-

Posts

120 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gluedandscrewed

-

only reason i can find for the main channel falling over the gun port is that dimensions taken of flat drawing dont compensate for the curvature of the hull,, just gonna have to run the chain above the gun port to the hull,,live and learn

-

thanks 1234,,started early june,,say 14=15 weeks times at least 40 hours a week,,,, think the wife might just be right

-

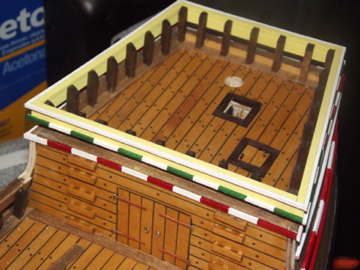

mistakes have been made but for a first build i am very satisfied, wife thinks i have become posessed, maybe shes right,,already thinking of what to build next,,,,she came into the cave yesterday and observed " youre almost done"

-

i know the planking is not right,but, being the prime and only contractor on this build i took a few liberties, besides she's a work horse destined to ply the seven seas not sit on a mentle

-

think i'll quit posting,,went around and saw some of the work being done by guys with cnc mills, routers,lathes, minature saw and the like, absolutely museum quality work, beautiful, i'm working with a 20 yr old scroll saw, dremal tool and an antique drill press

-

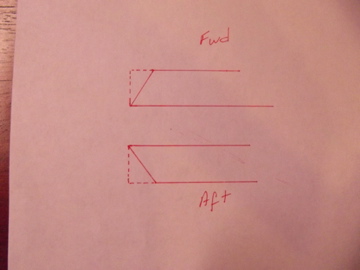

i know the purists out there will call it a sin but the thought of having to fair 1/4 inch 5 ply plywood bulkheads with a batten and sand paper by hand did not appeal to me at all. i know the project would have ended up on the bottom of the koi pond before i finished half a bulkhead so this was my approach to the dilema,,,after cutting out and dry fitting the false keel and bulkheads i took the bulkheads to my disc sander,set the table at 45 deg. and sanded them at that angle,,as can be seen on the little skatch..left a little land on the edge,1/32 to 1/16th of an inch,,just enough to hold some glue. took 20 minutes and she was fair...glued up the components and started planking not being very concerned with the look of it as the first layer is mostly there to give shape to the hull and provide a good bedding for the second layer.. minimal edge gluing only where the planks were twisted and lifting an edge CA glue is damn expensive,, that done,,i dug up some left over epoxy resin left over from the big build, thickened it with flour to the consistency of soft peanut butter, just thick enough to stay on a vertical surface,, those in california can use organic flour next took the putty and spread it all over the inside of the hull and the gap between the planks and the face of the bevel on each bulkhead,, let it cure over night,,rough sanded the out side,, applied wood filler ,,minwax,, great stuff,,,fine sanded and was done...end result looks ugly on the inside but wont be seen,,, the hull is so strong and rigid i think i could stand on it without hurting it... 1/16 planks on 2 1/2 to 2 3/4 inch spacing with absolutely no give in them,,,time ? two days for a 31 inch hull with an eight inch beam

-

rigging tackle size

gluedandscrewed replied to gluedandscrewed's topic in Masting, rigging and sails

chuck passaro,, who drew up the plans says double it so i think i will go with that,, it only makes my stays deadeyes 3/8 of an inch,,,on a 44 inch ship seems right,,thanks for the responses guys -

rigging tackle size

gluedandscrewed replied to gluedandscrewed's topic in Masting, rigging and sails

u the MAN chuck,,,not building a museum piece just want it to look right,,,thanks chuck -

rigging tackle size

gluedandscrewed replied to gluedandscrewed's topic in Masting, rigging and sails

the plans are from a kit so i'm sure the sizes of the tackle are dictated by whats comercially available, why i wonder if it would be truer to scale or not to leave them as called for on the plans or double them in size -

building the mayflower from plans by chuck pasaro of msw but at twice the size,, while not at that stage yet my question is should i also double the size of the rigging tackle thats shown on the plans or should i stay with the sizes called out?

-

didnt know i had a method 1234 being totally new to this I'm not confined by the " thats the way its always done" convention

-

stupid me only saw your first page,,boat is looking great

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

the hull is looking nice Brian,,,and thats the cleanest looking boat yard i have ever seen,, i flood my dry dock about once a month and wash out the trash

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

there is a 454 ci mercruiser under the hood,,unfortunately she sits in drydock about 90% completed

-

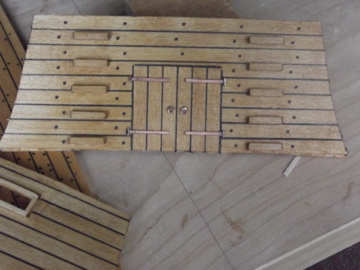

the kit was 22 inches,,i doubled that to 44 inches,,,putting on the second planking on the hull,,the launch is bread and butter construction with patterns of the msw plans,,, took about a week to do

-

I guess the mayflower must be considered my third build,,big red and black thing in the picture was my first,,five years the little life boat my second,, the mayflower my third...blew up chucks plans to double size and so far everything other than the eye bolts around the coaming and the rivets on the rudder is hand made,,turning the life boats rudder and oars was an exercise in tenderness

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.