Redshadowrider

Members-

Posts

301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Redshadowrider

-

Very Sorry…. We all know how plans/goals can be undone by real life and that is what happened here. Not only did the heat hold on what seemed like forever, health issues put a damper on most everything. My Admiral of 44 years got the big ‘C’ diagnosis earlier this Summer. Full attention was redirected to testing, 3 surgeries, and a final diagnosis in September that it had been beaten. Rechecking will be the rule from here on, but good news nonetheless. So, with that, I will, once again be working and posting here. I hope, you will, once again, follow along.👍

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Gammoning & Bumpkins…. Despite the continuing heat, we had a few days where I could get some work done on the Syren. I have been able to complete the bumpkins, including the mounting brackets. I tried the copper strips folded over, but I ended up using some card stock. The gammoning turned out to be easier than I expected, but ‘easier’ is very relative. To complete the gammoning I did make a small hook out of a RC control rod so that feeding the line would be easier.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Sorry folks…heat index has been between 100-110 degrees F. I am ready to continue rigging the bowsprit and will do so when it cools down a little.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

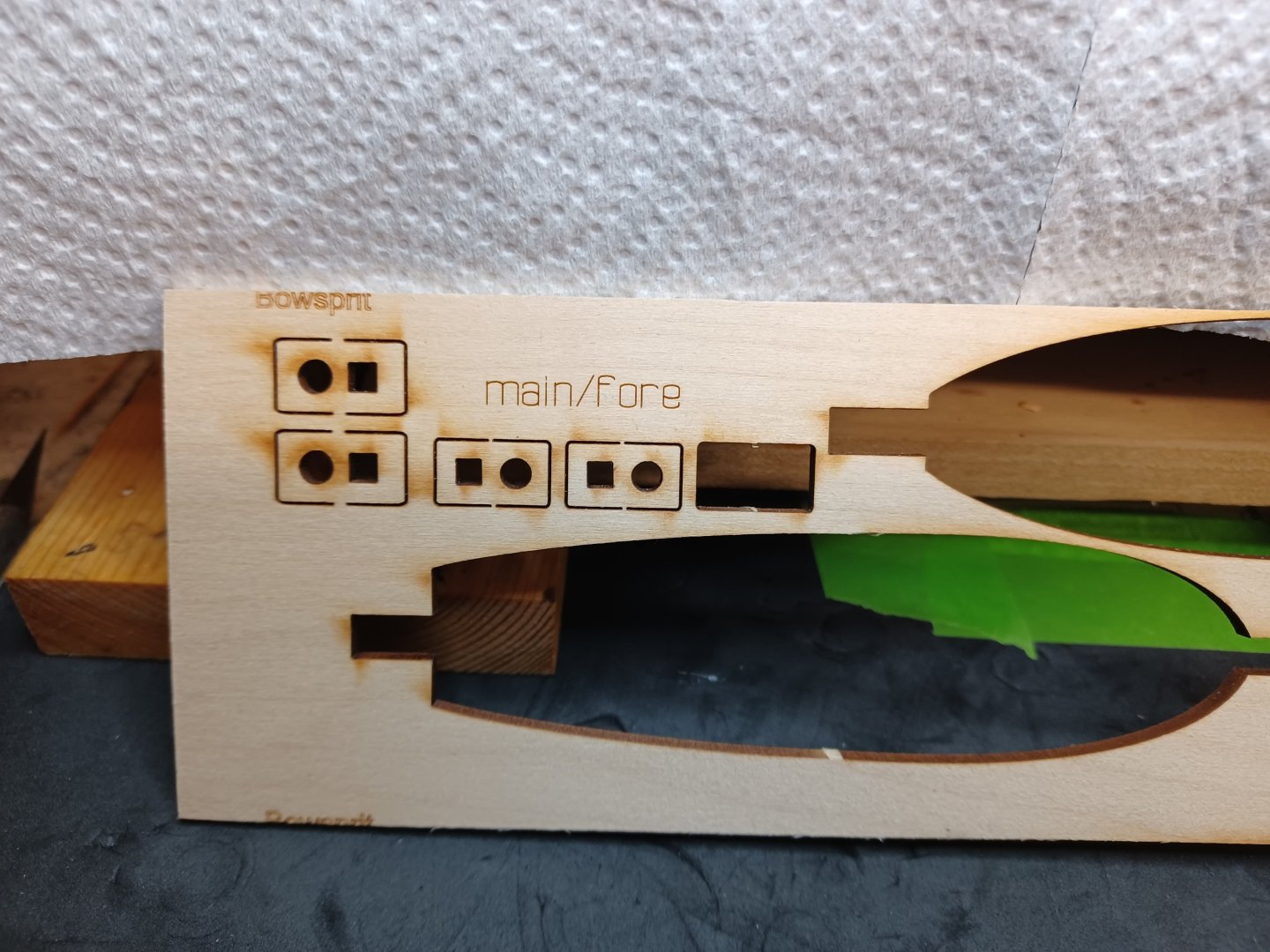

Newbie Note: What’s wrong with this picture? Give up?😁 Well, it’s a mistake I found by looking for something else. When I selected the part for the bowsprit cap, I used a part for the mast. It really didn’t make much difference, except for the room for mounting the jack staff and the wire brackets on the jib boom. There really isn’t much size difference between the two parts, but the bowsprit cap is just a tiny bit larger. The square and round holes on both parts are the same size, but the surrounding wood is wider by a hair. Just a reminder to watch your part selection.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you, @Dr PR After I completed the installs, I did think about how I could have done it differently. However, after, doesn’t help much to resolve the issue. Since the rigging is black, it is difficult to see how crowded it really is. The only thing I am wondering about is if the closed hearts are in a good position for attaching the follow on rigging. If not, I can see me redoing the whole section. That, however, will be a last resort. I can see me doubling up the closed hearts to conserve space. Thanks again for your comments and pictures.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

@PaddyO Thank you for the comments as they are appreciated. It’s exactly what I was hoping for when I started it. This is my very first build, and I find that many steps can be organized in a different order, and some I have yet to completed. I.E. I still have the netting to complete on the fire rails and the bumpkins are next on my list. On this step I found that rigging the open hearts and bobstays very difficult. Not because of the actual steps, but the space where the rigging attached under the jib boom. If I had to do it over, I would put some thought into doing it differently. I think the pictures showing before installation showed that I didn’t build them too big. I have measured all placements with dividers so everything is placed correctly. Unfortunately, this step is not very detailed in the manual or on the plans. If I was to do it over, I would reduce the line sizes to conserve space. Or, I would connect starboard and port lines differently. Here is a picture of the bowsprit glued in.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Conglomeration of Rigging, and some Profane Comments & Newbie Note It was like stuffing a size 12 foot into a size 8 shoe, but after some pushing, shoving, and appropriate encouragement I got the bobstays, and open heart rigging onto the bowsprit. I am glad that it is black which helps to clean them up visually. We had rain so the temp dropped some, allowing me to make a little progress….. now….a couple of warnings Newbie Note 1. Do not, repeat, do not attach the dolphin striker, or Ball Truck before this step. I know the instruction booklet has them installed before now, but if you are like me, you will just have to replace them.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

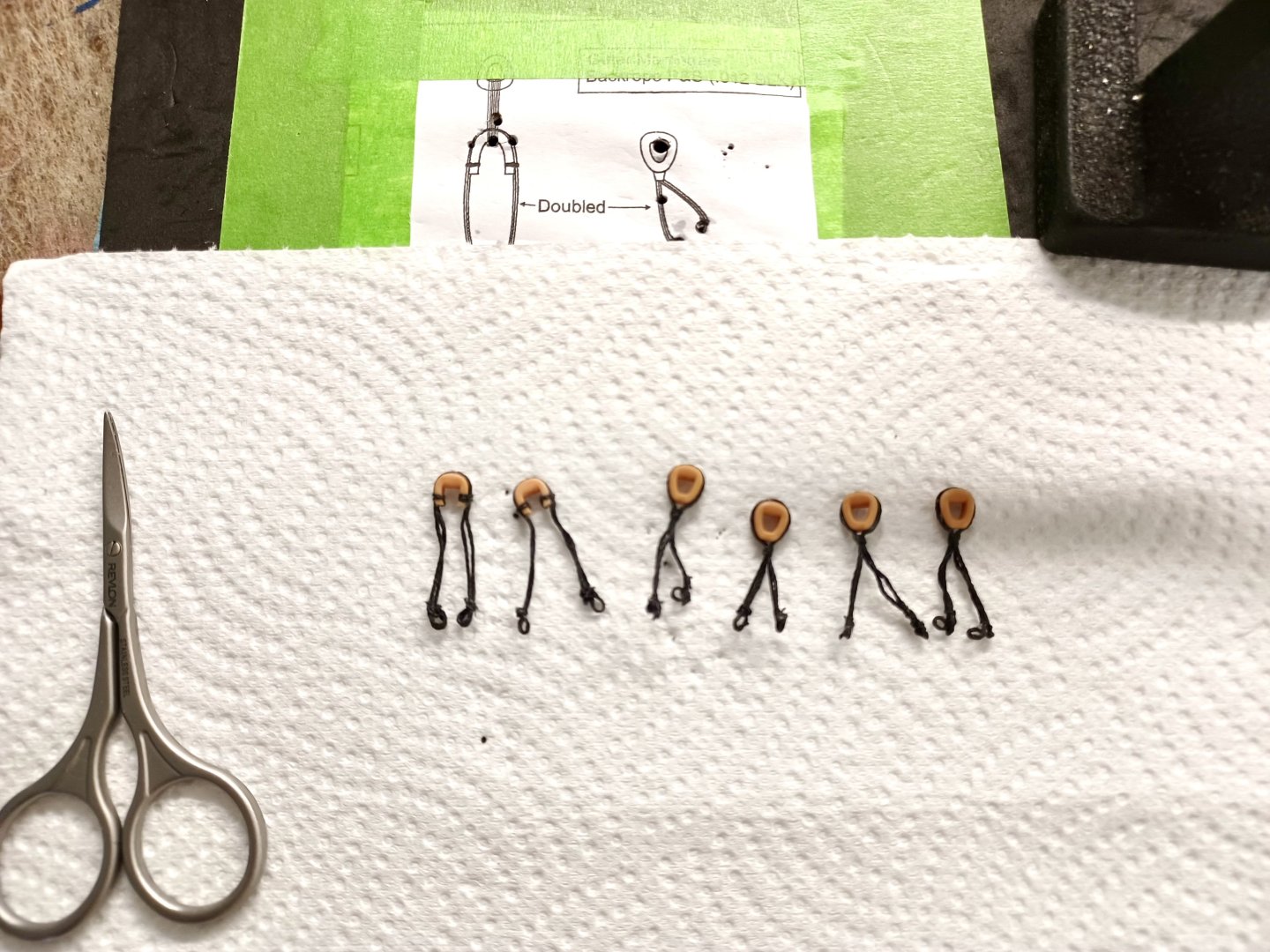

Even In The Heat It hasn’t been fun, but with a couple hours a day, I have completed the bob stays and stay collars. Still have the installs to do, but at least, they are together. Although, I will admit that looking at the space where they go, and how many there are, it’s going to be very tight fitting them all in. It’s also flying season, and I have some maintenance to do on a couple of planes, but should get to the Syren this week.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Slow and steady as she goes….. I have made some progress over the last couple of days. The single blocks have been installed on the flying jib boom, and the bowsprit cap. They are a little difficult to see, but came out fine. The open and closed collars are well along in their completion and will be installed when I get the loops in the lines figured out. Then it’s a matter of adding them in the proper order. Newbie notes: I highly recommend the open and closed hearts that I got from the Syren Ship Model Company. They are the 7mm size and are quite strong for printed parts. If you want to work with the wood laser cut ones do not let me stop you. However, if the wood is weak you can get pretty frustrated. My opinion only…they should be included in the kit due to their size, but that’s just me.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks, @Dr PR What you indicate about the small coolers is exactly what I expected. I work in a 3 car garage, so I don’t anticipate cooling the whole thing. I have decided to do what I have done in the past. Just work in the morning for a few hours and when the humidity is lower. I could move inside my home office, but there is so much to move. I can make progress. As seen by my next post.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Been Struggling….. To those following this build, hang in there. Two things have been slowing my progress on the bowsprit. First, this is the time of year that the heat reduces the time I can spend working in the ship in the garage. So much so, that I am considering purchasing one of those small “coolers” that work in small areas. I have been researching them and trying to separate truth from advertising. Second, is the creation and install of the open and closed hearts. The instruction manual, and practicum are a little hazy. So, I have been going through other Syren build logs to try and find clarifications. Last night I found the clarification on the build by @abelson To me it is the most clear, and concise set of pictures and instructions I have found. My personal thanks go out to him. I am now confident that I can begin moving forward. That just leaves the heat, which I am already working on. 😊

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Phil, I thought about light ply, as I have quite a bit of it. However, I just wasn’t in the mood to shape 10 of them. If the resin hearts turn out to be too brittle, I will go to elsewhere. The flying club I am in has a couple of members that make parts for us, but you are right about very small parts. To me, 3D printing still has a way to go before it can create strong usable pieces. I will be providing information on the quality of the resin hearts going forward.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

It Was Inevitable… After the open heart experience of crumbling wood, I started on the closed heart parts. I was able to shape the first one and it came out ok. The second, however, broke when trying to remove the laser marks. It took me less than a minute to decide that with 10 needed, I did not have the patience to create the closed hearts, nor did I want to go back and create the open ones either. So, I bought them. I have held off from any additional work until they arrived from Syren Model Company. I do not fault the kit manufacturer for providing them as laser cut parts, but there comes a point where parts this small just as well be included with the kit. That said, this is not the only reason I have not moved forward. Since my work area is in the garage, summer is not the best time to work there. It has been around 90 degrees, with 70-80% humidity. (Right now it is 83 with 78% and it’s only 10:15am.) Now that I have the parts, I will begin my work early, with a fan, and go until it is too hot. Should be able to begin updating again.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

And Here We Go Again…. Open and Closed Hearts Although I was not looking forward to another mini shaping process, I thought I was prepared to shape it with very careful treatment. (see picture). I decided to remove the closed hearts (10) from the laser cut stock, and begin sanding their shape. I left the center of them in place and delicately sanded clean their shape outside first. The one is in the picture is number 1 of the 10, and I think it is very workable. Only 9 more to go…yikes. However, the Open Hearts are another story. Like the fife rail, the wood is very crumbly, so much so, that I was barely able to remove the laser marks. In fact, the first two, came apart at the slightest touch. So, on the next two, I barely removed the laser marks, and then decided to bathe them in a mixture of white glue and water. My thought is to strengthen the parts before shaping and hardening their surface. Well, that didn’t work either…at least for one of them. In the picture, you can see one that is complete while the second has a part that has already fallen off. This while only soaking in the water/glue mixture. So, I will probably make 2 new open hearts out of different wood as I did with the fife rail. Once resolved, I will do another update. My Thoughts: I appreciate the fact that multiple copies of both parts are provided in the kit. However, for the open hearts there only 4 when the piece of wood they are cut out of has enough room for many more. Even then, I am not sure if it would make any difference.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you Phil, I have appreciated everyone’s compliments and input. As to your questions, no I am not going to add sails. Since this is my first build ever, I am following the notes from Chuck’s prototype build and the instructions in the manual. The points you raise are valid ones and I find them informative. However, I am posting this as a guide to other first time builders and trying to give them something that gives them direction on how and when I did things coming from another first time builder. I am totally amazed as to how complex, detailed, and intricate this model is even at 1/64 scale. I think it is a good thing that I did not know this before I started. If I had, I might have done something else. That said, I am going to press on and hope that this guide can help other newbies to build it, or to decide if they want to move forward. Thank you, again, for your ideas and input it is appreciated.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Ready for Rigging…Almost I completed most of the bowsprit today, but still have some final adds to go. I did, as the instruction booklet says, and did some filing work on the cap rail. The goal is to lower the sprit to 1/16”-3/32” above the figurehead. It is right at 3/32”, and I may very well leave it as is and glue it in, but I have some time to make the final decision. Before I move forward, I still need to add the 3/32” single blocks to the cap, flying jib boom, glue on the simulated staples to the cap, and dolphin striker. All of these will be much easier to do before gluing in the sprit. And, finally, I have two things to add that I have skipped, the bumpkins, and the rail netting. The bumpkins will be in place before running the bowsprit rigging, and the netting before l move to the masts. And, then finally, I will add the ball truck to the jack staff. See Newbie Note on post #426 before adding Dolphin Striker & Jack Staff for Ball Truck.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Progress Has Been Slow I haven’t been able to do much lately, but it is not on the construction side. I have been held up by 2 items primarily. First, is the figurehead and its appearance. What you see in the picture is after about 3 or 4 attempts using different colors. My goal was to have color, but not so much detail as to draw the viewer’s eyes away from the rest of the ship. And I wanted it to look like other figureheads of the day. I looked at numerous examples, and still wanted to get the mix just right. I am happy with the final result, and its gloss is what I was going for. Second, the bowsprit has taken much longer than anticipated. Most of the delay was due to one item. The 1/16” tape that represents the iron bands around the base. I did not find the tape in the kit that is used to represent them. Normally, that should not be a problem because I use similar tape as striping on my planes. However, in this scale, I do not have anything as narrow, nor any black striping. So, I took some 1/4” striping, cut down to 1/16” and then painted it. I tried ordering some from the hobby site I use, but they won’t have any until the end of June. I believe the substitute worked out fine and am now back on track.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Onto Chapter 16 - Bowsprit I completed the sweeps, attached them, and lashed them down along with the longboat. Two pictures are attached, one is the sweeps drying after a coating of tongue oil (See Newbie Below). The second is of the sweeps and tie down rigging for the longboat. For the sweeps, I used the drill rig to sand the shafts into the round shape required. I found that the shaping worked best by doing the shafts first, followed by the paddle end, and lastly the handles. (Both paddle head, and handle were done by hand.) Newbie Advice: If you haven’t worked with laser cut parts before, be very careful where the paddle head and shaft meet. Laser cut parts make it much easier to shape the final part, but as the cuts get closer together, the burned areas also become weaker. This can be seen in the circled area. The part where the paddle head became much stronger than the shaft, and it broke with just slight pressure. This is also relevant when lashing the finished sweeps together. When tightening them together in a group, it is easy to snap off a paddle head. I will not admit to having done this myself….oops, too late.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks for the kind comments. I am guessing that, although different media, I am able to transfer much of my plane building to this project. I don’t build them much any longer, I am allergic to balsa dust. Go figure.😁

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Big Change With Longboat It’s amazing how the height and depth perception changes with the addition of the longboat. The perception has really changed and the Syren is starting to look like a real ship…only in miniature. Those areas, and small blemishes have started to move into the not noticeable. I still have the sweeps to sand, lash together and add, but that should go quickly. At this point, I can only imagine how the result will begun to appear when adding each new element of the rigging. Unfortunately, it’s that time of year where mowing becomes a have to do, and the heat will begin to shorten my building time. I can always pray for rain, but that doesn’t help much. And the pics.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

@schooner…Thanks, I can say the there are some pretty thin areas, and one that needed repair. I think that my technique comes from shaping balsa airplane fuselages, and cowls.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Ready for the Gallows Bits Finally completed the longboat and it is ready to be added to the deck. I still have the rest of the sweeps to finish before mounting it in place. **One thing that became clear during the construction, using my drill apparatus to turn the oar handles does not work well due to the oar being quite small.**. So, they were sanded by hand. Many a profanity was issued when trying to attach the gudgeons and pintles. If they were any smaller, a sneeze would cause them to disintegrate.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you all. It took a while to figure out, and it’s not perfect. It is difficult to get the sweep perfectly centered, but if I loosely hold the sandpaper, the wood is flexible enough to wobble without breaking. And by using a small bar clamp on the drill (See post #373.), I can set the speed where I need and concentrate on shaping. One tip I have is that progress can be felt in my fingertips. With it starting out square, I can sand until no more vibration from the sharp edges is felt. Then it’s just a matter of shaping the paddle and the handle ends.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

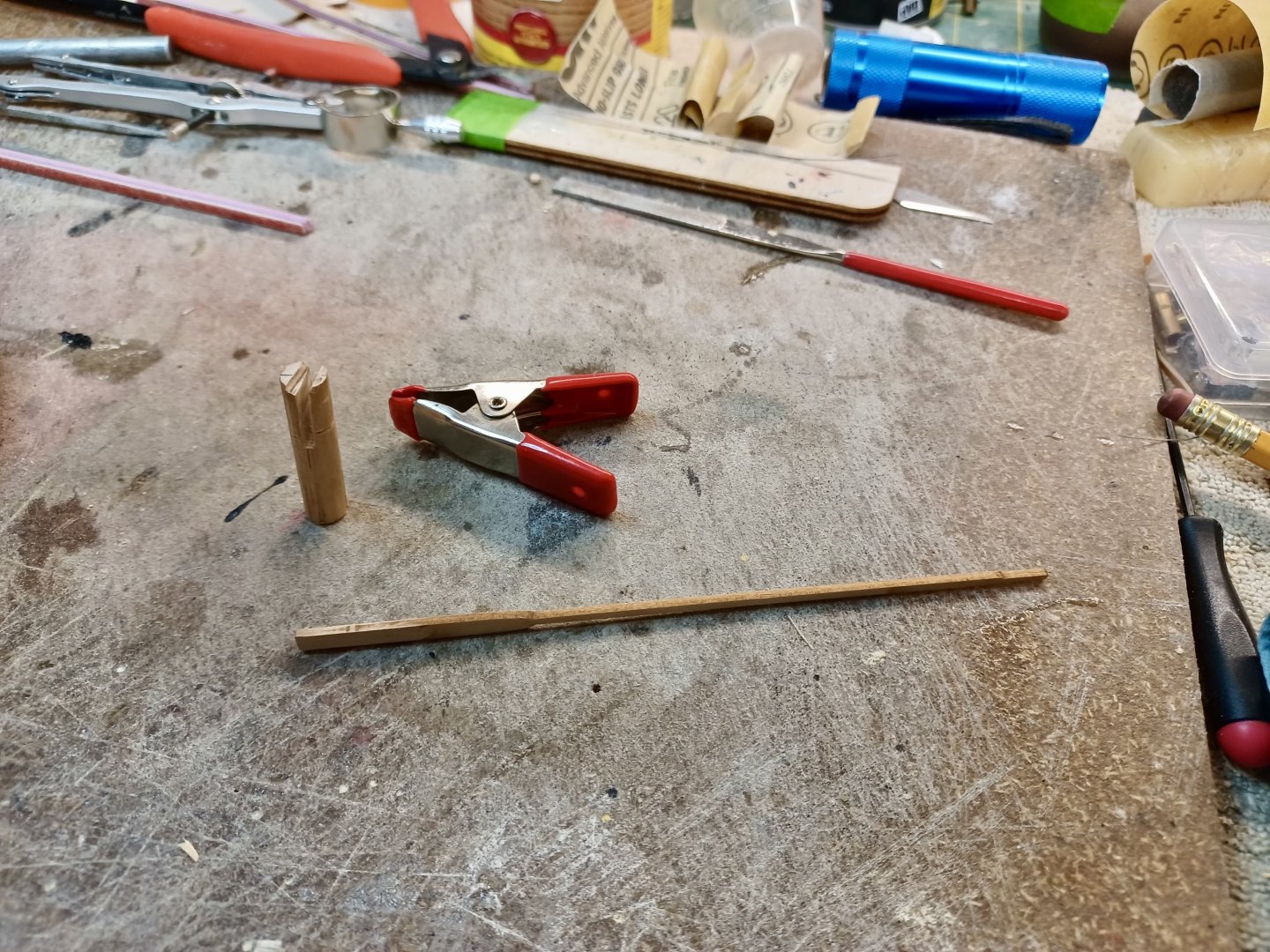

It’s Tool Accessory Time I am at the point where I needed to remove all 22 sweeps and oars from the laser cut stock and shape them. So, I either needed to figure out a way to make it easier to shape, or spend hours sanding the square shafts into round. I decided to try something in my cordless drill and found a solution that is not perfect, but does make possible to shape them quickly. Using a piece of 3/8” dowel, I cut a slot in the end. I then slip in the wide part of the sweep and shape the long round section and handle. Here are pics of the parts, then in the drill, and finally, the result.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

If I had sanded more, I think I would have a pile of sawdust. I know that in Chuck’s Practicum he indicated that 1/64” is probably too small for some parts. With that, I have to agree. The long boat is a good example. I still have the knees to go.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.