drumgerry

Members-

Posts

96 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drumgerry

-

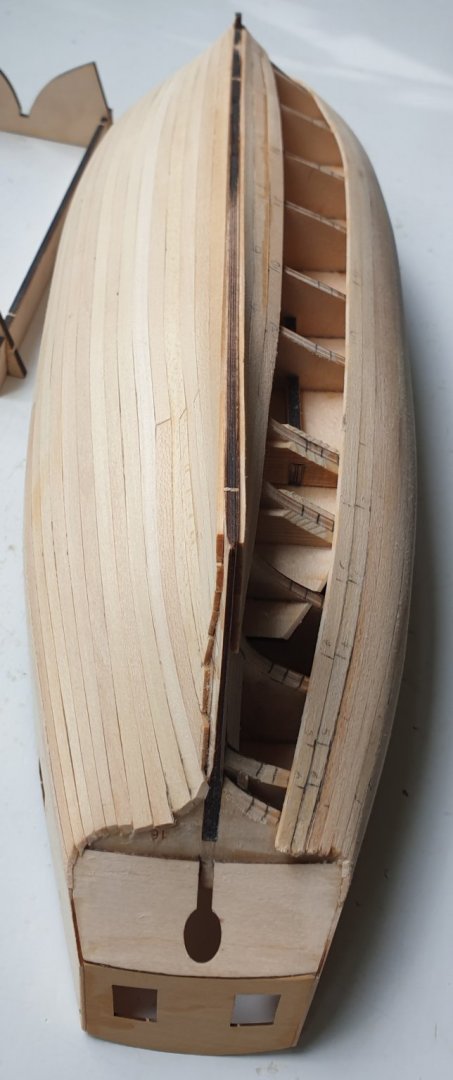

I bought this kit from Chris last year with great intentions. However life has taken over and I find myself needing to sell a few things. It is part built as you can see but I think it is at a decent standard. It is at the stage where second planking is needing done. There are two sets of Chris' boxwood planks in the box for that. Everything else is there and in a brand new condition. I'm looking for £225 incl postage by PayPal. This is a hefty discount on the kit as new which is £450. UK shipping only I'm afraid. All the best, Gerry Thompson (based in Moray in NE Scotland).

-

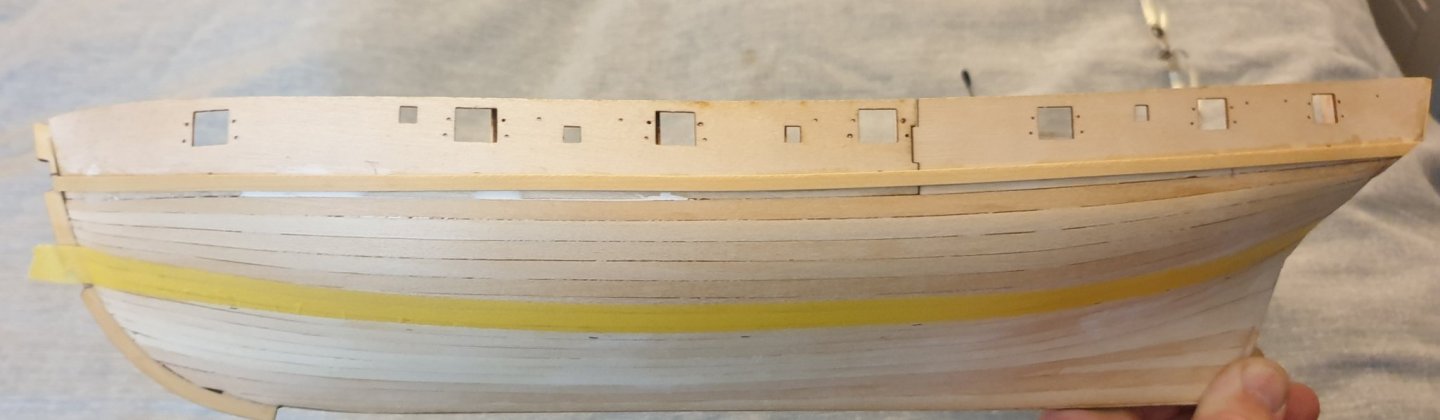

When doing the first layer of planking I miscalculated how many planks had to fit into the space particularly at the stern where I had to use stealers to make up the gaps. As a newbie it was my lack of understanding of the process. Actually getting some practical planking experience it's a little clearer now in my feeble mind. So in anticipation of doing the second planking I feel I need a proper sense of the space I'm dealing with and how many planks need to go into it. To that end I've measured the distance from the master plank down to the keel and marked a midpoint at various points along the hull. I've used this as a guide to divide the hull into two approximate bands with tape (the lower edge of the tape marks the bottom of the top band). The line that the planks will follow looks OK to me I think. I'll make up tick strips next for each band for 10 planks for the top band and 11 for the bottom. Hopefully I'll end up with a neat and relatively even result. Most of it's getting painted anyway so it doesn't really matter that much. It's all part of the learning process for me though. Cheers, Gerry

-

However you get it done it's fine as long as it gets done eh Spyglass? Sounds like you do just fine. One of the good things about the chisel thing demo'd above is that it's slow and with a sharp chisel not much pressure is required. The older I get the slower and steadier I like to take jobs. It gives me more time to spot a balls up coming along! Cheers, Gerry

-

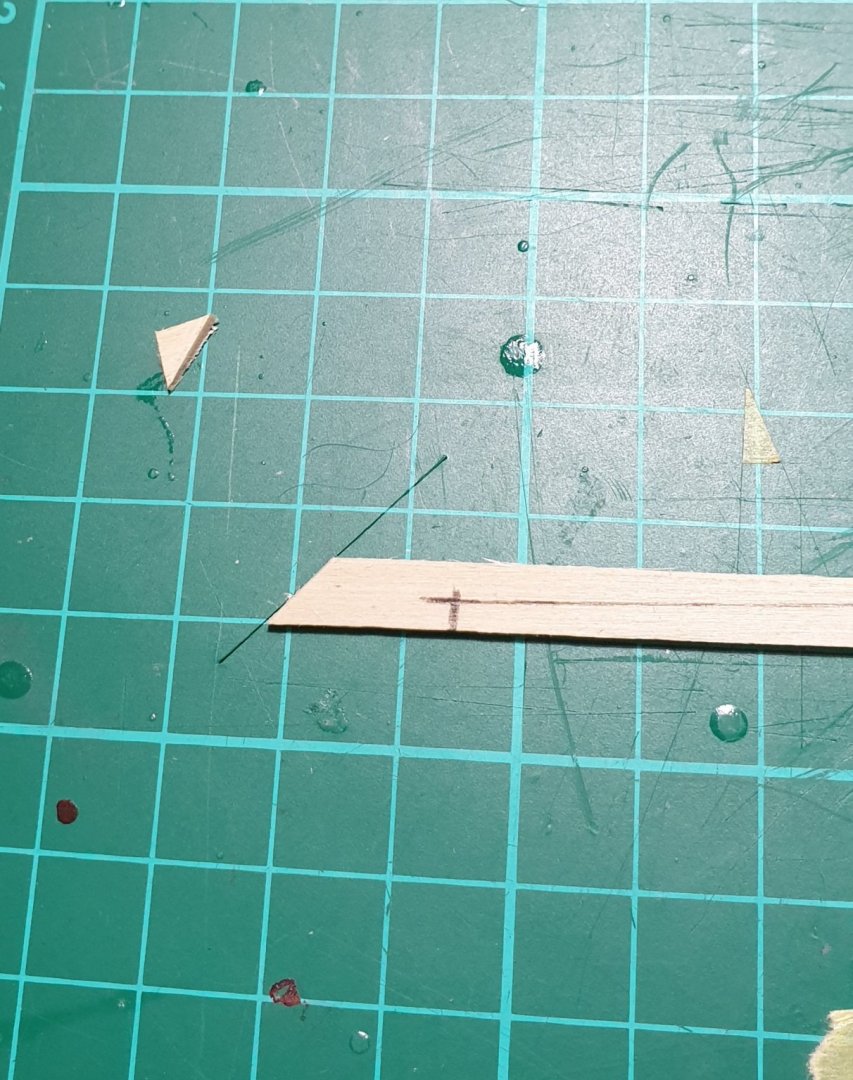

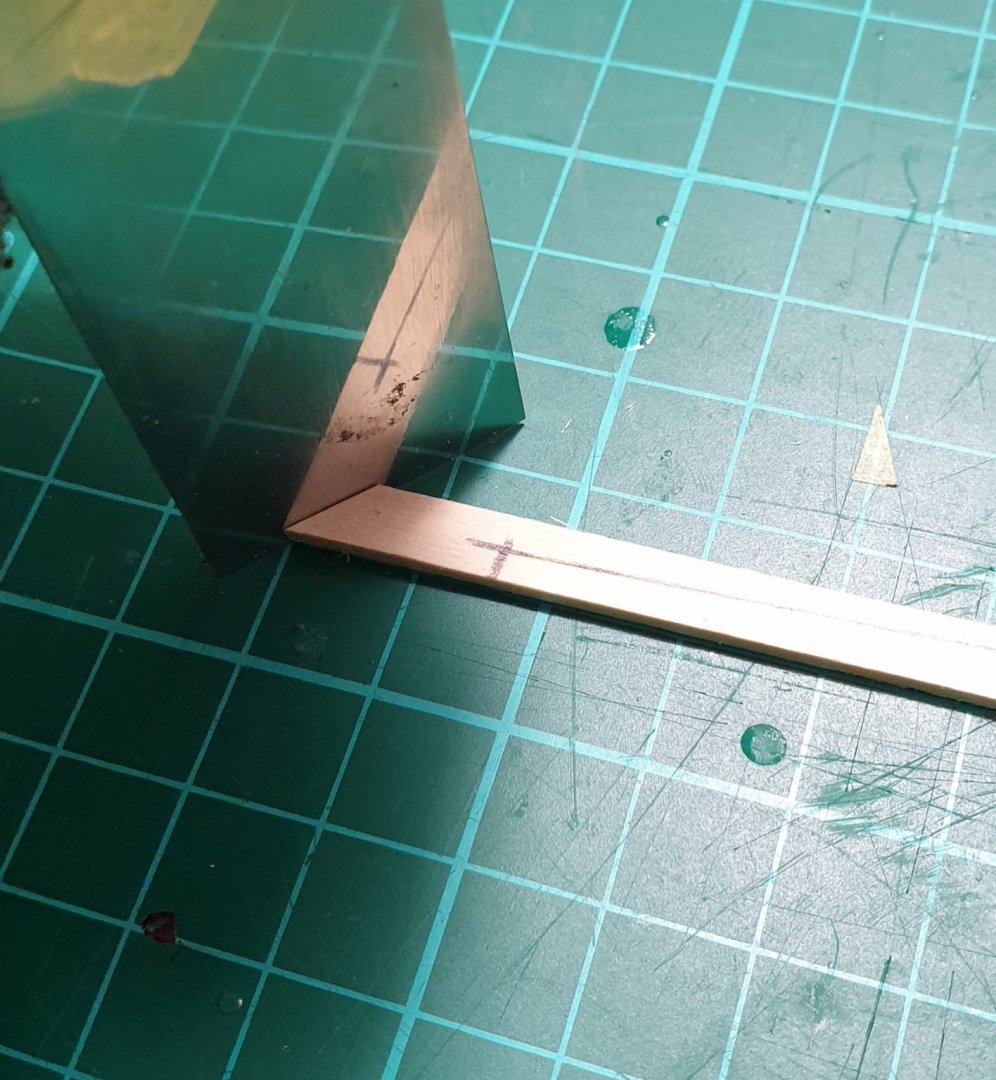

I thought I'd post this wee tip here as I used the technique when I was doing the drop plank on Flirt. You probably all know this already and I don't mean to teach yer granny to suck eggs but it might be of use to someone reading this who's never seen it. OK... So instead of using mitre boxes, fine tooth saws or any other gizmos here's a quick way to get a perfect 45° cut every time. You need a large-ish chisel (1 inch plus) and it needs go have the back polished to a shine. If you have the chisel but not the shine a flat surface and ever finer wet and dry papers to a minimum of say 1500 grit will do the job. Line your strip of wood along a straight line on your cutting mat and use the reflection of the chisel to cut your 45. The pics below will make it clear if my explanation doesn't. I should have made the cut using one of the boxes on the cutting mat to make it very clear but I re-lined it up after the fact for the final pic to do that. Hope it's of use to someone. Cheers, Gerry

-

Lime is also used as linings for musical instruments which is why I have some lying around. You'd need to be able to thickness them down if you bought them from here for example... https://shop.exotichardwoods.co.uk/lime-plain-lining-770-x-18-x-6mm.html I have two huge planks of lime about 2 metres tall, 12 inches wide and 2 or 3 inches thick that I haven't quite got around to dealing with yet! Cheers, Gerry

-

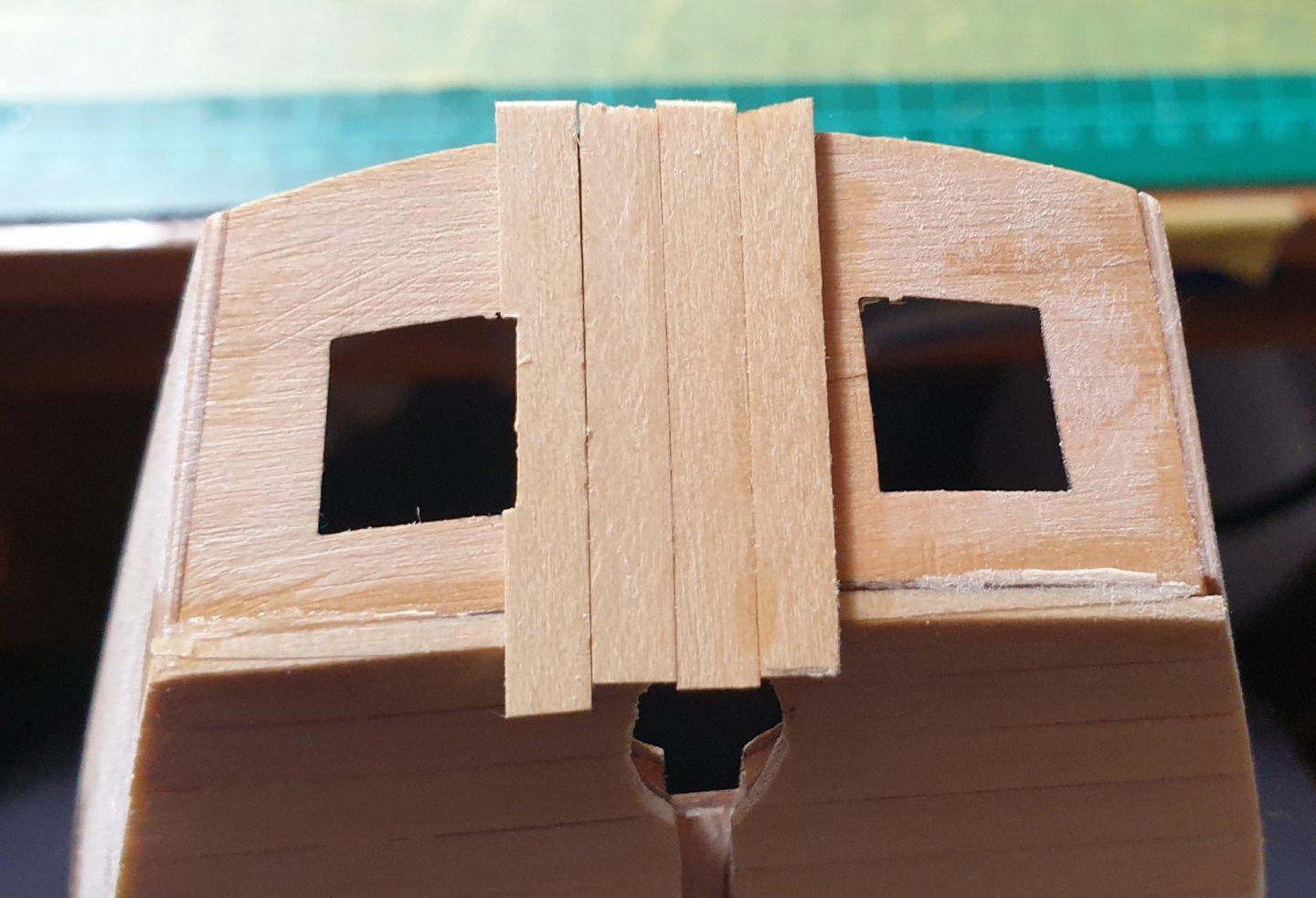

Well 'fancy' might be pushing it a bit Spyglass! Not a trick of the photo - good spot! I had a 6mm gap at that bulkhead and 5mm strips - I wanted to make the join at a bulkhead. Luckily I had a length of 12mm wide x 1.5mm thick lime wood lying about to cut a wider drop from. Looks a bit off but hopefully I'll plan things a bit better on the second layer of planking. Cheers, Gerry

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.