-

Posts

389 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Drazen

-

Making the wedge for fixing the tiller. The hole for the wedge was square in form and, after drilling a small hole, I needed to nail a metal part in it to make it square before setting the wedge. It seems to be easy, bit was not. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

… and making the reinforcements in the tiller area on the upper part… The nails were slightly smaller. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

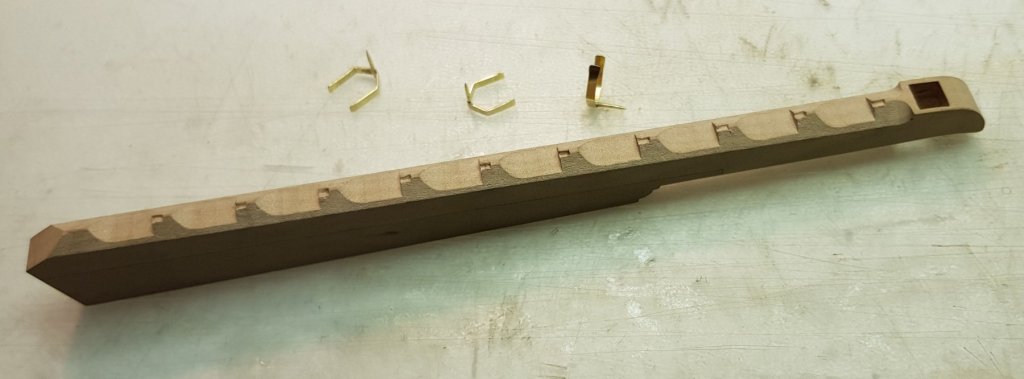

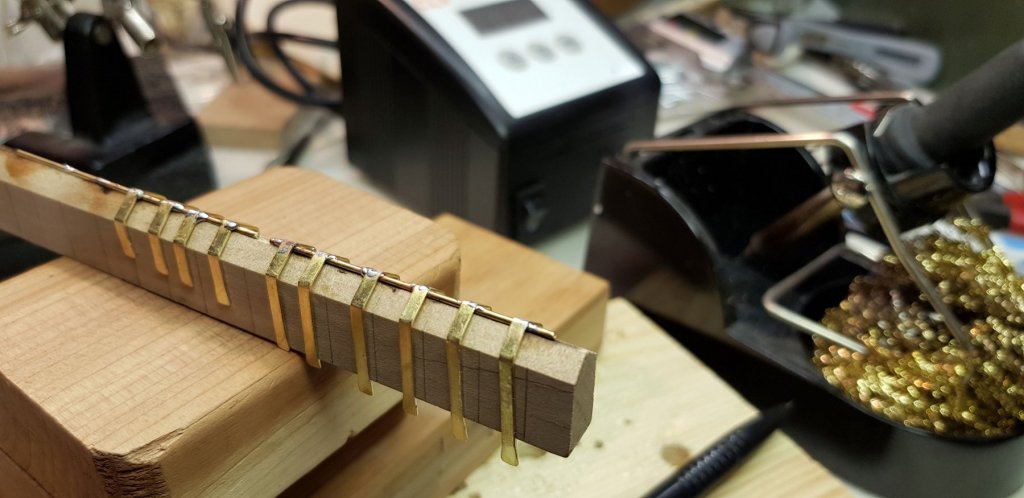

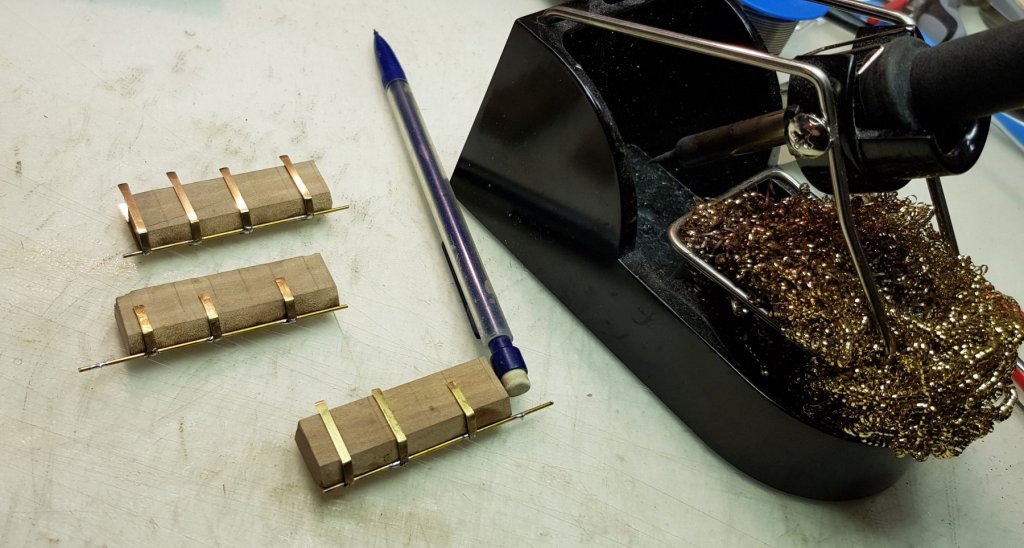

Making the other side – fittings on the sternpost. Here, it was necessary to get the whole thing into one line. For this, I used again a false-sternpost of the same size as the real one. I fixed the fittings into the right position on the false sternpost with some nails, … cut small cylinders which are going to be soldered … flattened them slightly on one side to get the right shape after soldering. When soldering, the rudder and the false sternpost have been fixed against each other in an exactly parallel position. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Patination … Before patinating, I cleaned it in the bath of citric acid. It is not aggressive, is cheap, easy to buy in a supermarket and cleans well. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

… soldering… After this, I cut the wire, but left enough wire to hold the whole piece in my Proxxon drill machine. Than, I turned the whole piece in Proxxon slowly and sanded the top with another Proxxon in order to get a nice sharp tip (not shown on photos - sorry). Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

… a jig to hold the fittings when soldering. It is not the rudder, but a piece of wood having the same form (false rudder). Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Here is the procedure of getting nice, smooth and sharp cut-edges. For this, I made a channel which will hold the brass stripe when grinding with a fine sandpaper. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

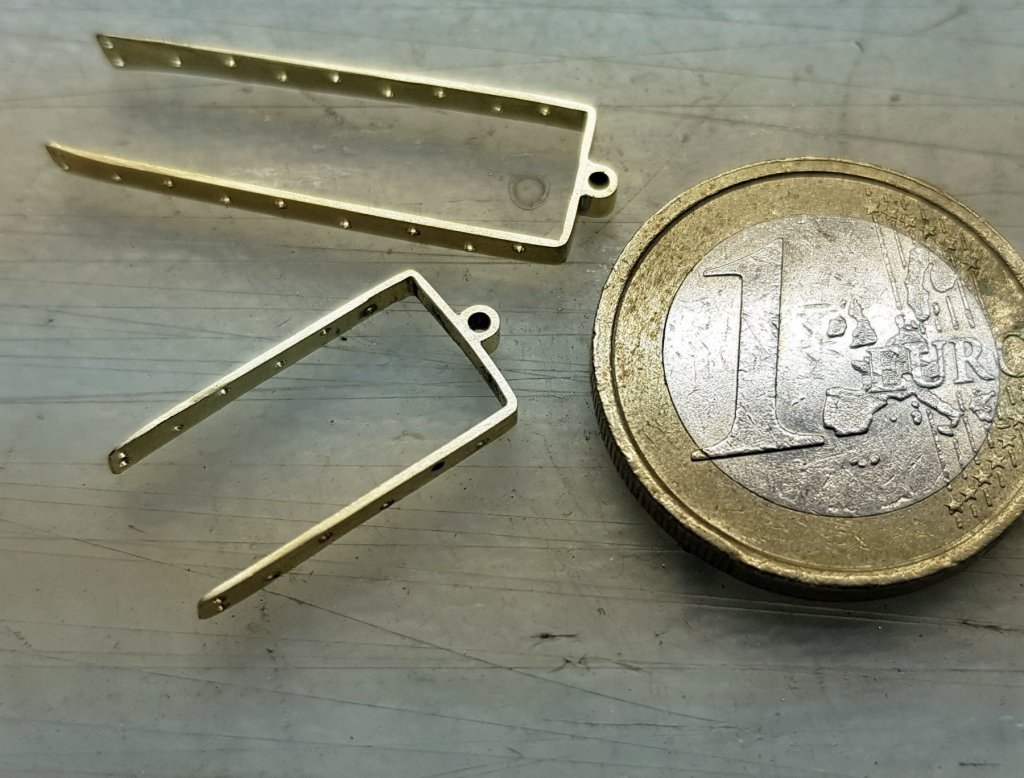

Making the fittings… I cut it out of the brass sheet with the Proxxon precise circular saw which is suited also for aluminium and brass. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Cut the wire in halves to get the right length of the nail. I needed also to grind the top of the nail (each) since the cutting with pliers made the tip wider – too wide for the holes Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Than I use a big knife to cut (actually - roll) the wire. The knife must be sharp, but THE CUTTING ANGLE must be large – something like 70°-80°… but you shall make tests. If the angle is to small/sharp, you will just cut the wire without any effect. Than you roll the wire back and forth – taking care that the knife rolls on the same place. What happens is, that the cutting place deforms and builds a sort of “mushroom head” which simulates a head of a nail. I am sure, many know this method, but maybe not everybody. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

I used a brass wire of 0.6mm, cut it into 8cm rods, and rolled with a piece of wood to get them straight. As a base, I use the “self-healing” matte. This is important for the nice rolling of the wire when cutting. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Let’s show the rudder... Before I show the making of the rudder, I will show the making of the nails. The rudder and the fixation required more than 200 nails. The nails were small and not easy to buy in this size (for my scale, I needed the head with width of 0.6mm-0.7mm). On YouTube there is a nice explanation by a Russian guy which shows the same procedure too. This procedure gives not perfectly round head. As the nail heads were slightly square (definitely not nicely round), this procedure gives in my opinion nice results. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

A complicated fixation when gluing… The paint below has been removed carefully… than… … despite the bent form, I needed to press the ribbon additionally to make it fit well. Gluing again with epoxy. … than, as it looks on the ship. The small windows have not been glued yet since I want to give the coat of varnish to the wulf & ribbon first, before gluing the windows. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

There was a lot of discussion on "blue or gold letters". Again, after consulting some experts and you in the forum and the historic paintings, the blue looked as the right solution. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

… and this is the finished ribbon. When mounted on the ship and oil paint completely dried, it will get a thin layer of mat varnish and will blend in beautifully. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Of course, one needs to erase the letters contours with a clean high-quality rubber. For me, it worked OK, but some excessive parts of the paint went away and were more light. Usually this would be a catastrophic for the lot of work behind, but, I have learned that mistakes are the greatest potentials for improvements and innovation. I am in my profession an innovation manager consultant and train my clients in seeing obstacles or failures as the greatest potential to learn something new. One gets the other perspective, seeing things different, getting “out of the box” with sometimes entirely new opportunities. Well, for me, the erased excessive areas gave even more reality to the look. I was grateful for the “mistake” done by my rubber/eraser on the weak layers of the oil paint. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

… than, milling away paint till the ground layer of wood – without going over (or even near to!) the edges of the letter contours. Getting away just the middle part is fine. I am working with a dentist’s device. I am not sure if it is possible with a Proxxon or Dremel, but, maybe some can manage it with these bigger tools too… Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

… than, I took a pen refill 0.5mm, fixed it onto an injection needle and made it very sharp. With this, I was drawing contours around the letters. Using it with any of my best pens was not possible since too big/chunky. Fixed on the needle, it was easy to move around the letters. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

On the previous photo, you can see a jig holding my ribbon. This was important in order not to touch the part. The photo shows ready painted parts – ribbon and the letters. The fine shades on the ribbon are difficult to be seen on the computer. Later photos will show it better. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.bd4181c0ea540bb116549f5a208385a4.jpg)

.thumb.jpg.3f4254179483d787573d11ff680e9e7b.jpg)

.thumb.jpg.f3e82158908d8d33b2d2a691ba4dcabd.jpg)

.thumb.jpg.1fc7f14856ea035cd247d55adfd027d5.jpg)

.thumb.jpg.73d4b2512f4061ab88f73ec6092640bd.jpg)

.thumb.jpg.5d82697767d7f934fb46ad4bd9922175.jpg)

.thumb.jpg.a816d6af08d1f7f33907b5c8162d3500.jpg)

.thumb.jpg.32ee8246c0aae177c8644929cd55b19d.jpg)

.thumb.jpg.0268ef45ec9102475da5e57cb591bd34.jpg)

.thumb.jpg.32a952df4c4b72862d02ad445860408a.jpg)

.thumb.jpg.2b6f3abc1c332b2edf7aa5fa7e240465.jpg)

.thumb.jpg.48dcab5144711199bdfeef6dd5e657ad.jpg)

.thumb.jpg.d044de00a5ab839b51dda1c038983a90.jpg)

.thumb.jpg.a394f1353181d1be949062037d7e3f45.jpg)

.thumb.jpg.c5fb2b602199e6482d115798770e479d.jpg)

.thumb.jpg.d3668555ec62161de4dd429a816306d6.jpg)

.thumb.jpg.824203fa6e8c82eff35cc7ee287b98cd.jpg)

.thumb.jpg.b71b418fd6471955882658e9e0b19d25.jpg)

.thumb.jpg.4c5884b64af2fce78eb536bd26e8821c.jpg)

.thumb.jpg.81e9220f1908906bfd8877b395777c64.jpg)

.thumb.jpg.678f80ff0ad28ccb26543e7423c476d5.jpg)

.thumb.jpg.80ff8fe66a9f31bc47998cdd49614463.jpg)

.thumb.jpg.f3f8781249cf458892f932bee154c7d1.jpg)

.thumb.jpg.826294635bb731407429dc8f1fb25d08.jpg)

.thumb.jpg.a7932490da009d11e7faf85f2574d362.jpg)

.thumb.jpg.1242f8dc6cf375f39176ff7d081097f6.jpg)

.thumb.jpg.976f054b430e175c4b793b573ab23cf8.jpg)

.thumb.jpg.a82356920c3d3228747bc51f2b542167.jpg)

.thumb.jpg.24e7c4b580d2677bd563521e4a02340c.jpg)

.thumb.jpg.000f8cc66f7bacc5c466e17779feafe3.jpg)

.thumb.jpg.34ad14d6c90ba1546d04157ee7576b6d.jpg)

.thumb.jpg.010468a5cf5328f75649d628b7aba75e.jpg)

.thumb.jpg.1762962c98684376c46aaae7fb2246d2.jpg)

.thumb.jpg.123e36ddbc63a0cdf45c2dd5be7b0c0f.jpg)

.thumb.jpg.2fd54d4d59e35572ed911d94130b552a.jpg)

.thumb.jpg.6ca182ca6199041a961df857a38a925f.jpg)

.thumb.jpg.497b87ae870945f40dd9983d66c70876.jpg)

.thumb.jpg.3d3d84f5f05cc5468a5b35359cd37bad.jpg)

.thumb.jpg.879b03d9229070d614e90b4f480a037e.jpg)

.thumb.jpg.aa0434bdd0c1c4adbdacd3a6f647c6db.jpg)

.thumb.jpg.6f574bc706ff50b68e6104f34587aa9d.jpg)

.thumb.jpg.f2fbd05395873c0e238eeb5872f88c5b.jpg)

.thumb.jpg.53d9678ade11b3ef3171667674e38ea7.jpg)

.thumb.jpg.2ab872c84d2edae38605e5ae2f207a4c.jpg)

.thumb.jpg.c76dc2116eb61461230b8419927d696f.jpg)

.thumb.jpg.ead7698725ec4ee6369c9aef1e96f656.jpg)