-

Posts

389 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Drazen

-

Diederik Thank you for the offer. I will be grateful if you can make some good photos of the sculptures of the ship. Somebody said, this work has been more or less, done on the replica. All other Photos are very helpful too. All other info you bring to be shared here in the forum can help us definitely. Thank you in advance Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Spijkertje, This is all here to be shared and helped other model builders to make them their job easier and have more fun when building. Please, share all my info I posted here as you like. I myself am grateful to Mile Bijelić, Ab Hoving, Cor Emke, Herbert Tomaesen and the Russian colleagues Dr. Mike and Alexandr Dobrenko for all the help, materials and advices I myself got from them. Drazen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

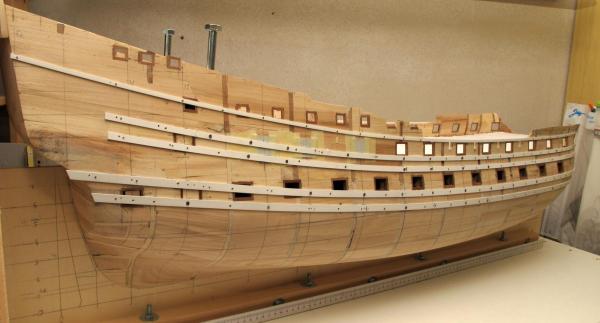

I have had a lot to do for my company in last weeks... ... but now, here are the new stands which will hold the ship later (when ready) too. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Jan, the main issue is how to bring these wales into an exact line (actually curve) without bends and in more or less same distance along the ship length (except at the area of the stern where they slightly separate). Well, now they are OK. After fixing the planks, the planks will, let’s say so, lead the right wales into the exact position. I will need to bend the real wales on the steam, but the final “fine tuning” job will do the planks themselves. I know, again, that this is not how the Dutch were building ships, but the final result should be – if (hopefully) nobody reads my build log and just observes the final model – without putting the model apart. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Just an additional clarification... I bent the plastic wales with the hot air gun only on the bow. The rest was easy to bend (elastically, not plastically) just by applying a slight tension -> holding with finger -> making a hole with fine drilling machine -> and inserting the nail in the hole. You can correct the “corners” (where the line is not nice) by: removing the nail out -> (slightly) correcting the shape of the partition -> drilling another hole near the old one. After correcting approx 30% of the originally set nails, I got a nice curvature. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Nigel, Please, use any technique you like. This is the nice thing that we help each other in order to make things easier and more beautiful . Your remark on “non-sticking wood glue on plastic” is indeed a great remark. I was primary not thinking on this, but is a kind of “ad-on” which would make the using of plastic even more preferable. Why I did use the epoxy to connect the beakhead timbers: The timbers do not stick/fit 100% together, but are, or could have a slight spacing in between (also historically). The wood glue shows with prolonged time tending to creep if the connection between two parts is not very narrow. There could be a certain load on this part (timbers) from the outside plank which I will lay on it, so I preferred the epoxy. Epoxy is also more transparent, so I do not see the glue in between. Some testing could prove these hypotheses, which one may try. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Today I finished them all and will next start planking. Here are some photos how it does look like. Controlling the line with slightly adjusting the nails appeared to be an efficient technique. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Last week I started to make the false wales before I start the planking. It turned out that a flexible plastic is much better for this purpose than a wood. The bending was very easy with a hot air gun and the curvature easier to control than with a piece of wood bent on the steam. This was just the experience I made. Dražen

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Nils, this is the work by Mile Bijelić. I am just the one who helps posting it here Regards, Dražen

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

- 86 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.