-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cricket

-

Wow. A masterful work of model ship building.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

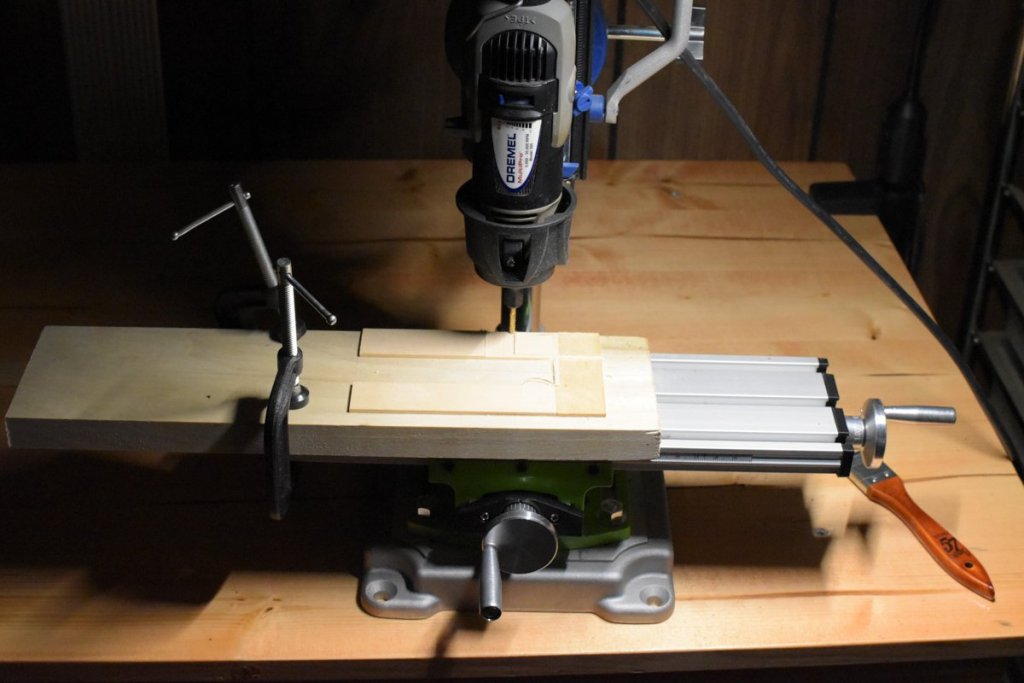

Hi Chuck. Your correct. I mounted the Dremel to the Dremel work station and purchased the Multi-function work table on Amazon from MySweety for around $40.00. It's probably no good for fine accurate work, but so far works good for me. Jeff I'll give the #10 a try. I really just need to practice, and to get some finger/hand/lap 🙄 protectors. Jim, could you recommend a source for mini chisels? I wouldn't know a good set from a bad set, and I almost always question third party product reviews. Thanks much.

-

They both look fantastic Kevin. Especially the scratch built. You did her justice. Gives me something to aspire too along with all the other excellent builders here. Hope it's ok to include a couple pics from our Tobago Cays vacation back in 2010. We flew over from St. Lucia. The last one of Petit Tabac is my current screensaver. Flying in to Canouan A visit to Mayreau And my current screen saver Petit Tabac

- 163 replies

-

- america

- constructo

-

(and 1 more)

Tagged with:

-

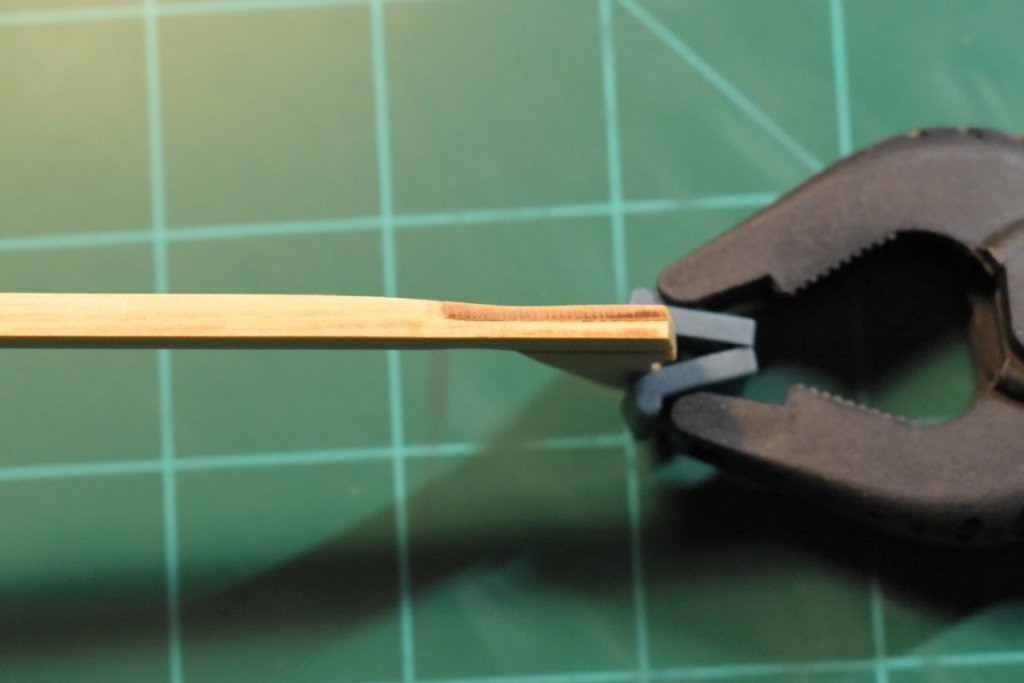

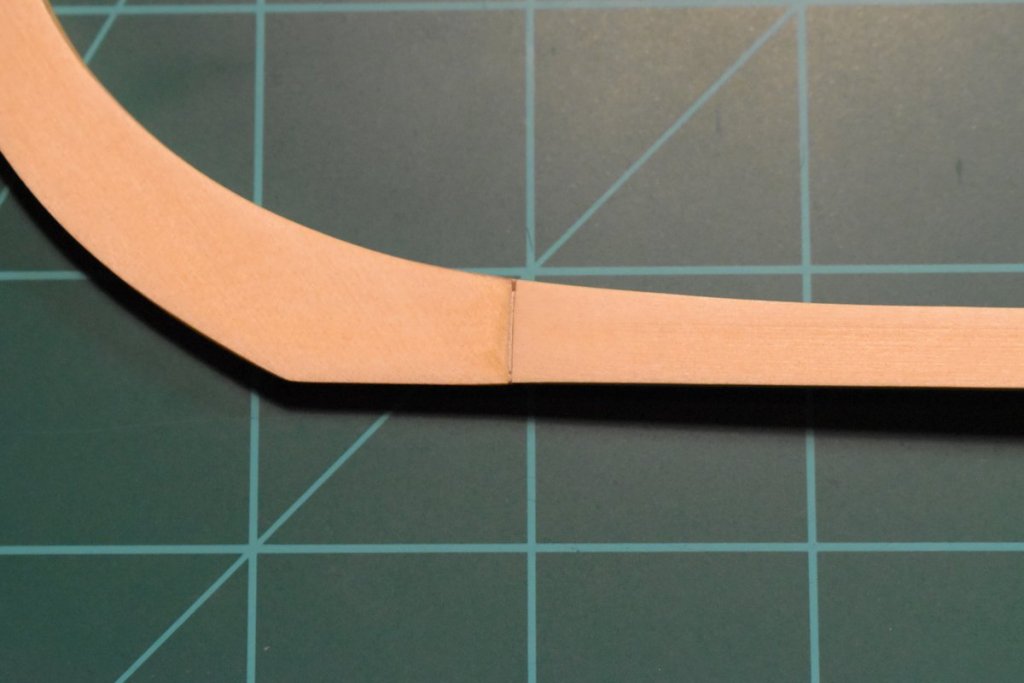

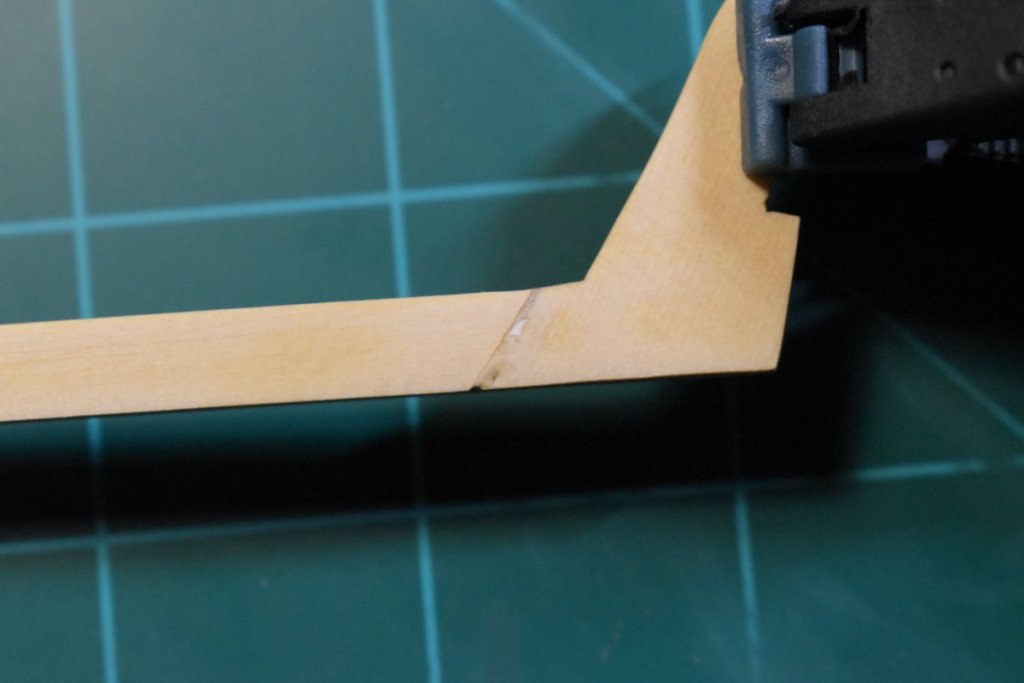

The kit arrived in perfect condition and I proceeded to start on the keel with the lap joint. I realized that I don't currently own any cool power tools except a Dremel, so I started off with the #11 X-Acto and some 220 sandpaper. I found out 2 things. I'm not good at all with the #11, and sand paper. Also I realized I would need to make these joint perfectly level. As per my normal method, I hacked away best I could till I biffed it up. Oh well, this will be added to my list of "things to learn better" and I proceeded with the other keel.

-

I finally found time to sit down and put together where I'm at on this build. As this is my first log, please be patient with any abnormalities or photo aberrations till I can come to grips with this. It's all new. I'm going to start off with a test pic to go through the process, and will go from there. Thanks. Thanks

-

I tried both on a test board of poplar and there is a difference. I'm not an expert on this type of thing, but this is how I tested. I applied three coats of each letting each coat dry with a light sanding between coats using 220 grit sand paper. The end result was as mentioned by Chuck. The water based was splotchy and even a bit shinier in places, while the oil based was smooth and even. There may be a way to apply the water based and achieve the same finish as the oil, but for now I'm going with the oil based.

-

The hard work really paid off. They look fantastic. Sail making is a way off for me as I decided to just show the rigging. When I get ready I will check out Tom Lauria’s videos.

- 163 replies

-

- america

- constructo

-

(and 1 more)

Tagged with:

-

Mr. Kenny your modeling skills and practicum instructions have inspired me to complete my own Constructo Model of the America. Your two models look fantastic. This kit was a first for me, and in hindsight I wasn't prepared for the lack of detailed instruction. My bad. I have learned from your build, and thank you for that. I look forward to learning more. On a more personal note, my wife and I day sailed the Tobago Keys. The day was perfect. Thank you.

- 163 replies

-

- america

- constructo

-

(and 1 more)

Tagged with:

-

Just wanted to say I've been following your build log and while I don't have a whole lot of time to spend on modeling, I have picked up some nifty tools for when I do. I applaud your attention to detail and efforts for a fine strong model. I look forward to your continuation after you've settled and have the time. Fair winds, following seas, and a fair lee.

-

double planking a hull

Cricket replied to pugman11's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks Mark. It's all fun and a learning experience. -

double planking a hull

Cricket replied to pugman11's topic in Building, Framing, Planking and plating a ships hull and deck

Hi pugman11, I was not considering a second planking of my build of the America (Americas Cup 1851) from Constructo as I felt I did a decent job of the first planking. In fact, I was ready to just move on to the water line and paint. Then I was reading up in Ship Modeling Simplified that to do a second planking, and make it possibly look better, apply some modelers paste, allow it to dry, sand smooth, then use an electric plank bender along with carpenters and acc glue to apply the second plank members. I decided to do the second planking, and purchased some Liquitex modeling paste as recommended by the book. I applied and let dry. Sanded smooth, and now I am second guessing my decision. The modeling paste is white, and now I'm afraid if my second planking layer isn't perfect I will see white first planking between the second planking stripes. I'm kinda at a loss here. Has anyone ever used the modeling paste before applying the second layer of planking? There is nothing in the instructions concerning the second layer. I guess they put it in the kit as a value add thing or something, but no instructions on what to do with it. I guess if it all goes wrong, I can hack it into some kind of cargo plane with mast and rigging.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.