-

Posts

183 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaffrig

-

Hello! Looks like you’re of to a great start!👍 I have just finished this kit and had a great time building it! Gaffrig.

- 20 replies

-

- Le Renard

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Jobbie, thank you! I’m glad you liked it! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello. Thank you all for the kind comments! Rick01, you are right, bilge pumps would absolutely be a great addition. Maybe I’ll have to make a couple and put on there.. 🤔 Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

You are correct. When tacking or gybing a schooner like the one in your plan, they had to loosen the downhaul, while someone aloft hauled the topsail over the stay and peak halyard. They had a downhaul on both sides, so once the sail was lifted over, the other downhaul was tightened. hope this claryfies a little! Gaffrig.

-

Moltinmark, thank you! I think the cannonballs and barrels fit right in! Any privateer with some self respect needs some shots for his cannons! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all. I've finished up the gunport lids, and tied and coiled the rest of the running rigging. The instructions call for what I think is lifebelt boxes on deck. I've decided to drop these as I think it looks a little cluttered on deck with them. Then again it looked a little empty without, so I decided instead to make a rack with two barrels and two cannonball racks. Dryfit of barrel rack. Barrelrack stained and glued in place with barrels lashed down. Dryfit of cannonball racks.. Stained and glued in place with cannonballs.. And with that I think I'm gonna call this model finished.. 😄 Maybe I'll add some more small details, but I need to let the model sit for a while and think about it. That's it! Stay safe! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all! Work continues, the finishline in sight! Got all the sails rigged, and the running rigging finished. (I think!) Got the deckhouses/skylights glued in place. Have also been mounting the gunport lids.. Still a few loose end's to tidy up, but it's getting there! That's it for today's update. Stay safe! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Tompslattery, that’s great to hear! Glad to be of some help. This makes keeping the buildlog going a lot more fun, knowing that it is useful to others! 😀 Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Thank you for the kind comments and likes! Rick01, yes, I’ll go with just one anchor. I’m sure they had at least two onboard the real thing though. Let’s just say they have the spare one below! 😂 Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

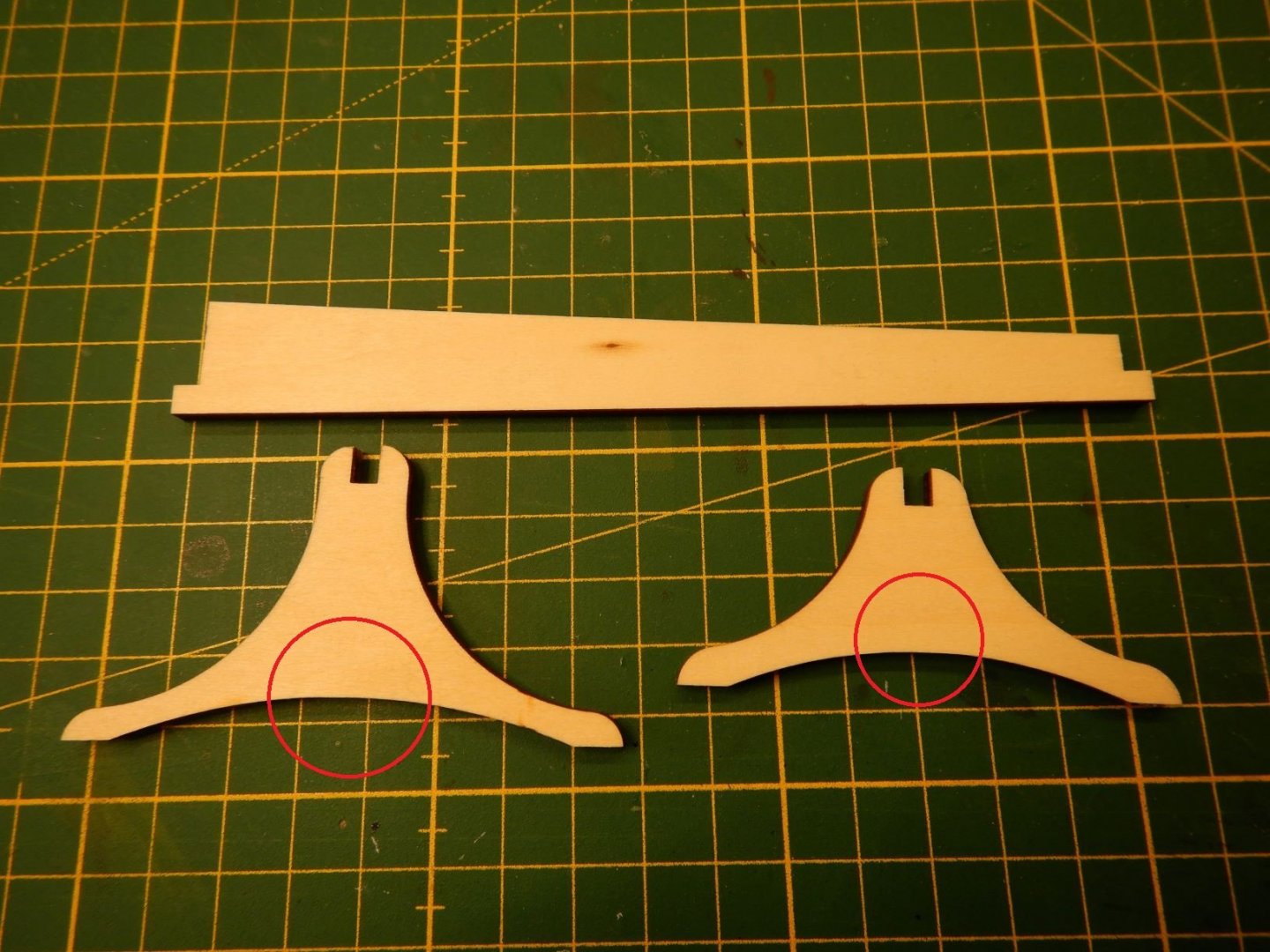

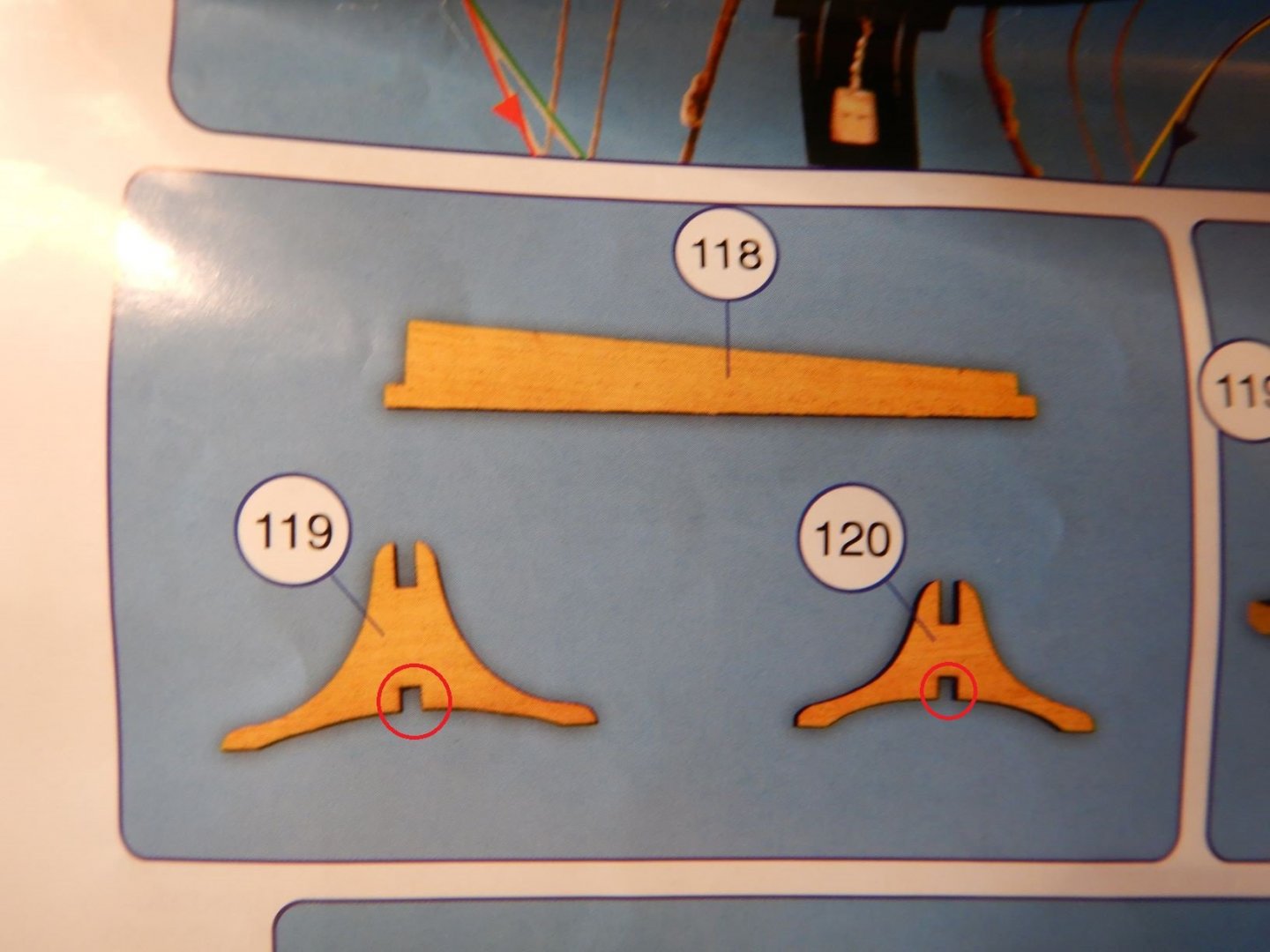

Hello all! In between all the rope coiling, I started the cradle that comes with the kit. It seem like there has been a glitch in the lasercutting as the pieces in the kit are missing the two notches for the crosspiece. (see red circles in pictures) I cut out the notches, but then decided to make a different cradle alltogether. I don't like the idea to have the model balancing with the keel in two small notches. So i cut out and glued together a contraption of some wood I had laying around.. Gave it a couple coats of oil and ended up with this.. I finished painting the scrollwork/nameplate and glued to the transom. I'm not happy with the result of the whit paint here, but I couldn't get it better with my limited painting skills. If anyone has a tip for painting small photoetched brass parts in more than one colour, feel free to share them! I also finished the crossbeam on the davits and added the "boomkin" piece as suggested by Rick01. I also replaced the blocks and hooks for the dinghy hoist with smaller size ones. Now the dinghy comes up pretty snug to the davits and I think this looks better. Stay safe out there, and happy modelling to all. Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Rick01, thank you for the tip. I've actually thought about exactly that, that a boomkin of sort would be good. I'll probably go for the same solution. Gaffrig

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all! A small update of todays work. Have been working on ropecoils for the most part, and have finished up (I think!) the coils on the pinrail around the mast. I'm using a mix of toothpicks and tweezers to get the coil to hang as I like it and then brushing some dilluted wood glue on it. Seem to work ok, although a little time consuming. The thread supplied is quite "hairy" but it is what I have. It seems worse in the pictures I think. Between coiling I have finished the anchor, and dressed(?) the ring. Or is this called served? Upon testing the anchor cable through its fairlead I realised the fairlead was to small. (or the cable to thick) I decided to find a replacement for the fairlead and got the idea that end terminals for electric cable would be good. So I found one of right diameter and hammered the end a little more to get a nice flange, and painted it black. Picture shows kit supplied part to the right. Homemade to the left. Then I drilled a hole in the bow and glued inplace. This, as discussed before in this thread is probably historically uncorrect but I have decided to follow kit instructions here.. I then proceeded to tie the cable to the anchor and mounted the anchor to the rail. I'm happy with the result! Now on to more tying lines and coiling! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Barkeater, thank you! Rick01, I’m also making a few changes from the instructions, so I’ll probably end up around that number! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello. The work continues.. Have mounted the stern davits, following Rick01's advice and beefed them up to double thickness. This looks a lot better to my eye. Still needs the crosspiece in the back. Had to testfit the dinghy and I think I'm gonna replace the hoist blocks to smaller ones to get the dinghy closer to the davits. I also gave the catheads the same treatment, and beefed them up to double thickness. The first ropecoil inplace.. I see a lot of coiling in my near future! Got the outer jib on, and started on the mainsail. I'm not superexcited with how the kit supplied sails look, but have decided to use them anyway. Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello. Tompslattery, thank you! Another small update, have started with the sails and their running rigging. Started with the squaresails on the yards. These were lashed to the yardarms using thin sewingthread and needle. The yards were then rigged to the mast as per the instructions. The sheets are still missing in this photo. Got the jib in place using the small brass rings supplied. Things are slowly coming together here.. Also started painting the stern ornament/nameplate. Still needs white paint where there is bare brass in the picture. That's it for todays update. Stay safe and happy modelling in 2021! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello to all. Sorry for the long abscense here. Got a waterleak in the bathroom that ended with a complete rebuild... This has eaten up all my modelling time the past month and a half. Seeing the end of the bathroom fix now, and hopefully some more modelling! Tompslattery, those instructions look even worse than the ones I have. I have the same ones that Moltinmark posted. Have done a little bit in between bathroom work. Have finished the standing rigging. Really enjoy the rig work. Even the ratlines was fun to do! Time to start the sails and the running rigging. Feels like I'm getting closer to the finish line! Stay safe out there and a happy new year to all! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all! Another update here as the work continues. I've made the bitts/samson posts for the bowsprit. Painted them and mounted them and the bowsprit to the boat. I decided to make a bolt to hold the bowsprit. The instructions just say use glue. I've made the pinrail around the mast and painted and mounted on the boat.. I've stepped the mast and got the lanyards in and tightened.. Dryfitting of the deckhouses/ skylights. The forward companionway is a little off in this picture.. 😂🤣 The pinrail in it's final position.. Started tying the ratlines.. I'm really enjoying this part of the build, the rigging that is.. The rigging instructions is not very good and self contradicting many times. I do have expert help in reading them, but the expert doesn't understand either... 🙄 That's it for todays update. Stay safe, and happy modelling! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello. Thanks for the kind comments and likes! Another update here. Got the "height adjusters" in place so the gunbarrels are more or less straight. Painted the channels (I think this is the right word for the "chainplate spreaders") and glued in place. Made and glued on the steps. I made the chainplates. I decided to solder a ring to the chainplate instead of just twisting a wire around the deadeye as the instructions say. I've painted and glued on the pinrails.. And I've mounted the chainplates. Things are starting to come together, and it is looking more and more like a boat! That's it for now. Stay safe out there, and happy modelling! Thanks again to everyone for taking the time to read and comment here. It's really inspiring! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello. No worries about hijacking! It's all good info. I have been looking at the rigging instructions and there seem to be a lot of simplified solutions compared to the real ship. I will probably make some adjustments as necessary. A small update for today. Have finished the rigging of the carronades as I think this will be good to get done before I start the rigging of the mast. I think the access after the mast is up will be limited. I made up two tackles, one with the kit supplied blocks, and one with aftermarket 3mm blocks, as suggested by Rick01. I decided to rig the blocks with rope instead of wire as I think this was easier and better looking. When using the kit supplied blocks the whole tackle ended up too long to fit, so I went with the aftermarket ones. The first one fitted on deck.. Time for some mass production.. Quite time consuming making all these small tackles, but a good feeling when they are all in place! Now I need to glue in place all the little "height adjusters" to get the barrels straight. That's it for now! Stay safe! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Rick01, That looks great! Congratulations on the finished model! 👍 I see that you have made a diffrent stand for it, I’ve thougt about the same thing as the kit supplied one is a little wonky.. Are you gonna add the sails? The ones supplied are not the greatest but I’m gonna use them anyway. I like how the dinghy turned out. It may be a little to «yacht like» for this model, but that’s how it will be! Thanks to everyone for looking in and liking! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello! Another small update. Been working on finishing the dinghy. Finished the caprails, and made the thwarts and floorboards. Made the rowlocks and decided to put a rope fender along the rail. Finally I made a pair of oars out of toothpicks and scrapwood. Also mounted two eyebolts to take the hoist from the davits. With this I think I'll call the dinghy finished! Stay safe! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all! Long time since the last update here.. Now that fall is here there will be more time for me in the shipyard again. Some work has been done on Le Renard inbetween other chores.. I've made the bollards to go inside the bulwarks. I've painted them, and made a small jig to file out a small groove for the caprail, since I made the caprail a little wider this was needed. I've filed/sanded the cleats that also go on the bulwarks, and painted them. A lot of burrs/edges that needed trimming on these. I've finished the "bench" in the stern over the tiller, and mounted all the bollards and cleats. I've drilled the hole for the bowsprit. Must say I was a little scared to do this, but with a sharp drillbit it went great! I've also finished the mast, booms and yards. All in all, things are coming together here, and I look forward to start rigging! All the best, Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all! Been a few days without internet here, but that translates into more time for modeling! Rick01, Thanks for the link, great pictures of a beautiful model. And probably a great book too. Regarding a traveler, looking at the pictures in that link, that is the way the travelers was rigged. I think I'll follow the Instructions more or less as they are, and rig without a traveler. The weatherforecast came true, with lots of rain and indoor time. 😆 So quite a bit has been done on the model. I've got the caprails painted and mounted. When dryfitting the transom I was not happy with the way it fit, so I glued on a strip of wood to the bottom to make it a little higher, and that made it fit much better. I've made the rudder fittings and fitted the rudder. I've fitted the "thingys" on the bow, don't know the english word for these... I've made the caprail(?) for the dinghy. I ended up laminating this from mahogany to get the right shape. And painted the interior white. Here one side is glued and sanded, the other waiting to be glued.. So, all in all a pretty productive weekend. Looking forward to start rigging. Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello all! Sorry for the long abscense, but we've had a couple of weeks of absolutely beautiful summer weather! So sailing and playing with fullsize boats has been enjoyed! Now there's a weekend of heavy rain forecast, so great modeling weather on the horizon! Rick01, Thanks for all the tips. they are much appreciated. About the rigging plan, it seems to be much simplified in many places. Single blocks on foresail halyards is one example.. I would think that the bowsprit in a vessel this size would be retractable and the tackles on the bobstay and sidestays also suggests this. Both of the jibs however is hanked on, and this would mean that no in/outhaul would be fitted. In/outhaul is normally used when the sail is set flying with or without stay. This is just my own (limited) knowledge of how it is done on boats I have sailed on. When it comes to books, I don't have any specific ones regarding vessels from this era, but I do have some more general ones. I think I'm going to build/rig this more or less as the plans show, even though this is not completely accurate. Also many thanks to all others for liking and commenting! It is very much appreciated and very motivating! Not much progress lately because of sailing, but some has been done. Glued on the rubrails and I made the mistake of gluing the top one first, which made clamping the lower one difficult. Did this lower one first on the other side! Also glued on the trim(?) along deck inside the bulwarks. I've also prepped the caprails with glueing on a thin strip on either side to hide the plywood endgrain and make them a little wider, as they barely cover the top of the bulwarks as is. Next up is to get them painted and mounted so I can mount the transom. That's it for now! Stay safe! Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

Hello to all. Been away sailing for a while, gotta play a little with the big boats too! Have been back at it for a couple of days and here's a little update. Rick01, I like your beefed up davits, they look great! Definetly something I'll copy when I get there if you don't mind. Your version of the forward pinrail looks great too! Something to think about. I've been thinking about the anchorcable, and maybe it would work to make a horisontal capstan on the bollards/bitts that holds the bowsprit? Might be tight between that and the forward companionway though. Rick01, you mention the bowsprit, here's how I did that. In between different coats of paint I have made the bowsprit. The kit supplies a 8mm round dowel that is supposed to be formed into a 8x8mm octagon... There's an interesting task for you! 🤣😂 I ended up sanding it square and glueing on pieces of 0,5x3mm mahogany from the Bluenose deck I'm not using. Then sanding "between" the square to get the octagonal shape. This turned out good enough. After sanding.. And painting.. For shaping the rest of the bowsprit I used a small planer first, and then put the whole thing in a battery drill and sanded it smooth. Finished it of with linseed oil. Also made a new fitting for the tip. I've soaked and shaped the rubrails, and started painting them I've masked and painted the black stripes, and cleaned up and painted the insides of the gunports. Still need a little "cleanup" here and there, but all in all I'm happy with the result. Gaffrig.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.