-

Posts

958 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Melbourne, Australia

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Archi reacted to a post in a topic:

English fleets and small vessels in the early 1700s

Archi reacted to a post in a topic:

English fleets and small vessels in the early 1700s

-

iMustBeCrazy reacted to a post in a topic:

Fairmile Launch RNZN Q406 by Pat Lynch - scale 1:24 - RADIO - Scratch design and build for RC

iMustBeCrazy reacted to a post in a topic:

Fairmile Launch RNZN Q406 by Pat Lynch - scale 1:24 - RADIO - Scratch design and build for RC

-

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

iMustBeCrazy reacted to a post in a topic:

Bounty Boat by AlfredoCampos - OcCre - 1/24 - FINISHED (fully planked hull)

iMustBeCrazy reacted to a post in a topic:

Bounty Boat by AlfredoCampos - OcCre - 1/24 - FINISHED (fully planked hull)

-

thibaultron reacted to a post in a topic:

Mucking about in 3D - Again - Santos-Dumont Demoiselle

thibaultron reacted to a post in a topic:

Mucking about in 3D - Again - Santos-Dumont Demoiselle

-

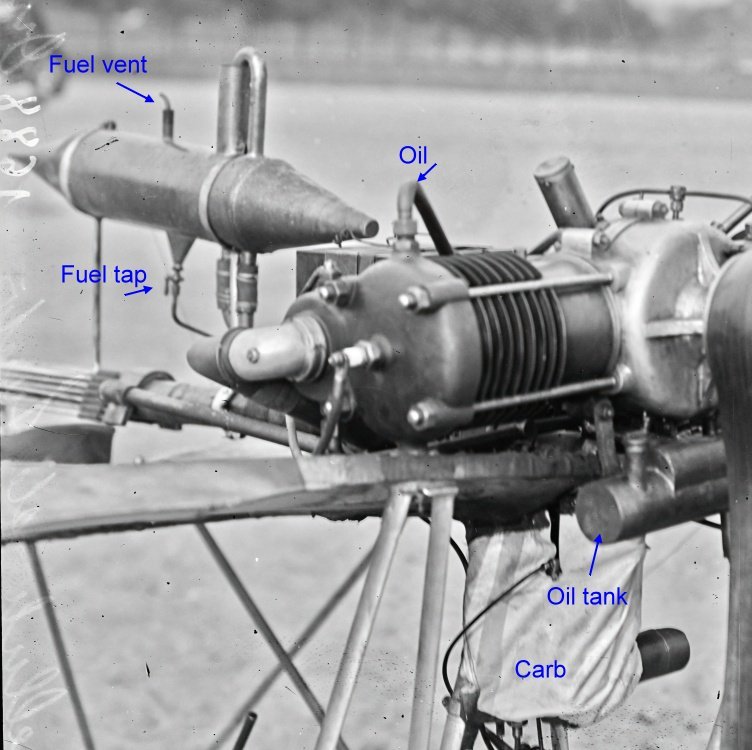

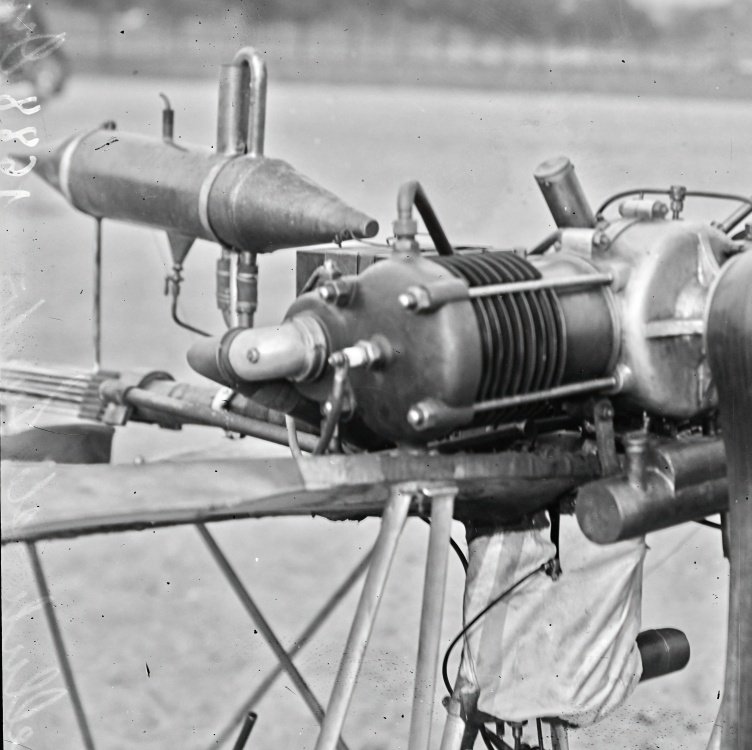

Not much to show this time, just push rods and a bit of tidying up. I got distracted trying to draw a prop for it and that's proved to be problematic, I see a way forward but it's going to be a pain. Still outstanding on the engine are a carburettor, oil lines, cooling system and extra flanges and bolts.

-

yvesvidal reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

yvesvidal reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

yvesvidal reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

yvesvidal reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Canute reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

Greg Davis reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Greg Davis reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

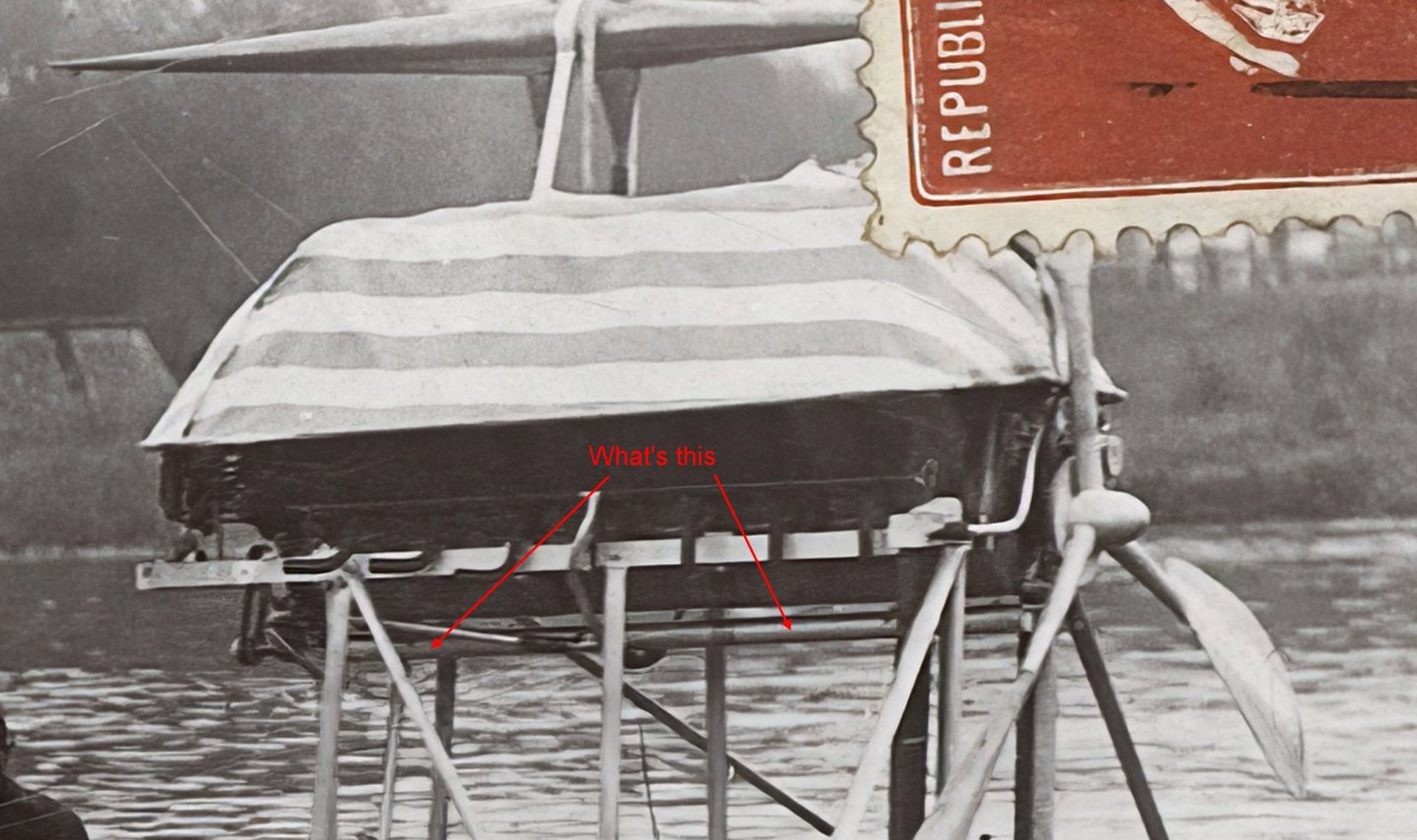

On the 20, yes (brain fade) the big one behind the pilot seat is fuel. But on the 19 there should be no coolant so it looks like he's using the fuel tank as an oil cooler or he's using the oil to heat the fuel (the oil tank in front of the engine would also act as an oil cooler). The piping appears to pass through the fuel tank. I don't know if there was a problem with something like wax in early fuels but I can't imagine why you would heat your fuel to the point it starts boiling off. 😟 On the 20, you're right, it's a coolant header tank. I assume it's unpressurised so the 'conning tower' out the top is to allow steam to condense and/or water to settle or perhaps not slop out when turning?

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

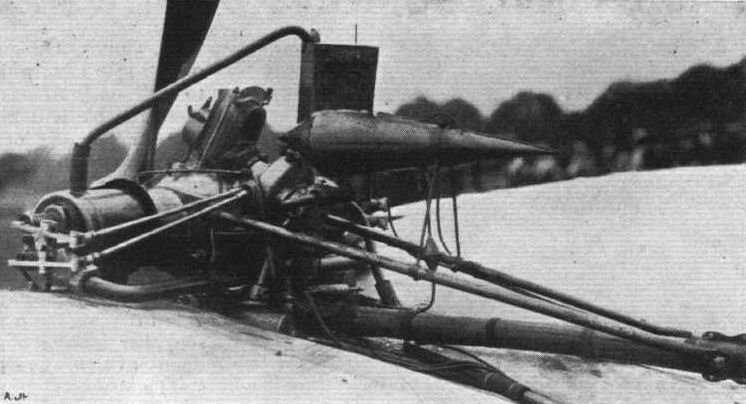

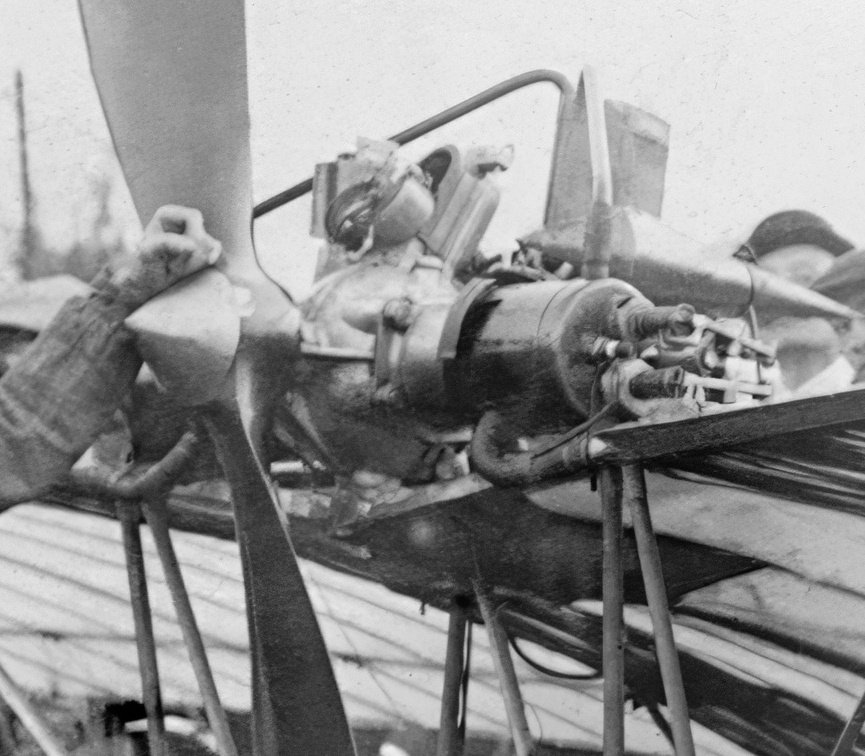

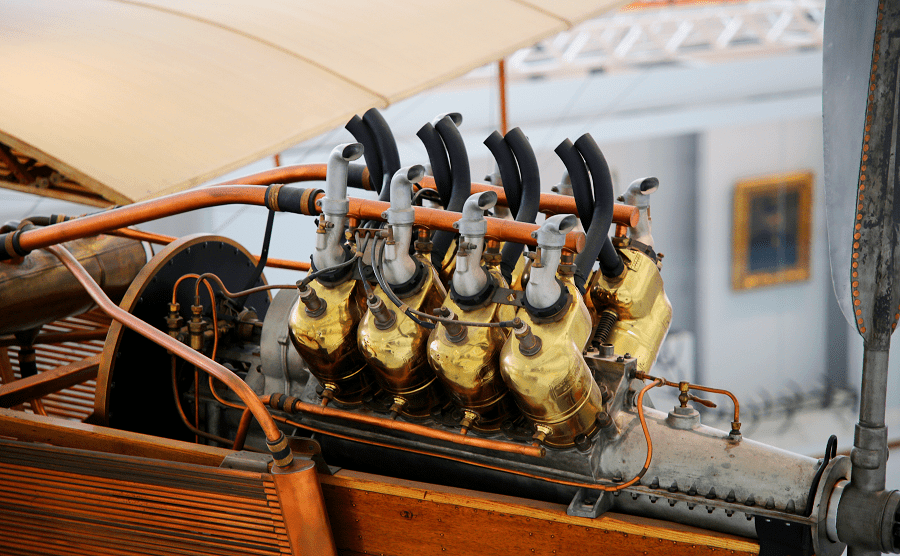

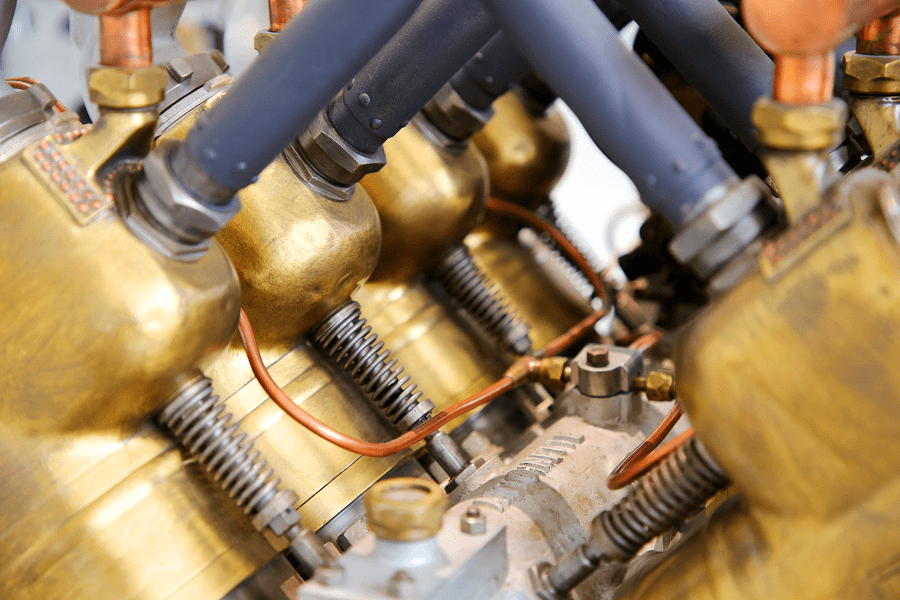

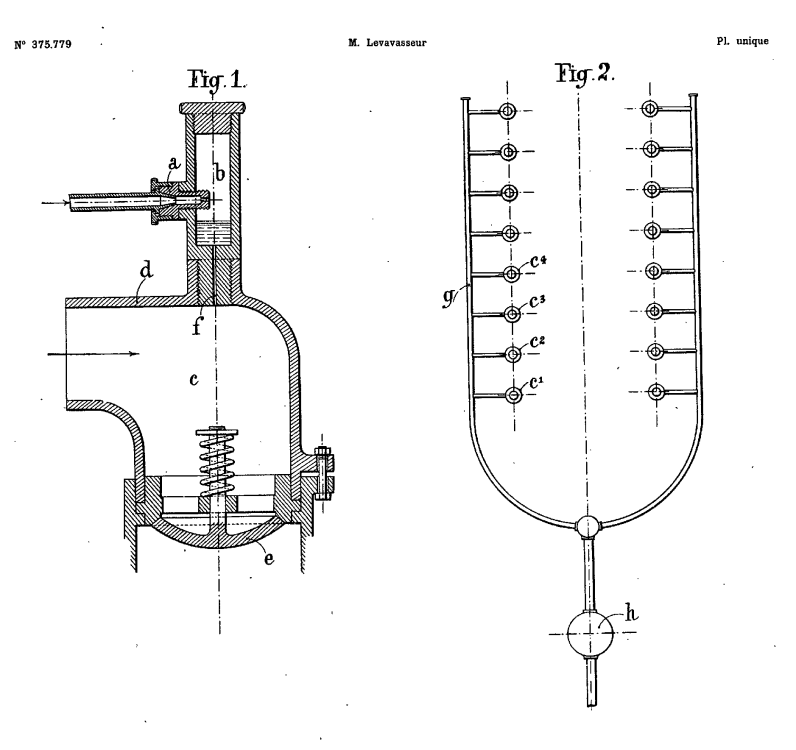

Alberto must have owned a worm cannery, there are more worms here than in Bounty's small cutter. No worms here, just run the fuel line to a 'T' and from that to each carb, no need to turn anything around. On to the worms. I was going to say you were lucky as on the Demoiselle the carburettor was under the wing wrapped in a piece of cloth which means I can't see it to draw it. When looking for a photo I realised that was on the 19 not the 20 I'm doing. Then I noticed the fuel tank with the associated plumbing, can of worms number one, this engine is air cooled, what's the plumbing for? The oil tank looks to be at the front of the engine. On the 20, the plumbing to the fuel tank is definitely coolant (it comes from the water jackets around the cylinders) which opens can of worms number two, why would you heat the fuel to above it's boiling point? Problems raised (for me) neither the coolant hose from the tank (there must be one, right?) or the carburettor (of the 20) are shown in any photos.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

iMustBeCrazy reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

Greg Davis reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Greg Davis reacted to a post in a topic:

Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

-

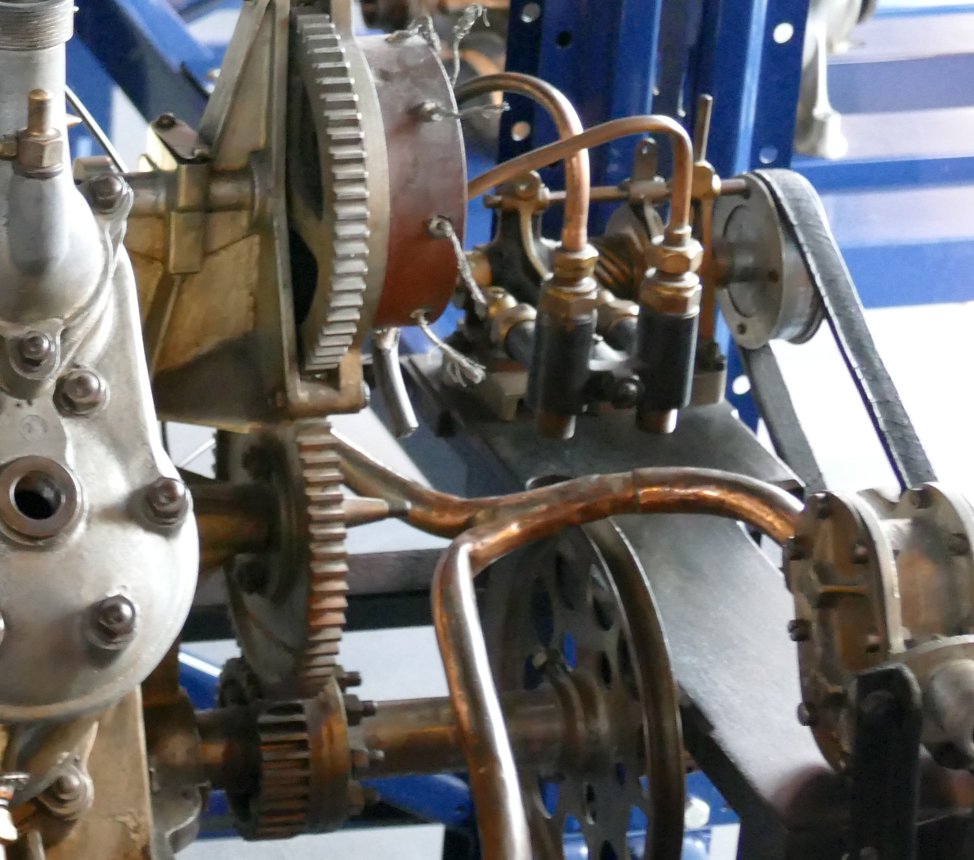

Well this version is fuel injected and has no way of controlling the amount of air ingested. The fuel injection pump timing adjustment (both coarse and fine) is interesting and the untimed pump will be oil. The water pump is hiding in the housing below and all three in this case are gear driven. As far as I can see Alberto didn't use fuel injection so yours should have a couple of carburettors, but I suspect you don't have any space left.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Greg, I found some bigger/better photos of the V8, https://muzea.malopolska.pl/en/objects-list/650

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

iMustBeCrazy reacted to a post in a topic:

HM Cutter Speedy 1828 by oakheart - from plans drawn by Bill Shoulders in 1972

iMustBeCrazy reacted to a post in a topic:

HM Cutter Speedy 1828 by oakheart - from plans drawn by Bill Shoulders in 1972

-

You can try sitting her on coloured paper to get a feel for how it looks. If you go high gloss it's going to have to be perfect, if you go satin finish it will be more forgiving. That said, I'd probably try a gloss black. Another option might be a diorama type sea (just the top of the plinth) with her floating above.

-

That's a tough question Tim, it all comes down to taste but it sounds like you're not convinced. Myself, I feel that there's too much wood and too much straight grain. I think a black marble (or faux black marble) would add elegance and contrast. Otherwise a heavily figured wood, something complex and contrasty. My tuppence anyway.

-

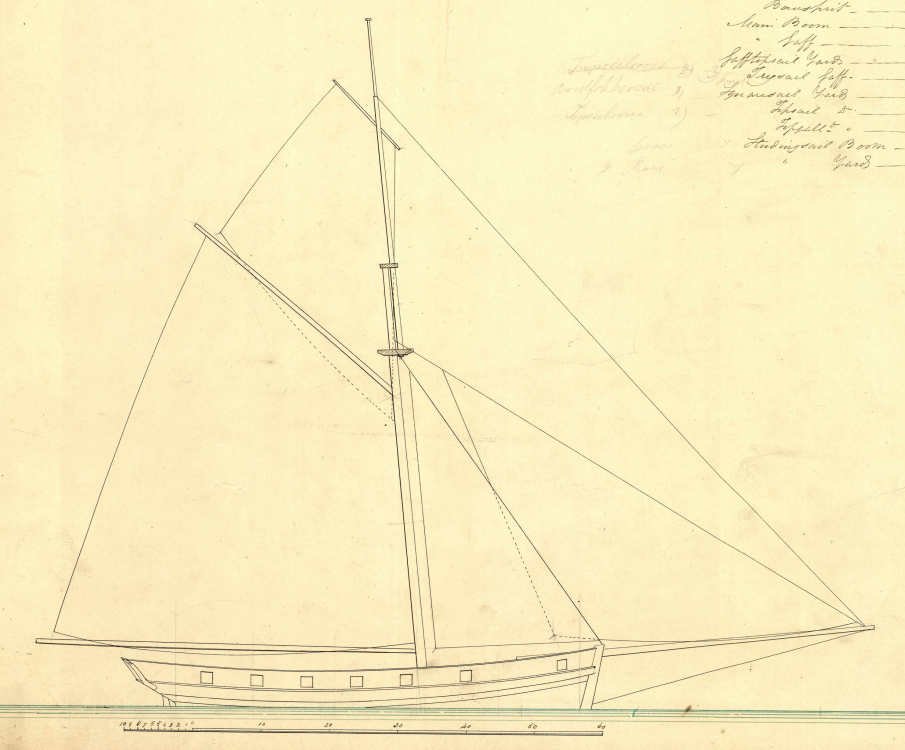

Bill, Cutters were traditionally of clinker (or lapstrake) construction. The launches, long boats, barges, pinnaces, and yawls, are carvel-built; and cutters, jolly boats, galleys, gigs, and life boats, are clincher-built. Also Cutters of a Ship, (bateaux, Fr.) are broader, deeper, and shorter than the barges and pinnaces-, they are fitter for sailing, and are commonly employed in carrying stores, provisions, passengers, etc. to and from the ship. In the structure of this sort of boats, the lower edge of every plank in the side over-lays the upper-edge of the plank below, which is called by ship-wrights clinch-work. Yawls, (canots, Fr.) are something less than cutters, nearly of the same form, and used for similar services ; they are generally rowed with six oars.

- 54 replies

-

- 18 ft cutter

- ships boat

-

(and 1 more)

Tagged with:

-

I don't blame you. I've spent about eight hours trying to draw a plug lead. 🤬

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

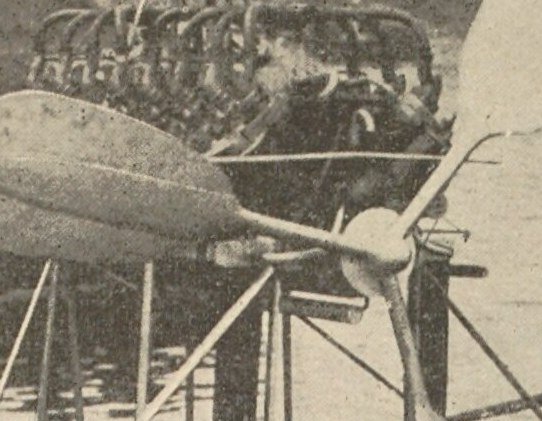

Ok, lets try this again: In this photo we see lots of oil pipes, we see the oil pump (or is that pumps?) at the rear of the engine with pipes coming out the top and bottom, we see an oil line running under and going into the front of the engine and into the prop shaft. In this photo we see a crankcase vent (fuzzy closest to the camera) and a junction block (mid engine) connecting a fuel line, coming from the rear of the engine, with the fuel lines going to the cylinders. This photo showing the crankcase vent tied it all together. This photo shows the oil pump (rear right, note the wide belt) better and a water pump (front right). EDIT: I think it shows the oil pump and fuel pump (together) and the water pump.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

You can see that in the shot above. I think William nailed it. Now, the only other shot of the tube I can find appears to have a narrower tube coming out the front then up. Tilting the head to the left when viewing helps.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

I certainly can't say for certain, they could have changed anything. The engine was designed with 'fuel injection' I put that in quotes as it was a continuous spray system spraying all cylinders at once, when the inlet valves were sucked open fuel and air were drawn in. I assume throttle was by controlling the amount of air.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Not by me, I'm certain that it's two tanks with the coolant to port of the fuel tank. It has a conical bottom like the fuel tank and is probably 'tear drop' shaped (like an aluminium mast). It shares the fuel tank mount. Meanwhile I've found a new puzzle.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.