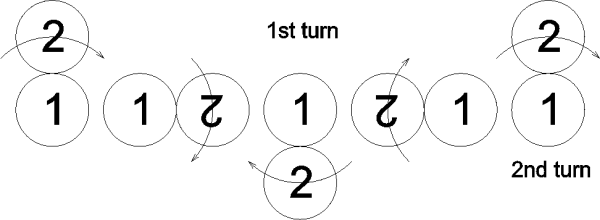

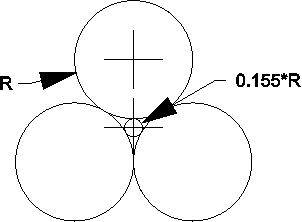

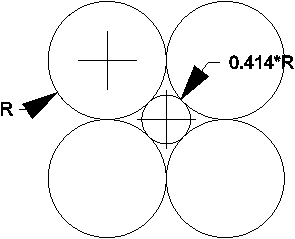

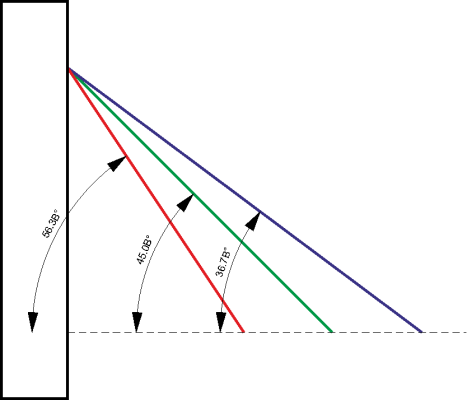

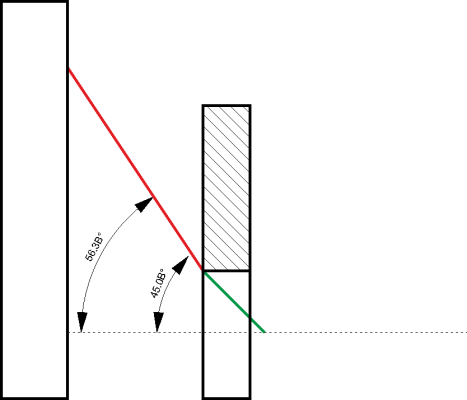

First of all: THANK YOU VERY MUCH, BOB, FOR THIS REVIEW !!! And let me explain some ideas I used in this ropewalk (sorry for my english...). 1. Ratio of "sun" and "moon" gears have a value, "Planet" gears are used only to reverse rotation of "moon" gears and their size may be any. sun:moon = 2:1. Why? Take a look at pic: Because thread is not wire, it's non-deformable. You have to "unwind" each thread while they wind one around another. Otherwise there will be tension in final rope which will try to unwind. How many turns? Two for one turn of all threads (look at the picture). Now if you put mark on spool holder and make one turn of all system you'll see mark makes two turns. One around "moon" shaft + one around main shaft. That we required. 2. Central core. Thank you, Bob, for good idea! Can I use it in my future machines? When do we need central core? Let's take a look at pics: This is 3-strand rope. You may see - everything is ok, all strands lay in their places. You may need central core (made from very thin wire) if you'd like to "form" rope as you like. Diameter of this core shouldn't be more than 0.155 * R. This is 4-strand rope. You HAVE TO add central core, otherwise strands will try to be in "center" of the final rope. 3. Quality of the resulting rope. Quality depends on angle in which strand goes into resulting rope in "wind point". Big angle (red) - tight rope, small (blue) - loose. Should be around 45 degrees (green). "Wind point" position depends on takeup block speed. BUT. There is one trick... Using cross bar (guide bar) you may make this "wind point" at any distance from ropewalk! Look at pic. You may see, 45 degrees angle depends not on position of guide bar but on... hole in guide bar! Even not on hole as it is but on the front point where strand "breaks"... You may see on photo - I use different types of guide bar:-) 4. Quality twist, without whorls. It depends on how even strands leave spools... If one goes jerky - wind point jumps and final rope has whorls.

- 26 replies

-

- Ropewalk

- Linen Thread

-

(and 1 more)

Tagged with:

-

In 2005 I made a lot of experiments and wrote article about this, but in russian. Most of that results I put at the end of this manual Prosak - User's Guide, v. 2.1.pdf Full version of article with graphs (at the end) you may find here http://www.shipmodeling.ru/content/tooling/detail.php?ID=302 (try to use google to translate from russian to english...)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.