crabbersnipe

Members-

Posts

28 -

Joined

-

Last visited

Recent Profile Visitors

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

Canute reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Canute reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

Valeriy V reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Valeriy V reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

Valeriy V reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Valeriy V reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

mikegr reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

mikegr reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

mikegr reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

mikegr reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

Old Collingwood reacted to a post in a topic:

HMS Argonaut (F56) by crabbersnipe - 1/96th - Leander-class frigate

-

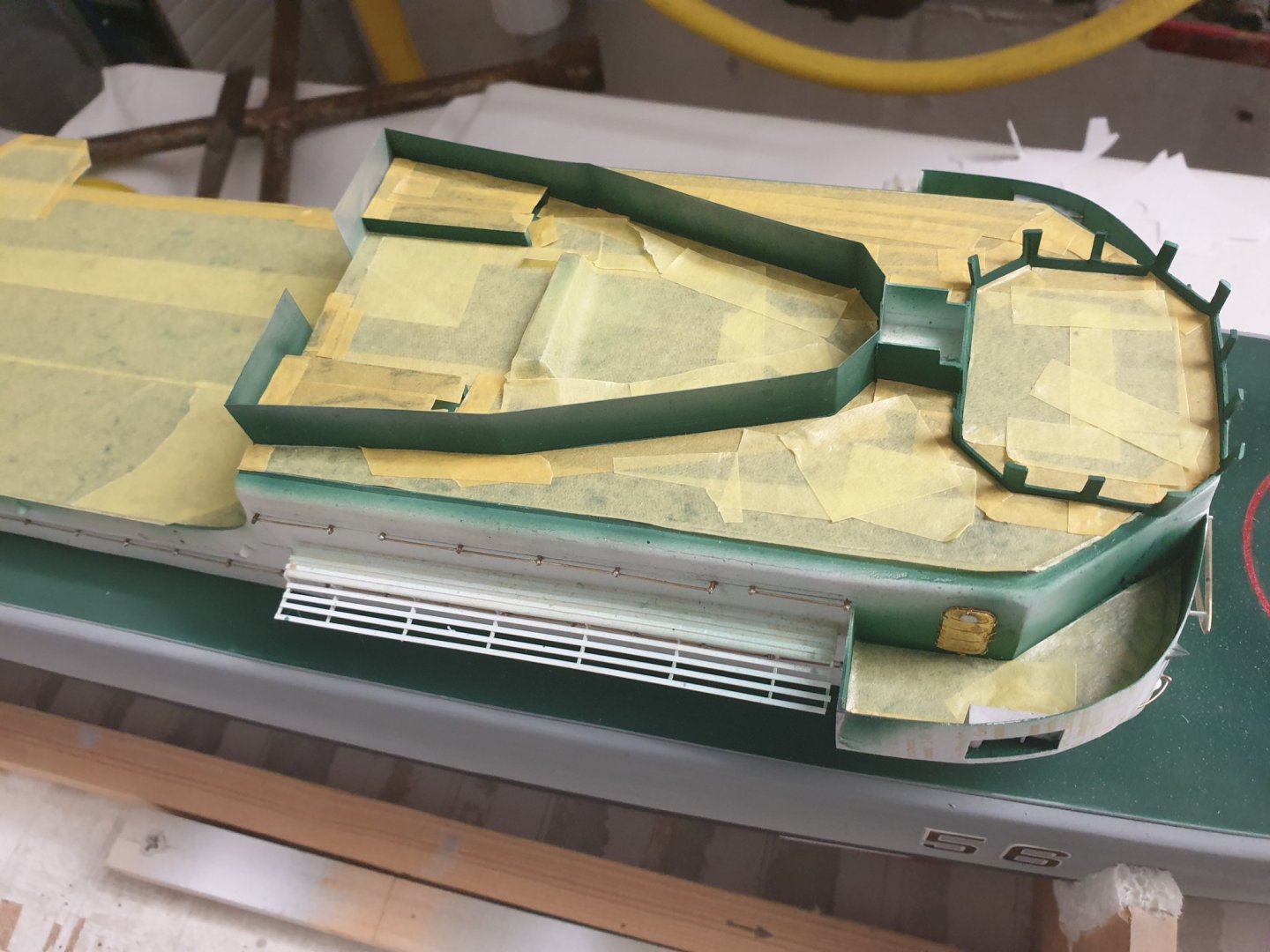

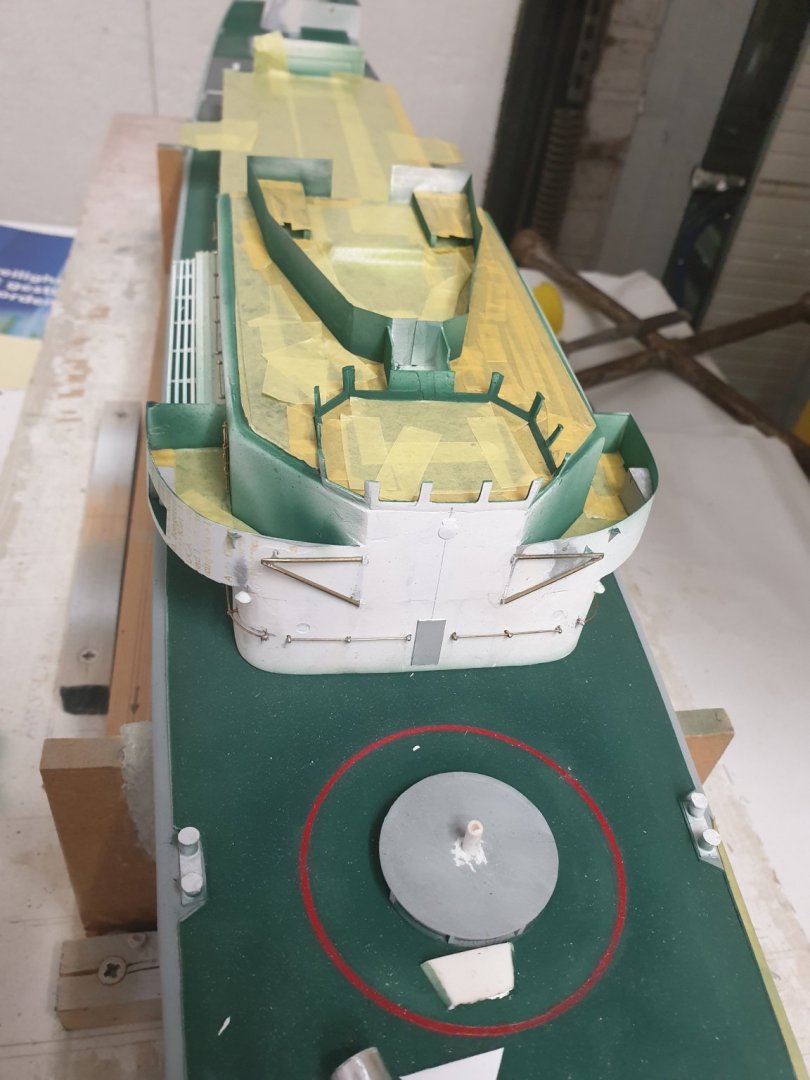

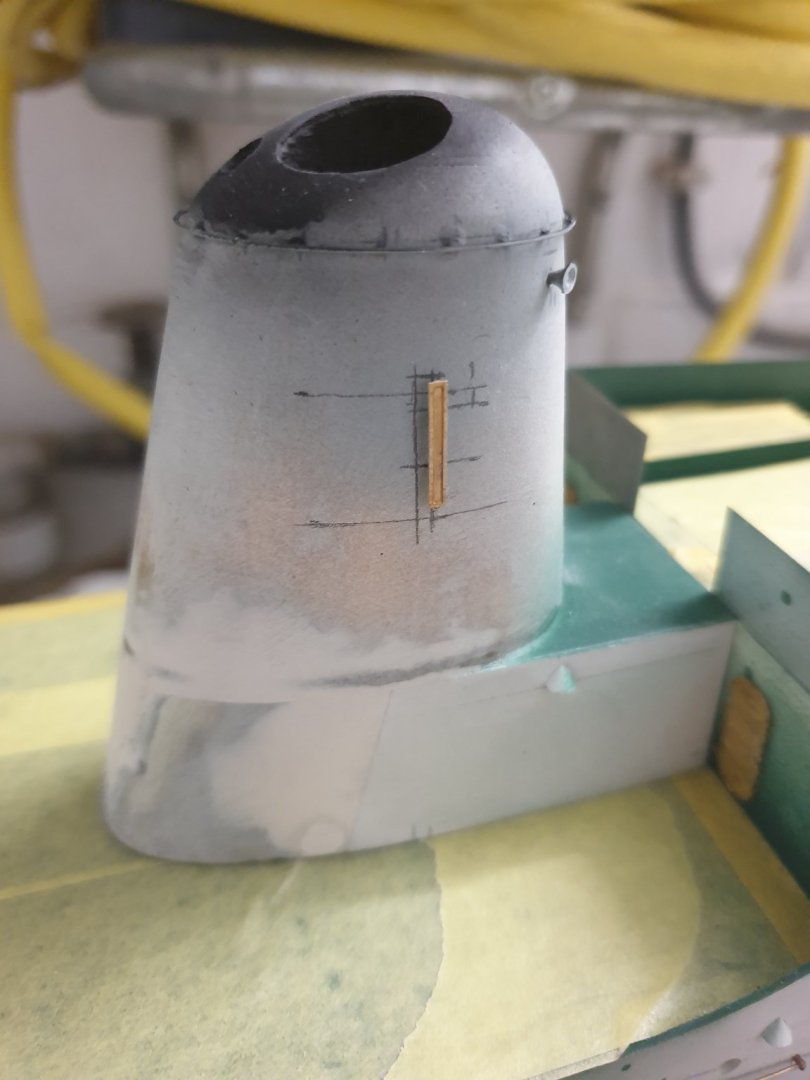

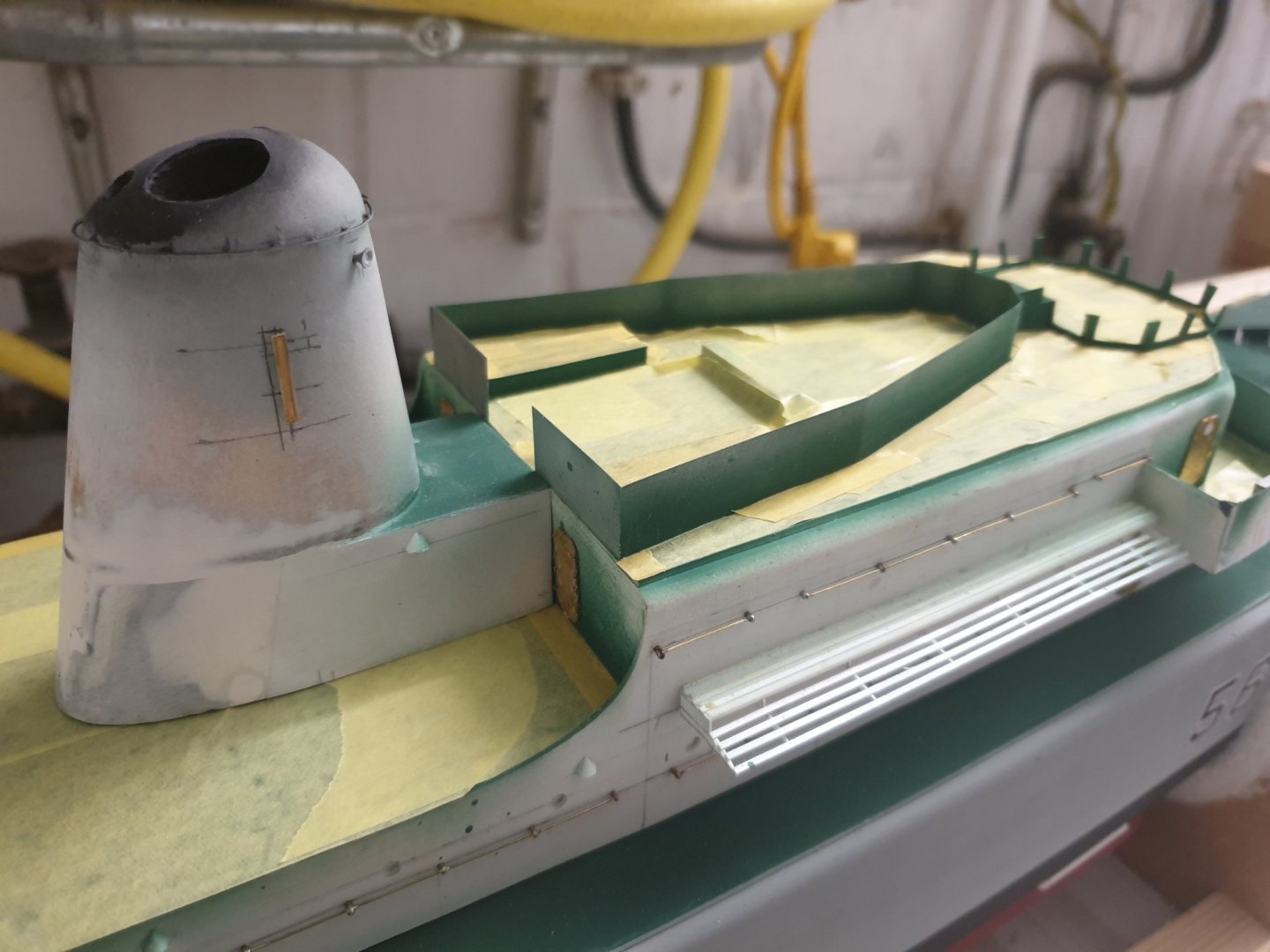

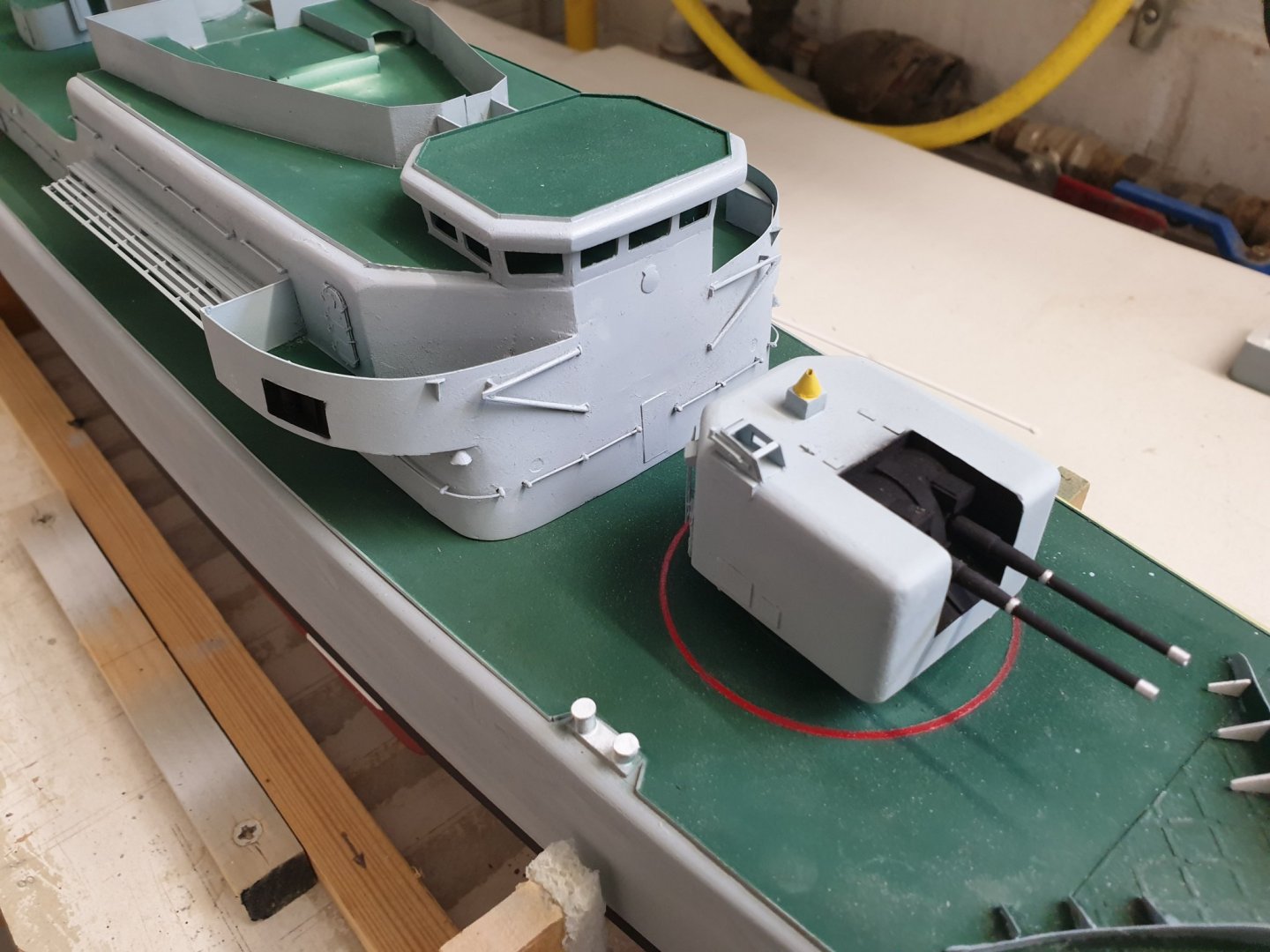

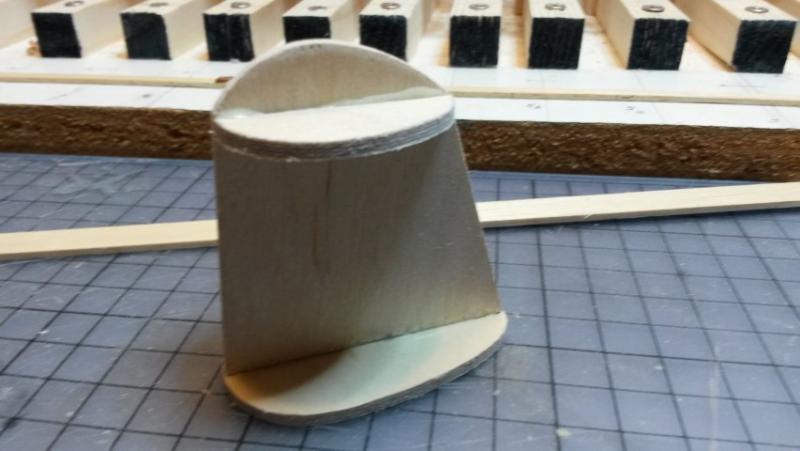

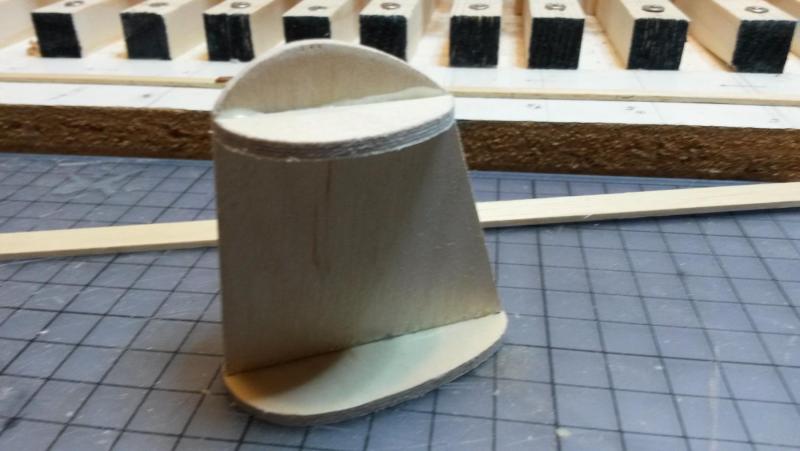

Can't believe 4 years have lapsed since first starting this model but sadly this build started to slacken after a while due to various circumstances. However, pleased to advise we have picked things up again and whilst I am sure there is a considerable gap in my photo record let me already share the very latest to show where I am with things - finished the 4.5' gun turret last night, worked on the funnel and gave the superstructure some colour. Enjoy, E

- 42 replies

-

Thanks for the advise Roger, will be removing the sonar dome shortly and re-attach once the fibreglass is put on. I suspect the same logic applies to the flat stern piece vs the hull ? Am considering covering the stern first, and then proceed with the rest of the hull thereafter - again because of the corners. E

- 42 replies

-

Argonaut sailed through some cottage cheese today - applied the first coat of filler...snowwhite ! Then sanded most of it off again.... E

- 42 replies

-

Gave the hull a first coat of resin + hardener, worked especially into the joints and where the seams are slightly opened between the various planks. Will rub this down once fully dried out and then proceed with filler and body primer - heading for a lot more sanding no doubt ! Glass matt have been ordered and are on their way, so no time to waste. Am pondering whether to remove the sonar dome (that is part of my keel assembly) to facilitate the matting of the hull, and re-attach later & separately. Seem to think this protuberance will stand in the way of a neat glassfibre cover...... E

- 42 replies

-

Thanks Jon, lovely lines these ships had - some great curves :-)

- 42 replies

-

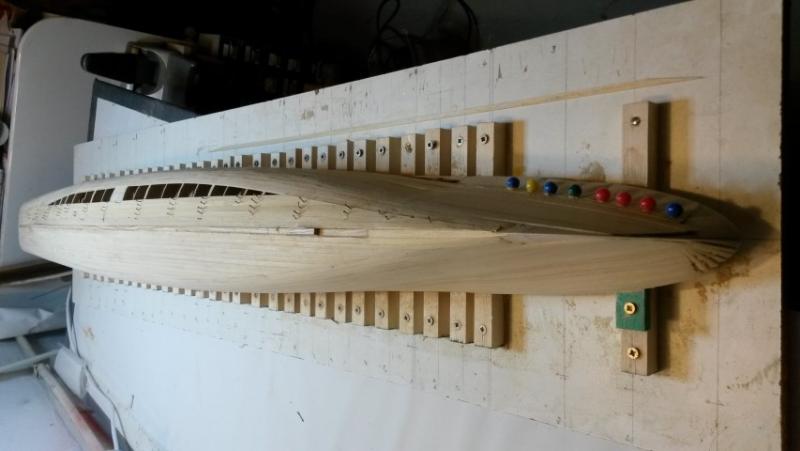

Completed the hull planking, quite happy with things so far - need to do some finishing touches to the bow still (used some vertical strips that need sanding), and next step will be a rough sanding using 60 grade grit, before applying some resin into the joints. After than some more sanding and applying filler where needed. E

- 42 replies

-

Thanks for your advice Roger, very useful intel, especially your comment about the pumps and different types of hardeners. I reckon I will be trying my hand in a week or two. Funny you should mention canoe building, was having a browse the other day about doing this plank-on-frame + fibreglassing exercise on a bigger scale and build myself a Canadian canoe ! Thanks again, E

- 42 replies

-

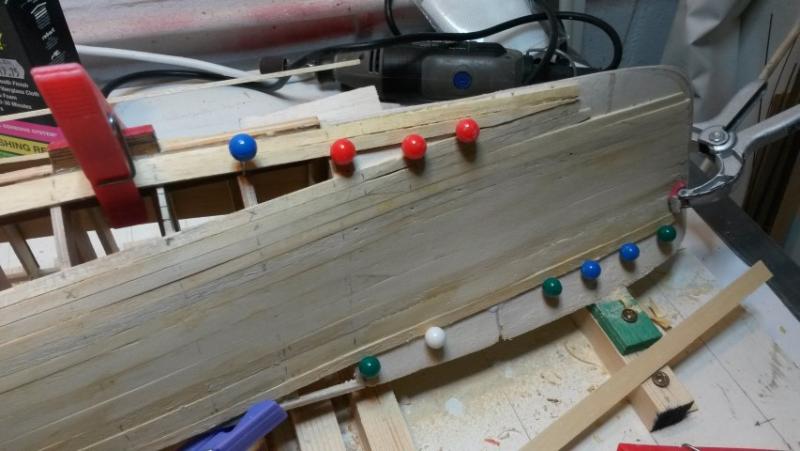

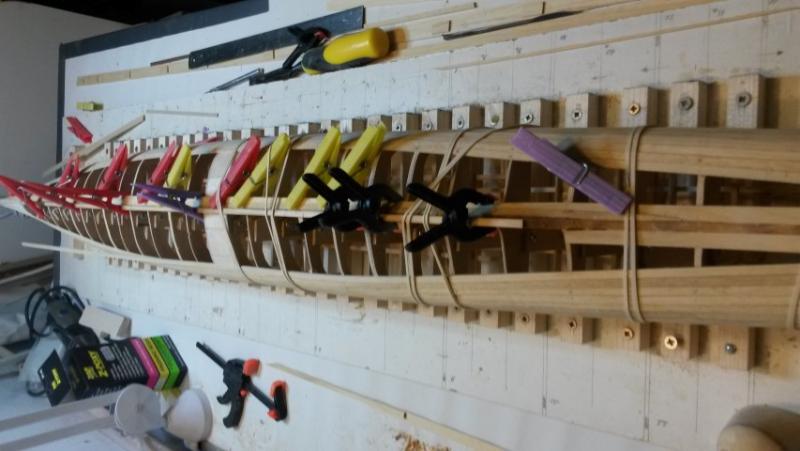

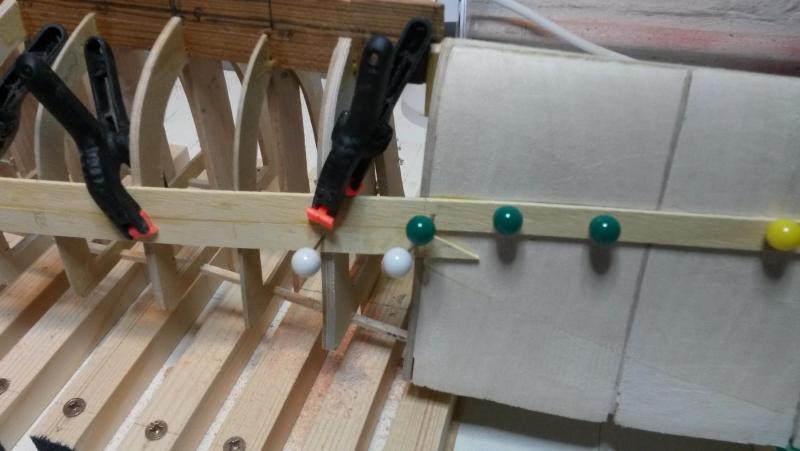

A few more shots - almost there, started planking from the keel down now - also needed to start using nails to keep things in place, the clamps do not have enough grip any more. E

- 42 replies

-

crabbersnipe reacted to a post in a topic:

HMS Naiad 1797 by albert - FINISHED - 1/48

crabbersnipe reacted to a post in a topic:

HMS Naiad 1797 by albert - FINISHED - 1/48

-

Thanks a lot Greg, Just the sort of advise I needed, there seems to be as many ways of doing this as there are modellers, but there is definitely no substitute for hard-won experience ! It certainly is a slightly daunting prospect but once mastered I think I can imagine myself doing all my hulls myself from here on - it certainly was fun getting this far. Will have a look at the EC stuff and will keep you posted on my experiences in a few weeks time. Lovely model by the way, what is it - quite big as well it seem ? Cheers E

- 42 replies

-

Hi forum I will shortly be finishing the planking of my hull and need to start thinking of how best to proceed in term of coating everything with glassfibre cloth. Can I call on some of your experiences on how best to proceed from here ? Some of the questions I have are as follows: - will be sanding and filling the planks - will I need a primer coat first, before putting on the glassfibre ? - and if so, should that be 'any' primer or are there specific advantages to using 'car body primers' ? - in terms of glass fibre cloth, I suppose I had best go for the finest woven cloth presumably ? - regarding epoxy resins, does anyone have any experience with the West System product range ? - what would be the recommended 'curing' time for a model of this size, bearing in mind that * I have never attempted this before and therefore will need sufficient time * will be doing this in one continuous process, i.e. the entire hull with one piece of cloth Thanks a million for any help you can provide, will be most obliged E

- 42 replies

-

Bit of an update, showing progress to date. Partially sanded some bow sections and will clearly need some filler and putty between some of the planks. Distortion of the planks is still manageable, despite getting nearer to the keel - am considering working 'downwards' from here, using stealers for the remaining gaps. Need to do some more thinking. E

- 42 replies

-

crabbersnipe reacted to a post in a topic:

HMS Naiad 1797 by albert - FINISHED - 1/48

crabbersnipe reacted to a post in a topic:

HMS Naiad 1797 by albert - FINISHED - 1/48

-

A few more planks added and also tried my hand a fibreglassing the funnel - resin took a long time to cure but fully dried out after hrs, will be sanding tomorrow

- 42 replies

-

Thanks John, so far so good - things will get a little trickier from here on, where I hit all the various curves, twists and bends. E

- 42 replies

-

Gradually continuing the planking. Am thinking of how best to proceed with the fibre glassing once the hull is completed and started doing my internet research. Bought a fine mesh fibre mat at my local modelbuilder's to give it a try and thought the funnel would be a good start - have started work on this and the idea is to coat this balsa/ plywood structure to see how well this goes, before doing the same on the hull. Must confess this is a bit of a daunting prospect, and notwithstanding a lot of research done so far, still something totally new to me. Am finding rubber bands quite handy to hold the planks together, in combination with the coloured pins which are pushed trough the obechi planks. Progress is steady and have struck up a good rhythm, but am expecting to lose more time as I get nearer the keel. Second photograph (a little blurry) shows where I have added filler pieces, to be sanded to the correct thickness prior to the plank being fixed in place. E

- 42 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.