-

Posts

111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mainstay

-

Hi Bill, Welcome to the 'club'. I am very glad to see a new member here. Now I have one notch of seniority. And you're building two! At least you will know how to do each job by the second one. I keep wishing I could do each task over again and you have the chance. I am happy not to own the first clavichord or the first harpsichord I built. I do live in the first house I designed and have some regrets. As to building a harpsichord, you could save time by looking for a project started by someone else and finishing it (assuming they did decent work). And I hope they have caught your wife's cancer in time. Joseph Osborne Carlisle, PA USA

-

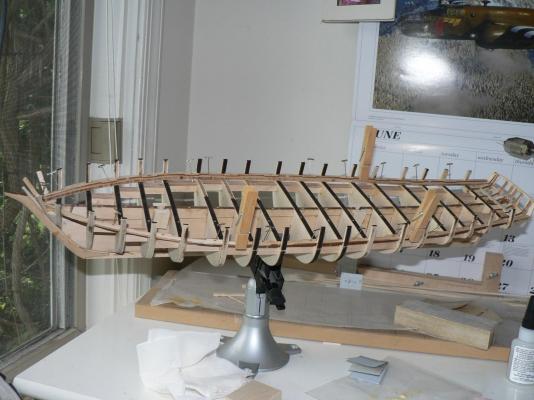

Thanks guys, I plan to paint waterway and planksheer once the ports are framed in but before I start the ceilings. Brian- I see what you mean about the clamp orienting the model. It does allow for some nice angles. Right now I am glad I did not bolt the clamp to a workbench. Works much better loose.

-

Finally. Some progress to report. It's not that I haven't been working, although progress is sporadic. I can get a few hours in some weeknights and then go a week without. I will stare at the next step for a day or two, then my plan evolves in the back of my mind, then I go to work. I love getting into a groove on a job. Flow. The state of Flow. That's what I like about this. Time slows down, problems drop away. I am in the present. Cutting and fitting and gluing (and occasionally swearing of course). Joseph Pictures follow.

-

Well, for what it's worth: I run two businesses, both quite small. After interviewing perhaps 30 people and making a very difficult choice, I have planned to call them all but found it so difficult I have let it slide. Human weakness. Hate to say 'no'. That said, these are one - three person operations. A large organization will have a policy in place and tell their HR people what to do.

-

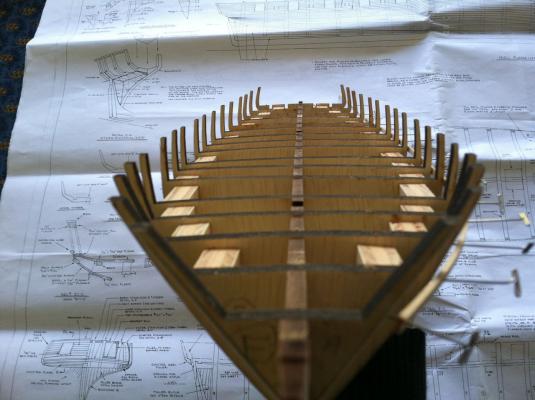

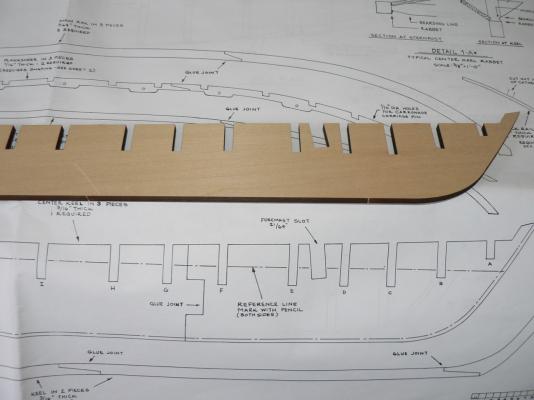

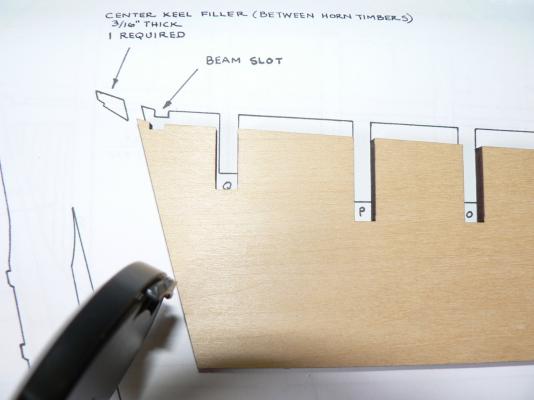

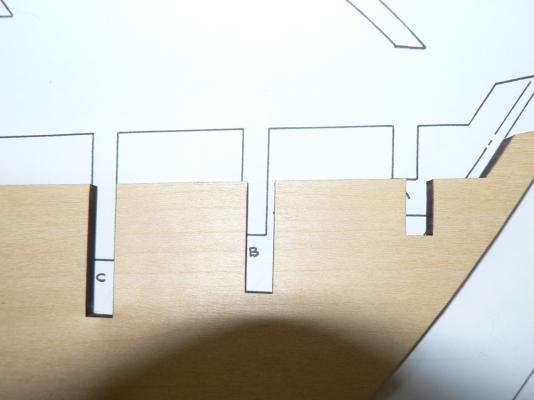

Progress Report. The rabbet is done. The bulkheads are glued in. It would be nice to start over now that I know how to do both these jobs. The rear half of the ship is nicely aligned. I started rechecking my reference lines about bulkhead G. And I stopped over sanding the slots in the keel and stopped sanding the slots in the bulkheads at all. Bulkhead E is badly catawumpus. Others are too high or too low. Looks like time for the Dremel and some patience before I begin planking.

-

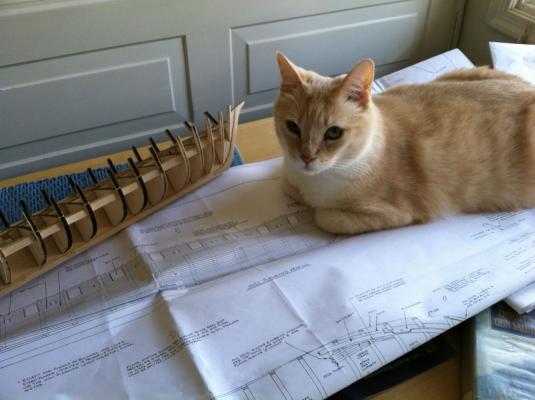

Why I'm not making as rapid progress as I would like. I could say it's because I operate two businesses and play in a band besides building this model. I could say that Margaret and I are busy maintaining the house when I'm not involved in the other activities. But the real reason is that I can't get a look at the plans when I need to. Hull Planking Layout? Where's that?

-

Hi Brian, Hi Patrick, Thank you for the suggestions. I am finally getting back to work on it. Hope to begin on the rabbet tonight. Time to sharpen my carving tools and perhaps my Dremel. I love the precision and speed of the power tool. But I am afraid I will need to spend hours making the setup if I am not to make an awful mess in a fraction of a second. So I may just draw the lines and use gouges. Basswood is completely new to me. Have carved balsa and boxwood and beech among other woods. I like working with it so far.

-

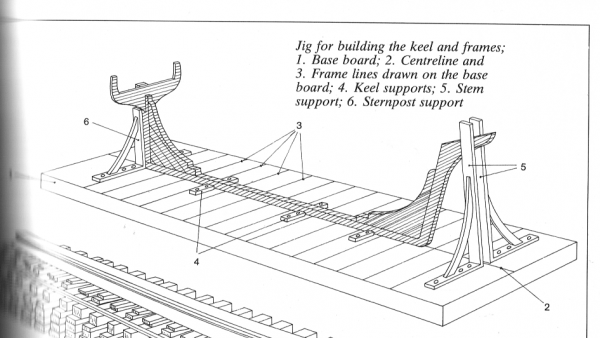

I seem to be hung up on the first step. My plan is to use a jig like the one in this picture from Wolfram zu Mondfeld's wonderful book Historic Ship Models So I guess I need to lay the center keel down on blank paper and mark the lines of the bulkhead openings, then put it in the jig and use the lines for alignment. Maybe tonight I can get back to it.

-

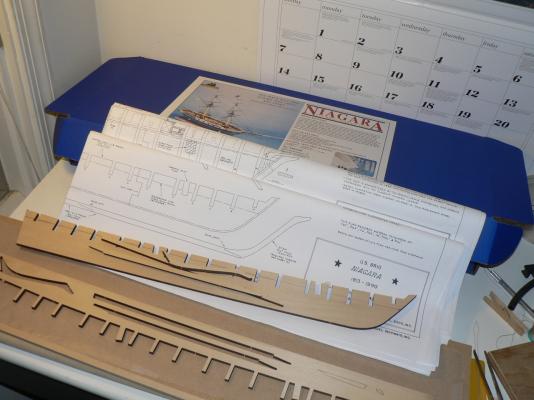

But I have run into trouble. On the first step. I punched out the center keel which is not in three pieces but one (what a great idea. They must have bought a larger laser cutter at MSW). It is 1/8" (8 scale inches) longer than the plan. Is this a problem? Has anyone else encountered it? Do I have the wrong plans? Or can I just fudge out the difference as I go? If I align the stern (better than in this picture)... The bow and the forward bulkhead slots are too far forward.

-

My current project and my first POB model. Previous builds include Sea Witch by Scientific, built in 1975 and recently restored. Also Constitution by Revell (plastic), built c. 1965, which ended its life as a wreck at the bottom of a fish tank. Also Yacht America, Plastic by Monogram?, which sat on our mantle for 20 years before being replaced, tentatively, by Sea Witch. Other things I have built include 7 clavichords, 3 harpsichords, a rebec, a mountain dulcimer, three treehouses, a bunch of kinetic sculptures, flying model gliders, static plastic models of many descriptions. Also mobile robots and a robot arm capable of feeding paralyzed people. So I am not new to design or building but am very new to POB wooden ship models. I became very frustrated while restoring Sea Witch that I could not do scale details. [i calculate the scale to be 1:76 but it seems much smaller than that]. I am looking forward to comparing photos of the actual ship with my model. I know I may come to regret that anticipation. But I have seen such beautiful results from members of the Niagara Club that I think I have some hope of building a nice scale model. The Build Begins

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.