-

Posts

253 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mfrazier

-

fire buckets

mfrazier replied to mfrazier's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Yes -

fire buckets

mfrazier replied to mfrazier's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Thank you. That was about the size I calculated . I just thought it was a little small, but evidently it was correct. Thanks for the confirmation. I am working on a way to make them from scratch. -

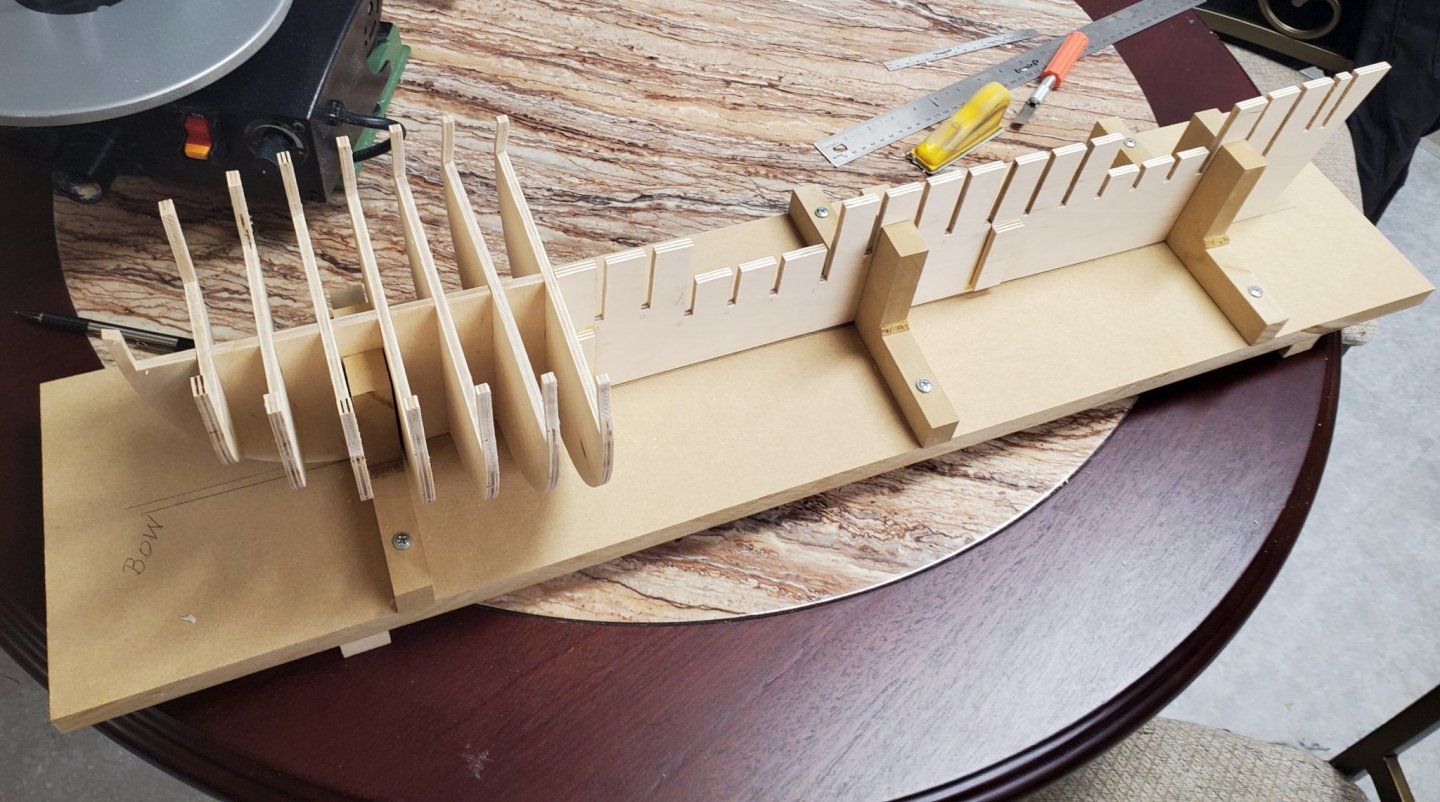

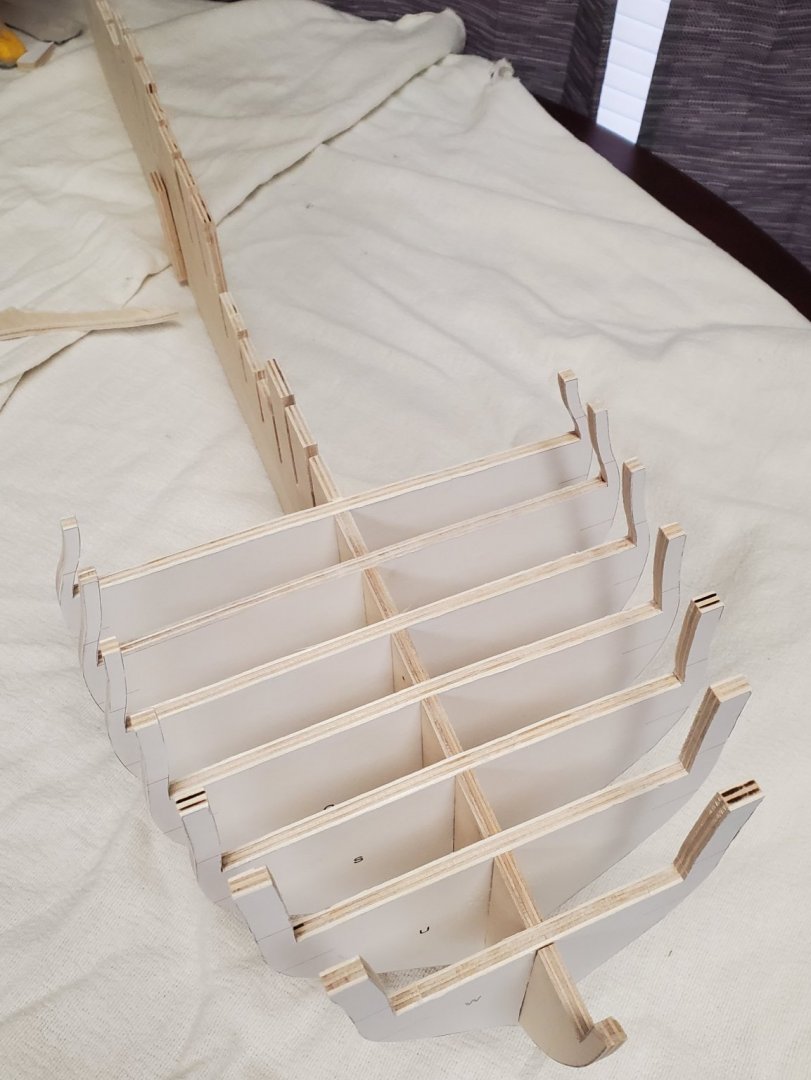

Well , I have a problem but I will be able to work with it. Like I said, I discovered I was not a master of the scroll saw. I couldn't get that thing to control for nuthin' . Only after I got everything cut out ,I broke the blade and put a little bigger blade in and WOW.... I can follow a line with ease. But too late now. Some of the slots in the bulkheads were a little rough and filling them straight, I got some a little off. This throws them way out at the outside. Sooooo.... there are a few bulkheads that will have to be shimed on one side and ground off on the other side. It will make planking a real chore, but I think I can overcome the problems caused by my inability to run that saw. I rough faired the hull to get an idea of how much trouble I was in. I am putting in the gunport frames now and will Fair it some more. I will post pics when the gunport frames are done. The hull looks okay until I lay a plank along it. Then I see the low and high spots. I will sand the high spots and shim the low while planking.

-

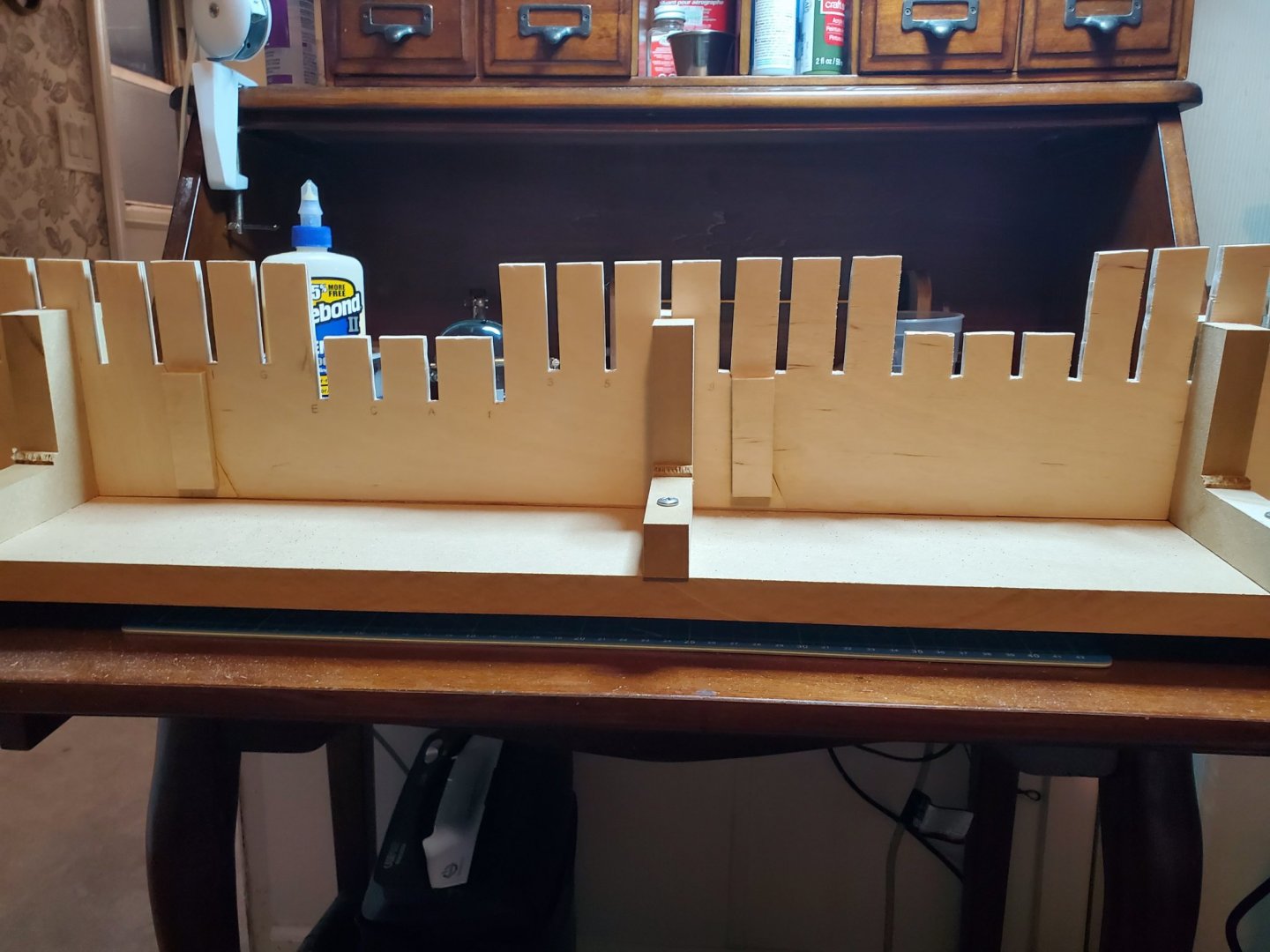

Everything is glued and all seems square and straight. The hull is very solid. I am ready to start fairing the outside of the hull and a little finish sanding on the keel. After that I can start the gun port frames. I recieved the chapter one and chapter two kits and the quality and fit is absolutely amazing. Chuck has done an amazing job on these kits.

-

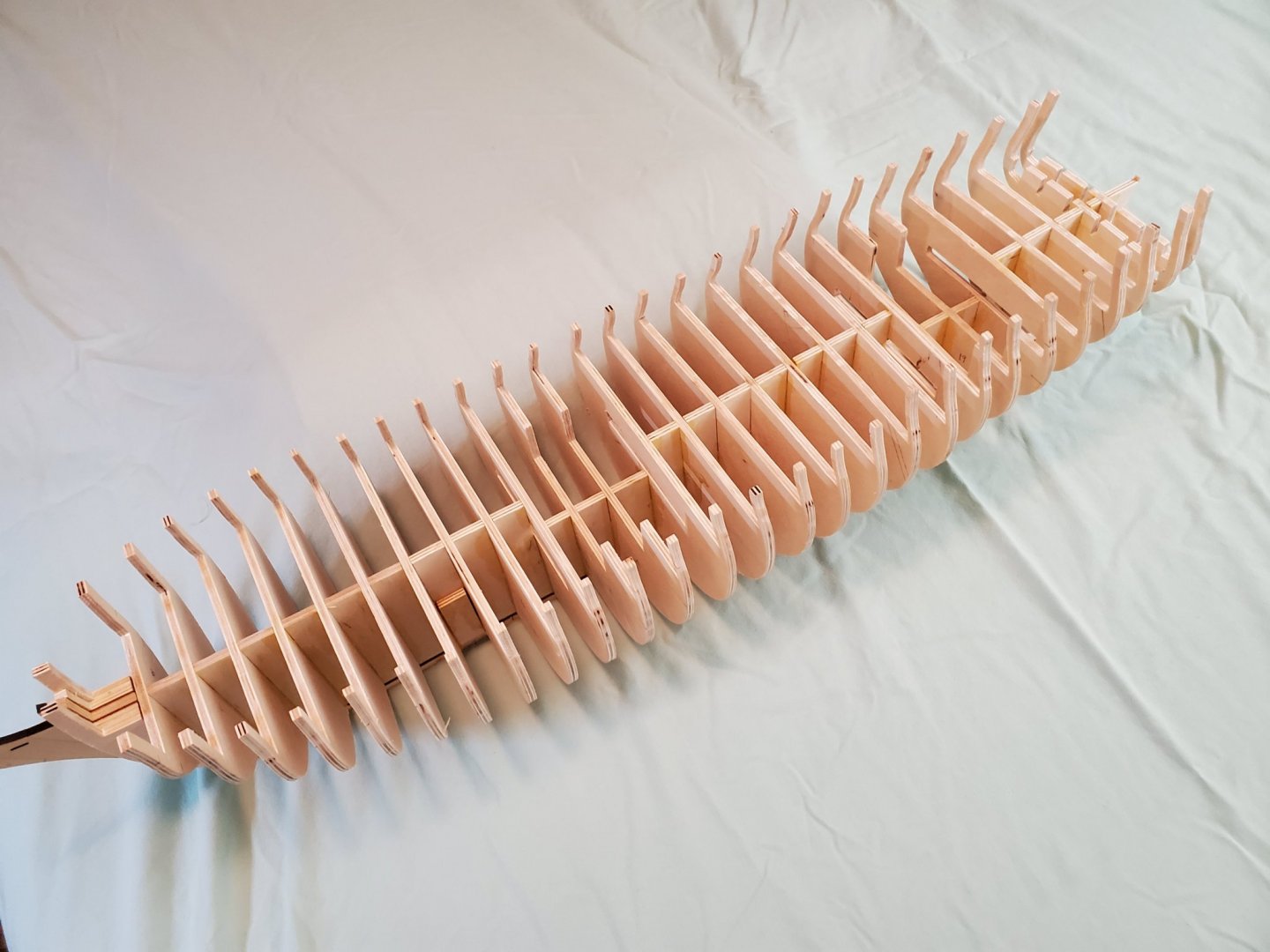

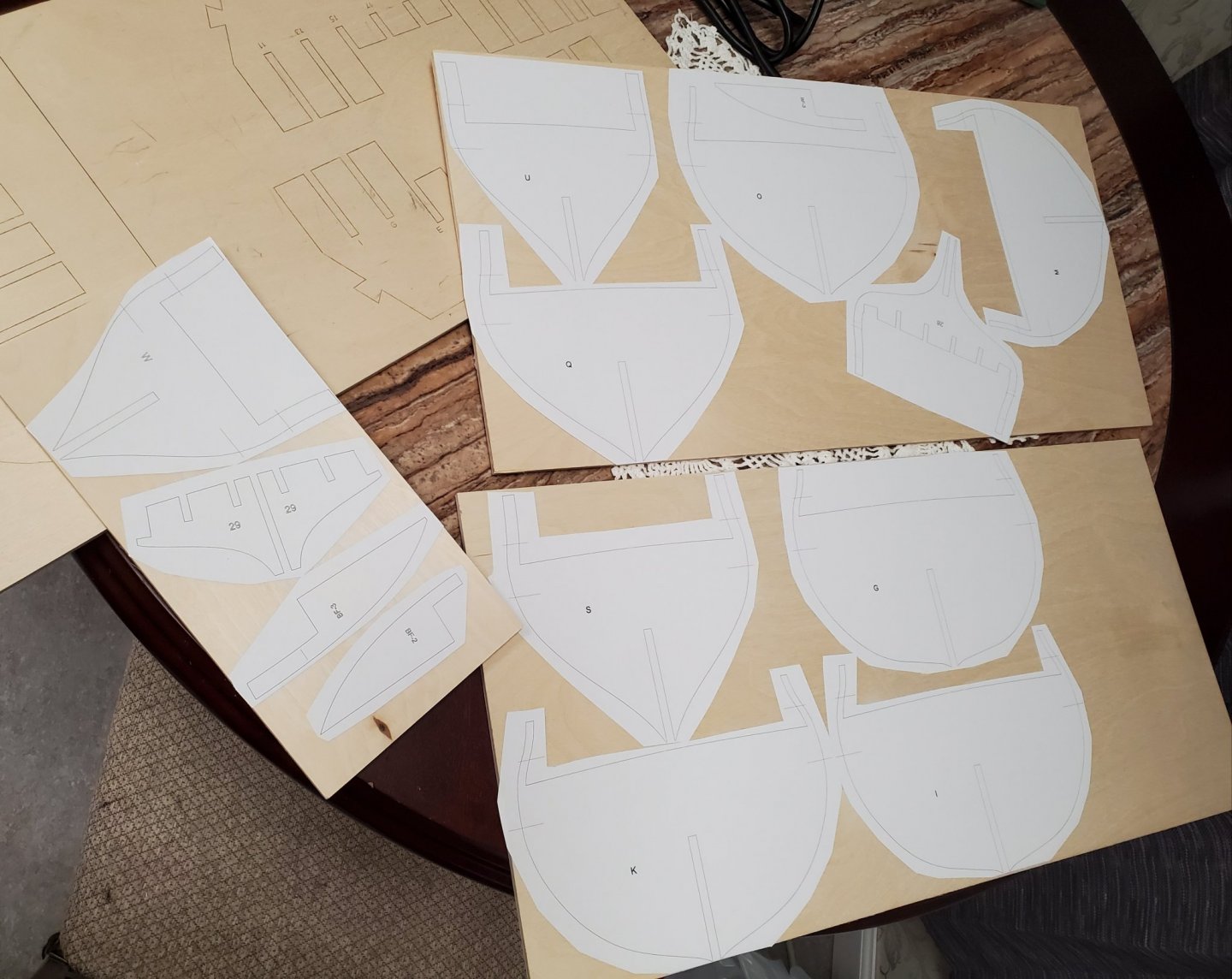

I got the rest of the bulkheads cut out. What a grueling process it was. I found out that I am not a master of the scroll saw. Thank God for the disc sander. I was all over the place with the saw cuts. I just stayed WAYYYY outside the lines and ground them back to the lines. There must be a trick to making that saw go where you want it to, but I sure don't know it. I couldn't control it. I thought I would have got better towards the end ..... but I didn't. Well now that is done I can get to the rabbit strip when it arrives. I am looking forward to this build. I am now thinking about ways to rip the planking when I get the blocks.

-

I understand. They are only dry fit at present. I'm not sure I understand what you mean about the first bulkhead being too small. It goes all the way down like you said and I looked at the other builds and they look the same to me. I am double checking everything before I do any gluing and waiting for the chapter one and two kits to arrive so I can do the rabbit strip. I will probably finish cutting out the last bulkheads today.

-

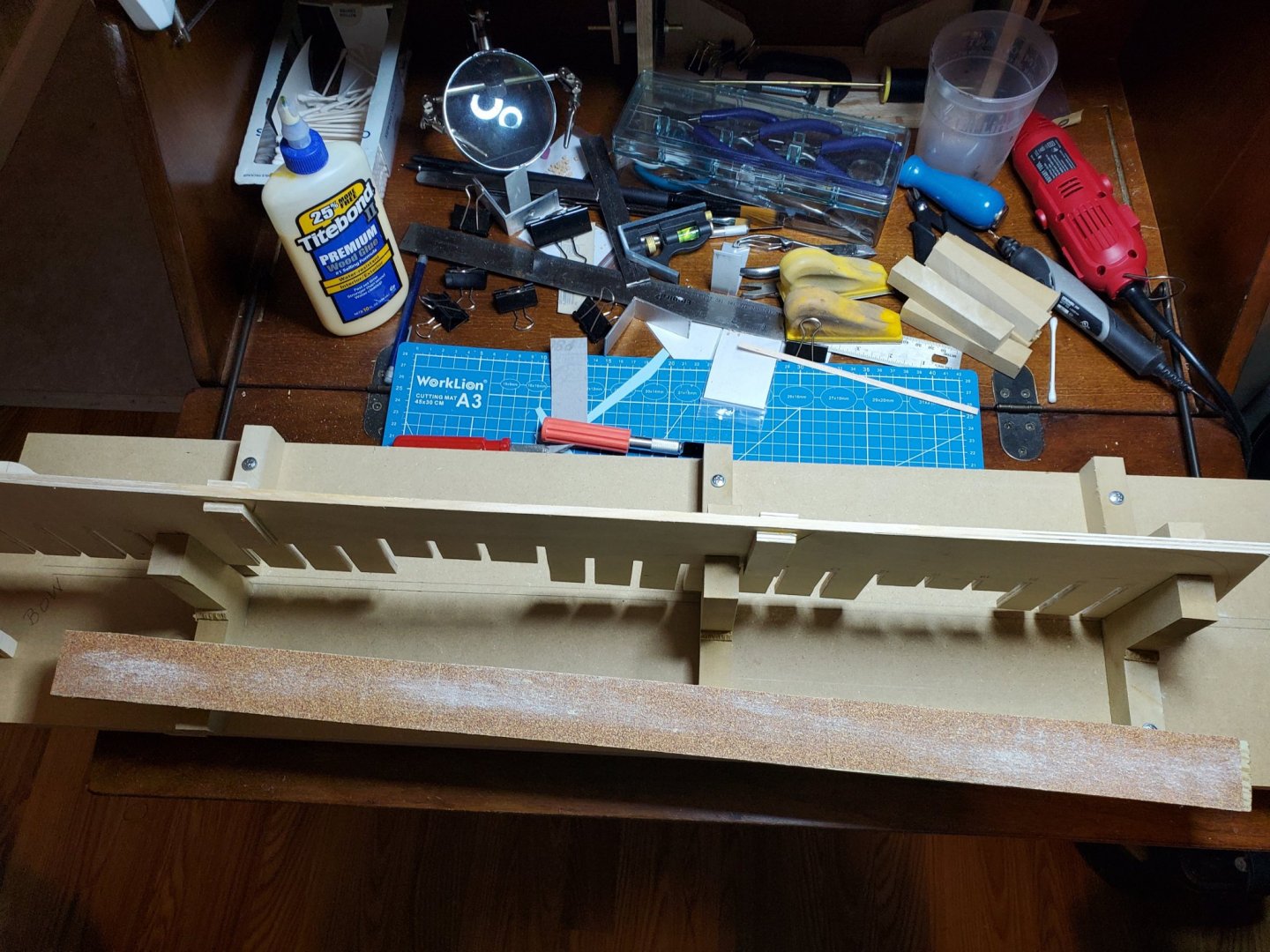

I discovered a problem. When I cut the 3 pieces for the hull former, I should have left them oversize on the bottom and sanded after gluing together. I sanded and then assembled. I ended up with the front and rear ends touching the build board and about 2 mm clearance in the center. While this may not have been too bad , I feel it needs to be FLAT. My solution was to glue a couple thin layers of basswood strips from my junk box.... I mean inventory .... to the bottom and I glued some sandpaper to a 30 inch flat board and sanded the whole length flat. Worked great. Now the former is perfectly flat on the bottom. I have ordered chapter one and chapter two kits from Syren. As soon as they get here, I am ready to proceed.

-

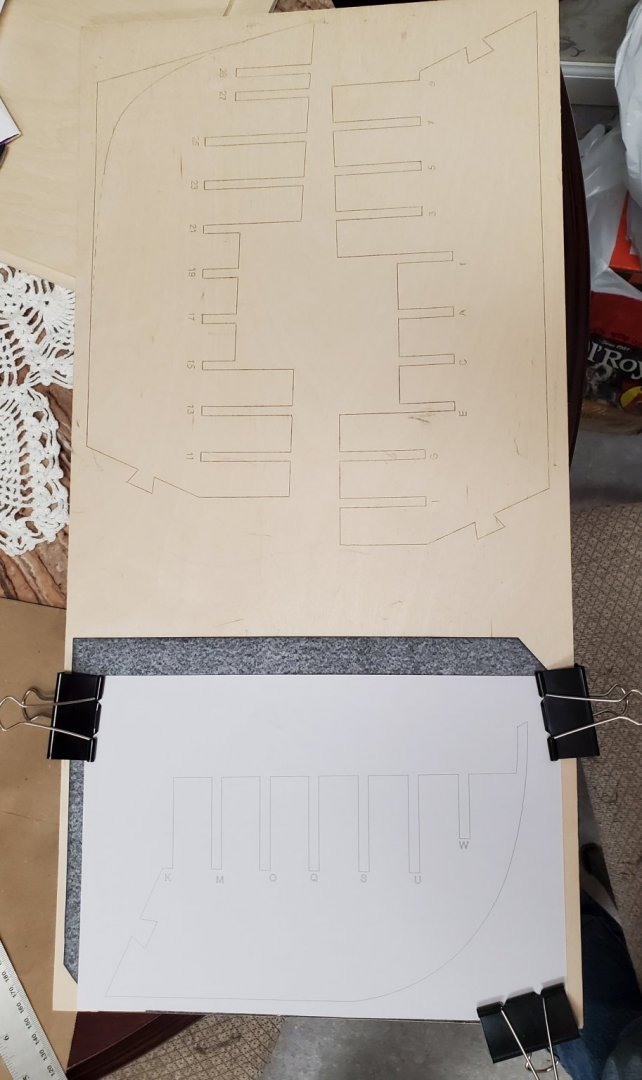

I place a piece of aluminum angle, that I cut in the machine shop, on each side with clamps. This holds the bulkheads square while the glue dries. This will take longer as I can only do two , maybe four in a day, but they will be right. Before I install the bulkheads, instructions say install the rabbit strip and keel, so that is next. It seems it would be more difficult fairing with them on first, but I will follow the instructions.

-

Cut the three pieces and glued them together. I got a good fit on the joints. I also glued a support block on each side of the joints. They shouldn't be in the way of anything but if are I can chisel them off. I am pleased with it so far. I will mount this on a build board and spend the next several days cutting out the bulkheads.

-

I printed the bulkheads prints on 8 1/2 x 11 Avery label sheets. They stick on the wood for cutting , but peel off easily with no residue. The weekend will be spent cutting them out. I will make sure to transfer the laser marks when removing the pattern. NOTE: Make sure if you use Avery Label stock, use the " easy peel" label stock. It is the removable one.

-

Left this morning, 55 minutes later got to Staples when they opened and they printed the large sheets and the three I couldn't print. So all is well now. used carbon paper to transfer the drawing onto wood. Worked great. ( staples told me to use graphite paper, but then said they didn't carry it. So I bought carbon paper.) I can start cutting this morning. 😁

-

My printer prints on 8 1/2 x 14 but the false keel prints are 11 x 17 and won't print actual size on the 8 1/2 x 14. They get cut off. I can print everything else actual size. There is an office supply store about an hour drive from me that says they can print them. Looks like a road trip this weekend , I guess. I just don't want to mess the prints up and ruin a bunch of plywood. I thought about cropping the prints to just the printed area and maybe the would fit, but don't want to chance messing them up.

-

I printed the plans for this project , but I think the false is the wrong size on my printing. I notice it says the document is 11 x 17 inches. This won't print on a standard home printer. Does anyone know where is a good place to get them printed? I think my printer scaled them down to fit on 8 1/2x 14. I can't print them actual size. I will have to sort this before I cut up all this plywood. All the rest of the plans printed actual size on letter and legal paper. It is just the false keel.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.