-

Posts

467 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by abelson

-

While waiting for an order of 0.010” (0.20 mm) black line to complete the starboard shrouds, I decided to temporarily setup the main topgallant backstays. Note: I ordered 9 meters of 0.20 mm black line from Model Shipways, which was not enough to complete the ratlines. I used 0.018” (0.4 mm) black line for the backstays. The backstays are seated over the topgallant mast shrouds with an eye splice. I had to make the eye splices on the mast because I had glued the mast truck onto to top of the mast. If I had not done that, I could have more easily made the eye splices off mast and simply fit them over the mast. I seized a 6” single block to the end of each backstay. I created a small eye at the bottom of the block to tie the backstay runner to. You could also reeve the runner under the backstay line before seizing the block. I strapped a 6” single tackle block with 20-gauge wire and created a hook for attaching the block to an eyelet in the port and starboard bulwark as shown on the rigging plan. I used 0.012” tan line for the runner. The runners are belayed to the quarter deck rail as shown on the belaying pin plan. Also, completed the starboard upper and lower ratlines (a major step in the rigging). Stepped the main and fore topgallant masts. Inserted a pin in each mast to hold the main and fore topgallant yards. Completed the main and fore topgallant shrouds (0.018” black). They were fitted over the top mast shoulder with seized eyes (one pair and one single P&S). Each shroud passes through a hole in the crosstrees and is wrapped around the futtock stave and tied off. Next, the main topgallant stay (0.018” black) was fitted over the top mast same as the backstays and setup with two 4” bullseyes and a lanyard (0.010” black). The fore bullseye was strapped (20-gauge wire) and hooked to an eyebolt (20 gauge) in the aft most crosstree as described in the instruction manual (there is no detail on the plans). Then, the fore topgallant backstays were added (0.018” black). They were fitted over the top mast shoulder with a seized eye and set up with a tackle (6” single blocks). The lower block was strapped with wire (20 gauge) and hooked to an eyebolt on the bulwark aft of the channel as per the rigging plan. The tackle runner (0.012” tan) was lashed to the inboard cleat as shown on the belaying pin plan. I added the fore top gallant stay (0.018” black). The stay fits over the fore top gallant backstays and leads down to a 6” single block at the end of the jib boom is belayed to a pin in the bow pin rail. This completes the running rigging. It this point, I would say that the ship is approximately 50% complete. Next up, main and fore stay tackle runners and Burton tackles.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Completed the port side upper and lower ratlines. I used thin, 0.20 mm nylon (purchased from Model Shipways), for the ratlines and fastened them with clove hitches as per the FA instructions. Once you get the hang of it, the clove hitches work well. To achieve the 15” recommended spacing, I used a legal pad as a guide. The grid lines are 15” apart at a ¼” scale (see photo). Note: At the recommended spacing, the number of ratlines is less than the number shown on the rigging plan. I also added 7 mm Syren boxwood cleats (not furnished with the kit) to the lower and top mast shrouds as illustrated in Fig. 34. The cleats are for both the top yard lifts and the topgallant yard lifts. I spray painted the cleats black, glued them to the shrouds, and seized them with 0.20 mm line.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

For anyone considering the Fair American, one thing that came to mind was how often I’ve uttered the words “not furnished in the kit” or words to that effect. I often wonder why certain items shown on plans or indicated in the instruction manual are not included in the kit. Purchasing items “not furnished in the kit” adds to the cost of the build. Just saying. Moving on, I completed the fore top mast shrouds and sheer poles same as the main top mast shrouds and sheer poles. Setup the fore topmast backstay (0.020” black line and 5/32” deadeyes) same as the main top mast backstay. The lanyards will be reeved after the ratlines are completed. The double fore top mast stays (0.020” black line) were seated over the backstay. Each fore top mast stay was secured around the mast head with a terminal eye and a mouse. The stays pass through holes in the bowsprit bees, port and starboard. Each stay end was seized to a 5/16” Syren fiddle block, purchase (0.015” tan line), and 7” single block hooked to an eyebolt on the bow as shown on the rigging plan. The hauling ends were hitched to the bowsprit bitt. Note: the instruction manual and the rigging plan call for the purchase to be rove through a fairlead hole in the knightheads. I could not do this because I pinned the knightheads and the pin prevented me from drilling a hole in knight head. In hindsight, I would have drilled a hole in the knight head before pinning it and made sure that the pin did not obstruct the hole. Although, I have seen other FA builds were the stays do not pass through the knightheads. Completed the jib stay (0.020" black line) and the inhaul and outhaul lines (0.020" tan). The jib stay is secured around the fore mast head with an eye splice and is seated on the thumb cleats. The stay passes under the outhaul ring and through the sheave in the jib boom. The end of the stay is seized to 5/16” Syren fiddle block. The outhaul tackle (0.012” tan line) is setup with a 6” single block hooked to the bowsprit cap beneath the jibboom. The outhaul tackle is belayed to the starboard bow pin rail. I used a little CA to aid in belaying the tackle to the pin. I seized the inhaul (0.012” tan line) to the jib stay out haul ring as shown in Fig. 35 and belayed it to the port side bow pin rail. Next up, the ratlines.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Progress Report: Completed the fore lower shrouds and sheer poles. Set up the fore stay (0.040” black line) with a 5.5 mm heart, 0.015” black lanyard, and bowsprit collar. Fig. 30E shows turns around the lanyard, but Detail N doesn’t show this. I opted not to wrap the lanyard. Fashioned the futtock shrouds as per Detail G on the rigging plan. For me, so far, these are the most challenging part of the rigging – a lot of seizing in a tight area. But I managed to complete them. Phew. I applied a little CA to the futtock stave and positioned it on the shrouds -placing the ship on its side made this easier. I then lashed a 1/32” x 1/32” futtock stave to the lower shrouds. I started with double overhand knots for seizing the stave to the shrouds. I applied CA to the knot and then trimmed the ends with a nail clipper. I didn’t like the bulky look of the knot, so I switched to a single overhand knot. Next, the futtock shrouds were rigged. I used 0.021” black line. I seized a futtock hook, made from 1/16" eyebolts and spray painted black, to one end of the line. I think the hooks are too long, but I’m not changing them. Then I hooked the shroud into the eye formed in the deadeye strop (Fig. 33B) under the top. The loose end is wrapped around the futtock stave and seized to the shroud as shown in Detail G. I added two catharpins seized between the staves (see photo). These are not shown or noted anywhere in the FA instructions or plans. I saw them on Chuck Passaro’s Syren practicum. The catharpins are 0.018” black line. I made the main top mast shrouds (0.021” black line) in the order shown in Fig 33. I used a paper clip claw (jig) to maintain the spacing between the upper and lower eye of the deadeyes (about 1’-9” @ ¼” scale). Like KenW’s FA build, instead of a thimble shown in Fig 33A, I lashed a 1/8” block between the first shroud pair and the second shroud pair for the topsail yard lift. This makes the yard lifts part of the running rigging rather than the standing rigging. The lanyards are 0.015” black line. I added shear poles (1/32" x 1/32") lashed to the top mast shrouds a la the lower shrouds. I added the main topmast stay (0.020” black line) next. The stay passes through the ¼” lead block (Detail I) on the fore mast and is set up with a 5/16” fiddle block, purchase, and a 5/32” single becket block hooked to a eyebolt on the aft side of the fore mast. The purchase is belayed to a cleat on the fore mast. I setup the main topmast backstay (0.020” black line) temporarily with paper clip jig. I plan to reeve the lanyards after the ratlines are completed. Next up, complete the fore top mast shrouds and stays. Stay tuned.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Following up the last post, I completed the main lower shrouds. The paper clip deadeye claws worked well to get the initial alignment of the deadeyes. With the claw removed and the lanyard reeved, the deadeyes weren’t aligned the same but are close enough for my liking. Getting ahead of myself here, after studying the rigging plan, I decided to make the lower yard trusses. I thought it would be easier to fit these without the yard aloft. Fig. 39 in the instruction manual illustrates how the trusses and pendants are “married” and reeved. The location of the purchases below the yard is not shown on the rigging plan, so it’s left to the builder to decide where to position the blocks. I decided to position them 3 feet below the yard. Note: Page 35 of the instruction manual states the lower lift purchase blocks should be midway between the deck and the lower mast cap (about 16' at 1/4" scale). You could assume that the lower yard truss pendant purchases should be the same. Using 0.021” line, I made an eye on one end, seized it, and applied some CA to it. I cut the line long enough (14’ @ 1/4” scale) to be wrapped around the yard, seized, and reeved through the opposite truss eye. I duplicated this for the 3 trusses. I fit the trusses to main and fore lower yard. The upper purchase blocks (1/8” double) will be seized to the pendants when the yards are suspended. Moved on to the sheer poles. I made the sheer poles from 1/32" x 3/16" plank from the kit, cut down to 1/32" square and painted them black. I glued a shear pole to each main mast shroud just above the deadeyes and seized it to the shrouds. Touched up the poles with black paint to cover the sheen of the CA glue. Completed the main preventer stay and main stay. Used 0.030” line for the preventer stay and 0.018” line for the lanyard. I set up the preventer stay with a 5.5 mm heart (not furnished with the kit) and eye per Detail M on the rigging plan. Note: Fig. 30C shows the preventer stay setup with a bullseye. I choose to follow Detail M. The main stay is 0.050” line set up with a 5.5 mm heart and 0.020” black line lanyard per Detail C. I had previously fashioned the lower heart with metal strap and eye. Next up, the fore lower shrouds. Seized to the main stay the main stay tackle pendent (0.210” black line), 7” double block for the forestay tackle, and four 7” single blocks for the fore topsail braces. These are positioned as shown on the rigging plan.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Progress update. Fashioned the main and fore mast burton tackle pendants from 0.018" diameter black line. Scaled the length from the rigging plan. Used a toothpick to create the pendant eye. Applied some CA glue to stiffen the eye. Strapped 9" double pendant blocks using 28 gauge wire. Next, I set the fore mast. The fore hole was slightly over-drilled, so I followed the advice of the instruction manual and set a ¾ x 18 brad in the heal of the mast. I drilled a hole in the heal, cut off the brad head, and inserted the brad in the mast hole. I then tapped the mast lightly with a hammer, setting it as plumb and at the proper angle as I could get it - it worked out well. Fabricated the topsail yard parrels as depicted in Fig. 41 of the instruction manual. The parrel ribs were made from 1/32” x 3/32” wood strips (I used some leeway in the shape of them). The parrel trucks are 1/16” glass beads that I had from my Rattlesnake build (the kit doesn’t include these). I painted the ribs burnt umber to match the masts. Fig. 41 says there are 6 ribs per yard. I found only 5 ribs are necessary. I used 0.33 mm (0.012”) hemp to string the ribs and trucks. Note: The ribs and trucks have to be strung on the yard because the line is seized around the yard inside the sling cleats. I created an eye at the end of the parrel as per Fig. 41. The hauling end of the parrel passes through the eye and belayed. This will be done when the yards are rigged aloft. I fit the topsail yard temporarily to see how the parrels aligned. Moved on to fabricating the closed heart and metal strap for the main fore stay. The heart (not provided in the kit) is a laser cut 7/32” boxwood purchased from Syren. The metal strap is 20 gauge (0.032”) wire painted black. Decided to try my hand at making a stay mouse. Cut a length of 0.04” black line for the main stay. Made an eye at one end. Measured the distance of the mouse from the main mast on the rigging plan, multiplied by 2, and allowed for wraparound the mast to get the length from the eye (16 feet at 1/4 scale). Using 0.040” line, tied a knot on the main stay at the 16-foot mark. Using 0.021” line, tied another knot. Using 0.018” line, tied another knot and then wound the line tightly around the knots. Applied CA to secure the line. This made a nice mouse. Unfortunately, and this is where paying close attention to the rigging plan is necessary, the mouse was orientated in the wrong position (see photo). So, I had to start over. Second time’s the charm, as I was able to create the mouse in the correct orientation. I touched up the mouse and eye with black paint. Repeated the process for the main preventer stay and the fore stay (The fore stay is 0.0021” line). Prepared the lower shrouds for rigging. Set up the first-seated, main forward shroud with a deadeye and seized it to a 0.021” line cut over-length to allow for the line to be seated over the mast tackle pendants and to seize a deadeye on the other end. To maintain the plan spacing between deadeyes, I used a deadeye claw made from a paper clip (see photo). I found this simpler than the twisted wire deadeye claw illustrated in Fig. 29B in the instruction manual. I set the first pair of shrouds on the port side instead of starboard side as called for in the instruction manual - oops. Yet, another reason to study the instruction manual. I set up the deadeye lanyards (0.015” black line) as illustrated in Fig. 29B. I repeated the process for the 2nd pair of shrouds on the starboard side. Still to come, the 3rd pair on the port side, and the 4th pair on the starboard side. Oh, one thing I overlooked, the 9” double block beneath the main top for the gaff throat halyard (Item 58 in the Key to Rigging Plan). This would have been much easier to fit when the main top was not aloft. I just looped it around the mast and tied it off. The gaff throat halyard tackle (Item 48) is not clearly shown on the rigging plan. It’s represented by dashed (broken) lines to illustrate that it’s behind the bulwark as viewed on the plan. It consists of a 7” double block and a 7” single block hooked to an eye bolt in the deck and belayed to a pin in the port side pin rail (see sketch). The gaff peak halyard tackle is not shown on the rigging plan nor identified in the Key to Rigging Plan. It’s set up the same as the gaff throat halyard tackle but is belayed to the starboard pin rail (as noted on the Belaying Pin Plan).

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Received my order of 15mm brass chain plates. They worked out, but I should have ordered more because some were wasted. They’re brittle. Once you bend them there’s no going back. The lesson learned here - order more than you think you'll need. The difficult part was trying to make them the same length. I stepped the masts in order to determine the slant of each chain plate. I marked the position on the black strake with a fine point awl. I found it easier to set the dead eyes in the channel notches without the chain plates in place and then cap the channels with wood strips. I put a dab of CA on each deadeye strap to keep them from falling off while the channels were capped. I sanded and filed the capping strips and painted them hull tallow. I hooked the chain plates into the deadeye strap eye, pinned them to the black strake and painted them black. I didn’t paint the deadeyes. As a matter of note, I noticed in other build logs that the chain plates are attached to the main whale. So, I thought I erred in attaching the chain plates to the black strake. However, the instruction manual and the plans clearly indicate and show the chain plates being attached to the black strake. I assume, therefore, that the black strake is correct. Although, I do like the appearance of the chain plates attached to the main whale. Spent a considerable amount of time studying the rigging plan, the key to rigging plan, and the belaying pin plan, and cross-referencing them with the 16 Gun Brig Fair American - Standing and Running Rigging (1:48 Scale) spreadsheet. There are a few rigging items in the spreadsheet that do not appear in the key plan, the rigging plan, or the belaying pin plan. To each item in the spreadsheet, I added the corresponding rigging plan key number to the spreadsheet for easy cross-reference. As I matched up the key numbers with the spreadsheet, I highlighted each number on the rigging plan with a yellow marker. I did manage to match up every number on the rigging plan with the spreadsheet. The belaying pin plan and the key to rigging plan use different terminology. Consequently, it’s confusing where some of the lines are belayed. Where I could match them up, I added the rigging plan key numbers to the corresponding belaying pin plan for quick reference. Also, I found it helpful to develop sketches to more clearly illustrate the rigging. I added key numbers, block sizes, and line sizes to the sketch (see example). I feel more confident now with the rigging. Set eyebolts in the port side of the fore and main mast tops for the topgallant tackle and on the P&S sides for the burton tackles. Set eyebolts in the P&S sides of the bulwarks for main and fore lower sail clews. Set eyebolts in the deadeye channels for fore lower yard truss tackles, main and fore tackle runners, fore and main topsail halyard tackles, and fore and main Lower yard tackles.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Decided to strap the 3/16” deadeyes. The kit doesn’t come with the 11/32” diameter MS #439 strops noted in Fig. 26B in the instruction manual. Fortunately, I had some left over from my Rattlesnake build. I found them easier to work with than the 0.032" dia. wire that comes with the kit. I used a toothpick to form the lower eye of the strop. I set them temporarily in the channels just for effect. The chain plates are problematic. Modelshipways no longer provides the #991 chain plates noted in Fig. 26B. I had some brass chain plates (see photo) from my Rattlesnake build that would have been perfect, but I don’t have enough of them. I ordered some 15 mm (0.59”) long brass chain plates from MS that I’m hoping I can use. I misplaced the 5/32” dia. deadeyes, so I ordered them as well. [Just a matter note, I have found that MS often overcharges for shipping when you order on-line. Their explanation for this is that they can’t check every order. If you bring it to their attention, they will credit you.] Finished the bowsprit horses. This wasn’t as difficult as I thought it was going to be. I fashioned the bowsprit horse netting from some vail (netting) leftover from my Rattlesnake build. For the wooden spreaders, I used 1/16”x 3/32” planking battens from the kit, cut to 2 feet (1/4” scale) and then halved (lengthwise). I glued the spreaders to the vail 3 feet apart (scaled from the rigging plan). For the horses, I cut two pieces of 0.021” dia. black line long enough (about 6.5”) to span between the bowsprit cap and the knightheads with enough to seize them to eyebolts and to account for the stirrups rigged to the fore stay. I glued each line to the spreaders with CA. I then applied CA to the vail to secure it along the horse line. Then, I trimmed the vail along the spreaders and the horse line with an X-acto . It’s not perfect, but I Iike it.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks. Sorry to hear the book was confusing. Agree, the FA instructions are a little confusing. I find myself relying more on build logs than the instructions. The FA rigging is lacking in detail. As I mentioned, I've been using the Rattlesnake rigging plans which are similar to FA but more detailed and differentiate the running rigging (red) from standing rigging (black). Due to my lack of sailing ship knowledge, I spend a lot of time cross referencing the Key To Rigging Plan in the instruction manual and the FA rigging plan to become familiar with the tackles, lifts, braces, backstays, etc. I found a spreadsheet on the internet called 16 Gun Brig Fair American - Standing and Running Rigging (1:48 Scale) that is very informative. It lists the various running and rigging lines, line sizes, and block sizes.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Progress Update: Added the foot ropes to the bowsprit. I made six individual square knots on each rope. I didn’t tighten them so that they could be slid along the rope to the desired spacing (2-feet apart). Once in place, I tightened the knots, added a little CA, and trimmed them. I made a loop in the rope at the end of the bowsprit and seized the lower end of the rope to an eye on the bowsprit cap. One rope is a little longer than the other – no big deal. Next, I fashioned the fore and main mast tackle pendants. I used 0.5 mm black line and 3.5 mm Syren walnut bullseyes for the eye splices. The pendant length was determined by scaling the rigging plan. I fashioned the bridal for the lower yard slings using 1 mm black line and a 5.5 mm Syren heart and set it up for eye splices. As suggested in another builder’s log, I seated the bridal around the mast before the shrouds and stays. With the mast off-ship it was easier to seat the bridal around the mast, but seizing the eye was difficult. Rigged the yard slings as shown in Fig. 38 with 5.5 mm heart. Fitted out the fore and main lower yards. Rigged the footropes and stirrups from 28-gauge wire as recommended in Chuck Passaro’s MS Brig Syren Prototype Build Log. I found wire easier to work with than thread – I like the finished effect. It’s a little frustrating, though, because the wire is so thin it tends to break when twisted. Set the outboard stunsail boom irons in the holes previously drilled in the ends of the yards. These were made from 20-gauge wire. Rigged the Flemish horses with 28-gauge wire. Fitted the yards with tackle pendants. Scaled the length of the pendants from the rigging plan. Seized a 5/32” DB to each pendant. Tied 5/32” single blocks to the main and fore mast yards for the topsail sheet, 1/8” SBs for the clew garnet, and 5/32” SB and 1/8” SB for lifts. Tied 1/8” single blocks to the fore lower yard arm for the leech lines and bunt lines. Note: These are not shown on the rigging plan. Fashioned the main and fore lower yards stunsails from 1/8” dowel. Painted them burnt umber. The inner boom iron was made from 20-gauge wire. Drilled a hole into the yard for the boom iron. Rigged the fore and main topsail yards (including stunsails) and the fore and main topgallant yards. Added pins to the main and fore mast to support the yard arms. I got this idea from rafine’s build log – it took me awhile to figure out what the pins were for – a good idea. Rigged the spritsail yard foot ropes. Fit the spritsail with brace pendants with 5/32” SB. Since I’m following the Rattlesnake rigging plans, I fit the spritsail with a “tye” (See plan). Suspended the spritsail from the jib boom with a truss (Detail H on the FA rigging plan). The ornate detail of the truss is not visible when rigged. Nonetheless, it’s authentic. Note: Be cautious working on the jib boom so as not to dislodge it as I did - no harm, no foul. Added 1/8” SBs to the main top mast trestle tree for the top gallant yard braces. Also, added a pin to the main top mast for the main topsail yard. At this point I'm about six months into the build. What's next? I may concentrate on the strapping the lower deadeyes and fashioning the chain plates.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

I think the purpose of the knots is to prevent slipping.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

I tried the clove hitch and found it difficult with the rope off-ship. It might be easier with the ropes on-ship. I used simple double knots.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks. The issue is how to knot the ropes so that the knots are evenly spaced on the foot ropes. From other builds, it looks like there are about 6 knots each side on the bowsprit.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Made a little progress in the last few days. Seized the bowsprit shrouds to the deadeyes, lashed them to hooks, and attached them to eyes in the main wale. Seized the bob stay at the upper end to the deadeyes and at the lower end to a hole in the stem knee. Seized the fore tack bumpkin stays to an eye in the stem knee. Added 3/16” SB to each bumpkin for the fore tacks. Note: the fore tacks P&S are not shown on the rigging plan. I looked back at the Rattlesnake rigging plan (my first build) which depicts the fore tack, fore sheet, and clew garnet and the 3-block assembly required for this (see attached). Chuck Passaro’s MS Brig Syren Prototype Build Log has a nice detail of the block assembly. The FA rigging plan does show a single block on the fore lower yard and on the main lower yard which I believe is the for the clew garnet. The fore sheet attaches to an eye on the ship side, passes through the clew block, through a sheave in the bulwark (shown on the rigging plan) and is belayed to a large cleat (shown on plan sheets 1 and 4). I’m getting ahead of myself here but, going forward, I think I’ll use the Rattlesnake rigging plan because it’s much more detailed. I forgot the sheave in the bulwark. If I’m going to add the fore sheets, then I’ll need to fit the sheaves – I need to give more thought to this. Also., the FA rigging plan doesn’t show the bowsprit and boom foot ropes. I’m not sure how to fashion them and haven’t found any discussion on them. Next up? I might tackle (no pun intended) the bowsprit horses and netting.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

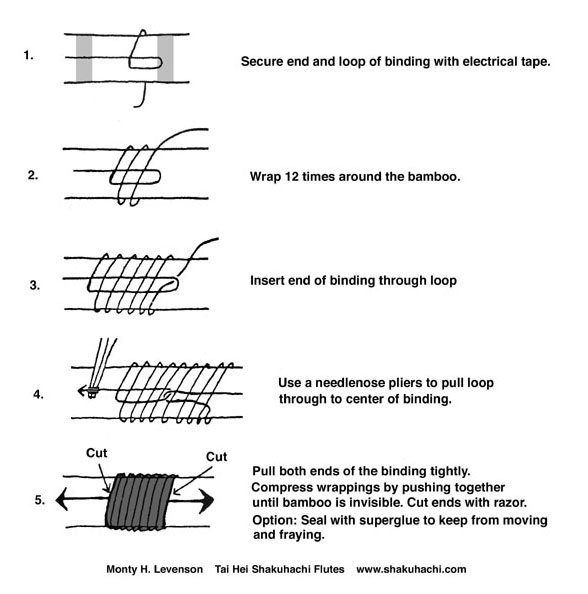

Continuing the build, after seeing wooldings and reading discussions on them on other build logs, I decided to add them to the fore mast. Note: Wooldings are not discussed in the FA instruction manual nor shown on the drawings. I located the bottom woolding just above the heart for the main preventer stay. The remaining wooldings are spaced 4 feet apart. I used 1mm black nylon for the wooldings and wrapped each one 10 times. I didn’t use hoops above and below the wooldings because they were not common until the 1800s. I found the attached diagram very helpful, and it worked well for securing the wooldings. Next, I added a 5/32” heart to the fore mast for the main preventer stay. Spent considerable time studying the rigging plan, instruction manual, and build logs before assembling the bowsprit and jib boom – this is of paramount importance. Fashioned the bowsprit heart and collar and attached it to the bowsprit as depicted in Detail N on the rigging plan. I made the shroud collar and bob stay collar with 5/32” deadeyes as depicted in Detail D and attached them to the bowsprit. Added 1/8” single blocks (SB) to the bowsprit cap for the sprit sail yard lifts and the jib stay. Added a 1/8” SB to the jib boom for the fore gallant stay, Fashioned the jib stay traveler from 20-gauge wire. Attached the jib boom to the bowsprit. Glued the bowsprit in-place and secured it with gammoning. Waxed 0.55mm cordage and seized and eye at one end. Passed the other cut end through the eye and then rove it through the gammon hole in the beak head as illustrated in Fig. 27 in the instruction manual. Fashioned some cargo hooks from 1/16" eyebolts and spray painted them black - I'll need more of these. I plan to use them to hook the shrouds to the futtock plates as well. Moved on to the fore and main tops. Fashioned the deadeye futtock plates from 20-gauge wire. Note: the #439 strap rings shown in Fig.33B do not come with the kit and are no longer available from MS. I used needle nose pliers to strap the deadeyes and create and eye for the futtocks hooks. I formed the strap such that the cut ends fell in the middle of the strap. I didn’t solder them because the ends are not visible when inserted in the main and fore tops. I did file them flat, however. Completed the main lower yard, main topsail yard, main topgallant yard, fore lower yard, fore topsail yard, spritsail yard, fore topgallant yard, main gaff, and main boom. For the main and fore lower yards, the 3/16” dowels aren’t big enough to create the 8-sided effect without using the built-up method in Fig. 22. I couldn’t accomplish the profile of the yards as depicted on Plan Sheet 2 using the built-up method, but I’m satisfied with how they turned out anyway. In hindsight, I would have used a larger diameter dowel and created the octagonal effect by filing instead of the built-up method. I fashioned the sling cleats from 3/16” x 3/32” wood strips. I traced the pattern from Sheet 2 and used a razor saw to carefully cut out the image. With some filing, I had one cleat to the general configuration shown on Sheet 2. I used this cleat as a template to create the rest of the cleats. The sling cleats for the topgallant yards and the main gaff, though not as ornate, are small and difficult to fashion. I made them slightly larger then depicted on Sheet 2. I attached the cleats with wood glue and later added a drop of CA adhesive to secure them. Securing the cleats with CA makes it easier to file them without fear of breaking them after they’ve been installed. The yards, main gaff, and boom were primed and painted black in keeping with the FA color scheme. I fashioned the boom goose neck and eyebolt from 20-gauge wire. The eyebolt is attached to the main mast as depicted on Sheet 2. Note: The rigging plan shows bent irons at the ends of the main and lower yards. These are for stunsail booms, which are not discussed nor depicted on the plans. I discovered these from other build logs. I’m planning to add them to my build. Chuck Passaro's Syren build log has a good discussion on how to fashion the stunsail boom irons. He recommends drilling holes for the boom irons into the end of the yards before you start tapering them as there is less of a chance of splitting yards. I was able to drill the holes after the tapering the yards without splitting them, fortunately. In hindsight, would follow Chuck’s lead. I found that there are enough 1/8” dowels to fashion the stunsail booms - I'll do this at a later date. Returning to the mast tops, I added the 1/8” blocks to the fore top for the sprite sail yard braces and to the main top for fore lower yard braces. I added to the fore mast the lead block (1/4”) for the main topmast stay and 1/8” blocks for the main top braces. To the main mast, I added blocks (3/16”) for the main boom topping lifts and the main gaff peak halyard. To the fore mast, added 1/8" blocks for the main lower yard braces. Next up? Probably the bowsprit shrouds, fore tack boomkin guys and the bob stay.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you. I try to impart a little practical experience. I’m not an expert by any means, but I do recognize shortcomings in plans and instructions. It’s my engineering background. I’m glad my buildlog is helpful. Stay tuned for more.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

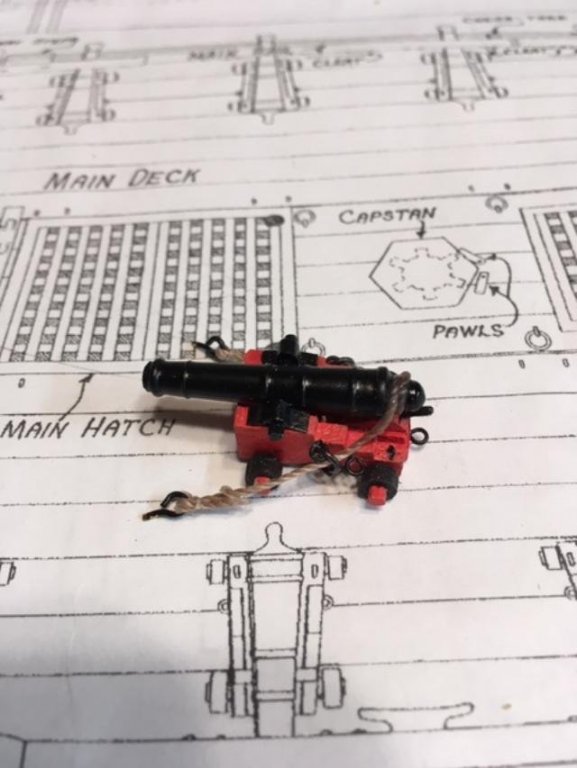

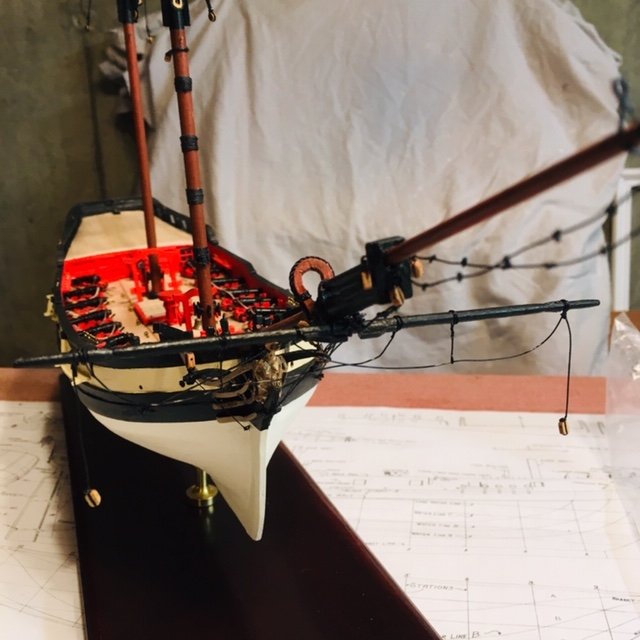

After a week on vacation, I’m back on the model. I read and studied more build logs and realized that, although I’m not an expert by any means, IMO, some aspects of my build are as good if not better than those of more experienced modelers - just saying. This is reassuring, as the goal for my current build is to be at least as good or better than my first build (45 years ago). I’m now about 5 months into the build. So far so good, but the more difficult part (the rigging) is yet to come. You can never study and research enough. I’ve made mistakes, which will only be noticeable to an expert eye. I realize the errors of my ways and accept my imperfections - I'm not aiming for museum quality. As for progress, I completed the fore topmast, fore topgallant mast, topgallant, and topgallant mast truck. I primed and painted the bowsprit and jib boom, the main and fore masts, the main and fore top masts, the main and fore tops, trestletrees, and caps, and the topgallant mast in the black and umber scheme. Returning to the cannons, completed rigging the cannons – phew, glad that’s done. I decided to add the coils as I completed the cannons. I snipped the 0.3 mm manila hemp tackle line and left a short piece which I glued to the deck. When I assembled the tackle lines originally, I used a 6-inch length of hemp for each tackle line. After it was snipped, I found the remaining length was ample for forming the coils. l ran the remaining line through bees wax, coiled it around a 1/8” dowel, and then flattened it out somewhat. Each coil was glued to the deck with a dab of wood glue. I’ve added the deck fittings temporarily just to see how everything looks. Next up, the mast yards.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Progress update: Except for painting and adding eyebolts to the cap, completed the bowsprit and jib boom. The bowsprit gammoning cleats were made from walnut cleats, cut and trimmed to scale. I traced the image of the bees on Sheet 2 onto wax paper and transferred the image to scrap wood by using a pointer to mark the outline in the wood. I connected the darts with a pencil and then cut the shape with a coping saw – I’m pleased with it. Completed the main topmast, topgallant mast and topgallant. The Fair American kit parts list says to use 5/32” dowels for the fore and top masts and 3/16” for the fore and main yards. The fore and main top mast caps have a 3/16” diameter opening. Consequently, when the 5/32” dowels are filed and sanded to the proportions shown on Sheet 2, they look too small for the cap opening. I think 3/16” dowels would be a better choice. I ended up making the main mast cap from scrap wood so that the fore mast fits tighter. Also, the castings for the small mast caps have a 3/16” square opening which is too big for the 5/32” dowels if used for the fore and top masts. I made these from scrap wood as well. I made the topgallant trestle trees from 3/16” stock, and the crosstrees from 5/32” stock. The FA parts list doesn’t indicate what size strips are to be used for trestletrees and crosstrees. I took the advice of Chuck Passaro's Syren build log and drilled the holes in the crosstress before fabricating them. Sheet 2 doesn’t show an end view of the topgallant trestletrees. I assumed, therefore, that the trestletrees are shaped like the main and fore top trestletress. I need to add the cap eyebolts and the topgallant mast truck. Next up, the fore topmast, fore topgallant mast, and topgallant.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

I found beeswax works well.

-

Completed rigging another cannon. Added the breech lines to the remaining 12 cannons and completed the outhaul tackle lines off the cannon. Decided to take a break from rigging to make a display board. I had a piece of 1” select maple from a home improvements project that I cut to 5 ½” x 20”. I pre-drilled holes for brass display pedestals. I chamfered the edges, sanded it, and applied 2 coats of Minwax PolyShades Stain & Polyurethane gloss Bombay Mahogany and one finish coat of polyurethane, and mounted the model. While waiting for an MS fittings order, I focused my attention on building the main and fore tops. The kit includes laser cut tops. The Instruction Manual says “you will find they require detailing” but it doesn’t say where you can find the detailing. The plans don’t show details of the top of the tops. I found some other build logs that had photos of detailed main and fore tops, so I mimicked a fellow builder. PS, I discovered Chuck Passaro-MS Brig Syren Prototype Build which details the tops. Passaro's build has a wealth of information. The topmast crosstrees and trestletrees where built from scrap timber. Note: The Instruction Manual says the trestletrees are laser cut, but the kit does not include laser cut trestletrees. I glued the crosstrees to the tops. The trestletrees will be glued later whence top and fore masts have been built. Squared and beveled the main mast and fore mast, flattened the sides for the bibbs, and created the tenon for the cap as depicted on Sheet 2. Using the squared section of the masts as a guide, I glued the trestletrees to the main and fore mast tops and added chocks and bolsters. With the tops in temporary position, I glued the bibbs to the masts. Next, I drilled holes in the mast cleats and temporarily installed the cleats for effect. I plan to paint the masts black above the bibb and burnt umber below the bibbs. Next up, the bowsprit.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Continuing the discussion on rigging the cannons, I completed rigging one cannon – looks good IMO. I followed the arrangement of the breeching and out haul tackle eyebolts in Fig, 20. I notice some build logs reversed the arrangement of the breech line and tackle line eyebolts. I found the arrangement in Fig. 20 gives you more room for attaching lines. With the carriage and attached gun barrel off the model, I seized one end of breech line to eyebolt, snaked breach line through split rings on carriage, wrapped it around the end of the cannon, and seized the other end of breech line to eyebolt. With the carriage on the model, I glued the breech line eyebolts into pre-drilled holes in the bulwark (I had to exercise care in drilling the holes so as not to penetrate the bulwark). Without gluing the carriage to the deck, I attached the out haul tackle to the carriage eye bolt and the bulwark eyebolt and then tightened the lines. The strop wire hooks on the tackle blocks made it fairly easy, though tricky, to attach the blocks to the eyebolts. The tackle lines will be trimmed and glued to the deck, and coils made and glued at the end of the line – not sure whether I will do this as the work progresses or after all the carriages have been rigged. One thing I discovered, in following the plans, there isn’t sufficient space between the cabin face and the aft gun ports (see photo). I lost a little space when I added panels to the cabin face, which I didn’t account for. In hindsight, I wish that I had read some build logs before I framed the gun ports, as many builders recognized this and made adjustments in their build. Oh well, chalk it up to experience. It will be difficult to rig the aft cannons. FYI, I followed the recommendation of another build log and applied a dab of 50/50 mix of wood glue and water to the end of the tackle line, which prevents the line from unraveling and facilitates threading the line trough the blocks.

- 61 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.572bcfc4da12891de1fae27d597b53e7.jpg)