Tschiller

Members-

Posts

34 -

Joined

-

Last visited

-

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

ERS Rich reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

ERS Rich reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

ERS Rich reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

ERS Rich reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

mtaylor reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

p40warhawk1 reacted to a post in a topic:

Fiber glassing over wood hull?

p40warhawk1 reacted to a post in a topic:

Fiber glassing over wood hull?

-

p40warhawk1 reacted to a post in a topic:

Fiber glassing over wood hull?

p40warhawk1 reacted to a post in a topic:

Fiber glassing over wood hull?

-

Tschiller reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

Tschiller reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

-

Tschiller reacted to a post in a topic:

Fiber glassing over wood hull?

Tschiller reacted to a post in a topic:

Fiber glassing over wood hull?

-

Scottish Guy reacted to a post in a topic:

Fiber glassing over wood hull?

Scottish Guy reacted to a post in a topic:

Fiber glassing over wood hull?

-

Scottish Guy reacted to a post in a topic:

Fiber glassing over wood hull?

Scottish Guy reacted to a post in a topic:

Fiber glassing over wood hull?

-

One easy way to fiberglass over wood is to do what RC aircraft builders have done. 1) Make sure is sanded to the final shape and then fill any low areas and sand until it looks perfect. 2) Cover area using Nylons (yes women's hosiery). Cut it to fit and lightly stretch until any wrinkles or loose fabric is taught and then glue using Thin CA to secure to the hull (you only need to glue at various points to hold the fabric to the hull). It will take more than one piece so you may have to overlap slightly to ensure complete coverage. 3) Mix you Fiber Glass resin (practice with a small amount at first to determine how fast it hardens to determine how much you can work with at once). Use a scrap piece of card to apply resin onto fabric, work it into the fabric to ensure that all air bubbles/pockets are worked out and the fabric is laying flat against the wood and get surface as smooth as possible. Let resin set up. 4) Add a second coat of resin over the dried first coat and allow to fully cure. 5) Sand the resin being careful not sand through t nylons, this will show areas where the resin maybe low and require additional coats of resin. If you sand into the nylon you will need to recoat that area with resin. 6) Once you get a decent smooth surface you can fill any small pinholes or imperfections with an Auto body Glazing Putty and sand them smooth.

-

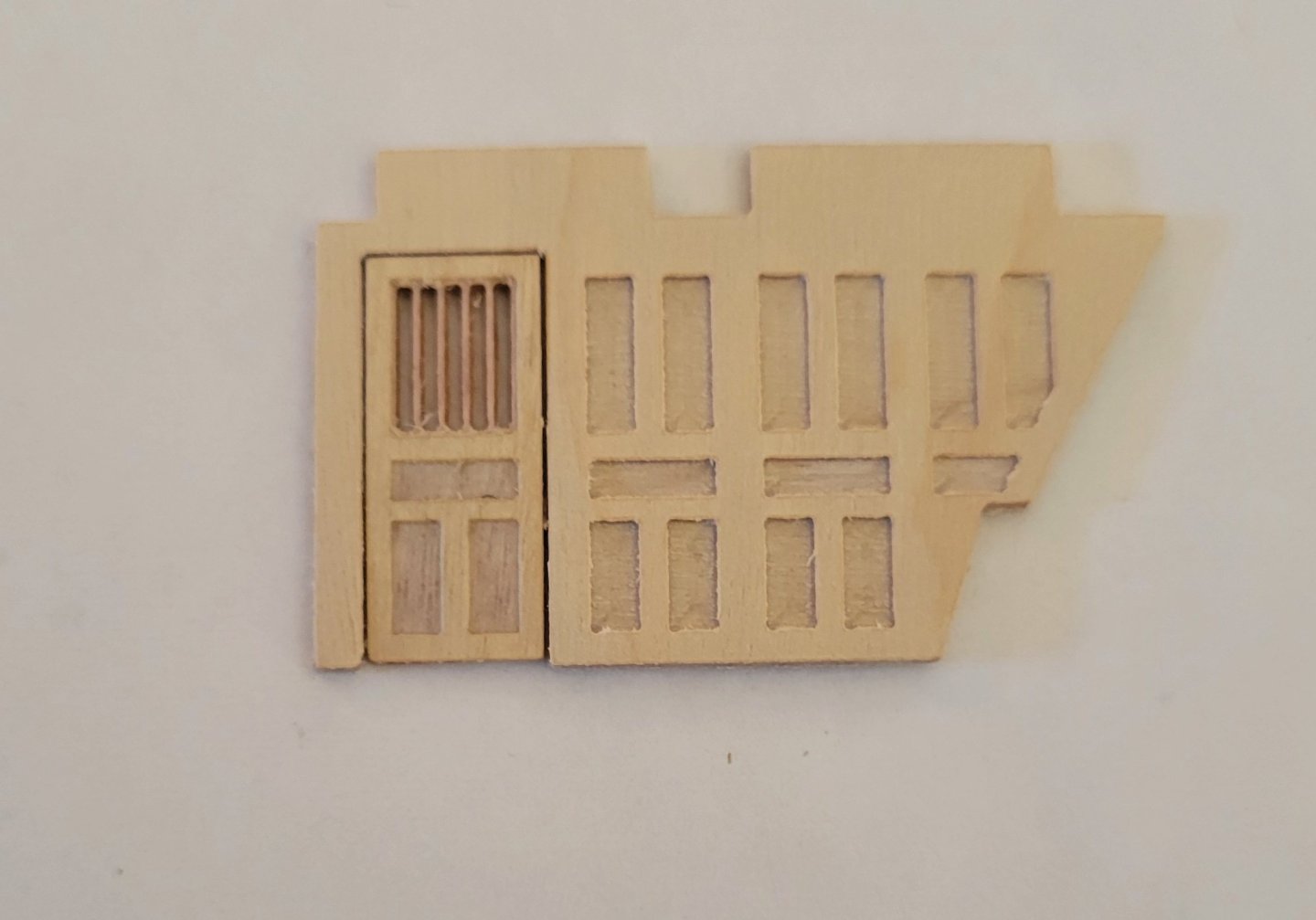

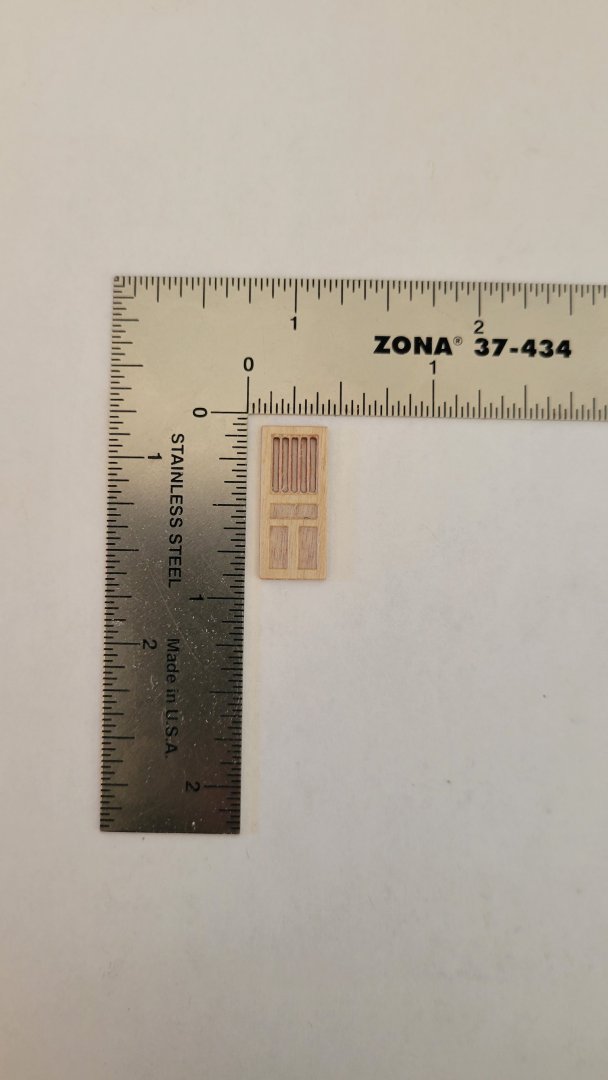

I cut out the wall leading from Captains Aft Cabin to the Starboard Stateroom and test fitted the door, everything appears to align well. and then I checked the fitment in the ship, not too bad nothing a little tweaking with a file wont fix! I plan on experimenting with doing raised panels vs recessed panels on the CNC just to compare.

-

Tschiller reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

Tschiller reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

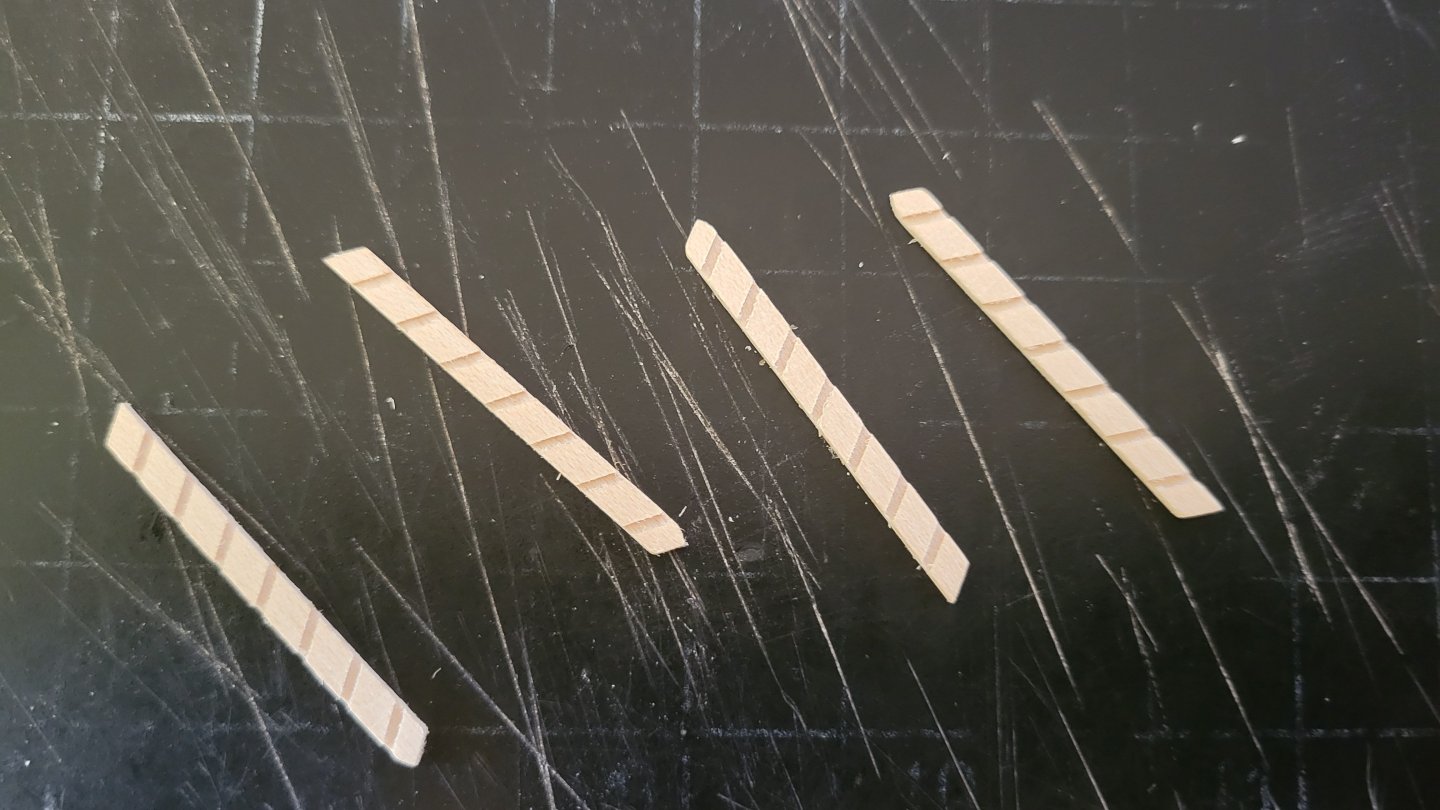

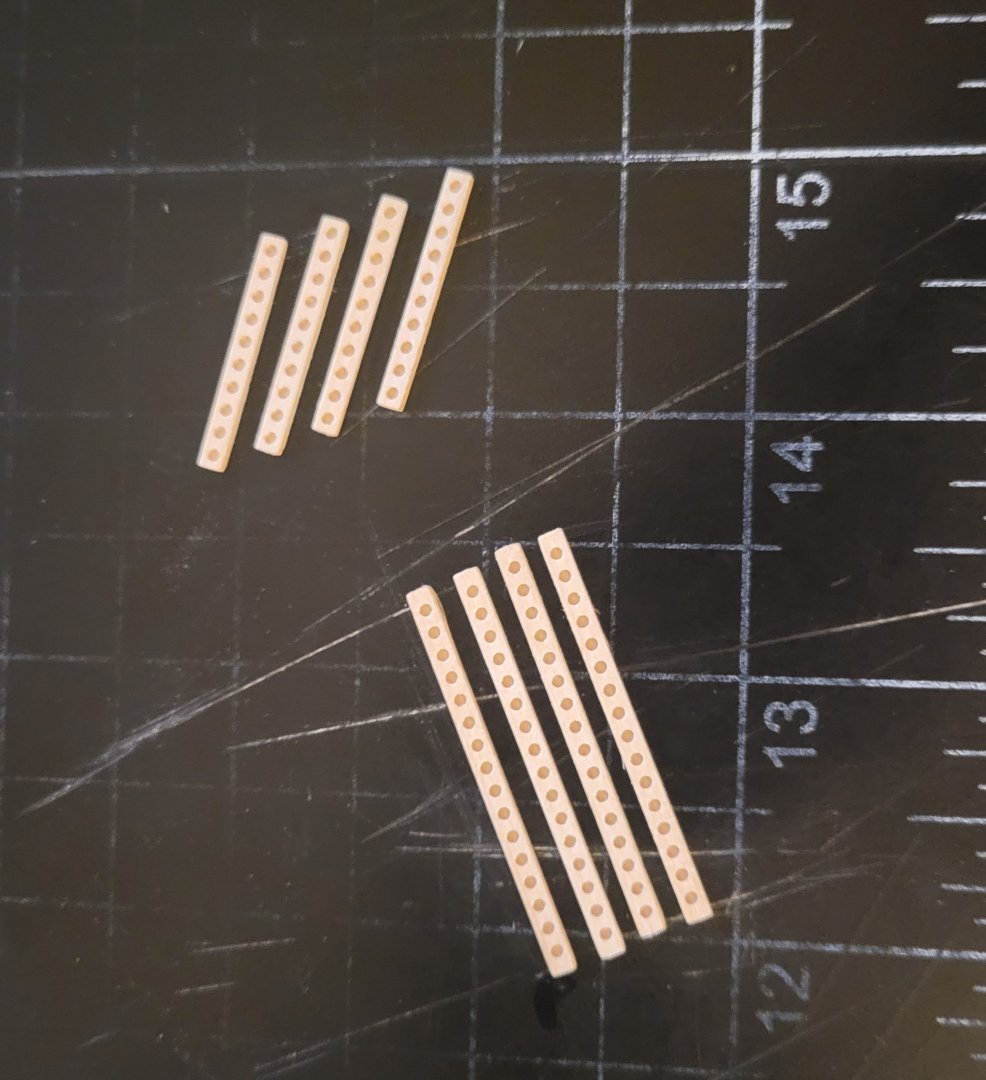

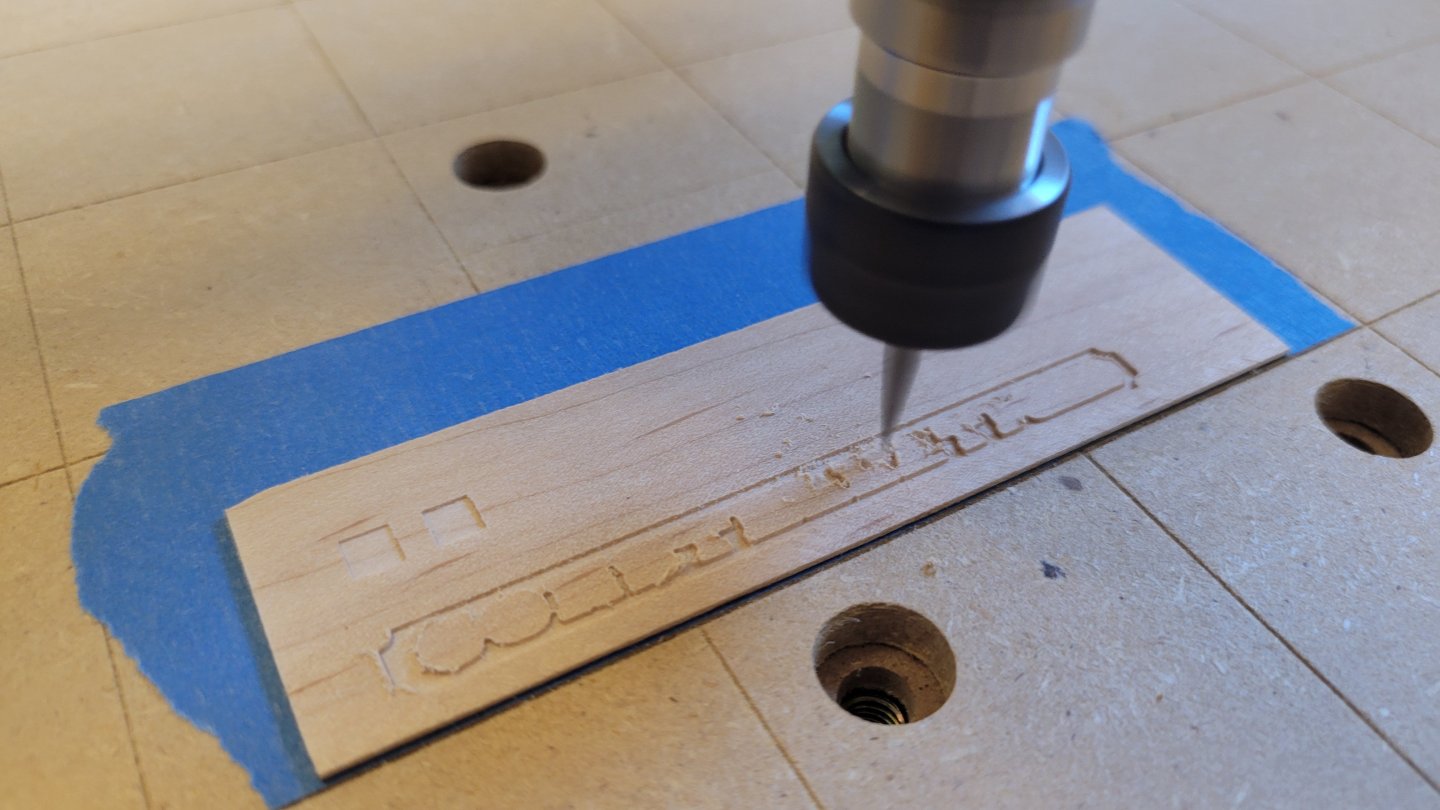

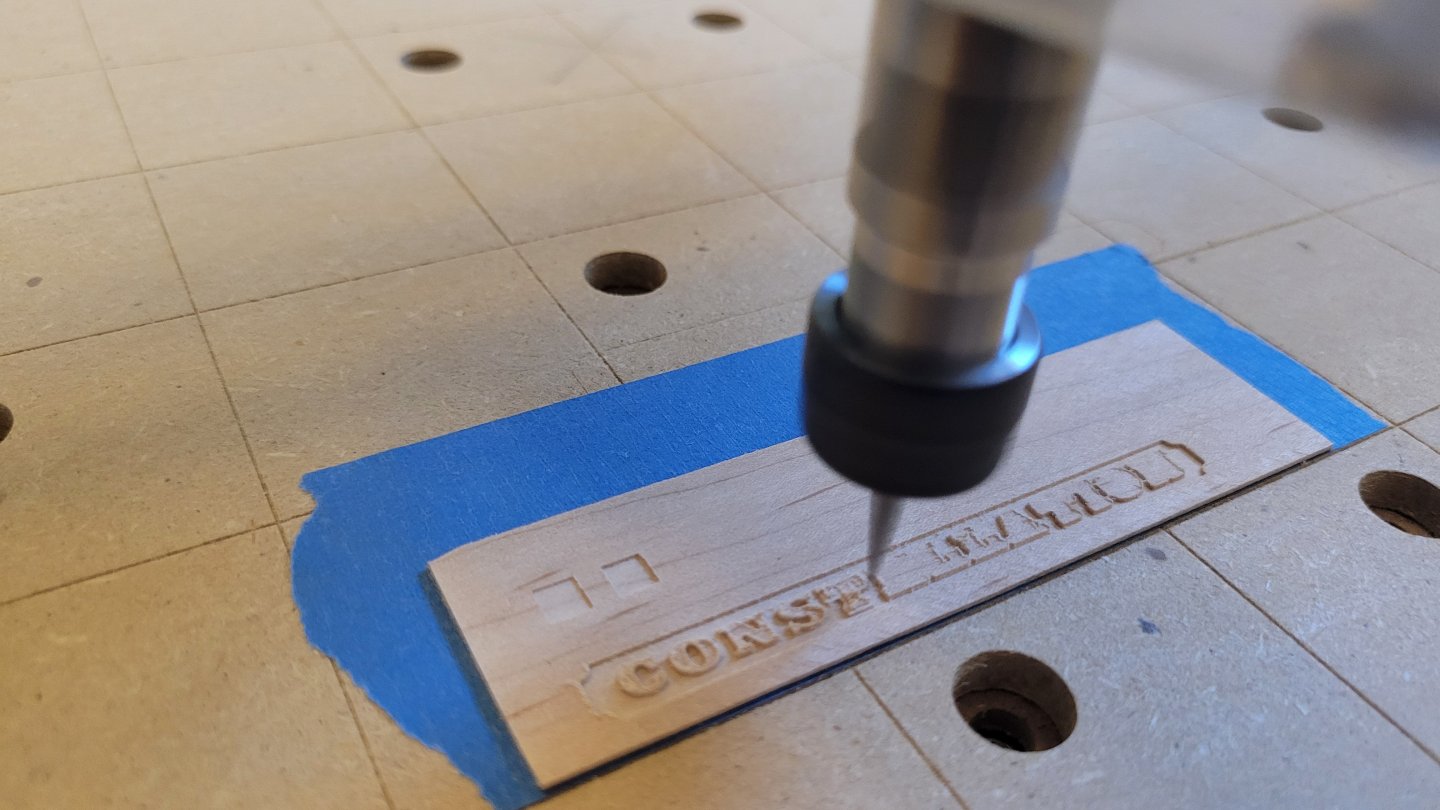

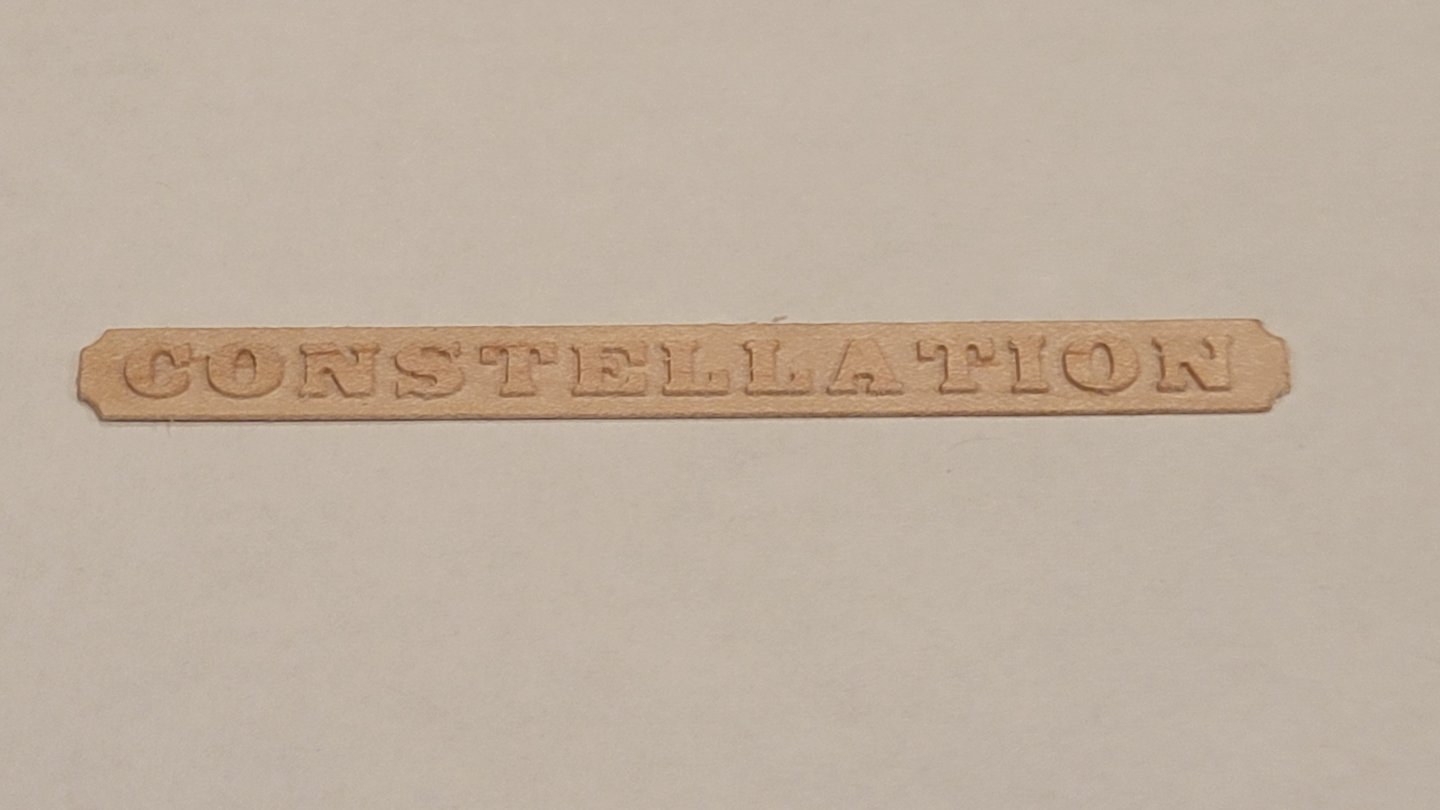

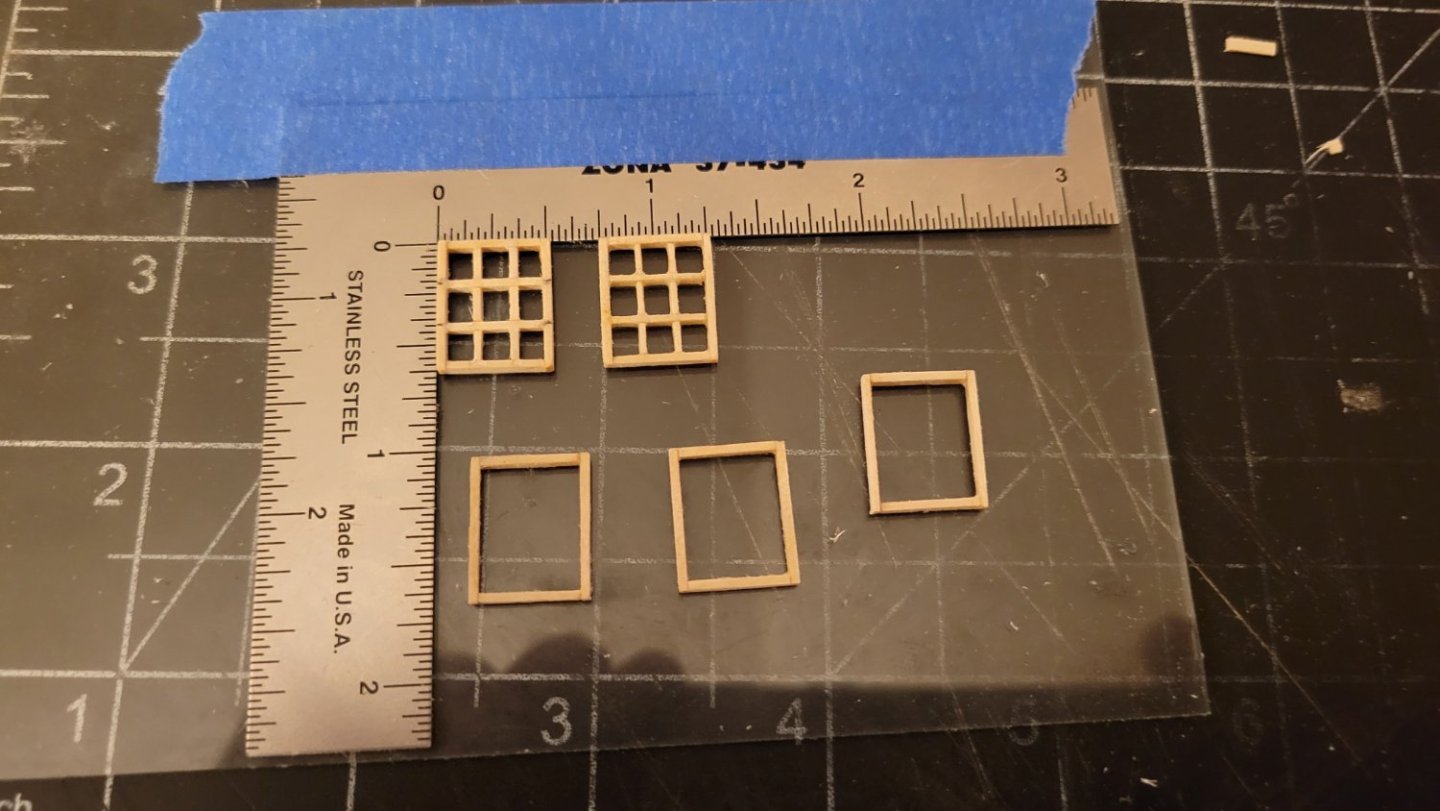

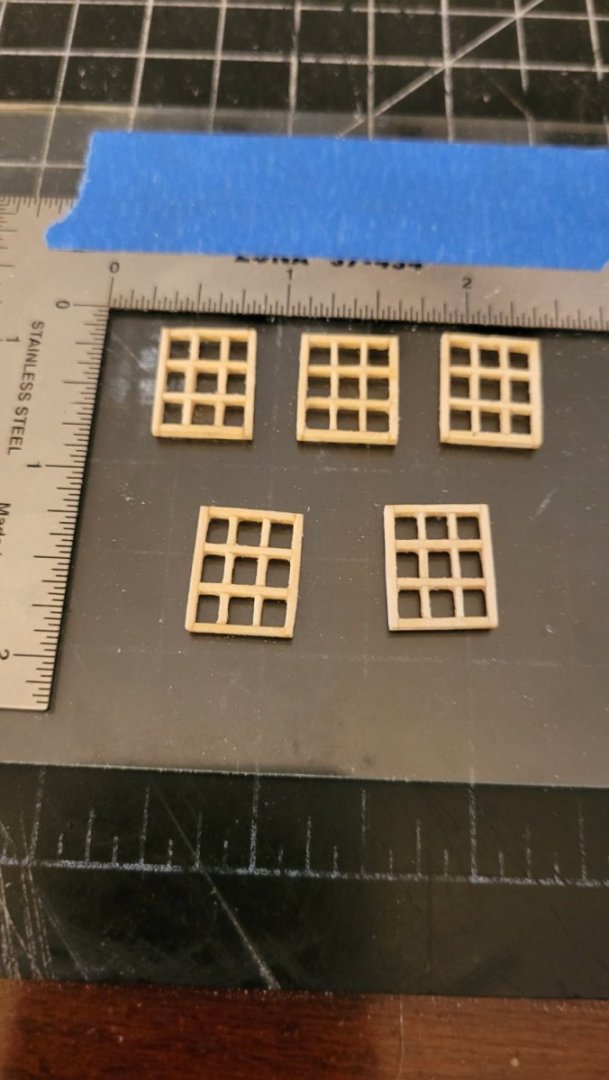

I pulled the trigger and got a desk top CNC the other week. After setting it up and researching how to use it and what software for creating the files, I have finally produced something somewhat acceptable.... Although I need to rework it with a slight arch to fit the stern and figure out why there's not a hole in the A.....

-

Tschiller reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

Tschiller reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

-

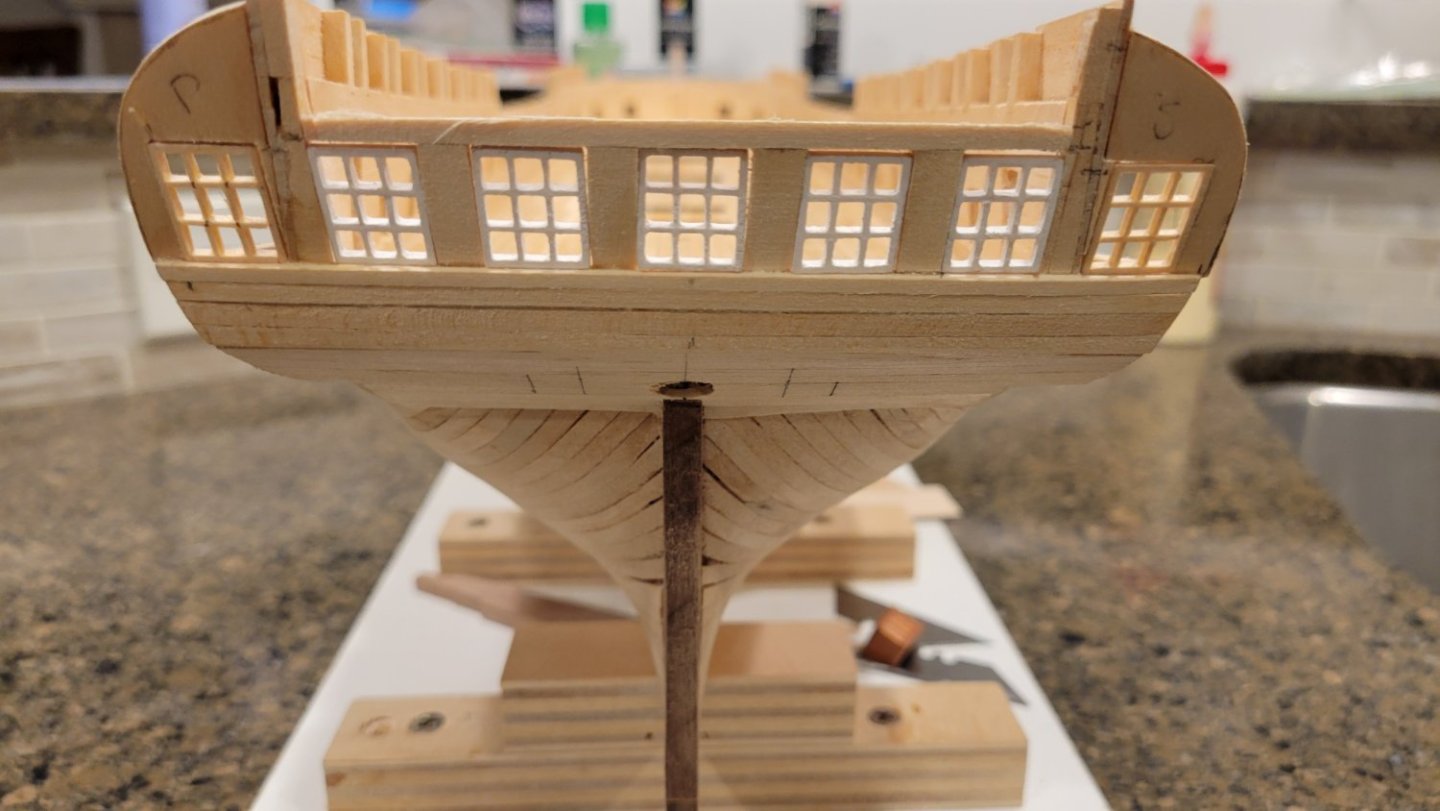

So I have made a bit more progress since my last post Completed the Breast Hook for the Spar deck... Started the Beams in the Aft to located the walls in the Captains Cabin... and finally was able to complete the lower planking on the Quarter Galleries... and lastly I completed the planking on the Stern and fitted the Stern windows. All in all, I think it turned out pretty good so far.

-

USS Constitution by mtbediz - 1:76

Tschiller replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Coming along nicely! -

Tschiller reacted to a post in a topic:

USS Constitution by Der Alte Rentner - Model Shipways - 1/76

Tschiller reacted to a post in a topic:

USS Constitution by Der Alte Rentner - Model Shipways - 1/76

-

Okay, so I have cut the Fore and Aft Bits on the gun deck and mocked them up with the first 3 Spar deck Beams (as depicted on the Lines of the frigate Constellation in Chapelle's book) to determine the final location on the Gun Deck. I need to turn a 3/8" rod for the Bowsprit so that I can determine the size and location and how to attach the Bowsprit step so I can finally determine the width and final location of the Fore Bits.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.