-

Posts

389 -

Joined

-

Last visited

-

Rodolfo Bigoni reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Rodolfo Bigoni reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

etubino reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

etubino reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

etubino reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

etubino reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Stavanger reacted to a post in a topic:

Royal Caroline 1749 by Mile - FINISHED - Scale 1: 35

Stavanger reacted to a post in a topic:

Royal Caroline 1749 by Mile - FINISHED - Scale 1: 35

-

Katsumoto reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Katsumoto reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Katsumoto reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Katsumoto reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

Archi reacted to a post in a topic:

De Zeven Provinciën 1665 by Dražen - Scale 1:45

-

Drazen changed their profile photo

-

Thank you Peter! Nice, and a nice Baroque music,. Does Clous van Mechechelen conduct? Is reminds ma also to Ton Koopman, one of my favourite old-music conductors. Relaxing and done in the spirit of the baroque. Enjoy your beer! I will enjoy mine - a smaller high-quality brewery here - "Hirter Bier" here in the region, who I support/consult in innovation management. Proost! Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

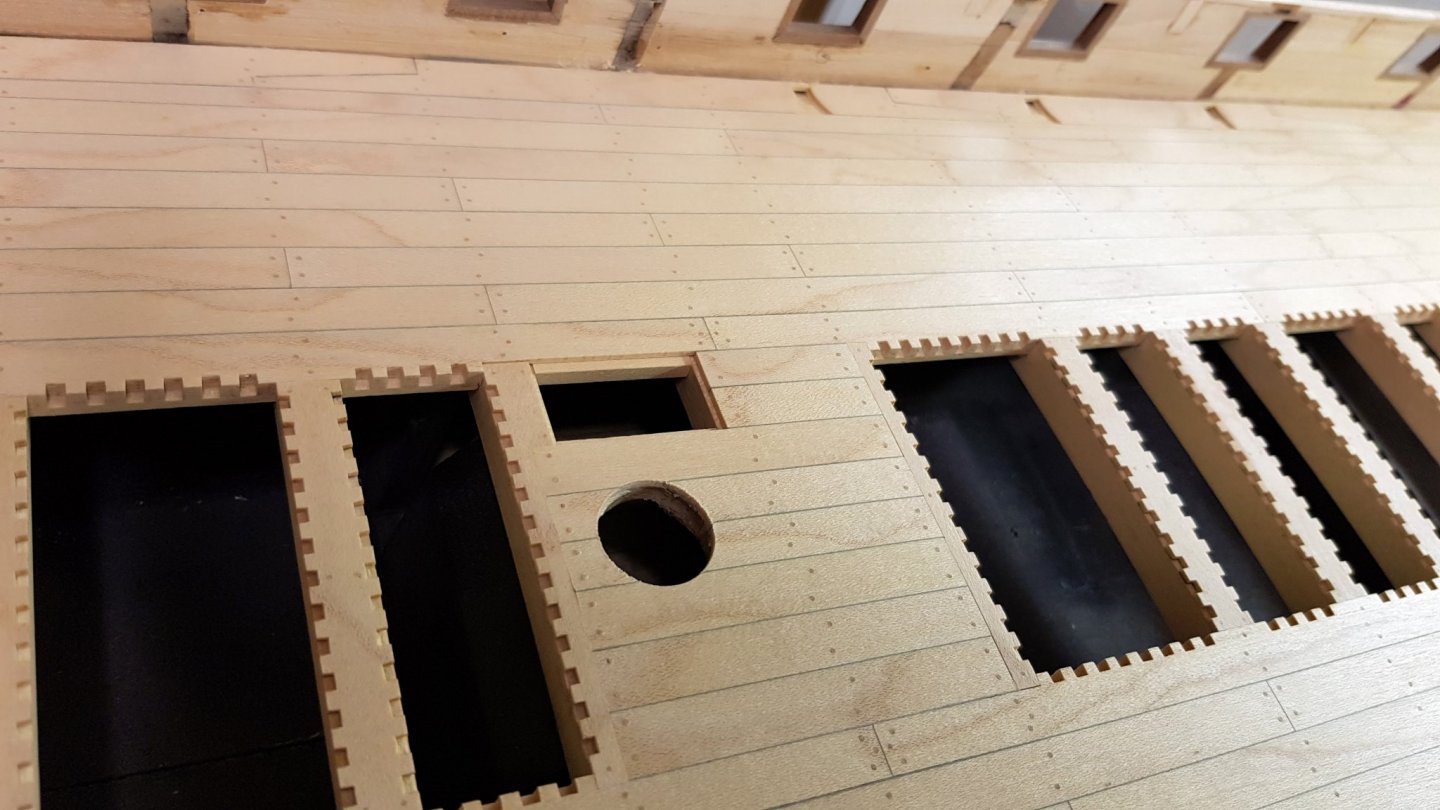

Jan, 1. Solution: You will find the answer on the last photo. On the wall, there is a small humidity measuring device. I am trying to keep the humidity between 45% and 55%. In the winter, I have a humidifier and in the summer a dehumidifier. In a normal situation - if I would not work in the cellar - this would not be any problem since the deviations in my flat are from 42% to 58%. 2. Solution: I have reinforced the areas which were opened and I could work with epoxy and glass wool. The complete stern lower part (area near the sternpost), I have filled in with epoxy and glass wool and the vertical walls on the kampanje dek and hutdek, I covered with the several layers of glass wool. 4-6 layers come out thin, but this holds very well and will be covered later on with the klinker anyhow. 3. Solution (did not work): Since the cracks on the deck near the gratings were not possible to reinforce with epoxy laminate, I tried to spray the shellac through the gunports. I sprayed several layers of shellac, starting with very thin, to normal. The idea was to cover the wood also from inside and thus prevent humidity coming in. This did not work. It seams that the covering is not well or not possible and the humidity finds some possibility to enter the wood. Still, keeping the humidity under control makes these cracks nearly not visible (see my next photos). If I one day decide to live in Norway (what is a heart wish of mine), there, I may have again the problem due to the low humidity. Conclusion: Next time, I would do the walls of my base layer much thinner and think about reinforcing the structure from inside. I was talking to a colleague of mine (Alexandr Dobrenko - unfortunately, he died in a car accident last year) and he said, the problem is less with peer and he also covers the wood with special oil from inside. Just as an option to think. Strong humidity deviations + thick wood - without reinforcing structure inside is really a big problem. Following photos before and after my actions... Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

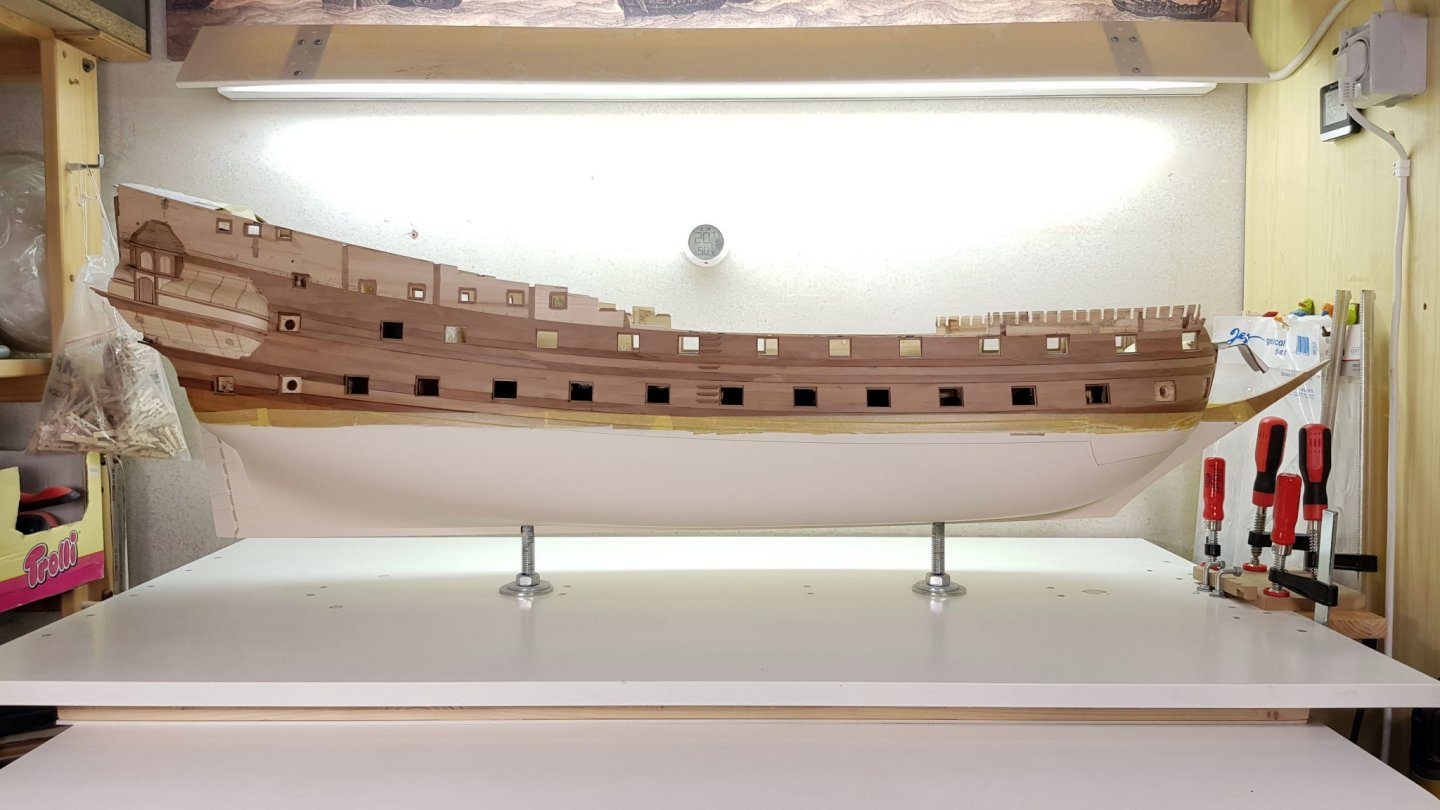

With this, the klinker is ready. I didn't show the whole railing, which is ready since months, I will show the making of the railing later on, when it will be installed in place. Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

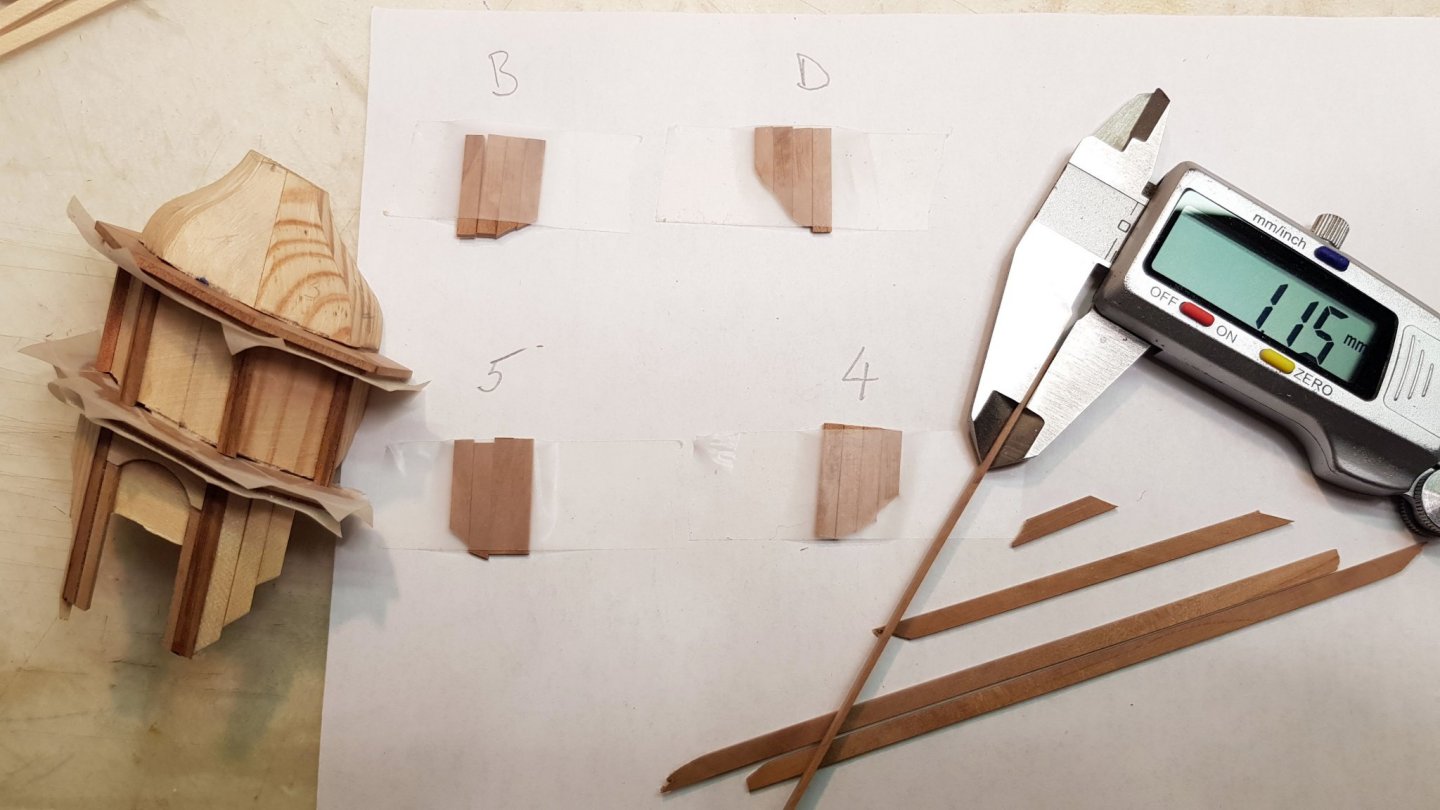

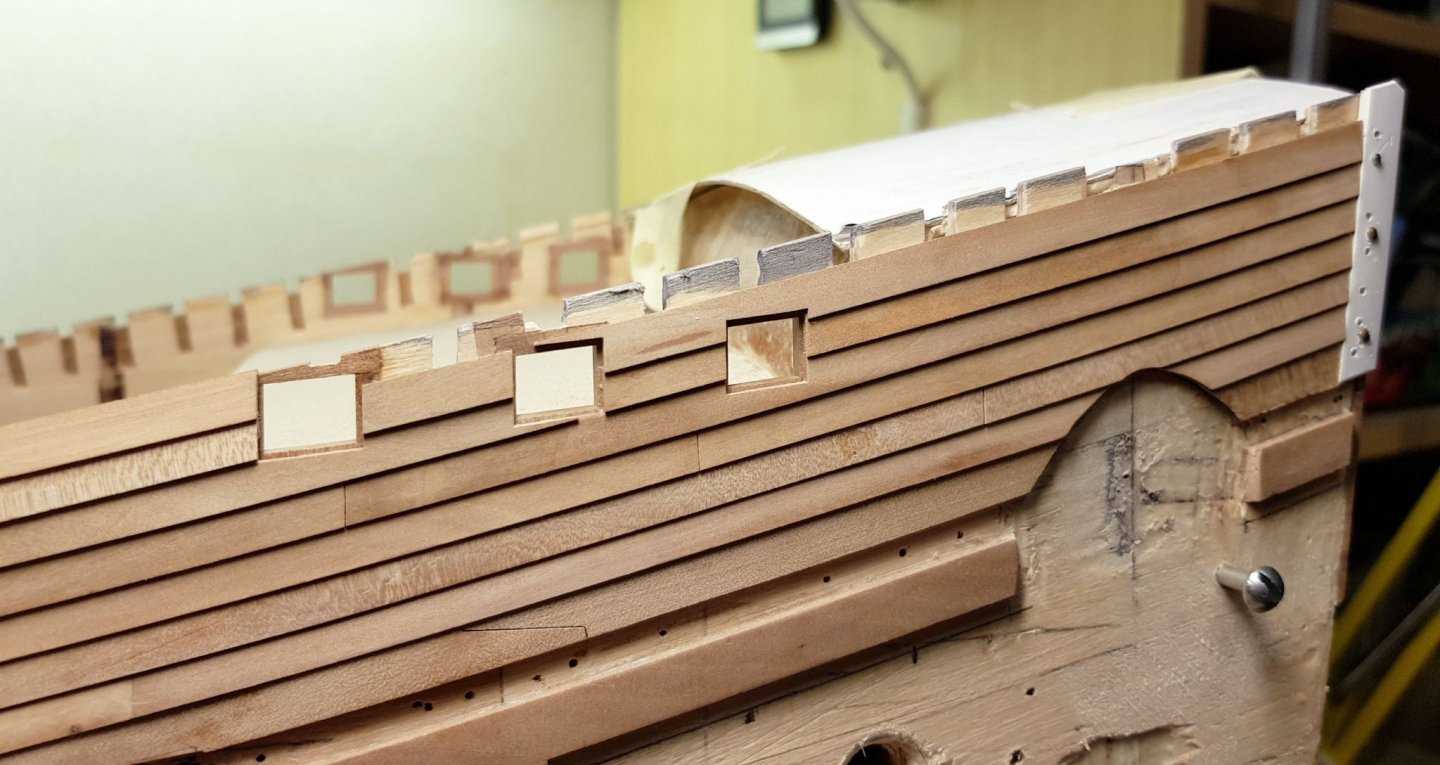

Making klinker on the hull... For this, I needed to cut different widths of the klinker planking and on some areas - continuously narrow them. So I have the same number of planks at the beginning and the end of one section of the hull. (The part of the hull which I needed to plank with the klinker is higher at the stern.) Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

My protection for the hull - same level as the waterline. One can imagine how the ship looks in the water. This protective parts can be disassembled easily if needed. Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Here is the ship with painted area below waterline and I did later some construction to protect the painted hill from unintended touching with tools I am working with. Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Towers are ready. The windows are missing and some details. This will be done later. The sharp edges where the klinker are connected are not very exact, but I didn't care since the sculptures are going to cover this areas. The whole system is like LEGO - it can be disassembled in order to paint the parts later separately. Also the other parts on the side galleries can be removed. This will be shown later. Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.b618e7c105ab70d68c2377978fb5cc30.jpg)

.thumb.jpg.cbc8022bcd7a0c4471e5e00c089eb89d.jpg)

.thumb.jpg.94bbb7c0e8f8e0daaf27efdba9fac56b.jpg)

.thumb.jpg.d009df1963c5c74b2b3d6d167b346d9f.jpg)

.thumb.jpg.e1429e02fb69e79f70488e87e0f7934b.jpg)

.thumb.jpg.e7576d6c86b0df226c827c47ebba7487.jpg)

.thumb.jpg.894a2f98735a1cfdb9b25f7253f6a3a7.jpg)

.thumb.jpg.8ef66a5f6b2ed0228a7fc8b644247556.jpg)

.thumb.jpg.afe82d555155f19b3ce26c0094496ff0.jpg)

.thumb.jpg.1aa374c1949207f0f89c3f591b979ead.jpg)

.thumb.jpg.5ee4c0e65efe0d0466b6608a44ca2d69.jpg)

.thumb.jpg.d24c59ea2d0d2b6991a35616a64dfca0.jpg)

.thumb.jpg.9dae519a978c8b091acf25cff12ad2e5.jpg)

.thumb.jpg.39aa2461c2229ae975957a00c44d5be6.jpg)

.thumb.jpg.c4d6dfc59fa3e869b31a7e24b6e5a66c.jpg)

.thumb.jpg.351e61f4987c4f1eb1487d52c4c8c63a.jpg)

.thumb.jpg.29beb2c1728578ccbc6bd1901034747d.jpg)

.thumb.jpg.bfec1bd66eb2aa81d6ee8be9fbf89eda.jpg)