-

Posts

465 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gbmodeler

-

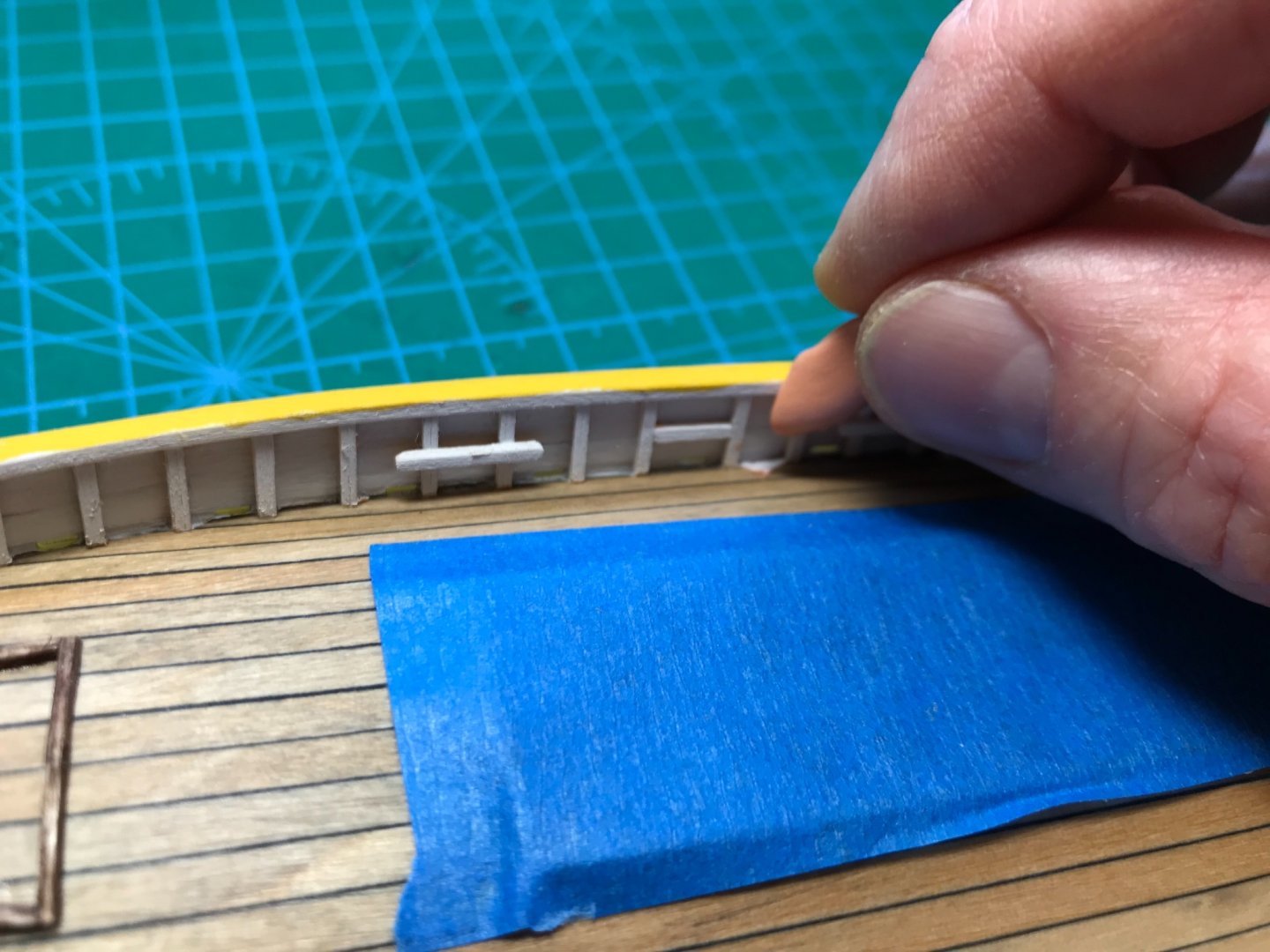

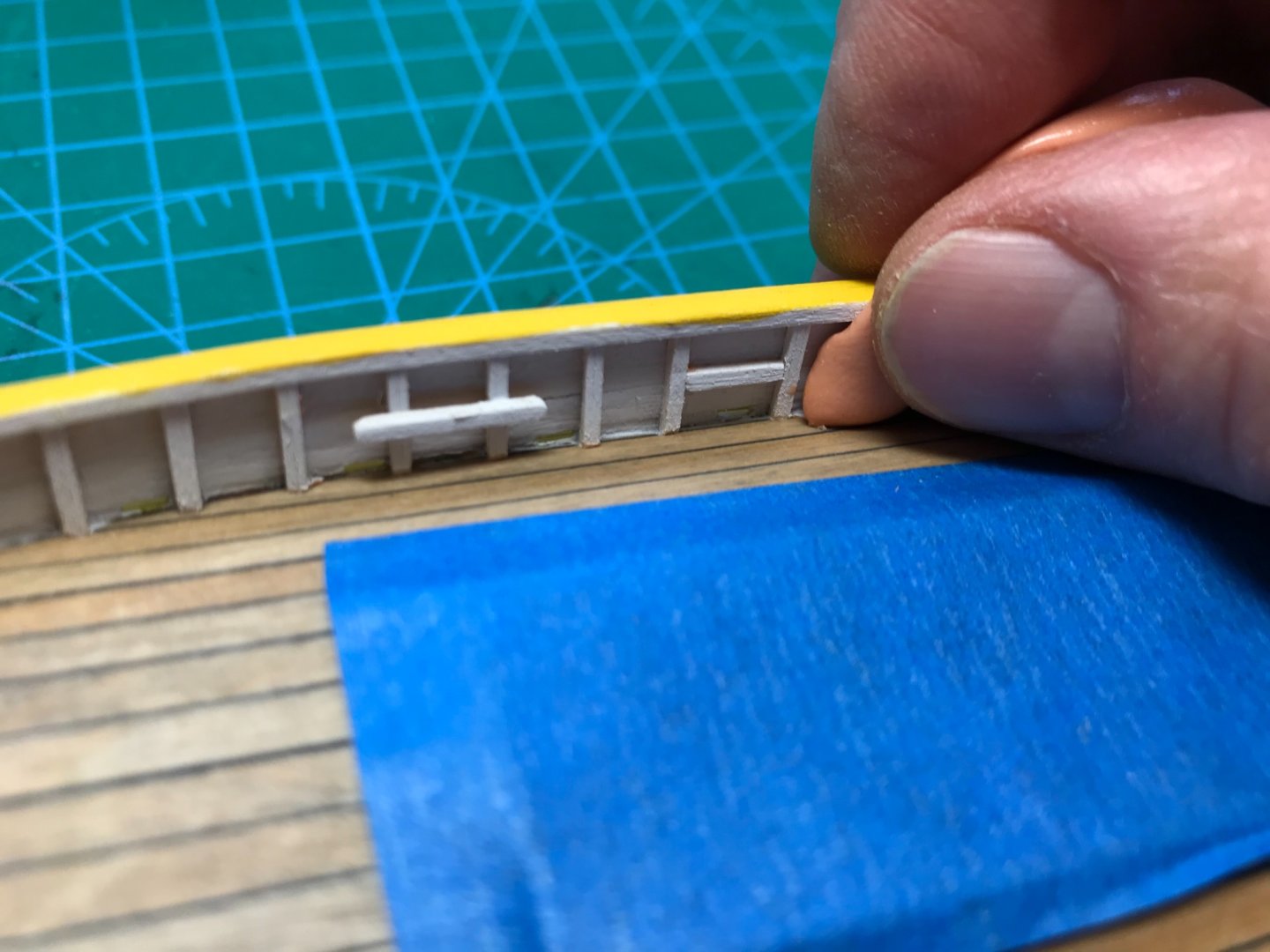

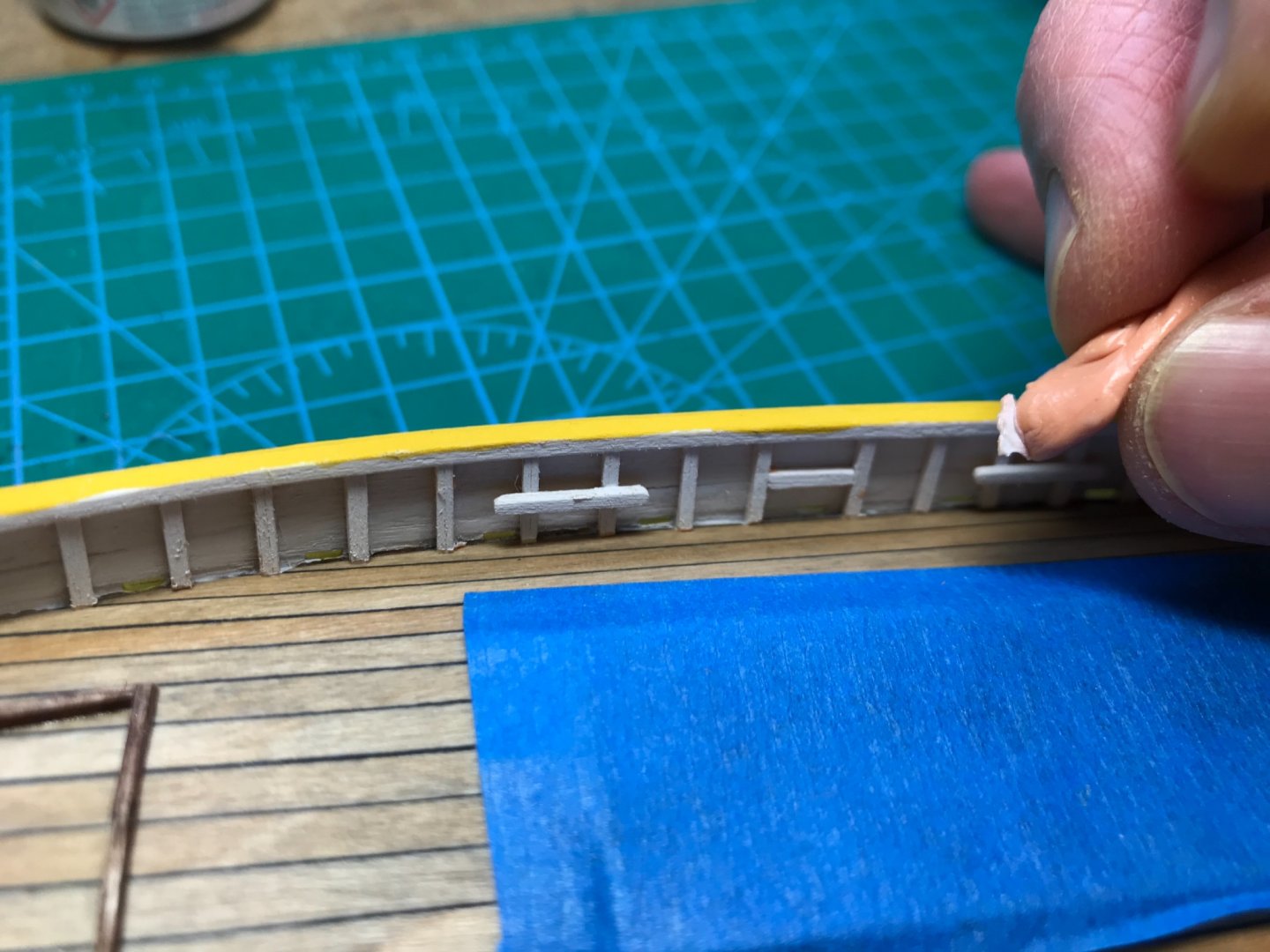

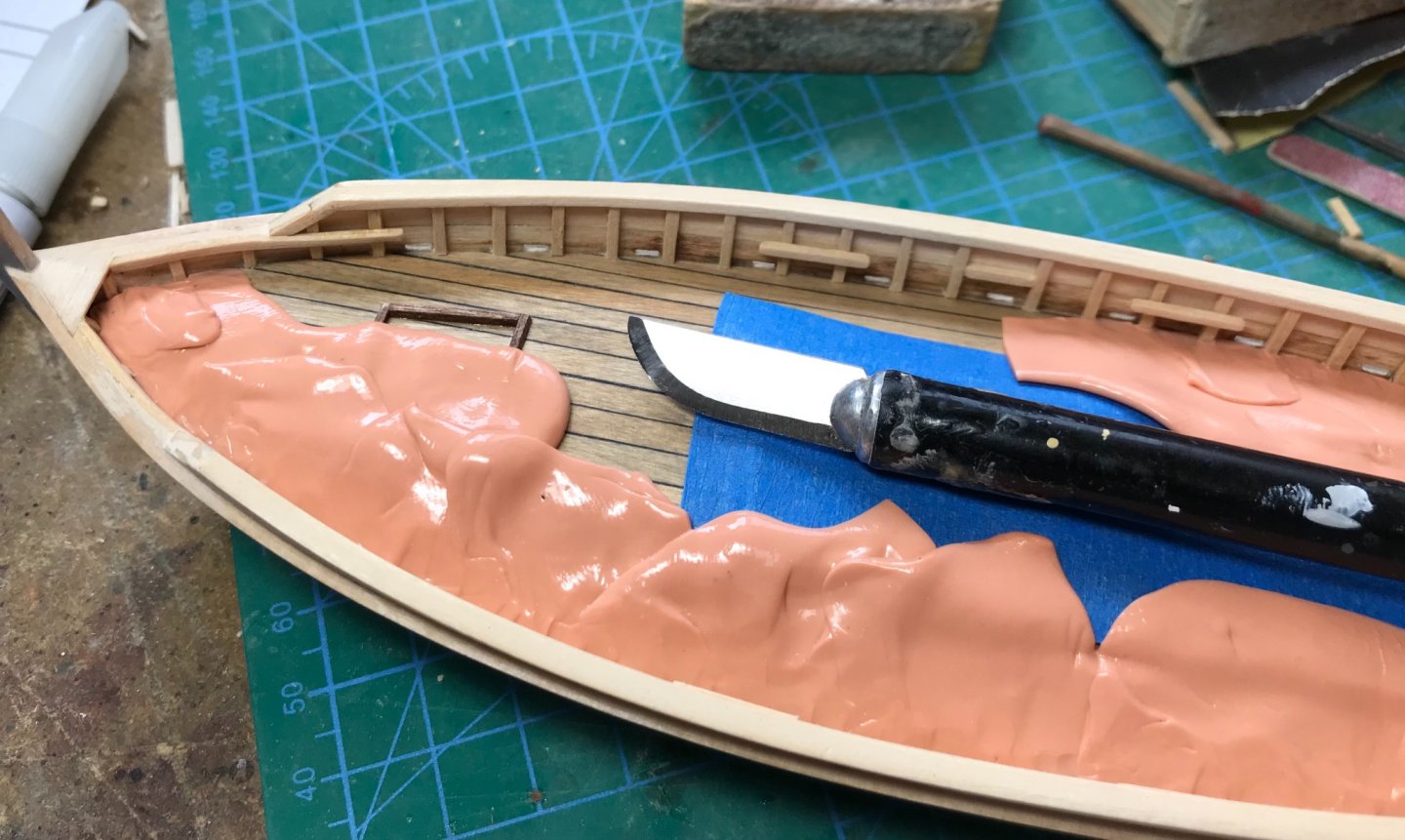

After painting the base color on the upper hull, it was time to remove the tape and putty masking. It all came off okay, but the putty was a problem on the inner bulwarks. Although it lifted right off the deck, with no problems, it did not want to come off the sides. There are four potential reasons it was so obstinate: 1. The putty adheres to wood more than other types of material. (Not likely, since the wood is painted and the deck is wood. The deck was smooth and varnished, but not painted. The putty came off the deck, easily). 2. All the nooks and crannies of the ribs, and the rough surface of the bulwarks "held" the putty. (This was probably a factor, but I think not the only one. When I've used putty before, I noticed that recessed features can hold it a little tighter. This time I wondered whether I'd be able to remove the putty at all!). 3. The putty was applied to the bulwarks before the paint dried sufficiently, causing the putty to attach to the paint in a strong way. (This seems very likely to me, but future experimentation is needed. I also need to be more patient). 4. The putty knew I was doing a build log and wanted to thwart me. (This is the obvious answer)... Except for the "scare" that I had ruined my model and would never get the putty off the bulwarks, the masking with the putty worked. A little "touch-up" was needed on the bulwarks, but not much, and the deck was totally protected - which was the intent. IMPORTANT HINTS: Unless you are experienced with using a putty mask, try it on smooth, easy to access surfaces for starters. Try NOT to use a "tool" to pry the putty off. There is too much danger you will to gouge the surface, or pry off a small part. Use your fingers and putty to pull off the putty, as shown below: Obstinate putty! Use putty to remove putty... Base coat done. Brush painting of the rails, trim, and other details comes next. Then weathering!

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Yes, I realize this is more common in the plastic model world. I want to learn if any it can be adapted, with success, to our genre. Even so, nothing beats the look of stained and varnished wood!

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

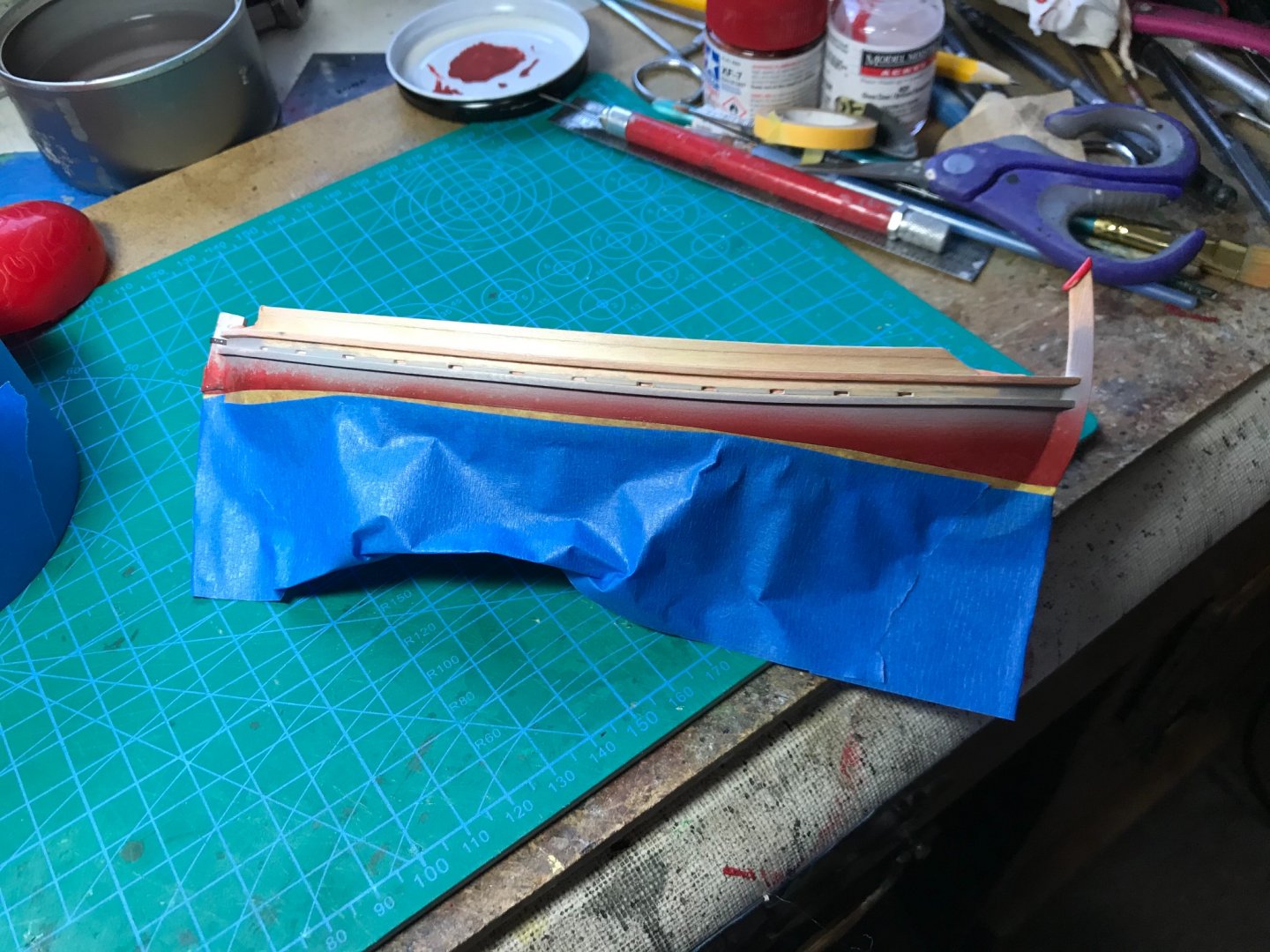

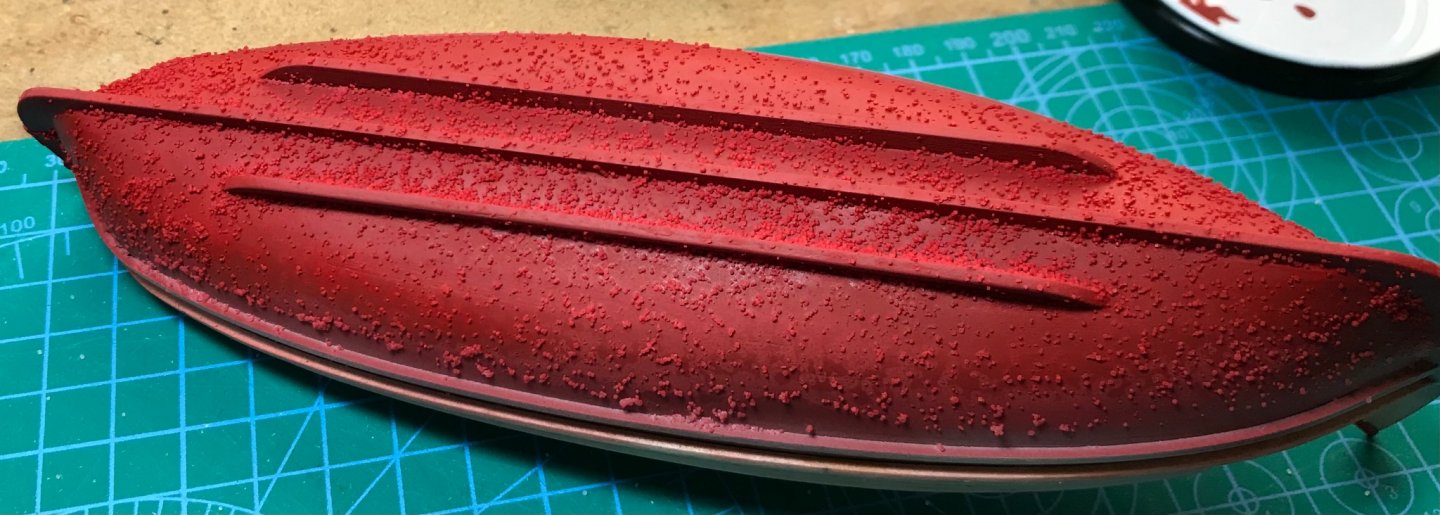

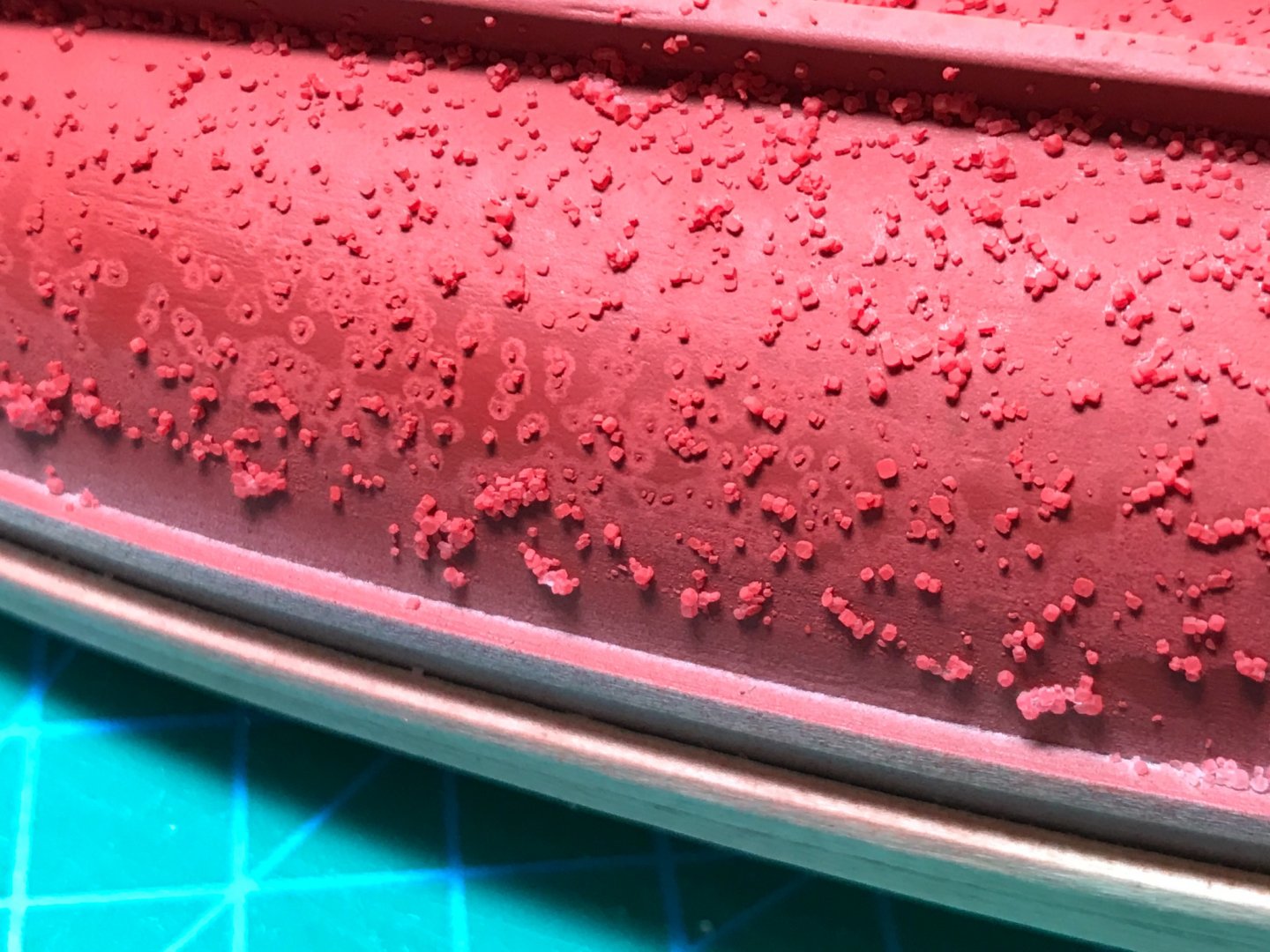

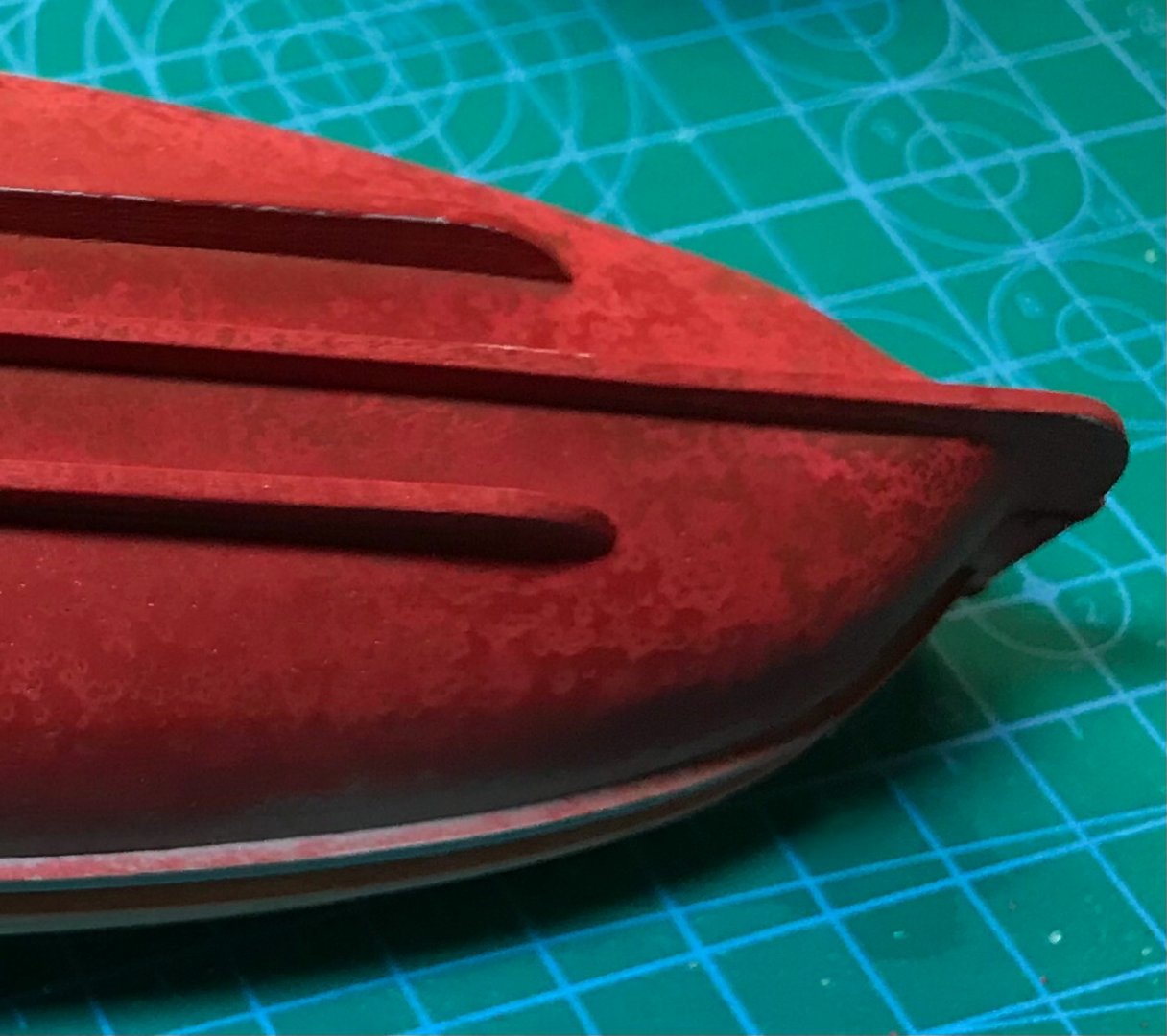

One of the things I wanted to do with this project was to try different weathering techniques I've used on other types of models, in the past. One of those techniques creates a heavily weathered, mottled and worn appearance below the waterline. It involves using different shades of paint and common table salt as a masking agent, as shown below: Using acrylic model paints, I mixed a reddish rust color for the base layer - applied with an airbrush... After drying, I wet the painted area down with water (with a drop of detergent in it to increase viscosity). Then common table salt was applied, right out of the shaker. The wet surface allows the salt to stick. Once the salt dried (about an hour), I applied the second color (in this case, a little brighter red). Since acrylics are water based, you can see how the salt "bleeds" out a little. I think this is great! It adds yet a third color to the mix! Some of the salt goes flying off into space as you spray on the paint, but no matter. Most of it stays stuck... Anxious to see the results, I started lightly rubbing the salt off with my finger. I should probably wait longer, but I never can... Some of the salt stays attached, so gentle washing with water and a stiff paint brush loosens things up. We're done with this phase of weathering, but I do plan on trying a dark "wash" for the recesses and dry-brushing for the high-lights, later...

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

The putty can lift off the paint, but it is far less of a problem than when using masking tape. Like tape, it can also pull off small parts, so you have to use care.

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

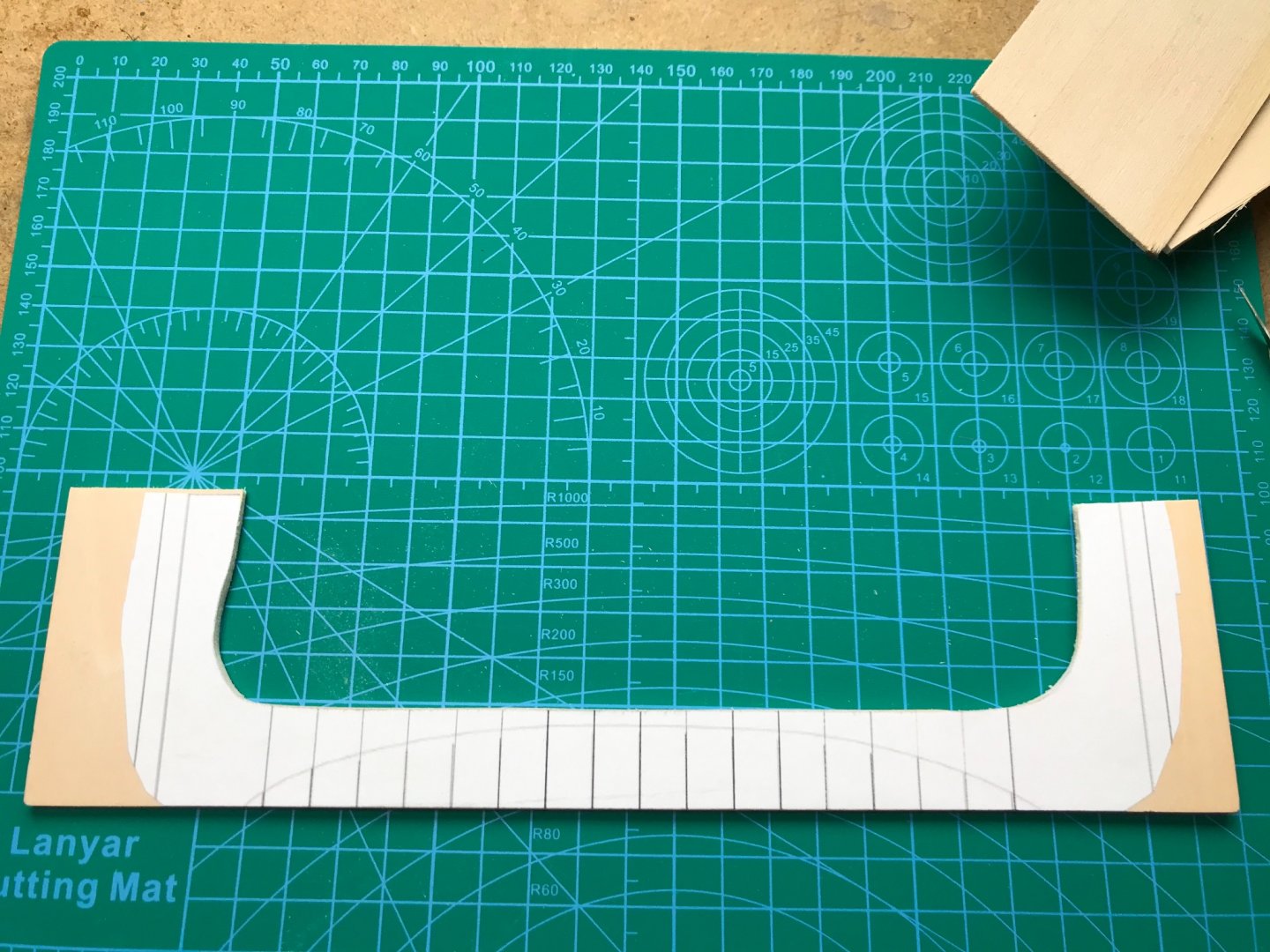

Painted the interior bulwarks white, then covered them up with more putty as exterior painting begins... The putty on the left is new; the right is years old - filled with dirt, paint and grit - but still usable.

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Most of the hull work is done, but before stepping the mast and tackling the rigging, I need to paint the hull. Prep work starts with masking the deck. I use "Silly Putty" and blue tape as masking tools. The putty can be used over and over again, until it finally gets saturated with dry paint and dirt. However, it takes years of paint jobs to get there. Applying the putty does get a little tedious sometimes. I used a dull #10 blade as a putty knife to push material into all the nooks and crannies... Hope to start airbrushing tomorrow!

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Thanks for the comments Louie and Tony!

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Thanks G.L. I'm hoping to improve my skills in order to tackle a bigger project, but I really enjoy the smaller boats!

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

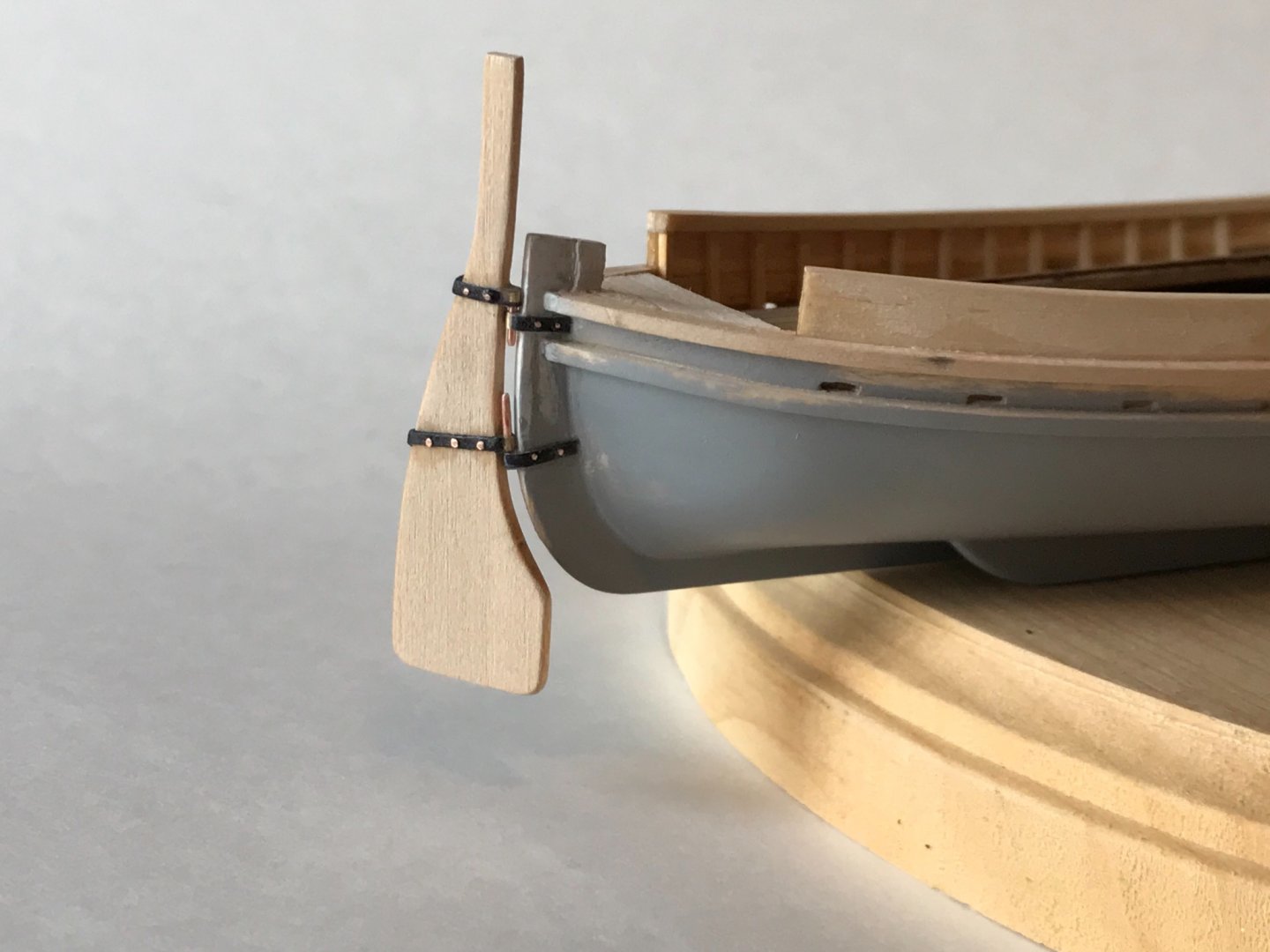

Finished up the framing, a front hatch deck coaming, and the rudder. Interesting that the rudders on these boats appear to be readily removable. I assume to facilitate frequent beaching to sell their catch of fish... Basswood rudder. The long pintles are prototypic, I assume to facilitate frequent removal and replacement of the rudder. My pintles are copper wire; the gudgeons are brass tube with heavy black construction paper and copper wire rivets. The rudder is moveable! Making a tiller arm... The finished product...

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

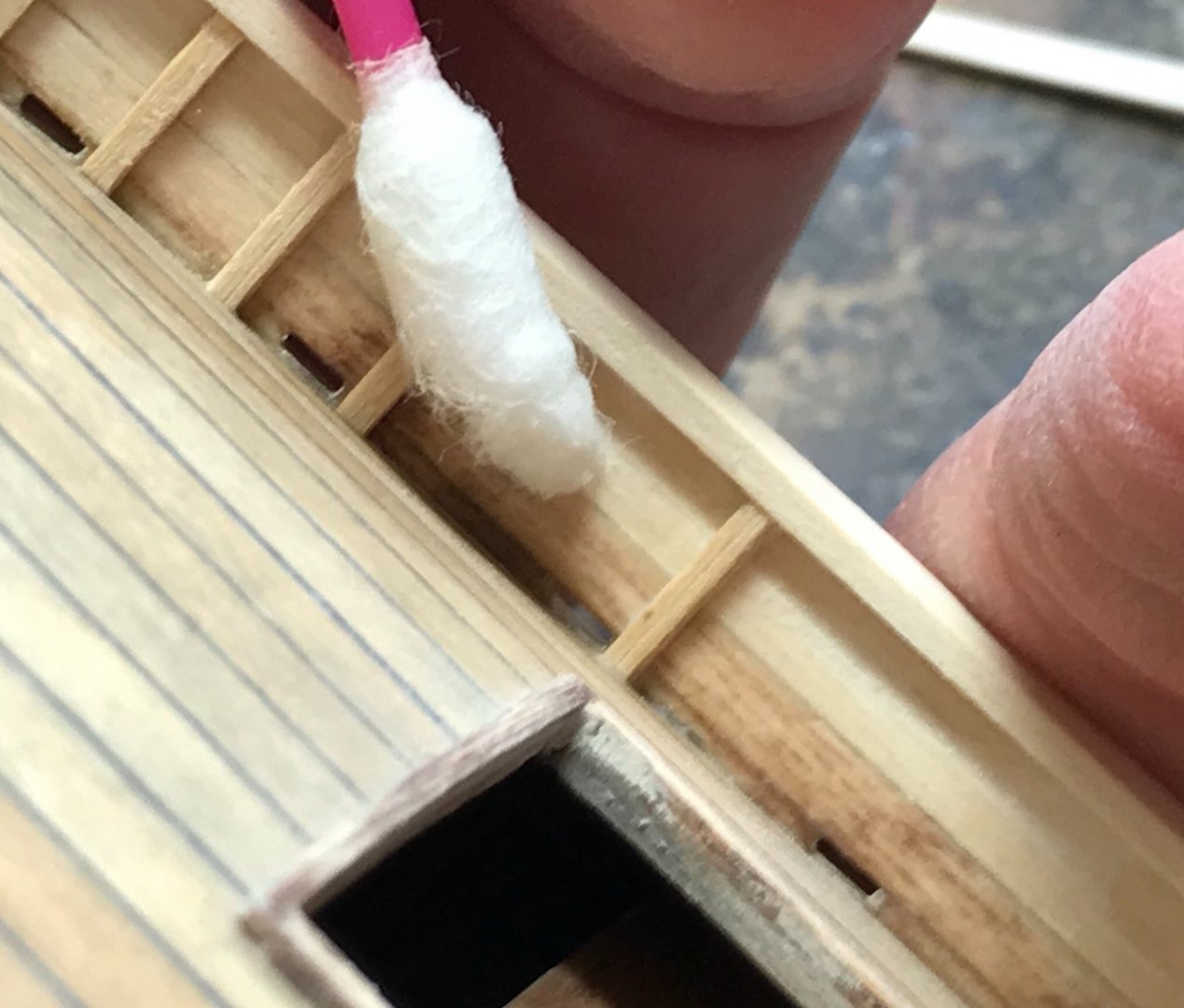

Yes Louie, just a damp cotton swab to remove the excess white glue (which is water based) before it dries.

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

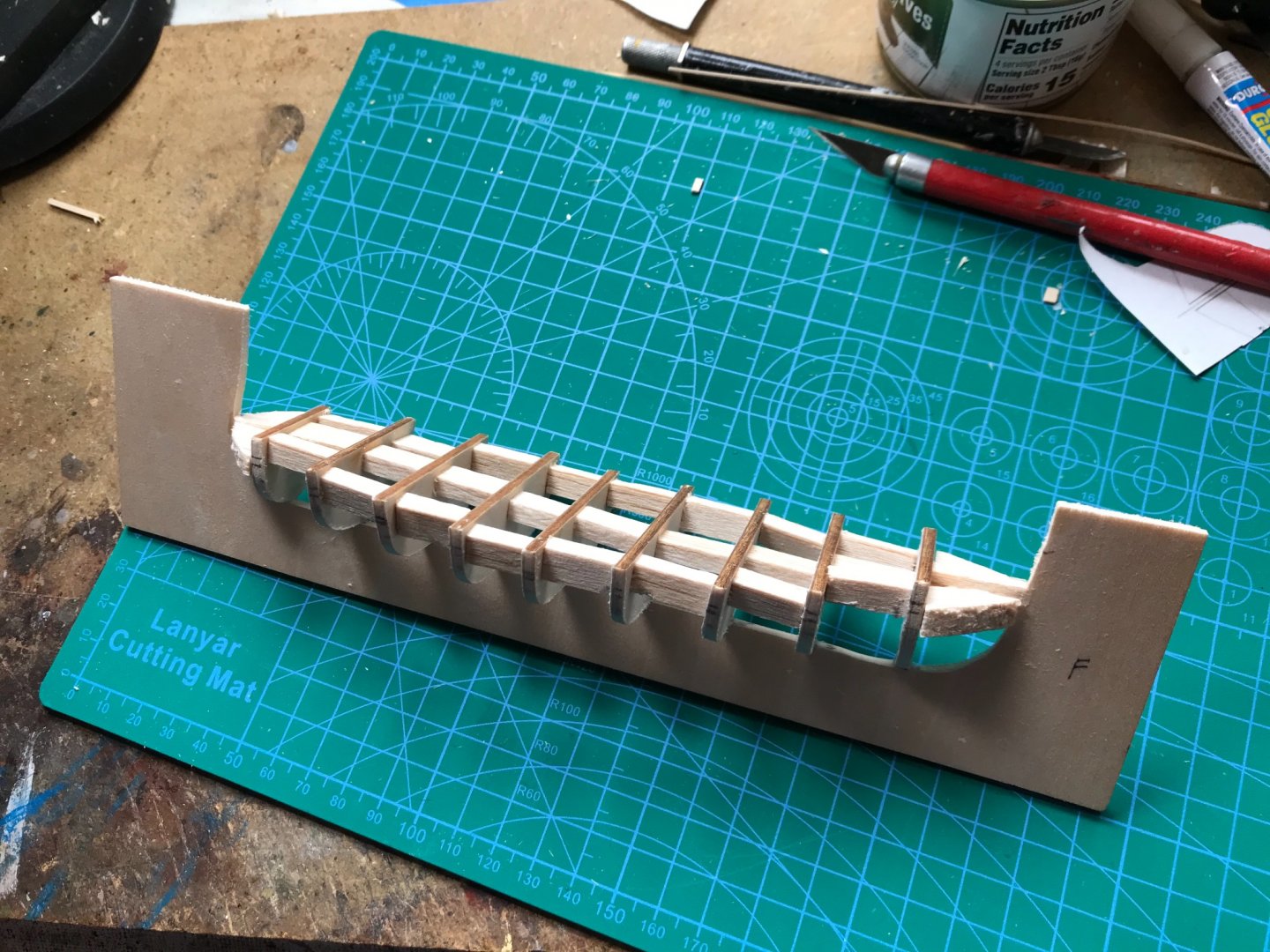

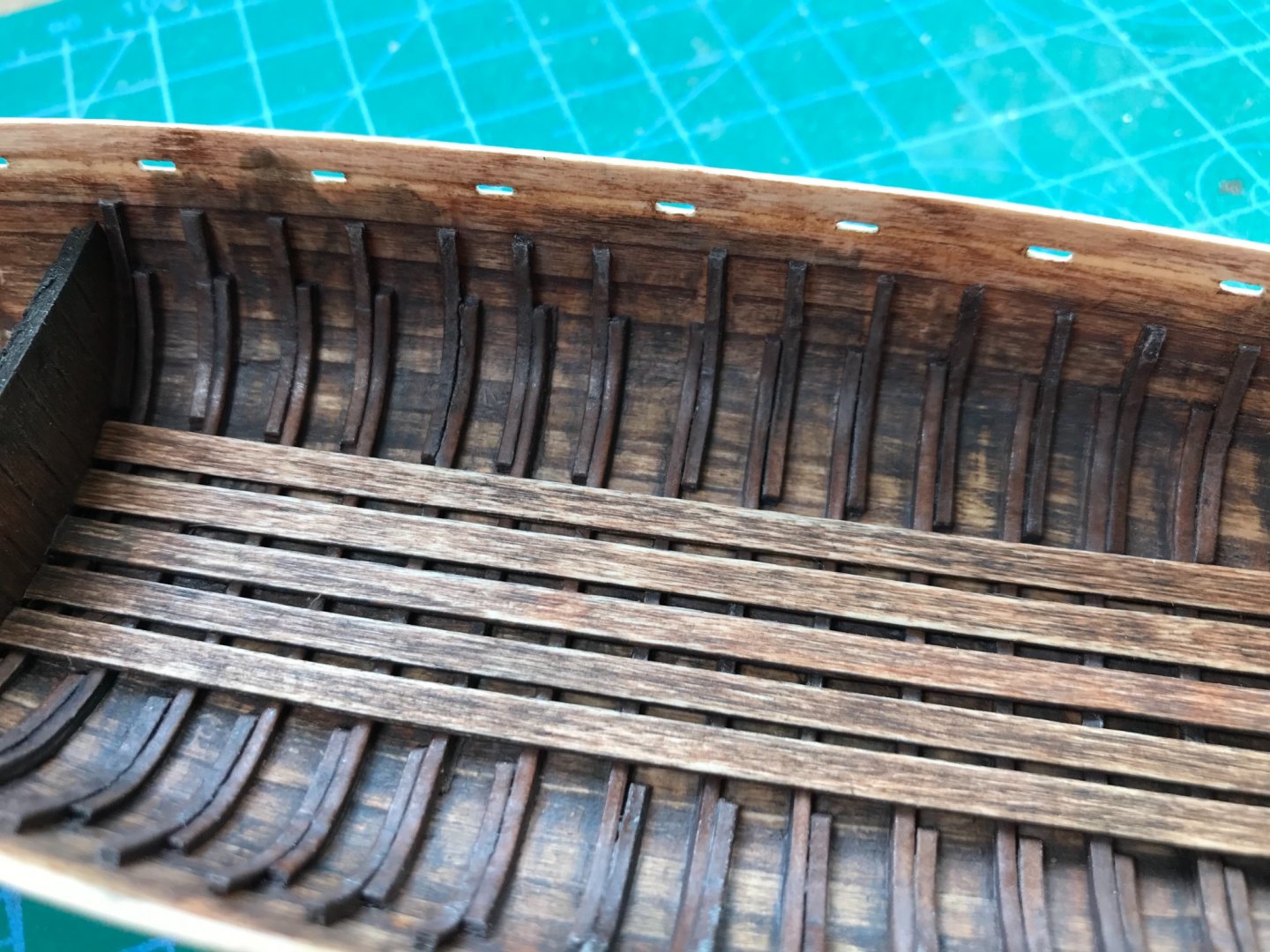

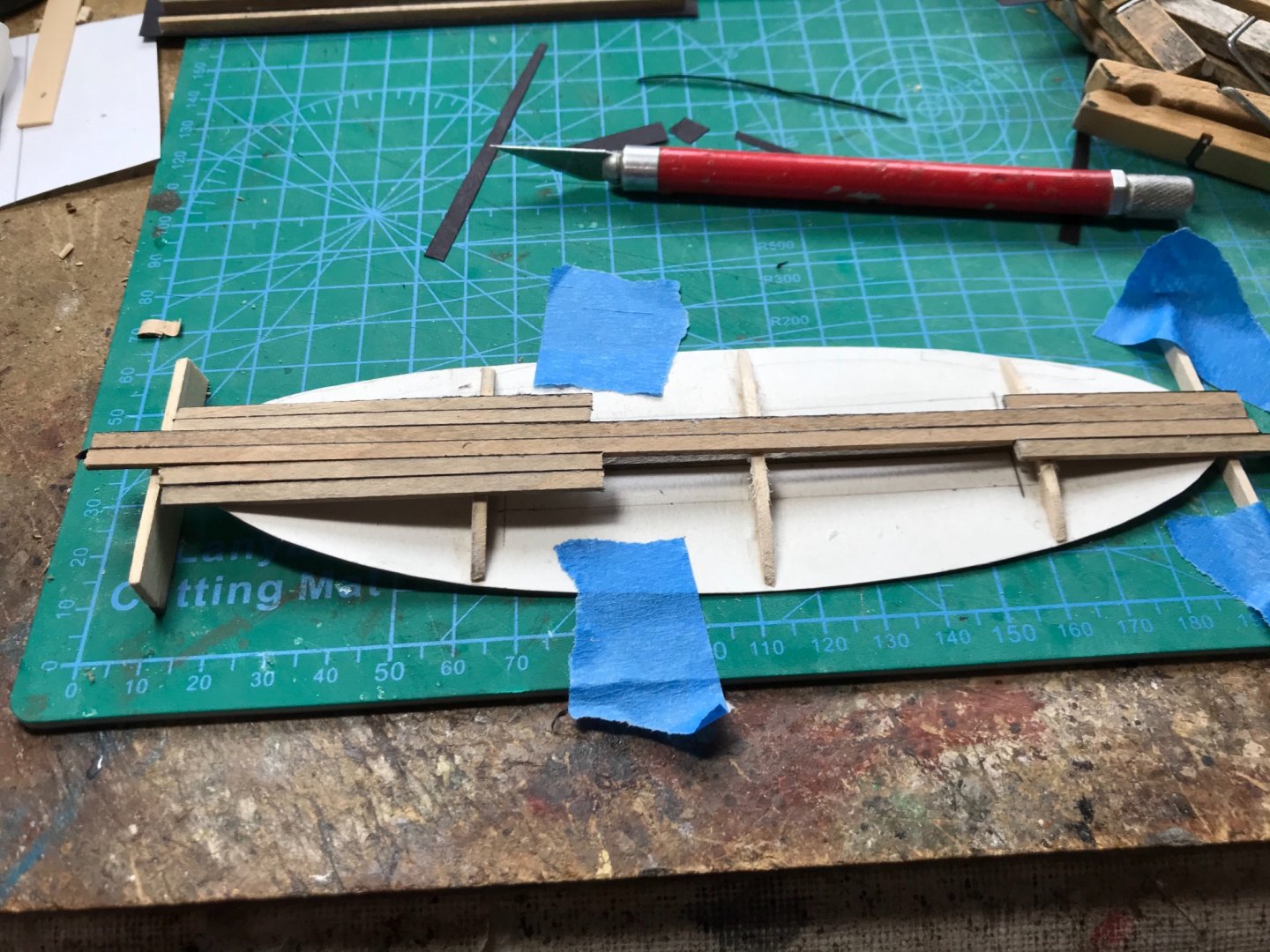

Started adding the false frames... The frames are only 1.5mm wide! I have to bevel the bottom to accommodate the steep camber of the deck. Measuring length for cutting the frame to size... Checking for fit... A little white glue... Placement... Cleanup... After a while, they add up!

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

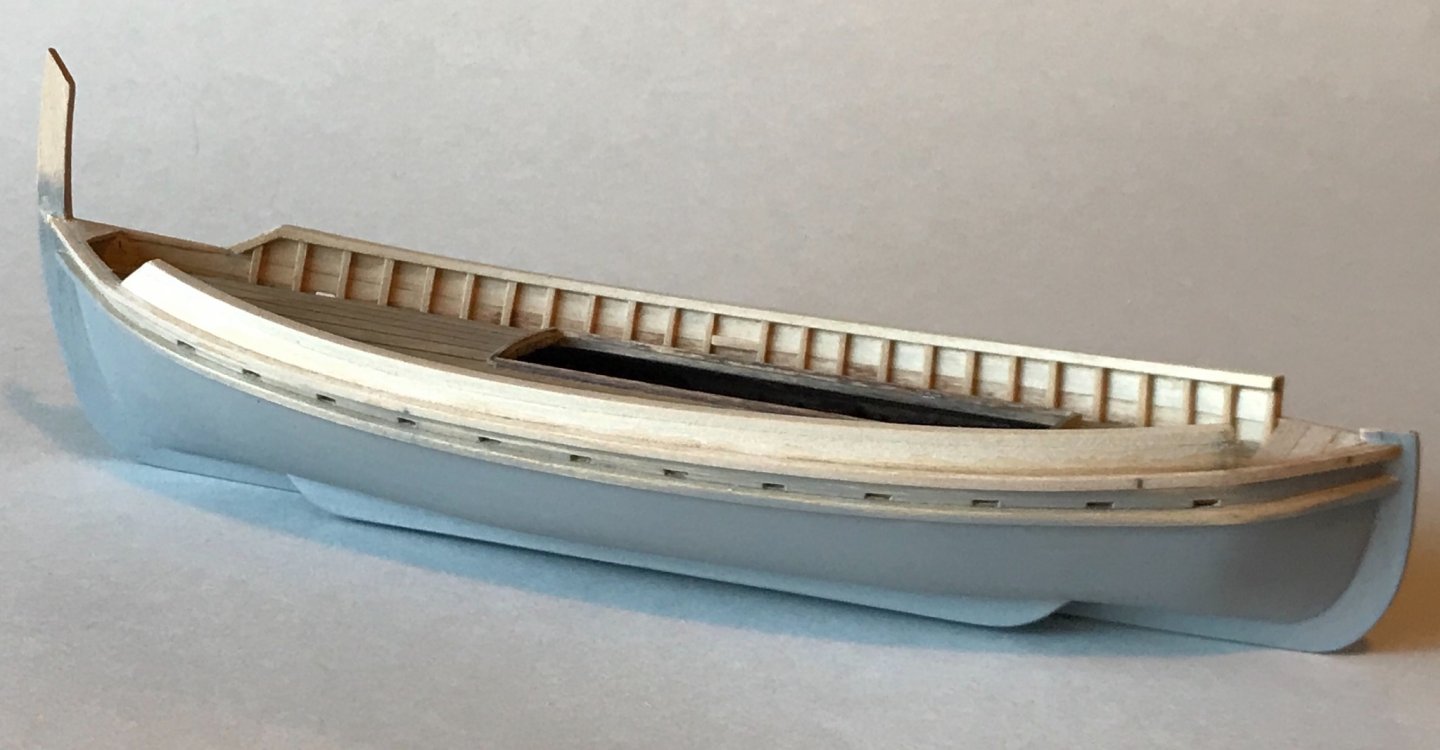

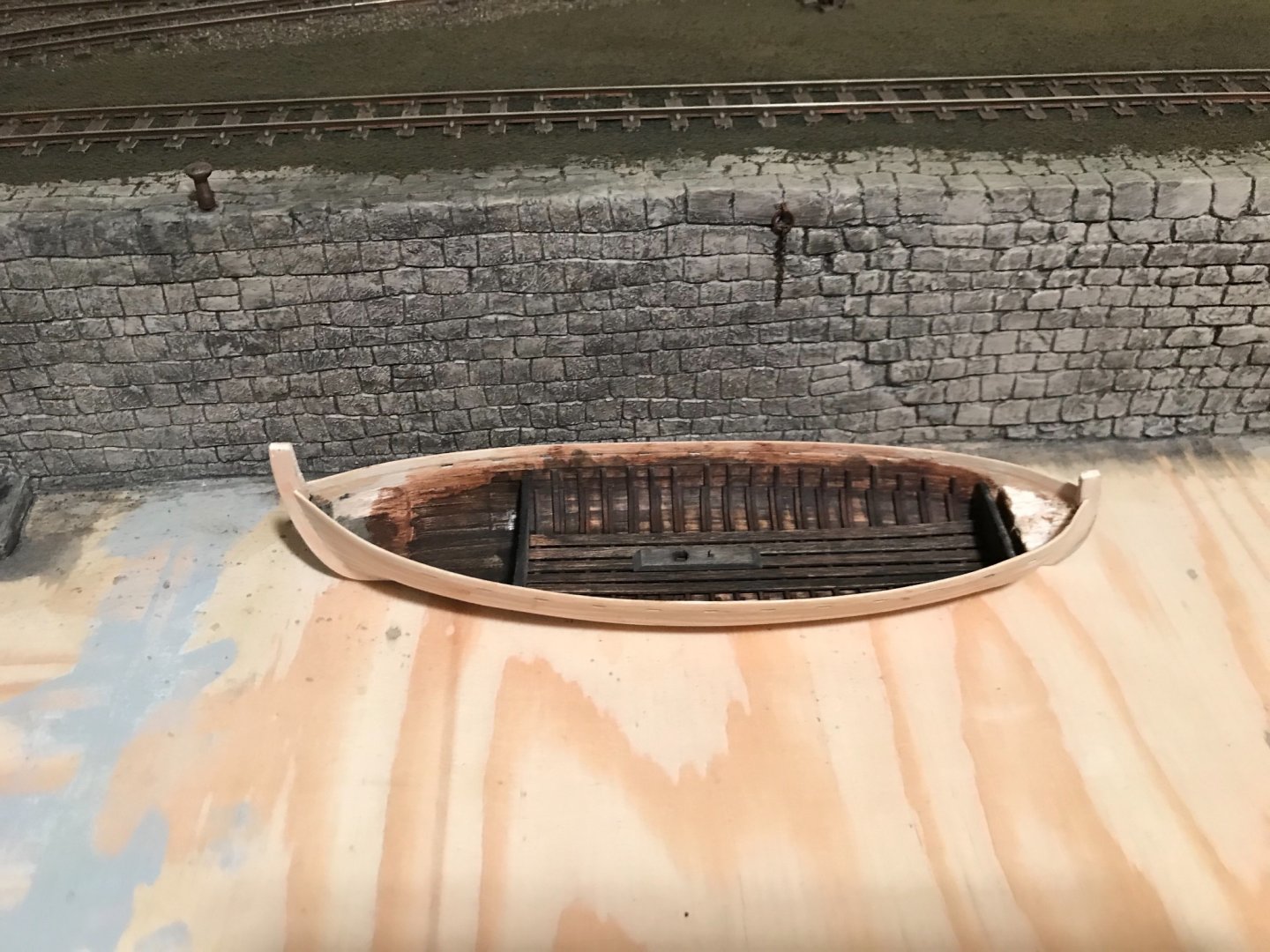

Progress on construction... Added the upper planks, capped the top rails, and added the aft cabinet seat.

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

During my research, I did come across a drawing and line plans for a "bateau boeuf." They are for a 16 meter boat (a little larger than I wanted) but definitely of the same DNA. There are so many similar boats throughout the Mediterranean, including Egypt and north Africa. Has anyone every classified them into one type? "Levanters?"

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Thanks for the interest Tkay11! Yes, it is 1:48 scale (about 188mm long). For the scuttles, I installed a plank (about 0.5mm wide), measured and marked scuttle locations, and the cut them out with a sharp #11 blade. After that, I placed the next plank, which topped off the scuttles. For the keel and posts, I just smoothed everything to the planks. No grooves....

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Thanks for the interest Tkay11! Yes, it is 1:48 scale (about 188mm long). For the scuttles, I installed a plank (about 0.5mm wide), measured and marked scuttle locations, and the cut them out with a sharp #11 blade. After that, I placed the next plank, which topped off the scuttles. For the keel and posts, I just smoothed everything to the planks. No grooves....

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

Thanks Wefalck! I took out all the bulkheads because they rose above the deck line. One could plan a build differently, but I wanted to do most of the planking above the scuppers with the help of the temporary bulkheads. For sources I did internet searches for contemporary and historic photos, models, plans, drawings, etc. using several different keywords (barco catalan, barque catalane, catalan boat, and other terms that the first searches revealed). I also kept changing the settings on my search engine by country. I noticed different results when doing that. Sometimes, you will find some good info you would not otherwise see (I suppose because of the language differences). For example, I got wikipedia hits on "Catalan boats" searching in "France," that I did not get when searching in the "US."

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

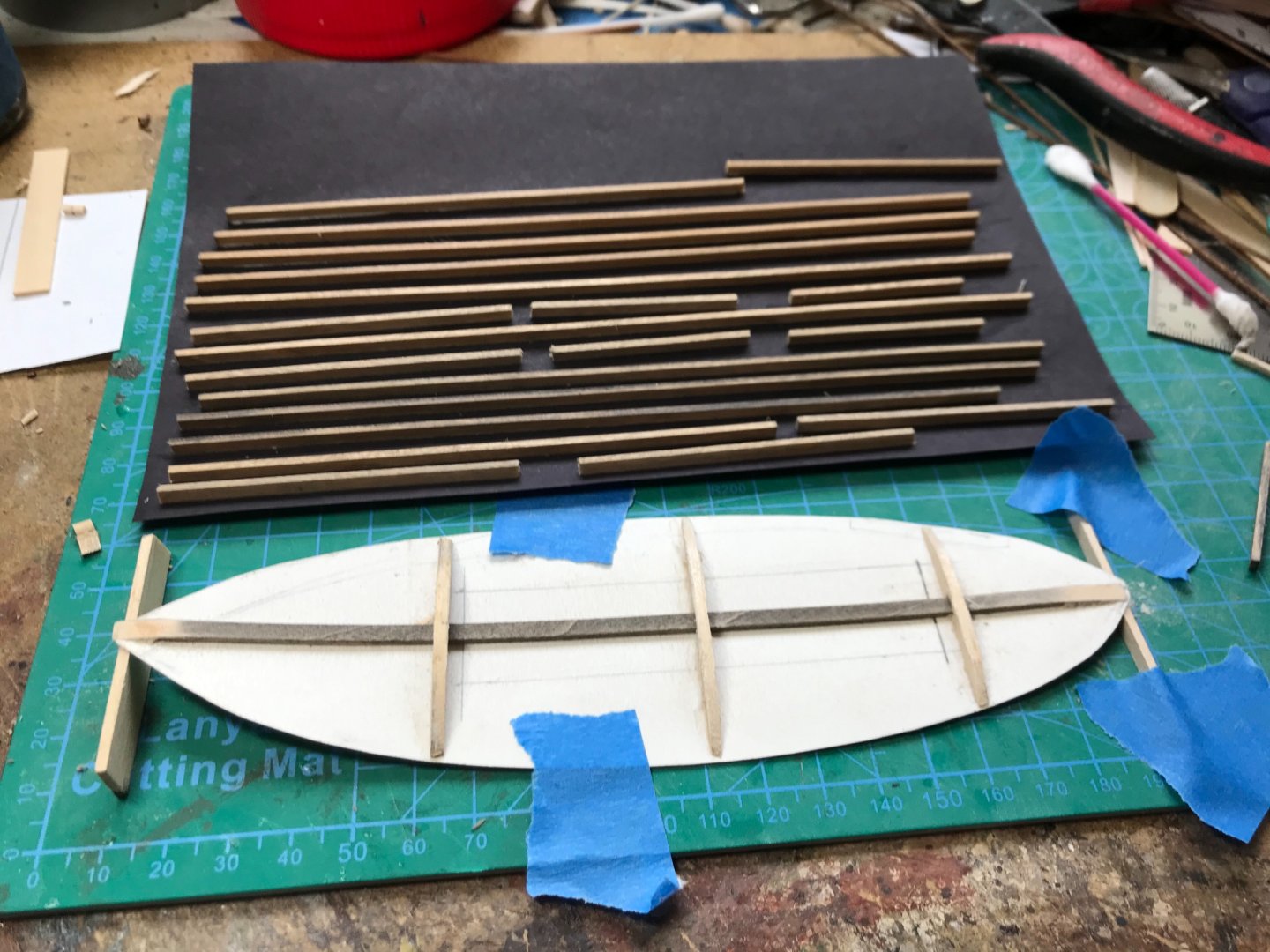

The Catalan boat is a small lateen-rigged vessel used throughout the Mediterranean in various forms. This model is suppose to represent a typical 9-meter boat from the late 1800s. Photos, plans, and drawings of surviving and modern-day boats are being studied. Also, I was inspired by MSW member Javier Baron's construction methods for his fabulous models, and thought they would work well for this attempt. The false keel, which doubles as a construction frame and handle. Bulkheads will be attached at one small point at each station. Plywood bulkheads attached and braced with balsa blocks. Planking has begun with basswood. Since this is an open boat, the bulkheads are temporary. They are only needed for the planking process. The edges of the bulkheads were rubbed with beeswax to prevent glue (super glue) from adhering to the planks during planking. The planks are just glued to each other (and often my fingers). I used a bandsaw to cut away unwanted parts of the false keel. The bottom has been cut and sanded flush with the planking. The stern and stem posts will be cut away later, and all replaced with new parts. Feeling confident the super-glued planking will hold, I gently started removing the bulkheads after violently breaking the balsa spacers... The "cleaning"continues. Note the balsa "deadwood" at the ends of the boat. Unlike the bulkheads, the planks were glued to the deadwood. I noticed that balsa wood smokes when super glue hits it. That can't be good! All clean. Reminds me of a corn taco.... Seems very fragile! Sanded the interior a little and stained it. Now adding ribs made from heavy card stock (doubled, stained, and cut into strips). Keelson added... "Real" bulkheads and a floor added... The step plate for the mast is added... Benches added (stained basswood). Beginning the decking. Deck planks are being edged with black construction paper. Also a cardboard template was made with the proper sheer to use as a base for the deck construction. The decks on these boats have a lot of camber, hence the three formers. Deck planking started in the middle. The middle two planks will guide alignment, but will be cut later to make the opening in the deck. Viola! Shaped to fit... The underside... Pretty good fit... You will notice new stern and stem posts were added, as was the keel. These boats had extra keel-like structures called "escues" on either side of the keel, and parallel to it. The escues helped to balance and support the boats when the crew ran them up on the beach, to sell their catch. Installed a pulley for the mast... Since the hull of the boat will be painted, I thought I better prime it to ensure I sanded out all the blemishes. Adding the upper planking and wales. Next, on to the rail trim and false frame ribs...

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.