-

Posts

863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Heronguy

-

Thanks Professor, I welcome ideas from you all and if by chance any idea I mention is useful then I'm pleased to share it! Google translate is pretty cool but hardly spot on when it comes to specialized terminology. Not usually as funny as Monty Python though - but then again its all in the delivery! Thanks Scott. I'm looking forward to working more on this model as I get its little sister moved along a bit further!

-

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

I won't be replacing the parts on this build but for my bigger bluenose I may have to acquire some better ones

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

(oops forgot the image) Please, nobody breath on it! (It is a tad loose - maybe I will go back to it later) I think this attempt will do as my 1st successful deadeye rigging. Surely it only gets easier from now on. Besides practice (all day!) I think having a meal and another espresso to calm my nerves was the real key to progress. On to the starboard shroud.

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

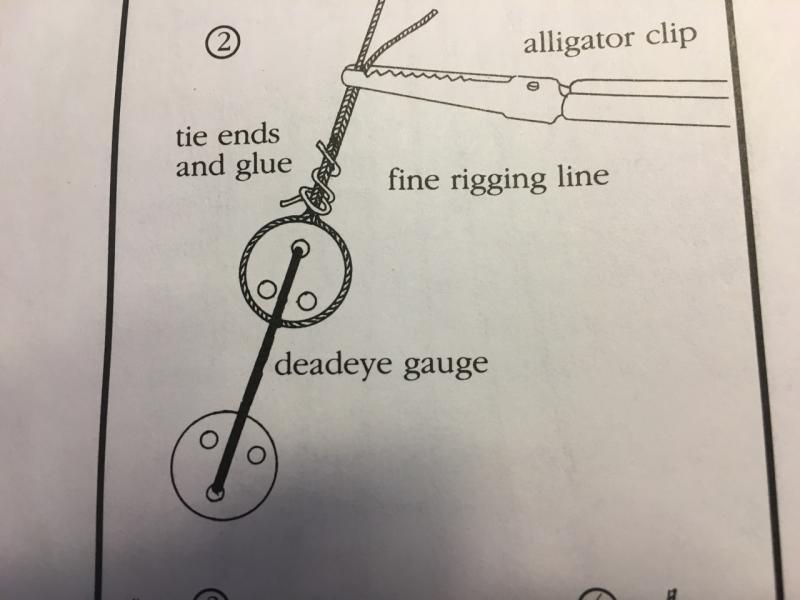

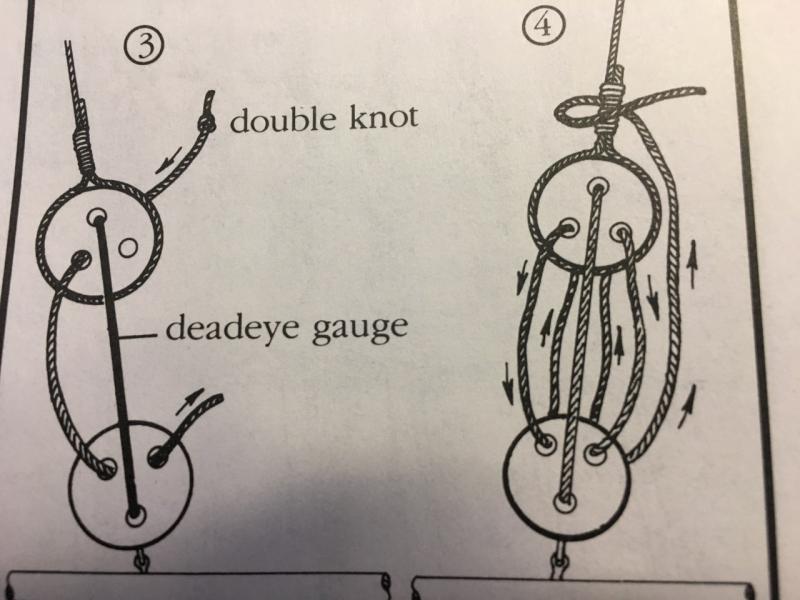

You're correct Derek - the figure (Fig 63 in Ship Modeling Simplified by Frank Mastini) only makes sense if you ignore the Step 3 diagram. Peter's above is correct as far as I'm concerned. I'm staring at the wok through magnifiers and using hemostat and tweezers from Lee Valley to wrangle the lines. It is pretty frustrating work but each failure seems to be getting me closer to a limited form of success. I'm really looking forward to the next build with its "huge" deadeyes!!!! You'll do great - you've shown that you can tackle problems and find workable solutions that look good.

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

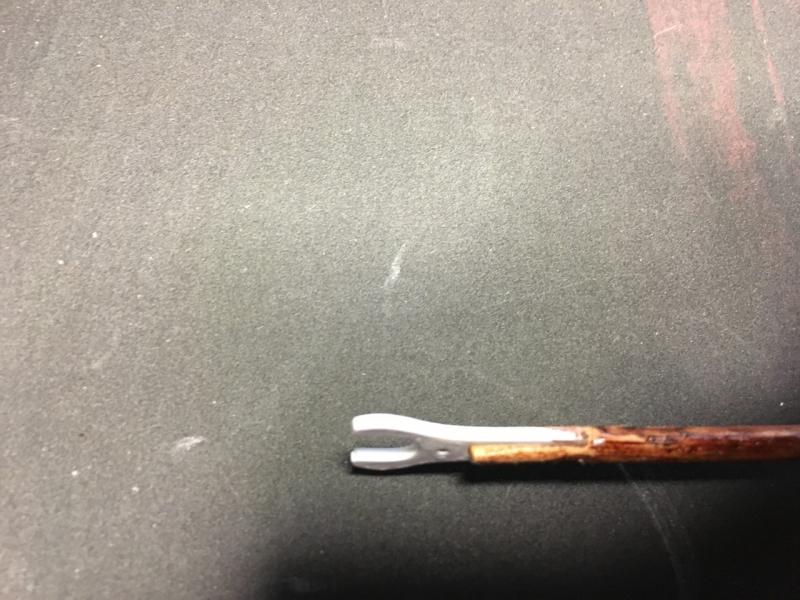

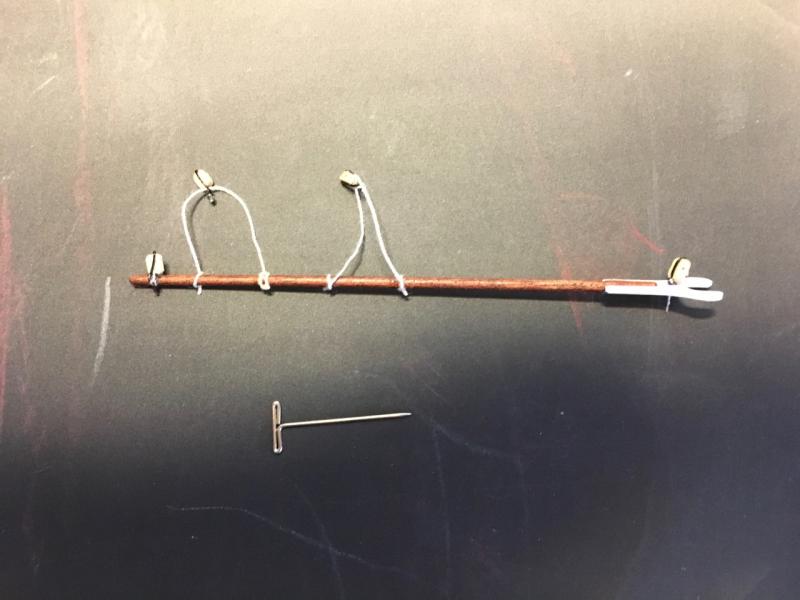

Scott and Peter, Just to give you an idea of the scale of these (infernal) little parts: on the left is the chainplate and beside it is the brass nail (not enough in the kit to attach all the chainplates and way out of scale for the job). In the middle is a normal straight pin for comparison. The two deadeyes are from the kit. My current struggle is with the larger of the two. I have no idea what I'll do with the small one!!!! On the left is a deadeye from my 1:72 Bluenose II kit while the one on the right is the one from this (scale 1:100) kit - the larger of the two I showed above.

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

Peter, Great jig - when I have a bit larger scale kit I will give it a try too! Thanks.

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

Thank you Scott. I'm trying out your ideas - glue drying on the lower deadeyes jus now before I re-rig. I've put some beeswax on the line. I've got some diluted white pva glue at the ready. The counter twist suggestion would not have occurred to me!

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

Let's see how we can develop some skill with deadeyes!! (This may sound a little like I'm venting so feel free to skip this post!) **** Venting starts It looks really easy - four simple steps and the shroud will be rigged! So far ok I guess - took a while to get here. Drat - the chain plate glue broke. Try again Well I don't like the glue, trying to seize with thread and just how am I supposed to get the lanyard straight!!!! Venting over **** How to you get the orientation of the deadeyes set so the threading of the lanyard is "organized nicely" - especially when these tiny deadeyes are somewhat randomly drilled. How to deal with the ugly glue bumps? Is sewing thread suitable for seizing a line?

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

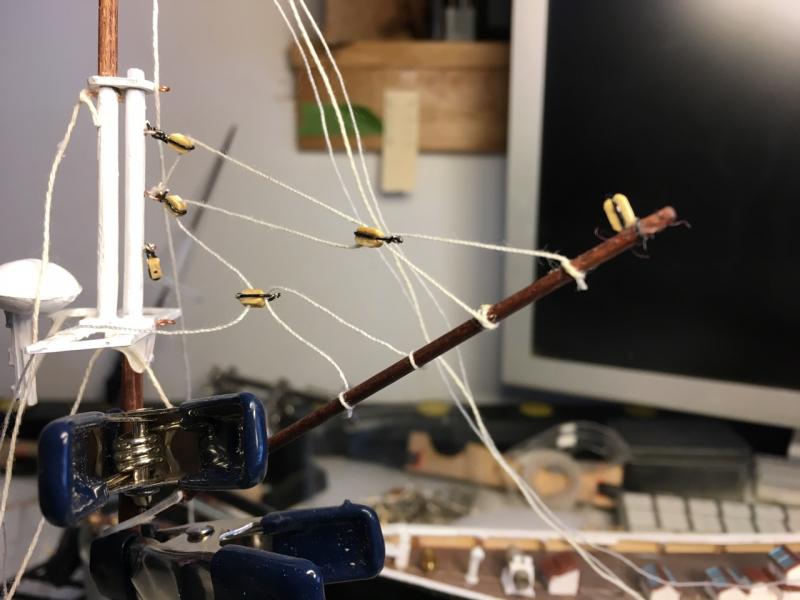

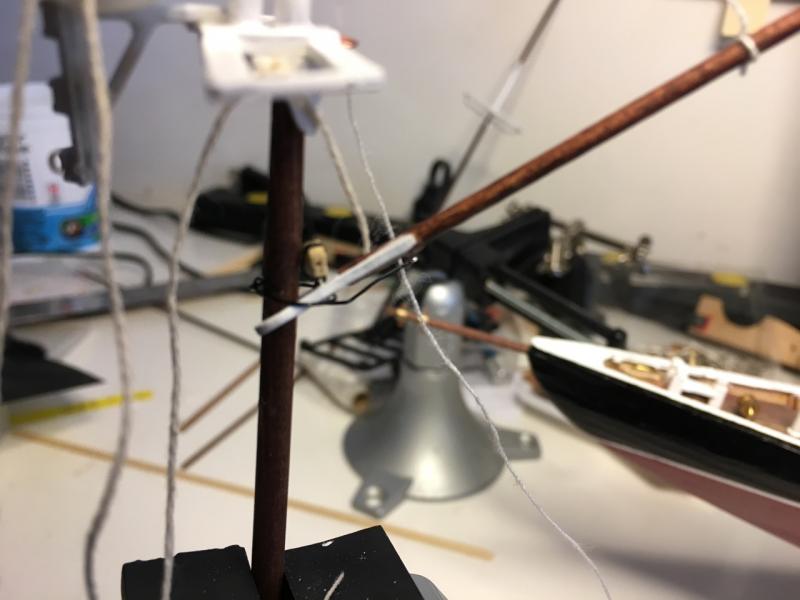

Going to tension them. Currently following Frank Mastini's dictum to assemble as much rigging as possible before I step the masts onto the ship. The pictures shown have the foremast clamped in a vice. The halyard for the gaff is just dangling. I think I'll mount the mast through the deck before I ring the shrouds though.

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

Thanks Peter, Yes, I know that is the usual way. This kit does not provide for that attachment. I may try to glue a strap around it eventually. Here is a comparison in size with the part from a 1:75 scale Bluenose II kit from AL.

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

I'm making my 1st tentative steps at the rigging. Part of the challenge with this 1:100 scale kit is the size of the blocks and deadeyes. My first successful attempts at stropping the blocks: Working on the foremast required my 1st gaff. Seemed to go without any major gaffes. The throat that that holds the gaff to the spar doesn't have any barrels to hold it on so I've temporarily wired it onto the mast. I presume at the end of the day (i.e when the model is done) I'll have to glue it to the mast?

- 93 replies

-

- billing boats

- bluenose ii

-

(and 1 more)

Tagged with:

-

It's my escape valve Derek! When little Bluenose rigging has me baffled I can go back to trying to put the bulwarks on big Bluenose. When that glue doesn't hold because I can't clamp it properly I head back to Krabby to add another strake to the hull or cut out another piece from the parts sheet. Round and round between the builds - seems like it progress is really slow compared with yours on the Mare! Now I've got 2-1/2 kits on the shelf - I'm tempted to crack them open so I'll be back at the "easy" (i.e. familiar) parts of the process. But if you saw my work area you'd understand why that would be really foolhardy. I'll finish one of these before I start another (I keep telling myself that!) Are you looking forward to starting your Bluenose??? Doug

-

Thanks both of you. I'm discovering lots of things I'll benefit from going forward. Learning a bit about the tools and the material, I'm gaining new respect for wood - previously I mostly burn the stuff to keep warm or fight with 2x4's to try to get some little building hammered together. Also learning about glue - when it holds and when it doesn't and how much of mess it it makes if you use too much! Files and sandpaper solve a bunch of problems. I'm pretty sure that wood filler will be playing a bigger part in my life too! All in all I'm having fun. Doug

-

I'm here to learn patience - ommmmm - (I'll still hope for daylight soon though!) Doug

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Steve, Are you just going to tease us with that or are you going to let us know????? Doug

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

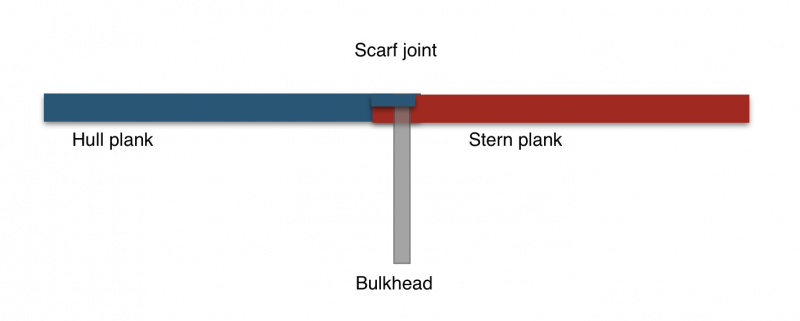

Popeye, I am using the original wood from the kit. I knew when I saw the kit offered that it wouldn't be laser cut or even punched out but I thought if I do one kit like this I'll appreciate the newer kits even more! One difference with my kit and the current Cux version (I downloaded BB instructions for reference) is in the handling of the stern. The bulkheads stop at #0. Below deck level the stern is to be formed by shaping a wooden block on each side of the stern post. are no planks that wrap around the stern below deck level. The top 2 planks (above deck) were supposed to meet at the stern post (my slip up). I'm Currently expecting to cut the stern blocks in slices and laminate them together (this decision came after I had tried to carve the blocks that were supplied with the kit - they were like little bits of concrete - slight exaggeration) I was expecting to make the top 2 stern planks a single piece from the port bulkhead around the stern post to the starboard bulkhead. Since it is above deck and visible I'll try to share the last bulkhead between the above deck hull planks and the stern planks by

-

Hello popeye, Thanks for the encouragement and the pointed to build logs. One of my early goofs was the bulwarks at the rear. When I discovered my slip-up with the stern filler blocks I thought I did't need to take any strakes around so cut the top two planks. I've been thinking of a fix - I'll try to scarf the stern plans onto the existing planks. That way both can have a good connection to the last bulkhead. The stern piece will of course have to be bent into a circle but my limited experience with plank bending has been relatively successful so far. I'll read you logs and reconsider if necessary. You have lots of experience with Billing Boats. Any reason in particular that you selected them - they had the ships you were attracted to? I'll look forward to your advice. Doug

-

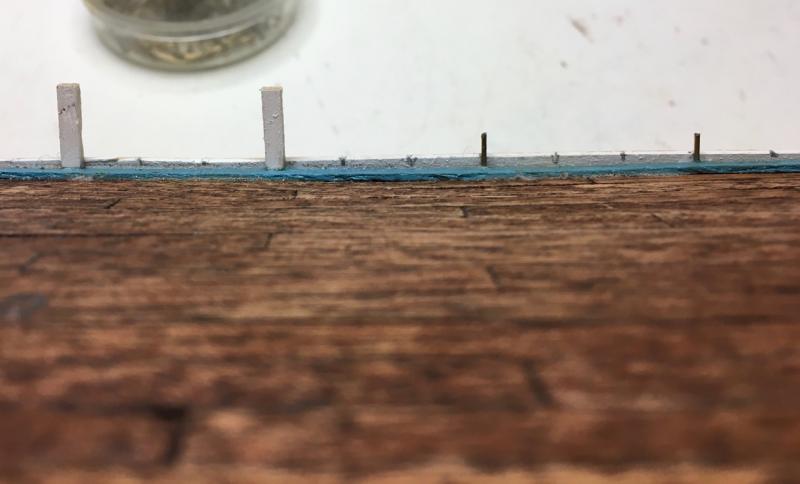

Finally back to paying some attention to this build. As mentioned earlier I'm generally intending to follow John H. Earl's suggestions for modifying the AL kit. However my 1st deviation was in the planking and waterways. Rather that install the waterways 1st and plank at the same level as suggested, I wimped out and planked first then added waterways on top (like the AL instruction suggest). John's mods to the deck involved cutting the supplied planks in half lengthwise, and laying them in a curved pattern (on the afterdeck) to more closely replicate the real ship. My attempt to split the deck planking lengthwise was less than satisfactory so I took the different path. It turns out there are consequences (one of the lessons I keep learning). In this case the consequence became evident when adding the bulwarks. John's mod replaces the supplied plywood with a spiled strip of basswood. This is required to fit the transom mod: The new bulwark is constructed from the basswood strip (about 2 planks wide) and then a stack of 1/16" square strips. There is plenty of overlap on the foredeck for attaching stanchions to the 1st bulwark stripped hence to support the stack of 1/16" strips. However there wasn't much overlap left because of the elevated waterway mention above - the consequence! In order to attach some stanchions I glued some pins into the deck, drilled holes in the bottom of the stanchions, and glued the stanchions to the deck. They provide a solid base for the rest of the bulwark. Consequence avoided!

-

Thanks. I looked at it on Amazon. I'll add it to the library wish list! Doug

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.