GDM67

Members-

Posts

103 -

Joined

-

Last visited

About GDM67

- Birthday April 25

Profile Information

-

Gender

Male

-

Location

Camarillo, CA

-

Interests

Muscle cars, HO Railroading

Recent Profile Visitors

-

FrankWouts reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

FrankWouts reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

-

FrankWouts reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

FrankWouts reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

alde reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

alde reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

billocrates reacted to a post in a topic:

HMS Naiad 1797 by GDM67 - 1:60 - using Ed Tosti Books

-

Tiz, I echo everyones comments to the max. What is your process for obtaining such a high-quality finish on each individual piece? Sandpaper, scrapper, both? I welcome your elaborating on how you attack each piece and then your assembly process. Your wood is of such high quality, do you pre-select and mill it yourself? Looks like Swiss Pear, but better. What type of finish are you using? Thanks, Gary

-

GDM67 reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

GDM67 reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

-

Generic Sharpie by DocBlake

GDM67 replied to DocBlake's topic in - Build logs for subjects built 1851 - 1900

Hi Dave, Great start. I have been eyeing this one for something different. I will follow along with interest. On a separate note, I see that you have the Rattler planned for a future build. I did this one several years ago using the Lauck Street Kit Bash. If you are interested, I have many insights on that one. Overall, it was an excellent practicum, but there are some things I would do differently a second time around. Looking forward to future posts. Gary -

HMS Naiad 1797 by albert - FINISHED - 1/48

GDM67 replied to albert's topic in - Build logs for subjects built 1751 - 1800

Albert, your work is simply stunning. Its an inspiration for my own Naiad build. I really like the uprights you use at mid-ships to stabilize the structure. I will build a set as well. Best, Gary -

Again, thank you for all the kind words and likes to my post about my Mom. Today would have been her Birthday. 610 Hours into the journey. I think I am at the most fun part of the build yet! The installation of the ribbands has proved to be very therapeutic and enjoyable. After the ribbands are installed, I can now beginning to apply finish to those sections that are complete. I am using turpentine and wax as Ed recommends in his book. You have to be incredibly diligent and disciplined on what you finish because it will literally be finished after that - no glue will stick... That being said, after applying the wax and turpentine, I sand the spots over the brass bolts to remove the residual CA that I spoke of in my last post. I am very happy with the results. The ribband installation is a slow process. Each piece has to be test fit and many have to be steam bent before applying. More next week. Gary

-

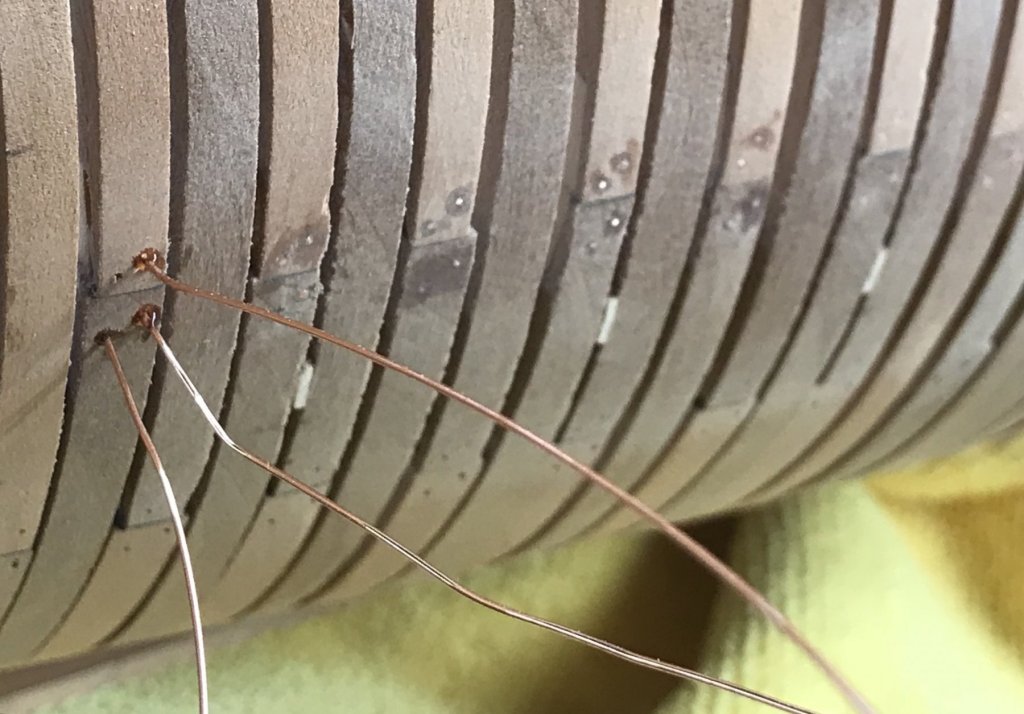

Thank you for the likes and nice comments. 606 Hours into the build and I have completed the brass bolt installation on the hull. I wish I did not use CA glue when installing the bolts. The CA glue stains show through the wax and turpentine finish. I should have tested this off the model! This was not a problem when using oil based finishes on past ships. Perhaps I need to add a little more turpentine to the mix? Any ideas on how to solve this? After the bolts were installed, I sanded the entire hull with 150 - 220 - 400 grit and then steel wool. I focused on one frame at a time. I then turned my attention to the ribbands. TIP: I used car pinstripping tape to layout the ribband sweep. It worked out great! I just ran the ribband in between the two stripes. It even helped with glue drips. These pieces are about 30 scale feet long at six inches square. I rounded them off slightly as Ed describes in his book. They are boxwood and are hook scarfed for added detail. An iron bolt will run through the ribband at the location of each frame. I absolutely love the clamps that Ed recommended be made for this model. They are simple to make and very effective. Prior to putting any glue on the ribband I test fit the clamps and had them ready to go. I plan to do four ribbands on each side of the ship. I don't intend on doing much planking. I really want the structure to show. There are a few trouble spots that will receive planking, just to hide the errors. All has worked out well to this point. My plan is to finish the lower hull, just below the gun ports, before turning my attention back to the interior of the ship. Thanks as always for following along. Gary

-

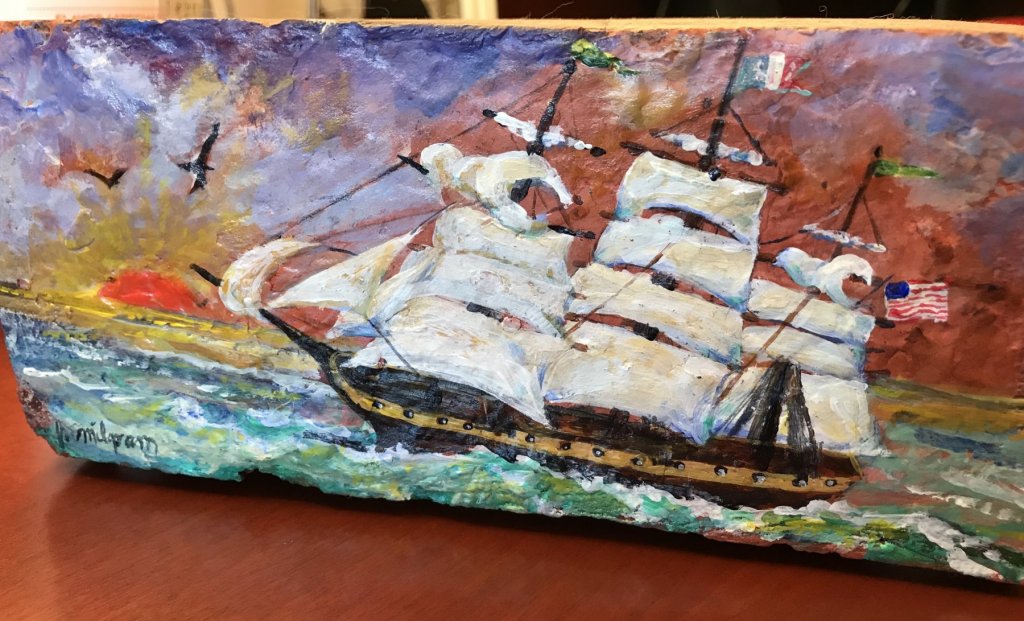

Below is a picture of my mom and me in front of my Naiad taken several years ago. Sadly, my mom, Judith Milgram passed away several months ago. She was a great lady and a great mother! My mother was a professional artist and an inspiration for my modeling habits. I owe her a great thanks for instilling in me a love of crafts and modeling (although, I never got her painting gene... that went to my sister…). I will frame this photo and place it on my workbench. Here are a few bricks she painted for me upon my request many years ago. They sit on my desk at work. When I was a child, we lived on the coast of Connecticut in a small beach house where my mother had painted the fireplace bricks with miniature sailing themes. Those were special times and a special place. She is now buried in that town. I wonder if those scenes are still there in that house. I also have dozens of her paintings hanging in my home and office, many of them with ocean or sailing themes. I am very lucky to have them in my possession as well as to have had her as my mother. Thank you for allowing me to share this. Gary

-

Hi All, Its been a solid 7-8 months since I have posted and almost a year and a half since I worked on Naiad. Funny how these things go. 590 hours into the voyage and I have successfully tackled the Stern Transom. This was an extremely challenging area of the ship to model. One of my greatest takeaways was that no matter how precise you are, you should always leave a little meat on the bone when it comes to making parts from patterns. For some reason I cant help myself, I tend to cut the parts too close to the pattern lines. I have learned to love the scroll saw on a build like this and am amazed at how quickly my skills have developed with it. That being said, leave atleast a 32nd of an inch or so of extra room on the parts. Doing so will allow you some margin of error when fitting the puzzle together. In addition to the Transom, I am doing a final detail of the lower hull. This includes inserting copper and iron bolts. I will also add the ribbands and other copper features. One other lesson that I am trying to learn is - know when to stop sanding! I have been sanding this hull off and on for two years. There is only so much material to work with, so resist the temptation to make it to perfect to early. I'm going to finish it and walk away. Thanks for following along! Gary

-

HMS Naiad 1797 by albert - FINISHED - 1/48

GDM67 replied to albert's topic in - Build logs for subjects built 1751 - 1800

Hi Albert, I have been away from my shipyard for a while, but am slowly returning to m own Naiad. Its really neat to see the progress on your Naiad. The carvings are exceptional as is the fit of each piece. I true pleasure to see. Gary -

I am late to the show on this one. I really enjoyed reading your log and seeing all the neat tips. Especially like those aluminum clamps. Outstanding work. Gary

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Joe, if you have the space for 1:48, I say go for it. The plans have so much detail in them that you should be able to capture it nicely at that scale. Looking forward to your build. Reach out if you have questions. Ed - as for perching the ship on the railing of that deck... I got distracted and actually left it there for over an hour! Wont do that one again! It would have been a 20 foot drop to the woodpile below... Thanks for all the kind words and follows! G

-

Hi All, Thanks all for the kind words and encouragement. Ed - I have to say, the times I didn't follow your advice are the times I sorely regretted it... Mike Y, you would be interested in the section of Ed's book around quality and setting a standard for your work. He gives some great thoughts on the subject that I am trying to live by. For instance - I will never drill a hole that I didn't first mark and pick. I think its human nature to cut corners at some points. I certainly have done that at times on this build and regret it. I am striving to make each piece as perfect as possible. But even then, there are challenges. To make one's sword so sharp is to make it dull. Here are a few photos of the nearly completed hull. I took these from the deck while on vacation in Northern California. Yes, I took my ship on vacation and yes, the Admiral did tease me about it. Another tid bit - Don't be too anxious to remove the frame spacers or cross-spauls. I spent more time repairing frames and adding new spacers. I should have just left well enough alone. Thanks for following along. G

-

Hi All, About 575 hours into the voyage of Naiad. I took this photo a while back, but never posted it. Thought I would do so today so as to keep the thread alive. These are the counter timbers and and various stern transoms. One of the things I learned is that for temporary spacers, use pine or other soft wood as Ed recommends. At various times, I used harder woods simply because of sizing. This proved to be difficult when removing. Just another of the many lessons learned. Now I just have to try and not repeat my mistakes... As discussed last week, I am at the point of final sanding of the hull. Prior to that, I will plan on building up the stern so as to attain a nice fair sweep. I am looking forward to this part since it is very detailed and somewhat complex. All parts are book matched for uniformity. These pieces are sitting on a cork lined tray that I made that clamps to the side of my build table with a thumb screw. Thanks for following along. G

-

Hi All, I am now 565 hours into the journey of Naiad over the last 16-months. Feeling good about where I am thus far. Since my last post, I have completed the gun ports on the p/s and have completed the sills on the s/b side. In this first photo, is my small cutting board clamped to the build board. Note the half cup in the far corner. This is screwed to the board and I insert the larger cup of water in it. I use the water to wash off excess glue. I was tired of spilling it all the time. Also, I mounted a pencil holder and caliper holder to each side of the build board. I am trying to train myself to put these items back after each use. I figure this will save me thousands of hours of having to looking for pencils and calipers. (I don't know why this text got underlined, oh well...) I built these measuring calipers at the start of the build as recommended by Ed. They are lap jointed and pinned and have proved to be invaluable. I used scrap babinga wood. Recently, I added a brass strip for the screw to clamp down on. This has limited the movement of the caliper once tightened. As I placed each sill, I would use strips of bass wood as a "winding stick" to check for level from sill to sill. I am very happy with the results and have recreated the slope of the sills as outlined in the plans. There is a gentle rise at the ends of the ship with a low-level valley at midship. There is probably a nautical term for this sweep. I still need to fair the inside of the top timbers. While this picture is upside down, it shows the squareness of the gun ports. I cannot emphasize enough that each piece you place is of great importance to the overall symmetry in a build like this. Mistakes, no matter how random or remote will likely be magnified somewhere else in the build. This is just an exterior portside view of the gun ports and illustrates the gentle sweep of the ports. Yes, that's a dead rat hanging from the light... fake of course... I used pinstripe tape to establish the fair sweep of the sills. The sills remain horizontal throughout the ship, the sweep is very subtle. You will note the use of a spacer block for the ports. I found this essential I getting the correct length and height of each port. I colored the block so I could easily find it among all my scraps. Yes, I uploaded these photos backwards... Next on the to do list is to finish the upper sills on the s/b side, rework all the spacers within the hull so they have a uniform sweep, cut the top timbers on the s/b to length. I then plan to sit down with the hull during our family vacation this summer in the mountains and go over it frame by frame. I will spend my early mornings for those 10 days with scrapers, files, and steel wool. I am looking forward to those quiet moments on the deck, sipping coffee and filing away - long before the kids get up! Thanks for following along. Gary

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.