-

Posts

442 -

Joined

-

Last visited

About Ondras71

- Currently Viewing Forum: - Build logs for subjects built 1501 - 1750

- Birthday 03/30/1971

Profile Information

-

Gender

Male

-

Location

Czech republic

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Thank you very much Mark, I wish the same. So in the new year, I measured the Topmast shrouds..🙂 Tied up temporarily. Topmast will be removed.. -

serikoff reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

serikoff reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

Ondras71 reacted to a post in a topic:

HM Gun Brig Adder 1797 by Geordie Tyne - Vanguard Models - 1:64

Ondras71 reacted to a post in a topic:

HM Gun Brig Adder 1797 by Geordie Tyne - Vanguard Models - 1:64

-

petervisser reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

petervisser reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Ondras71 reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Ondras71 reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

marsalv reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

marsalv reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

marsalv reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

marsalv reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

marsalv reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

marsalv reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

GrandpaPhil reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

GrandpaPhil reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Baker reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Baker reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Ronald-V reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Ronald-V reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Siggi52 reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Siggi52 reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Rock_From_Korea reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Rock_From_Korea reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

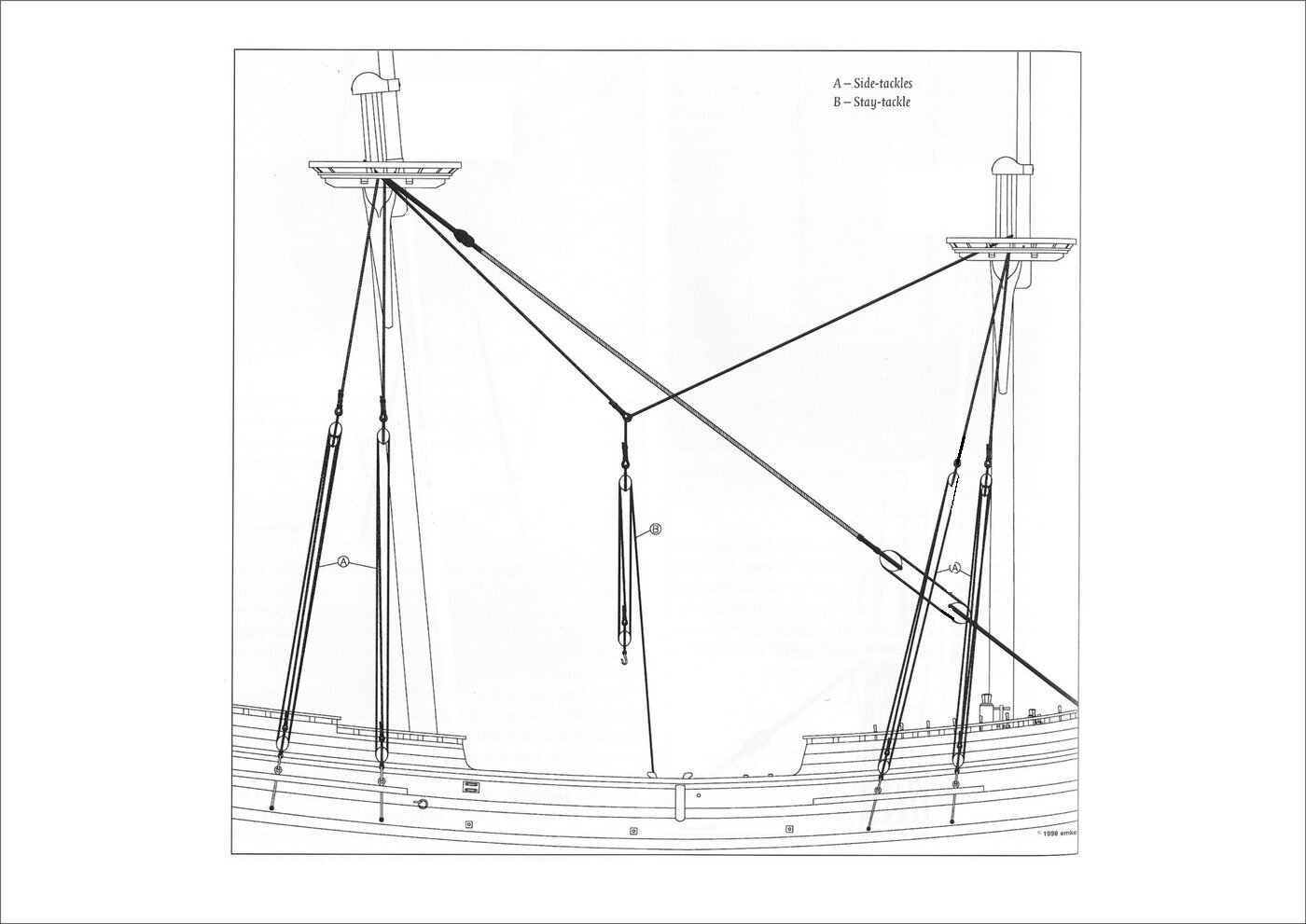

Thank you very much Kirill. Definitely useful for many modelers! Another component. Removable loading hoist "Stay tackle".. It was nicely discussed here by modeler Mati and the author of the book "The ships of Abel Tasman" Ab Hoving. https://shipsofscale.com/sosforums/threads/pinnace-papegojan-1627-1-48-completed-build.7055/page-2#post-159810 On the last day of the year, I wish all modelers a lot of peace in their construction, personal well-being and, most importantly, health until 2026. Ondras -

Ondras71 reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

Ondras71 reacted to a post in a topic:

Roter Löwe 1597 by Ondras71

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

-

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

Ondras71 reacted to a post in a topic:

L'Amarante by marsalv - 1:36 - POF

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Thank you very much Ronaldo. Thanks for the like. Lower Ratlines finished..🔥 Next is the Catharpins component, seen from the William Rex ship model.. -

Ondras71 reacted to a post in a topic:

Golden Hind by Rock_From_Korea - 1:48

Ondras71 reacted to a post in a topic:

Golden Hind by Rock_From_Korea - 1:48

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Bottom Ratlines strung..🔥 ..compare again, glue the end knots and cut..🙂 Measurement by the figure of a sailor.. Sometimes a rung had to be replaced.. This is how Ratlines are knitted on the replica "De Witte Swaen"..💥 At 6:00 minutes... -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Bowsprit equipped with blocks.. Ready and tight Stays.. Added Ratlines metal crossbar (Futtock stave).. Ratlines knot tying begins.. -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

I continue tying the deadeyes. Mizzen mast..🔥 After measuring and tying the deadeyes to the shrouds, I glued the masts.. "Tackle" and Deadeyes tied cleanly. Just need to adjust the height..💥 -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Hello Johann. Thank you for the compliment. I admit that I didn't recognize the groove, I only saw a thick line. The groove is really needed!!🔥 Hello Bella. Did you mean this crossing of blocks? Fortunately, the distances are fine.💥 Before gluing the masts, I tied the boat up, as Kirill had pointed out. I put in a thicker rope and immediately created smaller deadeyes.. All sizes created by me.. Deadeyes of the foremast measured.. -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

This is how I tie the Deadeyes to the main Shrouds. Due to the different distances between the upper and lower Deadeye, I used the system that modeler "archjofo" uses when building his beautiful rigs. It is a log with a diameter of Deadeyes, which is at the correct height even with different inclinations of Shrouds..👍 Then another binding.. Result ok..💥 -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Thanks Kirill. Now with the installation of additional ropes, the boat rope really seems weak to me. I plan to install stronger ones.. Hello Bela. Due to the poor plan, I am still working on these things during the installation to make the result look believable. Thanks for the timely warning.. Thank you Marsalv. I have a good teacher...👍 -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

As I reported, I enjoyed a weekend in Sweden with the main goal, the Vasa Museum. https://www.vasamuseet.se/cs I had been preparing for this for about 40 years and it was worth it. When I arrived, my watch reported increased blood pressure and heart rate... I spent over 4 hours here, I could have stayed longer, but I took into account the company of my son. I walked around the ship several times and compared the beams and planks with the strips from which we model them... Having the ship about three meters away from each other is unreal. I tried to look at and photograph every detail. Simply indescribable, at the end a very long viewing with contemplation..🔥 I've made some progress on the boat. Front and main tackle finished, I'm tuning the Stays and the Schrouds are waiting for me.. -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Thank you very much Ab and Kirill. I have been making tackle pulley halters for a long time. I chose a system of tying and gluing the tapered ends of the cables.. Now I'm already preparing for a weekend trip to see this beauty..🔥😍 https://www.vasamuseet.se/cs -

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

-

Roter Löwe 1597 by Ondras71

Ondras71 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.