-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CTYankee

-

@DougTx Welcome! You might be able to tell from the chart in my profile we come from the same general area of CT. @Ryland Craze That dory model looks fantastic. I think I am going to order it as my first plank model to complement the solid hull model I am working on now.

-

Hello! From another brand new ship modeler.

-

One thing that I am thinking about is using pre-thinned paints to get started learning. They'll be more expensive and the palatte might be more limited but it should help figure out the brushing technique before I work on the thinning. Anyone have any thoughts on this?

- 40 replies

-

- best airbrush

- compressor

-

(and 1 more)

Tagged with:

-

I just bought the badger 150 through this forum (thanks Kurt!). I was initially a little worried about double action being too hard but I played around a bit with it last night and it seems great!' I have a small 3gal air compressor that I use around the garage and that seems to be working just fine. Best of luck!

- 40 replies

-

- best airbrush

- compressor

-

(and 1 more)

Tagged with:

-

Hi All- Can anyone point me to some good tutorials (video or otherwise) on brush application of enamel paints, preferably on wood? I am a total painting newbie. I just started priming the hull on my first model and am scratching my head. FYI- I am using True North paints that came with my Blue Jacket kit. I know lots of folks like Acrylics but I am trying to stick with the paints from the kit because as a beginner I am hoping to work through the kit with as few 'ad ons' as possible so that other total newbies like my self can try to emulate without buying a whole bunch of extra stuff. To that end, I am not using the brushes in the kit at this point because they seem too small for the large surface of the hull. I am using the 10mm brush from this kit that I had knocking around like these: https://www.amazon.com/Artists-Loft-Fundamentals-Natural-Brushes/dp/B01CV00MQS. I have been practicing on various scraps etc and am having trouble finding a recipe. My questions are generally around: 1) Thinning- I have gotten droppers so I can be precise with dosages but cant find a good balance between something that goes on without at least some amount of brush strokes and something that is basically a wash. I cant seem to get that nice self leveling I have heard so much about. 2) Sanding- the instructions in my kit manual suggest I sand, prime, sand prime, etc. When I do those between coat sandings how much am I looking to take off? If I try to get it smooth and get rid of the ripples left behind then I end up sanding through in some areas. Should I use a block and just hit the high points, use a block to get something that resembles smooth and worry about the sant through on subsequent coats, or go our every surface with a compliant finger (hitting the highs and the lows) to take off the haze and then re-coat and worry about a perfectly smooth surface after I've built up a number of coats? What grit would you use. The smoothest the kit comes with is 220, which takes off way too much. I'm experimenting with 600, 1000 and 0000 steel wool too. 3)Coverage- the kit I bought came with one 5.4oz (16ml) bottle of primer. Is this really going to be enough to get the hull primed 'to resemble fiberglass' as the instructions state, and then prime every other bit in the kit? It seems like even thinned out I am going through it fast- granted I have done a bunch of practicing, etc... I apologize if I missed a thread on this. I searched far an wide before posting but couldn't find anything. But, my wife will attest, I'm a bad looker. I think she is referring to my ability to find things...

-

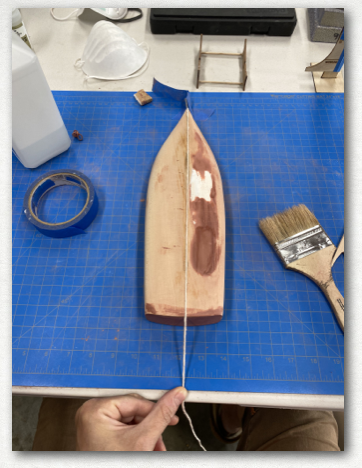

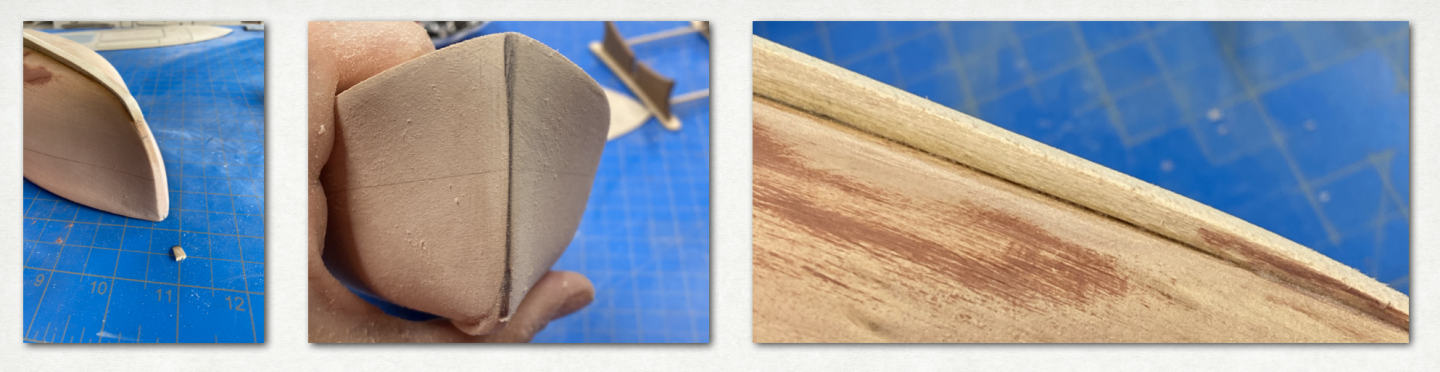

Onto the keel, but first… I sanded the well deck. The guide instructs to do this after attaching the keel but given how rough it is in there I felt that I would be better doing this first as not to manhandle the boat too much after the keel was on. I tried a few things to find the centerline of the hull along the bottom. This is much harder than the top where it was relatively easy to make relative measurements. Because of how the keel tapers i just couldn’t find good references. So here is what I did. I used to the centerlines that I measured on the top of the hull and transferred them just a tiny bit around the stem and the transom. I took both of those reference marks and aligned them to the lines on my cutting mat. I then taped a string to that reference line (not too close to the bow) and draped it over the boat and aligned it on the stern end. Then being very careful that the string wasn’t chasing some errant bit of curvature (it would do that if you tried to pull too tight) I marked a few reference dots on either side of the string. Then I connected the center point between those dots to create the line down my hull. The reason I have been fearing adding the keel is that a) I am sure i will break it off at some point and b) in an dry fit early on I just couldn’t see how i was going to get this thing to fit. Its shape seemed significantly different than the hull at the stem. The first picture, above, shows the keel aligned to where it ‘should’ be if I placed it according to the distance that the rear or the keel should be from the edge of the transom. As you can see there is a good gap there. I don’t think that this was a result of the initial shaping of the stem as there was never material removed from that far down. Instead I slide the keel back until its tip really tightened up around the stem. It means the keel is ~3mm further back than it should be. I hope it doesn’t affect the stability of the craft above 50 knots. After scooting the keel back the fit to the run of the hull isn’t great. It seemed way more than I’d want to just sand to fit and certainly way more than I’d want to close by brute force with glue. I read a number of other posts about soaking planking wood to help with forming it so I decided to try that. I soaked the keel in 95° C water for 10 minutes then clamped it in place for 24 hrs to see if it work take on a more complimentary shape. I thought about glueing it up whilst soaked but I didn’t for a few reasons. I plan on using wood glue to place the hull because I am afraid that if I used the CA that came with the kit it would set before I got the keel aligned and I’d be forever staring at a cocked keel. But the wood glue i have says to apply to a dry surface. I think some glues, like one of the Gorilla Glues, actually want you to wet the surface first, but that’s not what I had. After releasing the clamps i had some spring back but not much! After a little sanding I glued the keel in place using Titebond III. The directions clearly state not to use the product for joints below the waterline, but I think its okay to make an exception in this case! In the process of sanding the keel before it was glued I broke off the tip. D’oh. After the keel was glued to the hull I glued the broken bit back on with CA. Most of that got sanded away during the final shaping of the stem and the blending of the keel but I think having it there was important. I noticed some small gaps running along the seam between the keel and the hull, most likely due to the edges of the keel piece part getting rounded off during pre-sanding. I filled that with the glazing putty, which was a pretty fussy application in such a small crack. Are there better fillers for gaps like this? Keeling over…

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

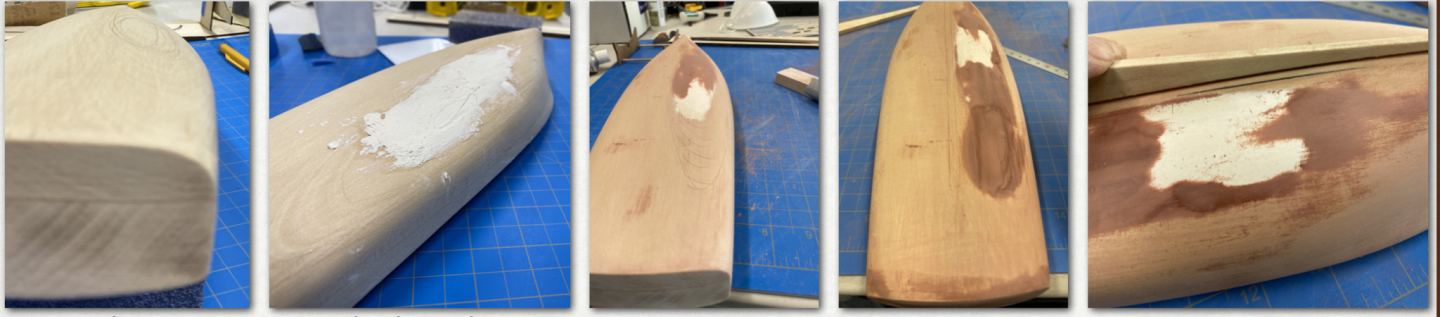

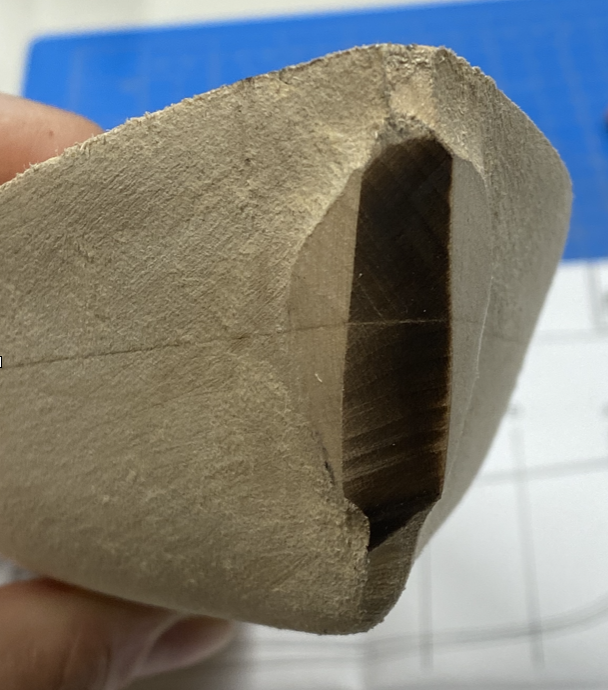

Time to brave some serious body work… After getting the bow shape pretty close to where I want to to be I notice that the remainder of the hull had a distinct concave curvature to it on the port side. This was well past an area where I had been sanding, so, this was not my fault (fhew- I was worried for second there). What I noticed is that this area is exactly aligned with a set of growth rings in the grain of the wood where it look like the trunk was growing a branch (though i’m not an arborist so this might be baseless speculation). It creates a really noticeable asymmetry in the hull. I don’t know if it will be visable after the keel breaks up the sight lines and the paint is on but i’m not going to chance it. I broke out the wood filler that came with the kit and found it hard to work with. Putting H2O in a dropper and dripping one drop at a time to mix i still had a hard time nailing a consistency that was workable that also didn’t harden up before I had gotten it all to where it needed to be. After that coat hardened I sanded smooth I transitioned to the auto glazing putty that so many speak highly of. I used the Bondo Glazing & Spot Putty. It goes on much more smoothly, but its working time is also not super long so you need to work fast and then resist the urge to keep soothing because after some point you just start making a mess. Accept what you have and then sand it to where you want it to be. I coated, sanded, checked, coated, sanded… Sanding to shape is truly an art form. It's easy to sand wrong and get flat spots. You just need to go light and easy modulating pressure to help blend into the bare wood. I used the 220 grit sand paper here (any coarser would gouge). I even used 0000 steel wool when I got towards the end. I learned to close my eyes and trust my fingers when trying to feel if I had god curvature. My eyes played tricks on me as they confused changes in color (between wood and two filers) with change in curvature. I won’t lie- this step of shaping the hull took a long time but I am much happier with the symmetry of the hull. Its for sure not perfect. I would love to learn from the body shop folks who do this down to perfect curvature continuity. Onto brave the keel. A step that I have been dreading for reasons to be revealed shortly.

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

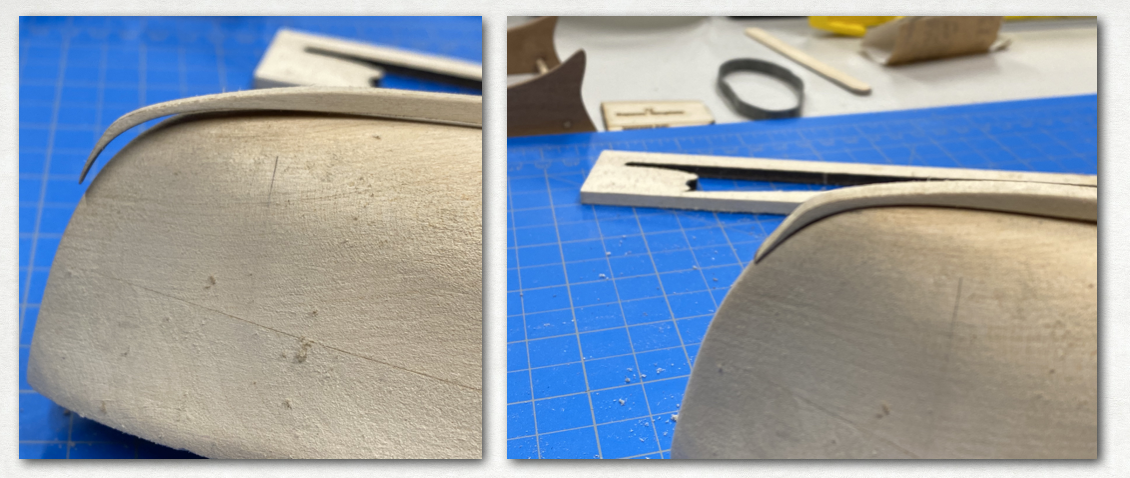

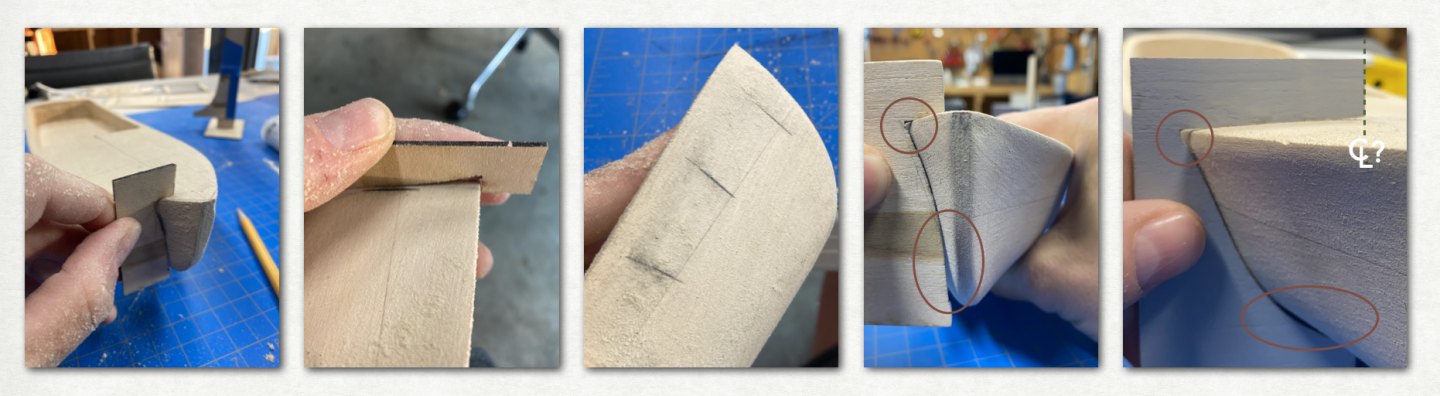

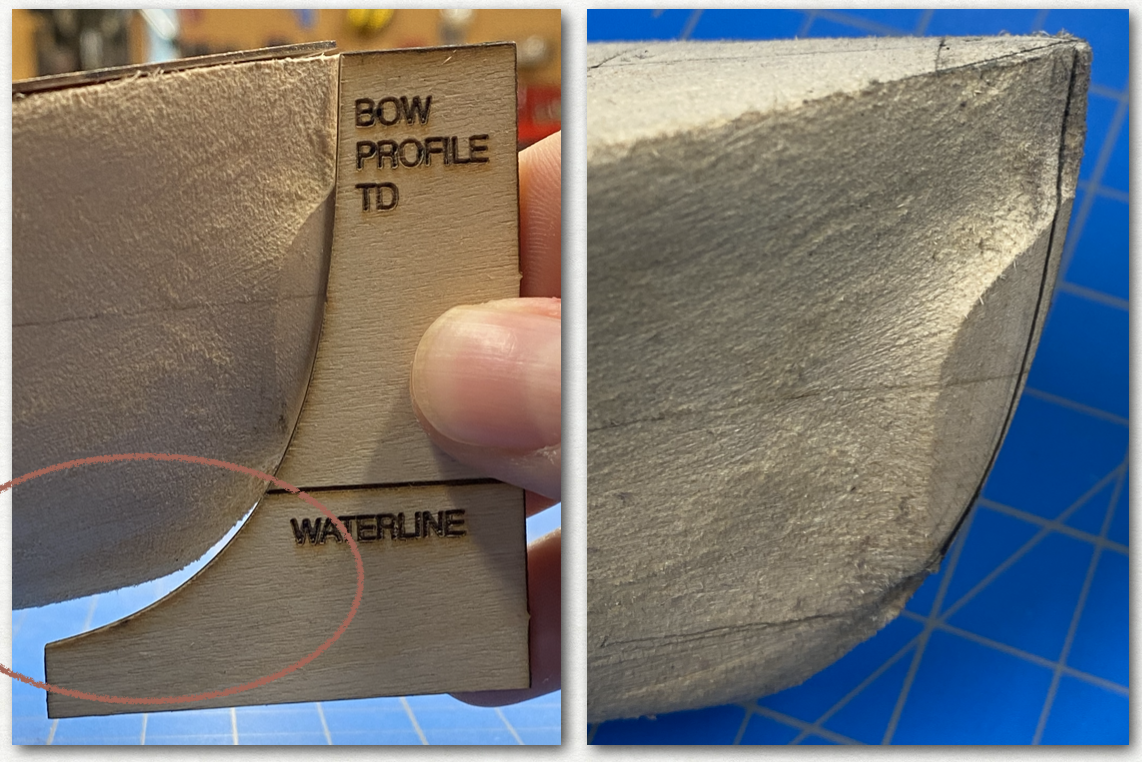

The shaping continues... I showed how I marked the reference lines a few posts earlier. It was definitely a challenge to hold the templates perpendicular to the centerline of the boat and the waterline while taking my readings. A little shift one way or the other definitely changes things a bunch. My process was as follows: lay each template on the hull and mark with a pencil the area where the template touches the hull. This represents the material that must be removed to get the template to lay more flush. Then, using the coarse paper, sand each of these areas. Whilst doing so I interchanged two methods. In one I went up and down along the line modulating my pressure to be a bit heavier in the center of the line. In the other I played 'connect the lines' sanding fore and aft- the thinking here is that in order to avoid a hull with massive undulations along its length I would need to strive for curvature continuity and the best way of doing this is to blend along the way. I checked my templates frequently- well before the pencil mark fully disappeared. I was surprised to see how fast the overall shape would change; sometimes a few strokes would change where I needed to focus my pressure. In the 'end' I'm getting close to the templates, with the exception of a few spots, shown in the red circles above. I'm stopping now for a bit and will reevaluate once the keel is on and I start shaping the stem to a point. I'm not sure if I should go any further as the centerline of the template is just about on top of the centerline of the boat. That seems like the place you'd want to stop, however I don't think I'd ever be able to get those aggressive scallops at the deck-line. without going quite a bit pass that point.

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

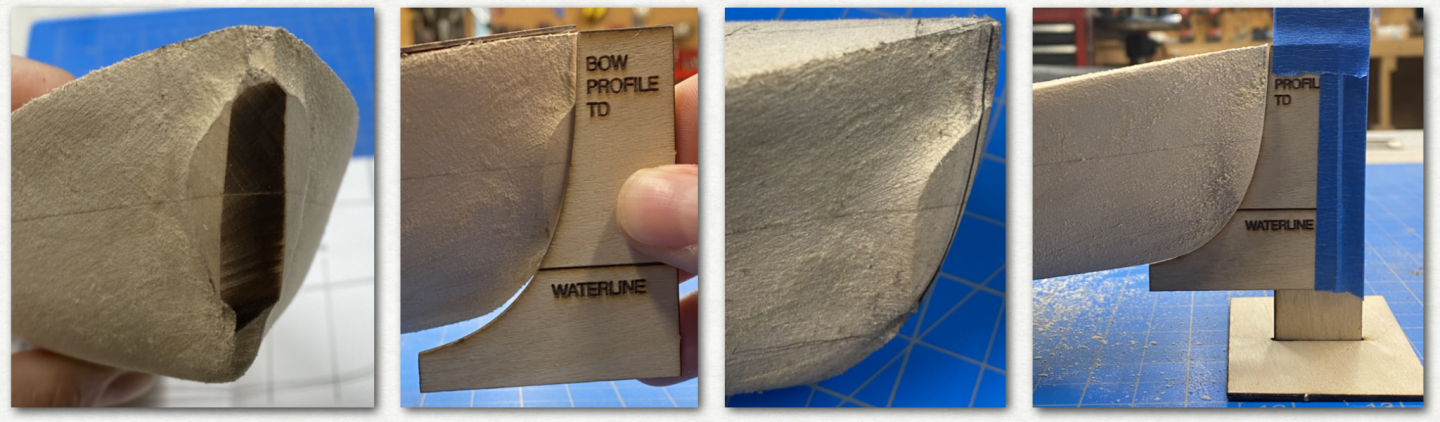

Time for shaping the hull, starting with the stem. This went faster then I imagined. With the exception of a small zone below the waterline I am able to match the the template pretty well- and i didn’t even remove that much material. I still cannot comprehend how I got from the first picture to the last here so removing so little material.

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

@MrBlueJacket - Hi Nic, you make a very good point. I'm trying to get get close as I see this as an opportunity to refine my craftsmanship, hone my patience and get tips tricks and feedback on where I went wrong. I am certainly determined not to let this frustrate me- we'll see if I succeed!

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

Paul- Great to se your log- you and I will certainly be learning together as we go. Have you painted with enamel before? Any tips? I have been trying to find a good tutorial and cant seem to find anything on wood. Most of what I have found are airbrushed on plastic or brushwork on miniatures, which I imagine is a different technique. Enjoy your trip up the coast! -James

- 87 replies

-

- bluejacket shipcrafters

- red baron

-

(and 3 more)

Tagged with:

-

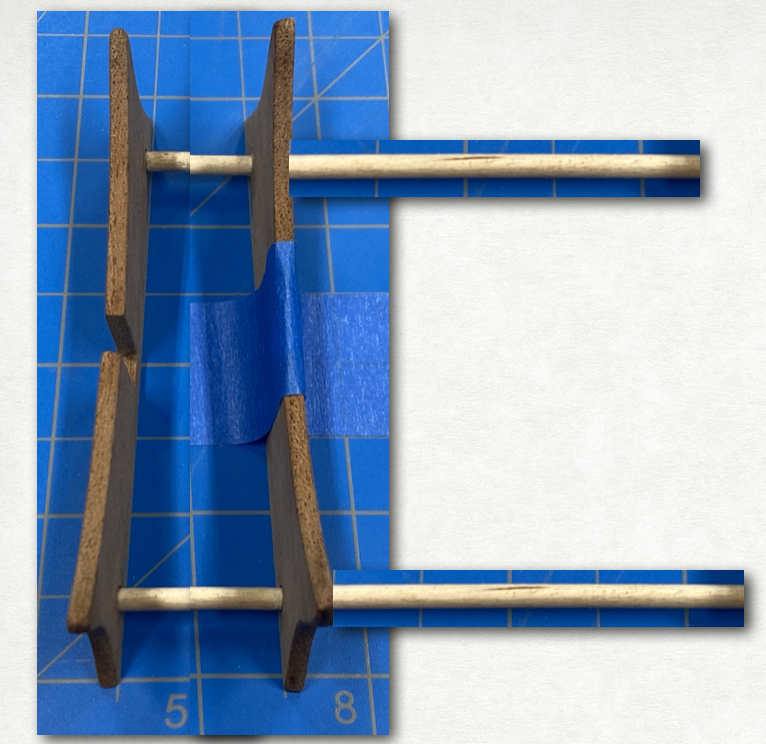

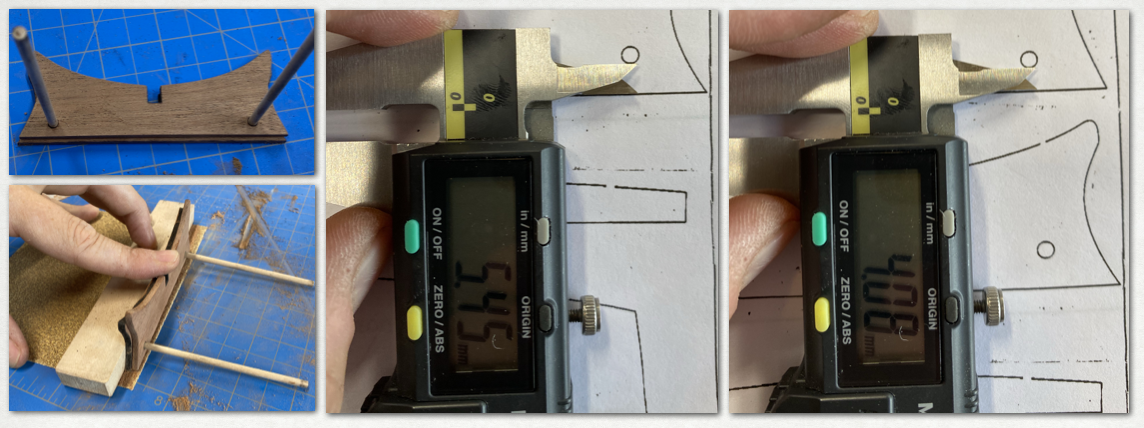

I forgot to document the glueing process. This is unfortunate because this is a point where I was totally perplexed at how to do this in a high quality way. The rods didn’t fit their holes tight so it was going to be impossible to get everything square without some fixturing, so, I came up with the following process: The above picture is a photo-cut-and-paste mock up (which is why nothing aligns in the picture) of what I did. First, I used masking tape to tape one side of the stand to the cutting mat, aligning it to one of the reference marks, ensuring it was plumb. This part would be the “fixture”- I won’t be glueing this one up on this step I inserted the two rods so that approximately 10mm was sticking out of one side of the fixture. I stuck these ends into the other stand saddle. I used the reference marks on the mat to get the two saddles and the two rods parallel to each other, respectively. I let the rod poke out past the end of the saddle so that I could sand it flush. With everything aligned I hit the inside and outside of the joint with some CA and let things cure. Then I could un-tape the fixture, align it to the glued up sub-assembly using the lines on the mat as reference and glued this up, again with a bit sticking out. All said and done things were square to less than 0.5mm, not perfect but I’ll take it. Remember the tapers left on the part from the laser cutter? I oriented the pieces so that both pieces had the tapered side on the inside facing each other. Its super subtle but looks kind of neat. Now, it was time for some sanding to get the posts flush and remove the excess glue. It cleaned up very nicely. The instructions say to prime the sanded panel pieces and gloss the stand, but I am going to save these steps for later when I have more painting to do as I don't have a dedicated paint station and don't want to set-up and tear down repeatedly. Also, since I will be using the stand during assembly of the boat it will probably get handled a bunch so I'll finish that when the boat is done.

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

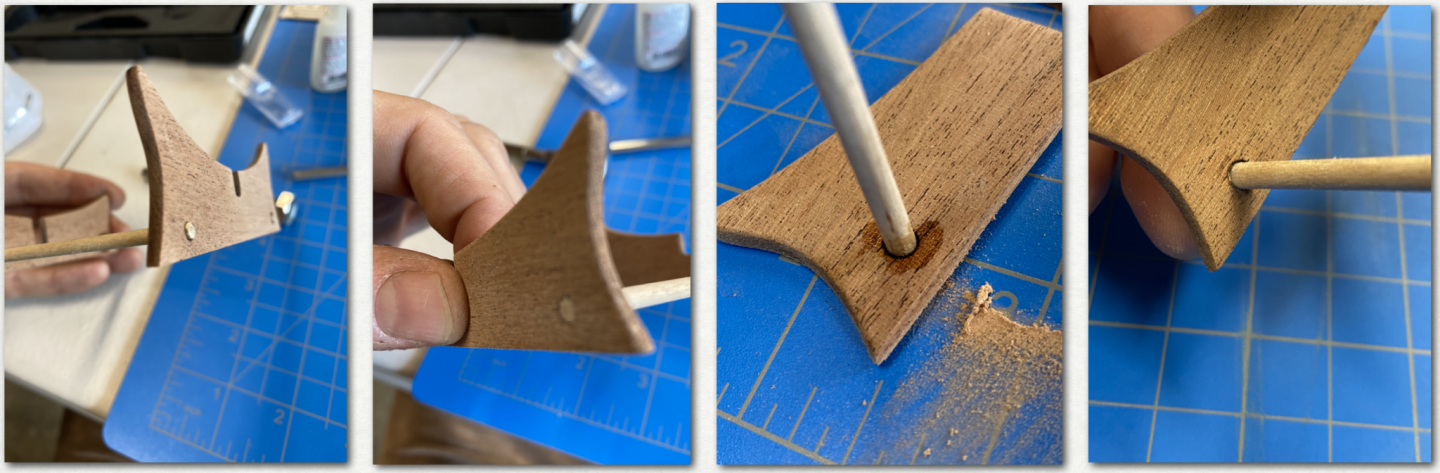

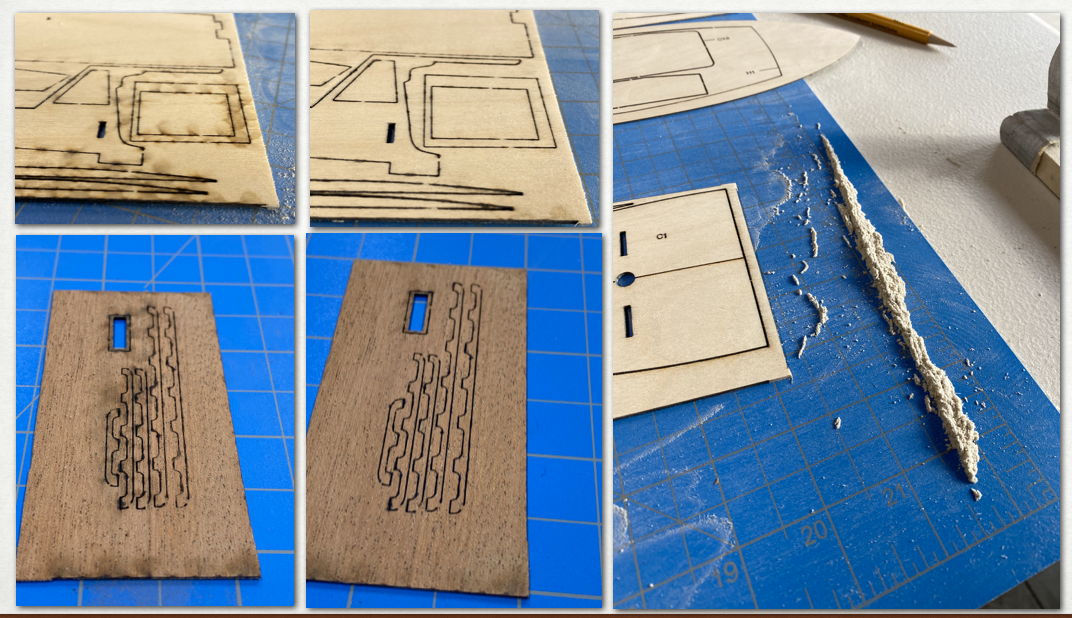

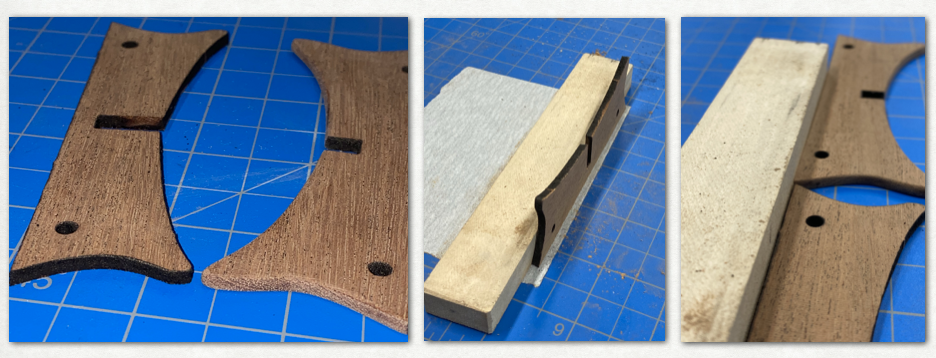

And it continues... As I sit here to write this, the log is trailing the actual progress by about a week and change- hopefully I'll catch up over the next few days/posts. Following the instruction manual like a good student (for now) I begin with sanding of various parts whilst still attached to the panel. As I had never don't this before I wasn't sure exactly how long this would take or when I would know if I was finished, but I found that it goes pretty fast and that its pretty obvious. The un-sanded bass wood has a lot of texture that smooths out nice when sanded, the burn marks from the laser cutting are also a good indication of when you are done. This will be obvious to anyone who has done this before, but this creates a TON of fine dust. A note to the noobs (like myself) get some dust masks and wear them. In a perfect world I'd recommend N95 particulate masks, but times being what they are those are unavailable. I found some non-medical KN95 masks on amazon that appear to be just as good. Next I began prepping the stand saddles. The first imageshows one before sanding and one after. After sanding I noticed that the laser cut leaves each of the cut edges tapered- this becomes very obvious on the thicker pieces. I have a plan for how to leave it as is and deal with it on the edge that contacts the boat, but i want a flat bottom edge so I first sanded each saddle flat using the sanding block as a guide to keep it vertical. The last image compares one sanded and one un-sanded to show the bevel more clearly. After sanding both pieces and dry fitting them I discovered that the rails were not parallel to the table. This was because the rail holes were a different distance from the bottom edge. I initially assumed this was the result of my sanding job on the previous step, but when measuring the plans I confirmed that the offset exists in the prints as well. I couldn’t think of any reason why this would be the case (though i am sure there is) so i decided to gang the two saddles together on the rail and sand them flush. Will I live to regret this decision? I think I plan to add a felt strip to the underside of the stand so if the above offset proved to be important I can just apply a different thickness on each piece to revive the lean if it was by design. (9/3/2020 EDIT: Yup this removal of material led to an issue. If gotten around to attaching the keel- posting on that soon- and found it now collides with the table. As I said above, I know how I'll fix this- with some green felt on both the bottom and the cradle of the stands. I think that's going to look sharp and it will boost the model up a bit. If the aft saddle needs more height I wonder why that was added to the bottom, casing a tilt to the rails, then on the top... hmm... Anyway, I want to let anyone who was filling close behind know so they can choose to go down my path or just live with a bit of lean.) Sanding is done for now... next comes the glue-up of the stand.

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

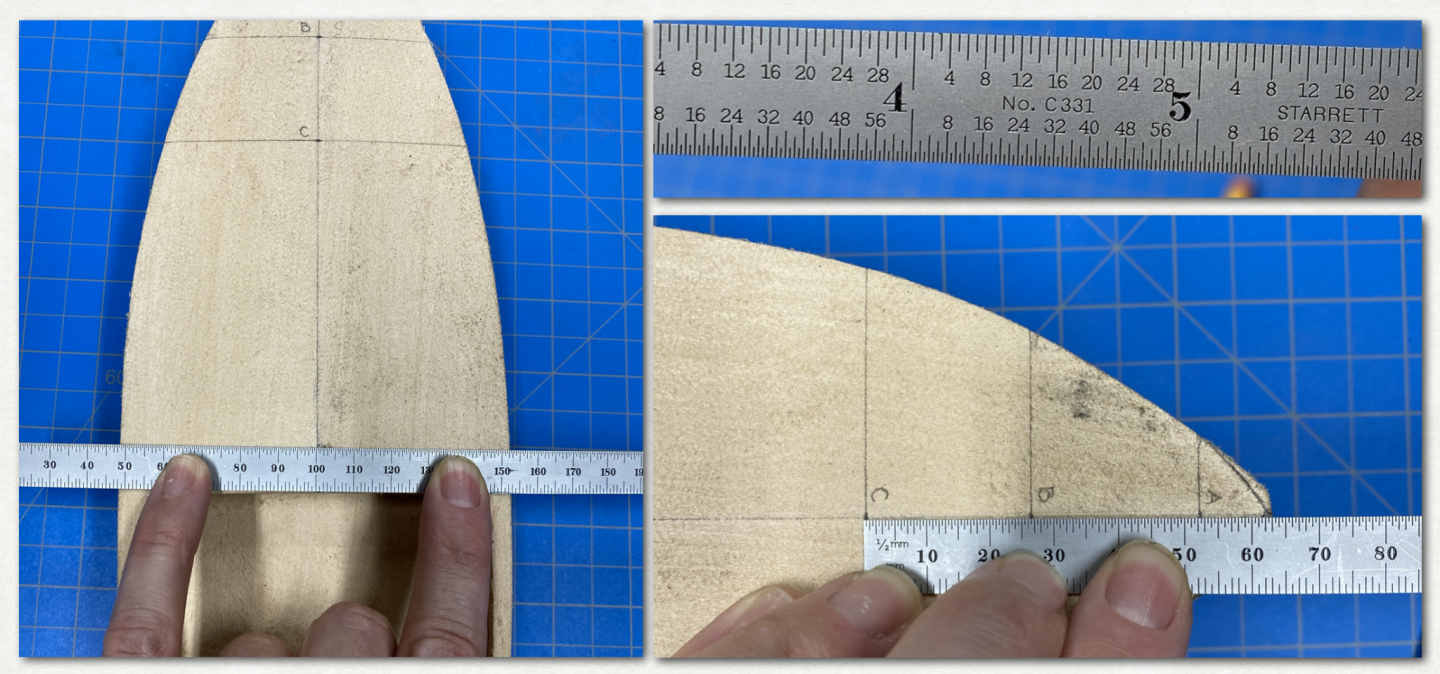

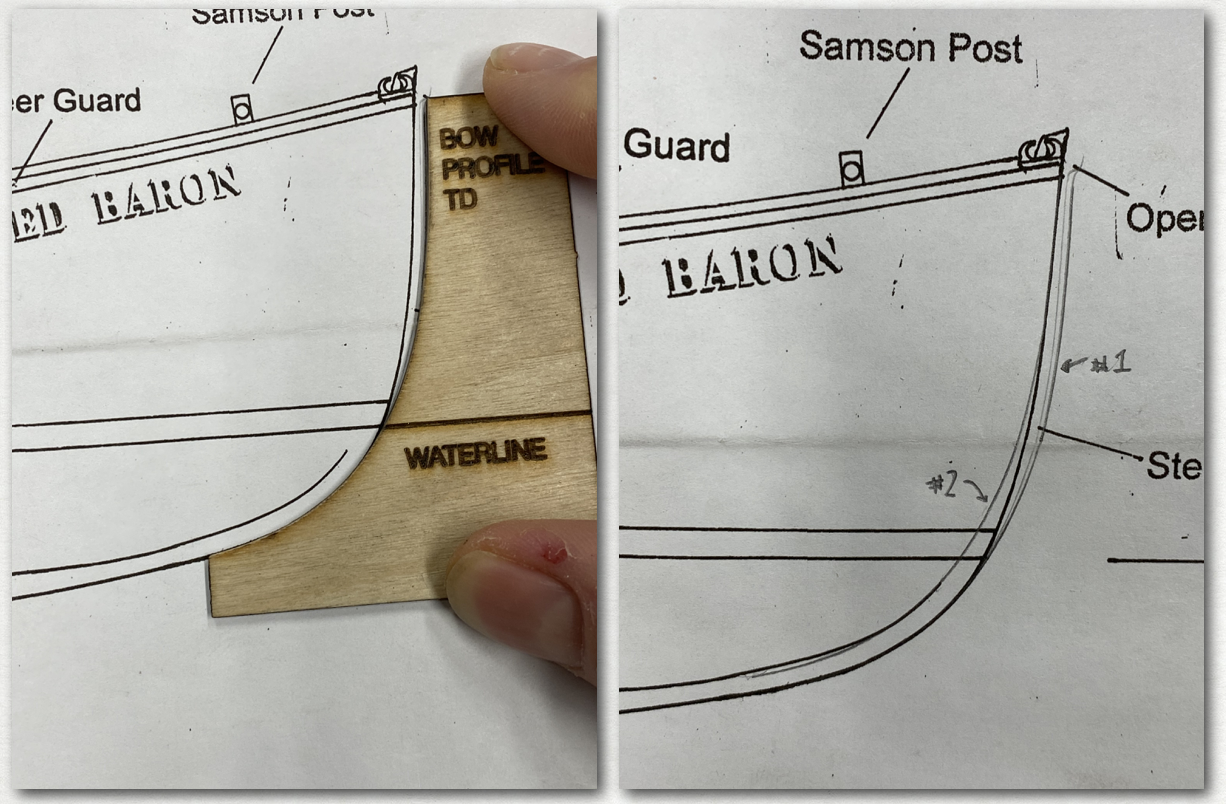

And so it begins... The first thing I did (after the requisite review of the inventory to make sure that it matched the manifest) was to asses the state of the hull blank. I used my flexible metal scale (mine is a Starrett C331) to find the centerline of the blank. I did this by eyeballing the center of hull and putting the 100mm line at that point. Then looking down the side (at as straight of an angle as possible to eliminate parallax) I kept checking and adjusting the rule until I landed with the same number of mms on each side of the boat. For instance in the photo below I was reading ~152mm on one side and ~48mm on the other (that is 52mm on each side). I did think at a few points along the length, then before connecting the dots I used the deck ply to confirm that I was in the ballpark. This step is a bitt tricker than you'd think because it is hard to know if you were keeping the scale perpendicular to the center axis of the ship. I found the best way to do this was to eye down both sides of the scale to ensure that both the top and bottom edge were measuring equal values (not to each other, but with respect to the P & S sides of the measurement; the top and bottom will be different because of how the hull tapers.) The next thing I did was mark off the A, B and C reference lines which will be used with the shaping templates. I did this from where I think the tip of the bow is going to end up after sanding based on the how the deck ply aligned to the hull blank. Now here is where I am getting into the weeds. I took a page from @schooner's playbook and compared my sanding template to the blueprint. For the life of me I cant see how this is supposed to align. I am keeping the waterline aligned and moving the template around to different datum but to my eye the shape of this template just looks different from the shape of the hull on the print. For instance, in the right picture below, line 1 uses the bottom of the step as the alignment spot. Line 2 uses the tip of the bow. That one seems to align both with the bow-point and the line which I think denotes the keel/hull joint so that one seems right, but in general this profile seems more bulbous and less sleek than the profile on the print. When I try to transfer this onto the blank to give myself some guidelines (not to sand to per say but as a warning that I am getting close) I get something like the below. What I notice is that there is a point where the template departs the blank leaving a big gap. Is that space going to be filled by the keel? (In the photo I realize I am not holding the template absolutely plumb, only because its hard to hold all these things and take pictures.) So as I prepare to sand, a few questions- 1) Do you think the last few pictures generally describe where I should be sanding ? 2) Will I sand back the stem so that the tip of the bow is roughly at the point where the deck ply suggests it should be? 3) At this point I know I should not be sanding the stem to an edge- but do a sand it flat or round it off a bit? The blank already is quite flat at the front. Thanks for the help in advance!

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

For those of you who didn't catch my intro on the New Members forum, this is my very first model. I have zero experience with wooden model building and only a small amount of experience with plastic model cars and planes, but that was over 20 years ago and generally ended with my fingers glued to the model. As a beginner I selected The Red Baron for a few reasons: The kits contains just about everything one would need to complete, including paints. The extensive instruction manual that comes with the kit The excellent build log by @schooner, which I reviewed countless times before buying this kit. Despite the above there are a few times where I’ve already feel like I need more advice and some clarification on the instructions. Which is why I am glad this community exists. Because this is a kit for an absolute beginner I am going to try to keep a very detailed build log. I haven’t decided if I will post every agonizing documented step here - as I don’t want to bore you all with the details of how I figured out how to sand that little piece where fingers don’t fit - or publish it later as a PDF or something like that. One thing I have decided on is that I am going to try to do the whole build with just what was provided in the kit and if I do supplement any tools, etc I will try to make them a simple and inexpensive as possible. As someone who is brand new to this I don’t want to invest a ton of money in speciality tools which I may never use again if this model ends up flying out the window in a fit of rage. That being said- is their anything you’d recommend buying now to minimize pain and maximize quality. Something like a specialty body filler, 600 grit paper, a brush upgrade in the $10 range? Off to work… more to come very soon- along with my first plea for help!

- 32 replies

-

- red baron

- first build

-

(and 1 more)

Tagged with:

-

Thanks to all of you for the warm welcome! I’ll be starting a build log very soon Glad to hear I picked a good boat @Chris- yes, Silicon Valley it is. I’ve been here 10 years, with two years in San Diego before that. Speaking of SD, The Star of India is a very cool iron hulled sailing ship that has been turned into a museum. That boat, along with the Mayflower II, are really what peaked my interest in old sailing ships. @Tom- I hope you are not leaving because of the cold! I am considering moving back and the though of winter frightens me. I guess I’d have plenty of time to dedicate to my new hobby.

-

Hello everyone, My name is James and I am not just new to this community but I am COMPLETELY brand new to the world of model ship building. I grew up on the coast of CT and have lived in a number of other coastal cities so I have always been drawn to boats and the history of shipbuilding, though I have spend only a small time on the water myself. In my youth I built a few plastic models here and there. More often than not I ended up with my fingers glued to the plane/car I was building, uneven paint and crooked decals. All of the above generally a result of rushing into things. I am hoping that with a number of additional years under my belt I can learn to take it slow, enjoy the process and improve the quality of my work. Especially detail work- this is the area where my projects fall apart. This is ironic, because I have a very critical eye for detail. I am a mechanical engineer who works in the world of product design. In my profession I lead teams that design consumer electronics products that at times work in micron and sub-micron accuracy. This model ship building endeavor will require an interesting balance between my instinct to grab the calipers and measure down to 0.01mm and the use of CAD, CNC and automation to achieve shape and symmetry and the need to find a solution with hand tools and technique. I am looking forward to share my project with you all (and to receive some help along the way). My first boat is the “Red Baron” by Bluejacket. It might take me quite a while as I balance the time demands of life and work with the need to go slow and learn new things on the way. I am on page 2 of the instructions and I already find myself in a state where I am doing more strategizing and thinking than doing- which for right now is fine by me. I will be starting a build log soon. See you all there.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.