-

Posts

8 -

Joined

-

Last visited

About Woodmiester12

- Birthday 07/11/1955

Profile Information

-

Gender

Male

-

Location

Calgary, Alberta., Canada

-

Interests

I have always enjoyed woodworking in one form or another. build a number of plastic models in the years past. Now to try a wood ship model.

-

Bobstrake reacted to a post in a topic:

HMS Racehorse by medic - Sergal Mantua - 1:47

Bobstrake reacted to a post in a topic:

HMS Racehorse by medic - Sergal Mantua - 1:47

-

medic reacted to a post in a topic:

HMS Racehorse by medic - Sergal Mantua - 1:47

medic reacted to a post in a topic:

HMS Racehorse by medic - Sergal Mantua - 1:47

-

medic reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

medic reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

medic reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

medic reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

GuntherMT reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

GuntherMT reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

I have finished putting the deck planking on. Next is to attach the first 2 planks (gunwales) to the side of the deck from the bow to the stern, attaching to the transom. The transom seems to be 1/4" (6mm) wider than the deck. From the drawings the side planks look like they should be matching up to the edges of the transom, however the transom is too wide.I have attached a couple pics, I hope they are clear enough. Looking at Dubz model of the Alert, I got the impression he fabricated his own transom, but it is still wider than the deck. Any suggestions or input, should I leave the transom wider than the deck or trim it to fit the width of the deck?

- 10 replies

-

trippwj reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

trippwj reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

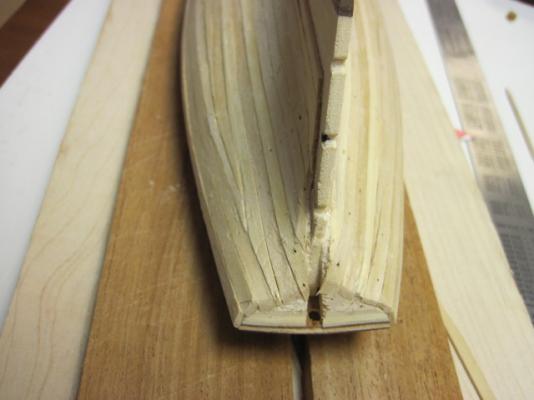

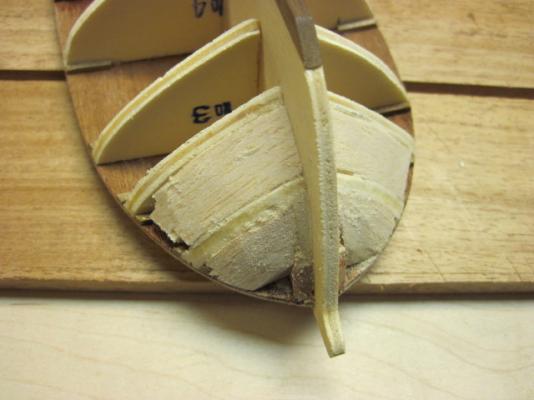

I had too many pictures to post in one reply so here the steps to get to where I am now. Finishing with the first layer of planking. It was pretty much a guess where the planking ends at the stern end of the keel, poor instructions (in my mind) and drawings that really don't show where and how they should look, especially when keeping in mind that the second layer needs to end properly at the stern. I feathered the ends of the planks at the stern to give a solid gluing spot for the second layer of planks as well where the bottom of hull meets the keel to make for an easier transition for the final planking. After the first layer of planking on(the balsa inserts gave a nice base for gluing and pinning the planks), I then sanded the planks smooth and then filled in the gaps with a tube of wood putty I had in the shop,( it was colored Red Oak, hence the red color). A second pass with 220 & 320 grit sandpaper gives it a nice smooth surface. I have also started laying the deck planking. I am just gluing them down but the plans show "nails" at the end of the planks, but calls for coloring the ends of the planks with pencil to give definition. The plans make no mention of using the nails in laying the planks. I am just marking the nails with an ultra fine black marker, I am suspicious that the nails would split the planks quite often and am sure that down the path of building I will find a nail embedded somewhere that will be in the way. Any suggestions or comments are welcome. And a planking I will go.

- 10 replies

-

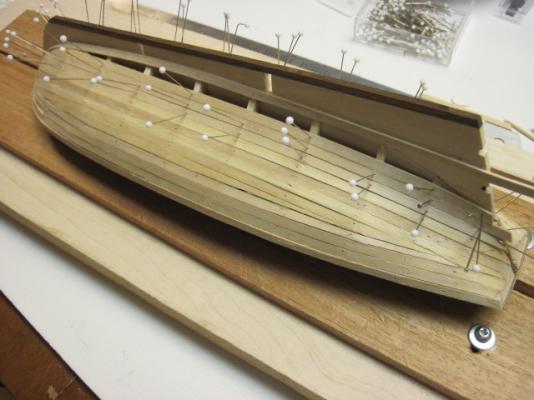

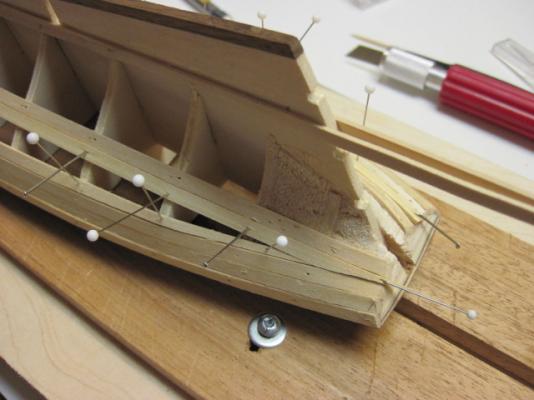

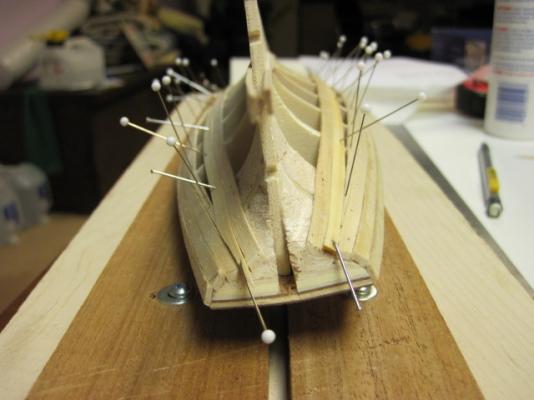

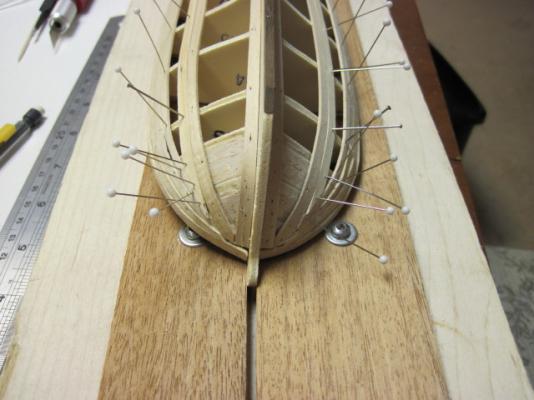

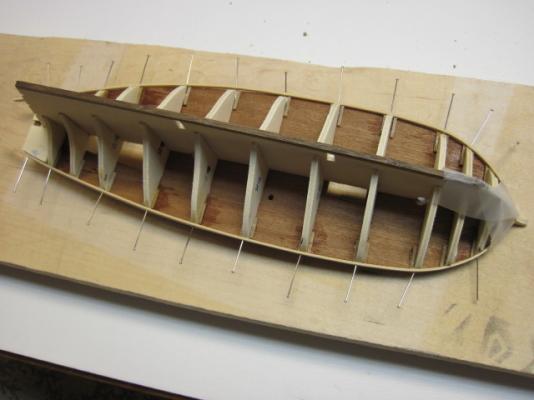

I have made a bit more progress. The pictures are the steps, process that I took in laying the first layer of the double planking for the hull. Some of the planks, especially the ones that needed more twisting and the first ones as well, I soaked well and then pinned them and let them dry well, overnight, before gluing them and again holding them in place with the pins. It will definitely take some sanding to give smooth base for the second layer of planks when that time comes.

- 10 replies

-

Salty Sea Dog reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

Salty Sea Dog reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

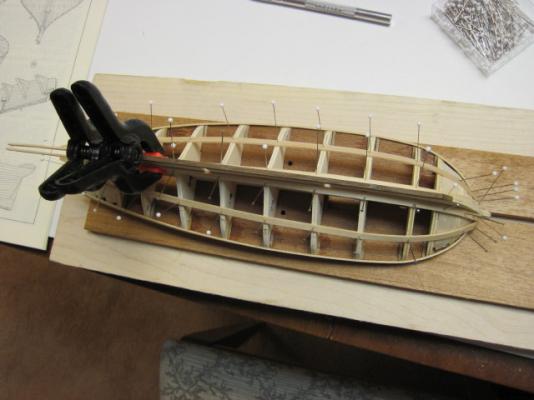

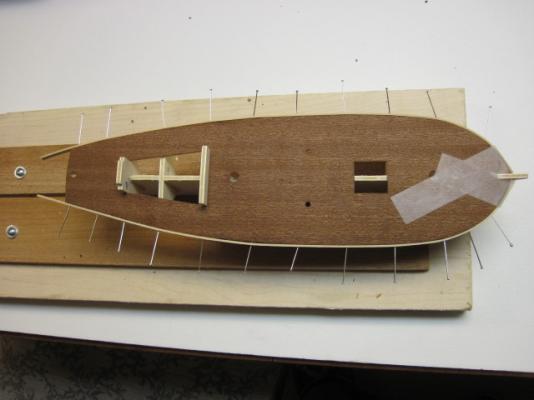

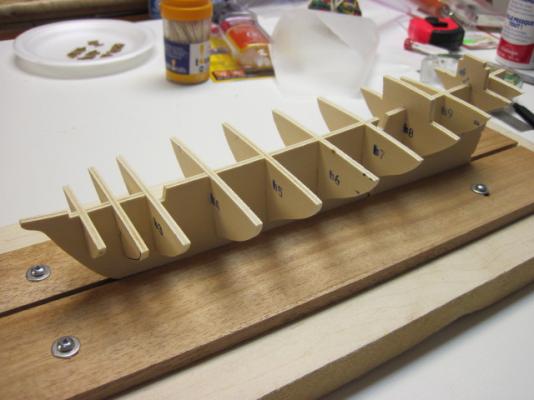

I have added some blocks between the first 2 ribs/bulkheads front and back and then shaped them to match the contour that the planks are to follow. I think this will be give more glue area to hold them down better. I was not worried that these filler blocks looked perfect as they will be concealed inside the model, I used Balsa Wood for the filler blocks. I have also glued down the top plank on each side. The next step is to glue down the rest of the first layer planks, I have seen couple different ways to do that, so still deciding the best way. One way is as the plans to just start at the top and go down the hull. The plans do not show clearly where they are supposed to end either the stern end or below the ribs as they join the keel. The other way is the top plank, then the bottom plank which will run up against the top plank at the bow end, then the third one join between the first two at the bow and run down the middle of the ribbing and finally to fill in the planks and shape them to fit to finish the sides. I am thinking this will be the best way as it should give a more solid base for the second layer of planks in the overall picture.

- 10 replies

-

GuntherMT reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

GuntherMT reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

mtaylor reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

mtaylor reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

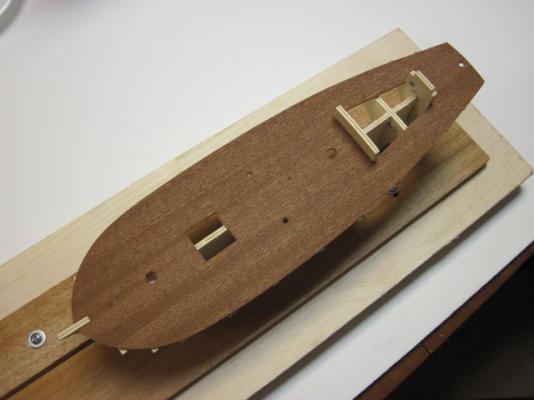

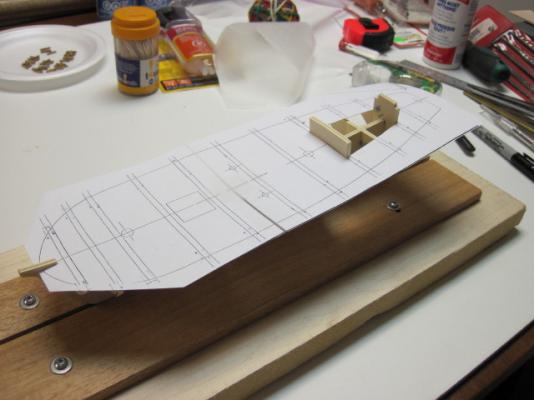

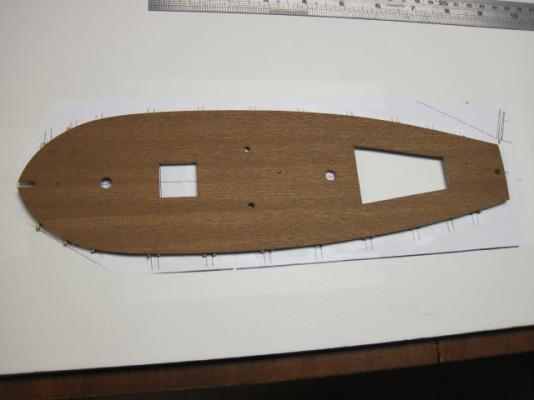

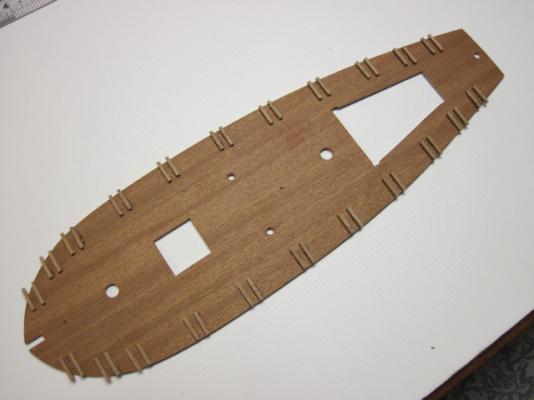

I now have the deck glued on have glued the filler blocks to the keel at the bow and the filler blocks under the deck on the stern. I have soaked the first two planks and have them pinned to the deck as they dry then will glue them on. After gluing the deck on I find that the cross ribs are not all aligned properly and some are wider than the deck so will have to Trim & Shim to get the correct hull profile before the planking on the hull. I am also curious on the angle of the transom. the instructions say to compare to Table A, I cannot find table A anywhere. Any suggestions. This nautical ship building is a new world to me, I find it intriguing, interesting and challenging, I guess that is what it should be, and I am enjoying it.

- 10 replies

-

I am using the white glue, different brand I have had good luck with in the past, I have also uses the CA glue in different applications and am familiar with that as well, so will incorporate the 2 of them. I liked the working time better for the steps I have completed already, Thank you both Matt and Medic for your suggestion.

- 10 replies

-

medic reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

medic reacted to a post in a topic:

USRC Ranger by Woodmiester12 - Corel - Scale 1:50 - First Wooden Ship Build

-

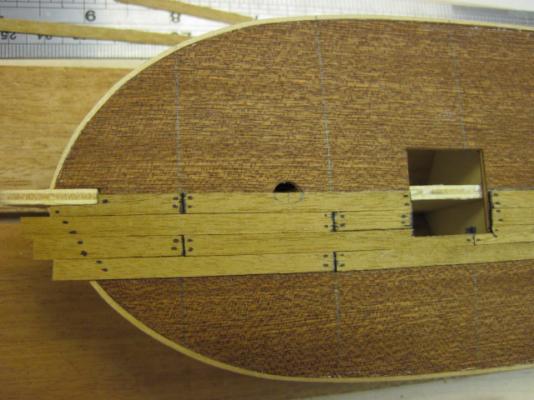

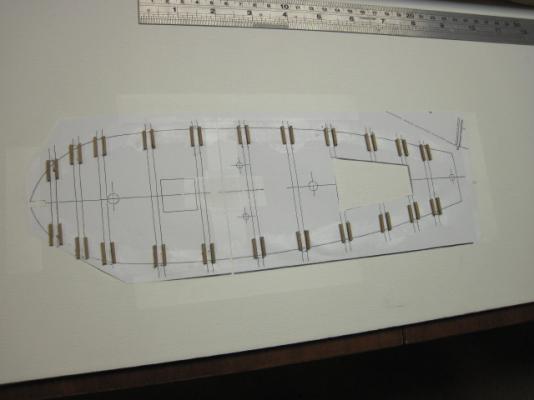

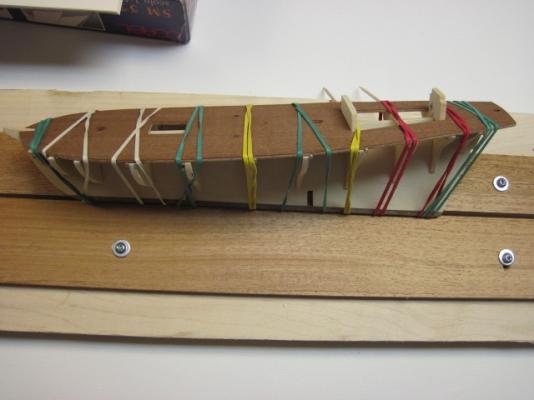

This is my first wooden ship model, Been looking forward to doing this for years. One question I have, In the instructions with the Corel Kit it says to use "Vinyl Glue" for the wood to wood glueing, I checked with the local Hobby store and they had no idea what that was, so I am using White Glue, however this is water soluble, Is there a better glue to use for the build? How to glue, wet bent wood? Doesn't work with water soluble glue. Also to glue the laths on the underside of the deck the plans did not line up with the spacing of the ribs on the keel. I ended up cutting and stretching the plans about 1/8" just after the 5th rib to get them to line up for gluing. See the attached pics. ( I hope). After soaking the deck in water (and losing 16 of the water soluble glued laths) I have positioned the deck with rubber bands to get the proper curvature of the deck. I will remove it next, after it has dried for a couple of days and glue it to the ribs and then re-glue the laths back into position. I have worked with wood in numerous situations over the years and have a reasonable understanding of its characteristics however, I welcome suggestions and helpful tips as I definitely know there is much I do not know. Thanks in advance for any tips and assistance. I am a land locked, non-mariner so i may get my terminology incorrect in naming pieces of the ship, no offence intended. Thanks for reading, Ken

- 10 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.