-

Posts

202 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by oneslim

-

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Update: Have been working on a new work area. Ran a 20Amp line with a 4 gang receptical box. New Oscillating Sander by Shop Fox. Good deal from Amazon.com at less than $160 with free shipping. Makes lot of noise, but can't beat the price. Craftsman 16" Scroll Saw. Its been sitting in the box for three years. Very smooth with not much noise. Needs pin blades, haven't found any with a small front to back size. Harbor Frieght Micro Mill. Love this mill, the 'Z' axis fine adjustment is the dial just above the light. Still need a tilting table. And the last item is a Brynes Disc Sander. What a dream to use. Makes fast work of chocks. Bob Wescott -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

BOY.....Ain't that the truth! Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Thanks Trussben and Greg, I had a great time and learned much. Re-doing the shop now to set up the scroll saw that's been sitting around. Then to get a Oscillating Spindle Sander and a disc sander, then I'll be set. Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

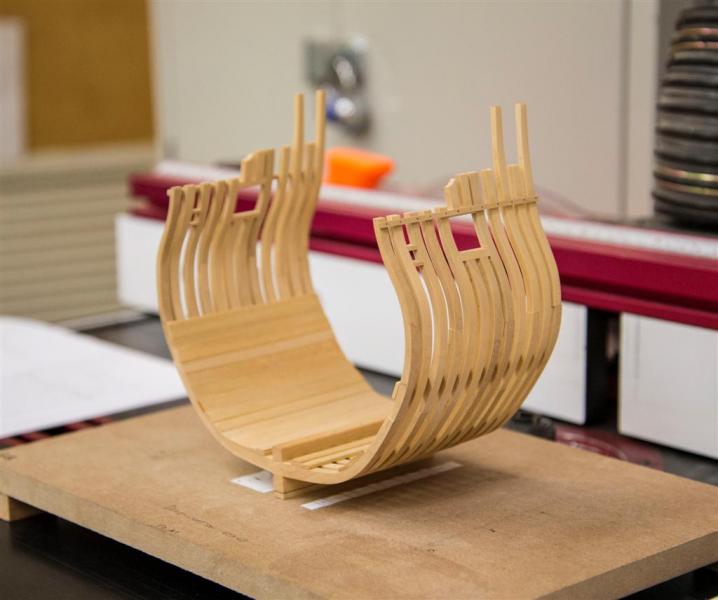

More workshop photos Greg showing Jim, Joe, and Pete the ins and outs of the Sherline Mill. David giving some instructions to Norm. Hard at work. Greg's full hull work in progress. My first frame. Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Workshop photos. Some of the class hard at work. Doing scrollsaw work. Layout. Greg's Echo crossection Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Thanks Rustyj, I have followed Your work for some time, allways excellent. Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg, I had the lexan on hand and wanted something that would not change over time . Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Thanks Christian! -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Cap'n Rat Fink, Thanks. Dave, Thanks, see You next week. -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

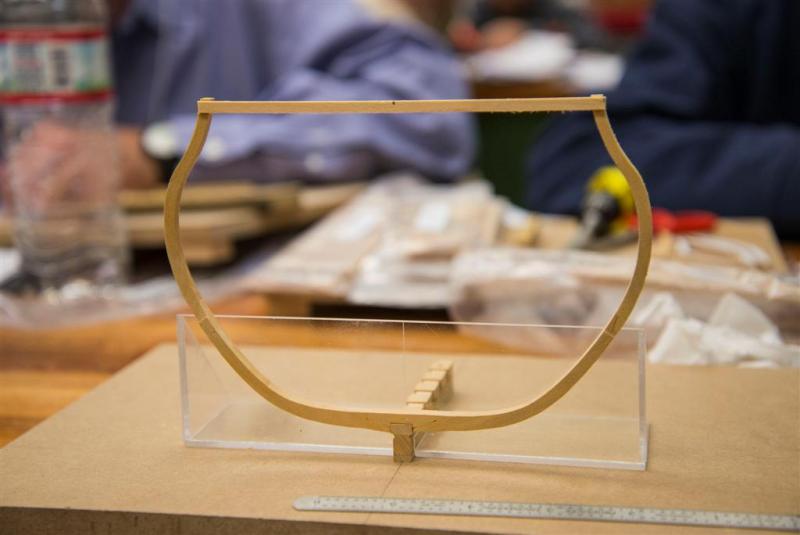

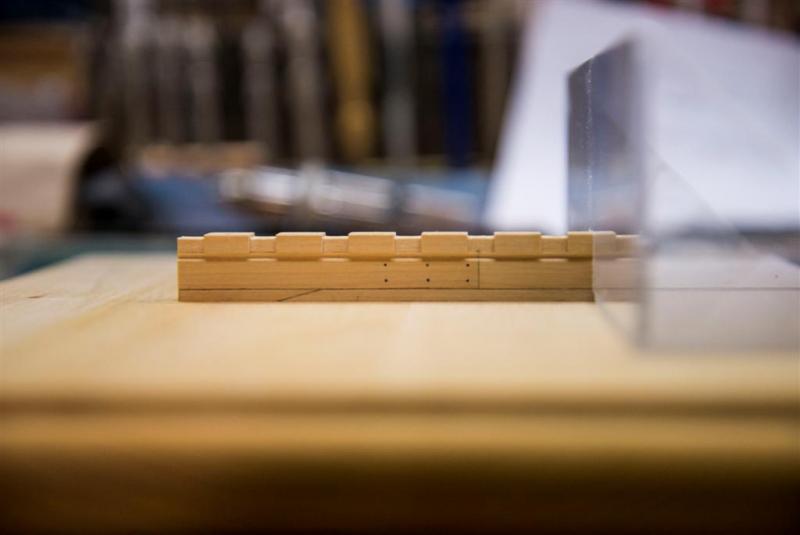

Well my homewok is done. Went ahead and mounted the Keel to the base to check the Frame Squaring device. Profile End view Bob W -

Echo by davec - FINISHED - cross-section

oneslim replied to davec's topic in - Build logs for subjects built 1751 - 1800

Hi Dave, Very Nice! See You in two weeks at the workshop. Bob W- 127 replies

-

Echo by jml1083 - cross-section

oneslim replied to jml1083's topic in - Build logs for subjects built 1751 - 1800

Jim, Looking Good! Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

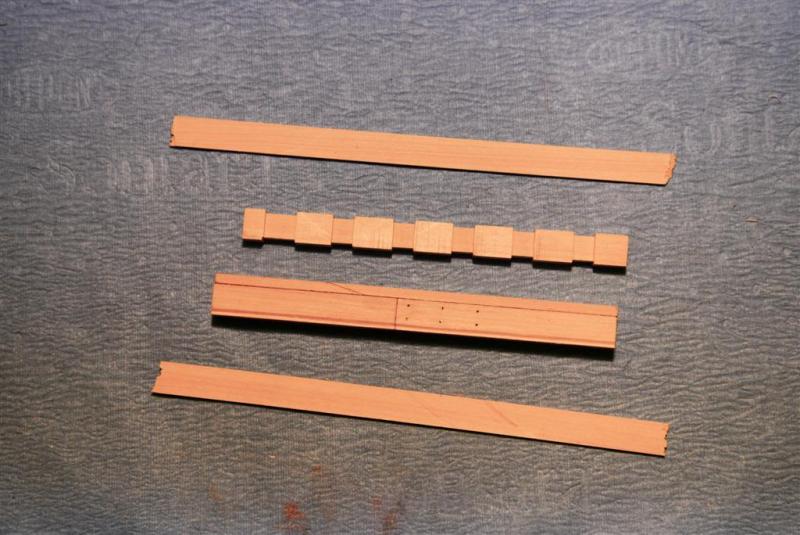

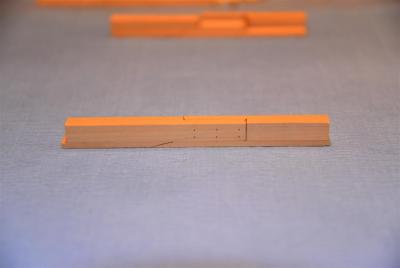

Update Here's a shot of the parts before attaching the Rising Wood. It shows the two 1 1/2" spacers to make sure the Rising Wood is centered over the Keel. All clamped up. More to come. -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Hi Jim, Used some 0.020" hard brass wire from a spool I've had for over thirty years. Can't remember where it came from. The holes in the keel parts were drilled with a sensitive drill chuck in a 8" drill press. Both halves were marked then drilled. The bolts were blackened with some brass oxidizer from a engraving shop that I've had just as long. Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

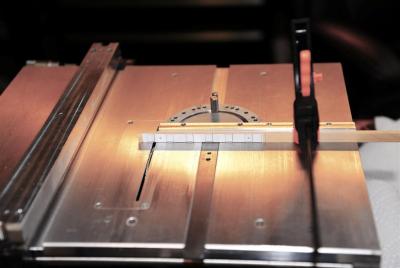

Working on the Rising Wood. I didn't think I could do a clean job of the three faces on the saw. So I used a stop clamped to the miter gauge to make sure the corners were sharp. -

Echo by jml1083 - cross-section

oneslim replied to jml1083's topic in - Build logs for subjects built 1751 - 1800

Jim L, Hi, nice work so far. Looking forward to meeting You at the workshop. See You soon. Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Bob, No, South Jersey born. My other hobby is 1:20.3 scale live steam narrow gauge trains (D&RGW). In 2003 spent two weeks doing the Narrow Gauge Loop, love the high country. Bob W -

Echo by oneslim - cross-section

oneslim replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Mark, I will test any finish I use. Thanks Bob, what area of Colorado You from? Bob W -

Hello Everyone, I will be attending the upcoming Admiralty Models Workshop on the Echo Class Cross Section given by David and Greg. I'll start by saying I messed up the parts Greg sent by using a black construction paper that was too thick. No shop in my area had any of the correct paper. So I sawed up some boxwood I had on hand from Hobby Mill and started over. What I came up with was some tissue paper that I colored with a brown 'Sharpie'. This seems to work ok. The False Keel The Keel and False Keel And the jig made for holding the keel for the carving of the Rabbet More later, Bob W

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.