-

Posts

662 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Alkmaar, Holland

-

Interests

Dutch 17th century shipbuilding

Airplanes

Flightsimulation

Recent Profile Visitors

-

J11 reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

J11 reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

-

Ab Hoving reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Ab Hoving reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

FriedClams reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

FriedClams reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

-

Siggi52 reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

Siggi52 reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

-

Keith Black reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

Keith Black reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

-

Ab Hoving reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

Ab Hoving reacted to a post in a topic:

The Gokstad Ship 900 AD by Siggi52 - 1:50

-

Ab Hoving reacted to a post in a topic:

Yacht Mary by catopower - FINISHED - Mamoli Dusek - 1:54 - An Inherited Model

Ab Hoving reacted to a post in a topic:

Yacht Mary by catopower - FINISHED - Mamoli Dusek - 1:54 - An Inherited Model

-

Ab Hoving reacted to a post in a topic:

Yacht Mary by catopower - FINISHED - Mamoli Dusek - 1:54 - An Inherited Model

Ab Hoving reacted to a post in a topic:

Yacht Mary by catopower - FINISHED - Mamoli Dusek - 1:54 - An Inherited Model

-

Ab Hoving reacted to a post in a topic:

English Royal Yacht by Ab Hoving - FINISHED - CARD

Ab Hoving reacted to a post in a topic:

English Royal Yacht by Ab Hoving - FINISHED - CARD

-

I don't think the length of the spreader yard is much of a problem. It is carried by the topsail. The pendant which is attached to the spreader yard is so long that it hangs loosely when the sail is in use. It only carries the yard if the sail is not hoisted. If you would consider to make another topsail (which would add to the atmosphere of the model, but is of course not necessary) you would see that the 'hollow' lower side of the sail goes much higher up, to avoid chafing with the halliard of the jib. With a yard hanging as low as on the model, very little of the surface of the sail remains.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

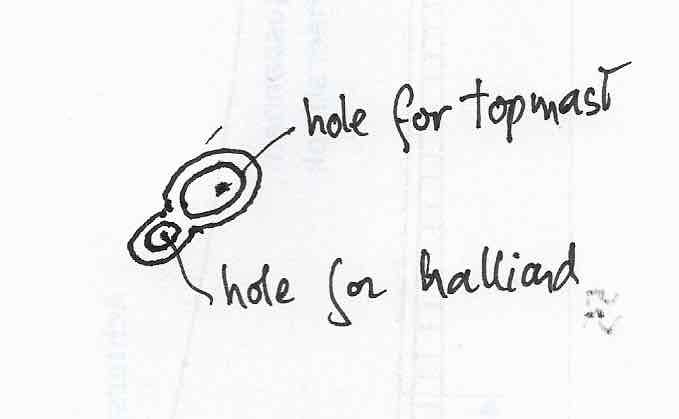

You did well on this model. But I have some small remarks on the side on this topsail if you allow me: The sheave of the halliard was placed inside the topmast and was situated much higher up, which caused the topsail to be much longer. And I miss the 8-shaped iron brace that kept the topyard close to the topmast. It was loosely situated around the topmast and stayed up, even if the sail was hauled down on deck: I hope this sketch clarifies it.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Ab Hoving reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

Ab Hoving reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

-

sorry for not replying your question. I just stumbled into this thread. It is correct that if there is no need to climb the mast, ratlines were omitted. On the other hand, I have seen lots of statenjacht models having them. I think that is a misconception, caused by the English yachts. For some unclear reason the English used lifts, sheets and braces for their topsail. In Holland the tradition was that the topsail was carried 'flying', which means that it was hauled on deck if not in use. The lower corners of the sail carried blocks, through which ropes ran, attached to the tips of the lower yard. They served as braces and sheets at the same time. Lifts were not necessary. The lower yard was carried by the topsail. If it was not in use, the yard was stowed upright against the mast, carried by a pendant, long enough to bring the lower tip of the yard within reach from the deck. Thus ratlines were not necessary. But of course it's your choice to apply them.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Thank you for all the likes. Many thanks for @Baker, @druxey, @wefalck, @GrandpaPhil, @ccoyle and @Michael Mash for their positive response. Too much honor. @wefalck: the crew was made by my friend Herbert Tomesen's company, which is specializing nowadays in making all sorts of human figures, using 3D photography. The firm hires re-enactment groups of people who are dressed in the appropriate clothing and can be delivered in any wanted pose or stand. Usually the scale is 1/87 (HO), but 1/72, 1/120, 1/160 and 1/220 are also available. For me he simply prints them at my 1/77 scale, but I am not sure he can do that for everyone... This is his site, the artwork is done by my son Emiel: https://www.artitecshop.com/nl/figuren/

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

I finished the yacht last month. Here is the result: The model is exhibited below the drawing hanging on the wall in my living room: Emiel tried to match the pictures he took with the drawing. It looks as if I was not far off: Once he is finished with his photoshop painting I will present the result.

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

Thanks to all the people who liked the model and especially of course to @flying_dutchman2, @Michael Mash, @dvm27 and @druxey for their comforting words. Much appreciated. Druxey: The funny thing about the rigging is that Charles II was transported from Breda to Scheveningen in a group of several yachts with spritsail rigging. The Mary, which that was sent to him as a present from the Dutch however sported a standing gaff rigging. From what I saw on pictures the English type of this rig differed from the Dutch in for instance the topsail, having no braces and lifts. It was just a flying sail, only having blocks at the lower tips, through which ropes from the lower yard were led and sometimes, but not always bowlines leading to end of the bowsprit. The sail was stored on deck until it was needed and hoisted with a halliard that ran through a sheave in the top of the mast and through a loose 8-shaped shackle around the top. The lower yard was stowed upright against the mast if not in use. In that case it hangs on a long pendant. The fact that this square rigged sail was handled on deck was the reason why Dutch yachts did not have ratlines on the shrouds. There were more differences about which perhaps another time...

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

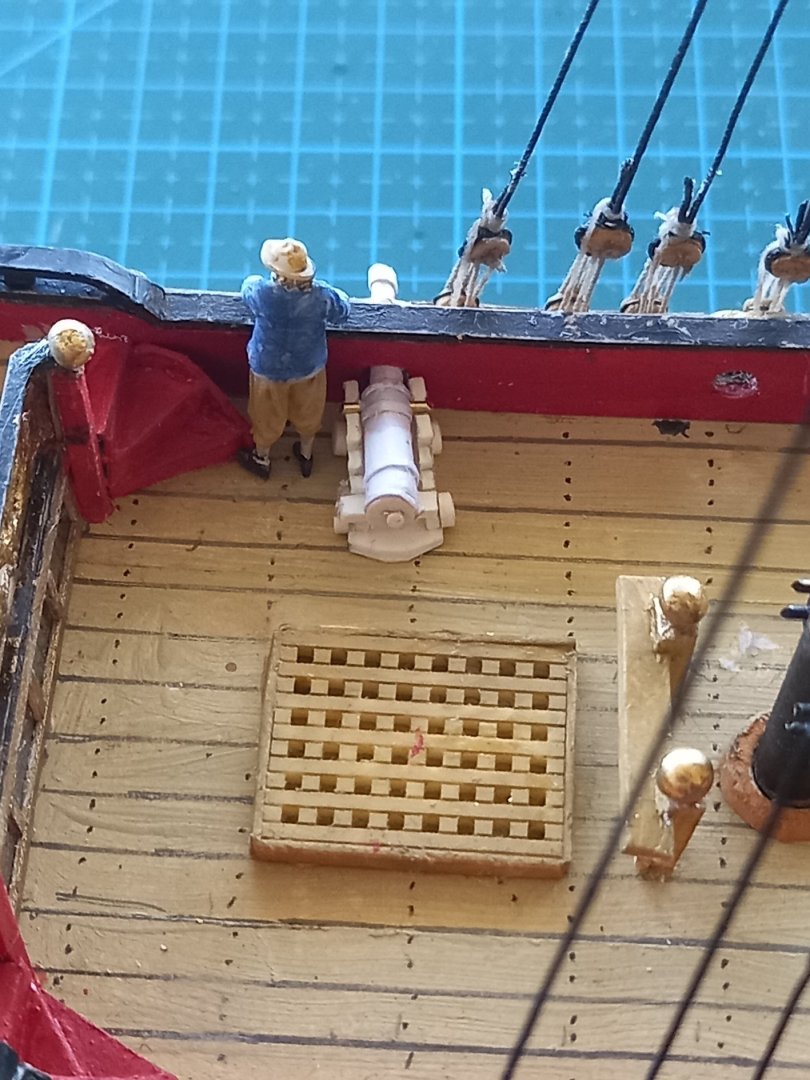

A lot of time passed since my last posting. Most of it was caused by people, family and friends, who start to die all over the place. In a very short period I lost six relatives and close friends. That takes away a lot of one's motivation and working power. Anyway, the model approaches its finishing stage, after which I will come up with better pictures than these. There is a lot to say about some choices I made, but as a whole I think I am reasonably satisfied with the result. For a ship with a totally different background the result could have been worse (and better for that matter). In a later stage I will give my remarks about the rigging, which on this model is mainly done after Dutch sources, quite different in details from the only rigged dockyard model I have found so far. Back to flags, anchors, lanterns and sailors.

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

Thanks @Doreltomin and @Baker. Alas, I'm on Apple.

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

Hi @shipman, I never heard this before. The pictures I take with my telephone are all 2 or 3 mb, too big for forum use. So I cut the relevant parts and use 'adjust size', which apparently makes them png. I don't know how to do it in a way that fits you. Do you mean my pictures in the thread disappear? If you want I can send you the original ones in a pm. Or you can explain how I still keep jpegs, but with a lower resolution.

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

This is one of the great side-effects of forums on the internet: help for free. Thank you both @Doreltomin and David (@druxey) for your help. Doreltomin: I agree that my aft deck is too long, causing big problems with the stairs to the lower part in front. I will see if I can replace the bulkhead, but I am heavily hindered by the fact that the standing rigging is almost done. This is really a beginners mistake, starting a build before thinking over the consequences of the early choice for a drawing. I'm really playing an away match. This would not have happened to me building a Dutch ship. 🙂 I am also happy with the information of how the guns were placed with the cloth wrapped around them in the gun port. I already found out that most of the decorated garlands on this ship were in fact fake, or serving different purposes than just giving way for a gun. Thank you David for your drawing of the small gun. I was not aware of this type of gun-carriage. I was however aware of the 3-pounder gun we had in the Rijksmuseum collection. I nearly broke my back on it, when I tried to hang it on a specially made iron stool mounted on the wall of one of the History halls. The hubris of youth! I will try my hand on this one, hoping for a better result.

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

I certainly plan to make guns, and of course they will be made out of paper. In fact I quickly did try one, but I'm not happy with the size, compared to a human body in scale: These were very small guns, without any significance for the defense of the ship. Just ceremonial I think and really tiny, like toys. That saves me the trouble of making rigging for them, they can be handled by hand. And the nine garlands around the gun ports are misleading, I can place 8 guns at the most, the rest is just for show....

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

-

Time is moving fast and though there is some progress to show, many doubts still occur. I was also hindered by a rigging job on a frigate I still work on. First my professional helpers delivered the garlands I asked for. I'm very grateful to them so the very thin curls were gilded and added to the model. The gold is still too bright, but once the hull is completely finished it wil get a wash of warm brown varnish, which will temper the looks. As I am used to the rather modest decorations on Dutch ships this excess of golden curls hurts my eyes a bit. I did learn from this project: it was a wrong decision to use the plans I showed: they result in a variant with a square bulkhead in the bow instead of the top planking leading to the stem post. The former was only done in a later stage, when the ships became bigger and were equipped with two masts, while I was aiming for a model of around 1670. It was also a wrong decision to make four windows in the stern with no extra space between de middle two. If the rudder is supposed to be steered from the top deck like in this model, it has to pass the great cabin, partly covering the two central windows. A wider space between them would have been a much wiser option. Too late. Fortunately I did not promise you a model without any flaws... Furthermore I am struggling with the entrance to the main cabin and the size and shapes of the guns. First this entrance: I guessed that it was far below the king to bow in order to get inside, so a man-height entrance was an option. I just have to find out how it was decorated. I saw something like this on a 1701 model of the MMG. Perhaps I will leave the guns out, perhaps not, I have not decided yet. On several locations they interfere with the rest of the deck furniture and I am trying to find locations with some logic in them. It is weird to place a pump besides the mast right behind a recoiling gun, or to find room for stairs with a gun so close by that there is no room for any feet. It is nice to know that there was a complete fleet of this sort of vessels, which releases me from the obligation to work after a specific ship. I like that sort of freedom. I developed a theory about the introduction of yachts in England, after Charles II received two Dutch 'statenjachts' as a gift from the Amsterdam Lord mayor. He ordered an English 'translation' to be built by his shipbuilders resulting in a more luxurious and faster vessel for his pleasures. It seems logical to me that many things from the Dutch version were adopted. I mounted a horse (the horizontal beam a few inches above deck to attach the fore sail's sheet to) after Dutch design. I will get back to my theory once we are dealing with the rigging, which in the mean time was prepared as far as I could. So more on that item in a later stage.

- 77 replies

-

- Royal Yacht

- card

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)

.thumb.jpg.891f66d64fd4486179970eca1dfee43e.jpg)