-

Posts

129 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by achuck49

-

Greetings, In the past several years I have tried, and failed horribly, to plank a ship. To be as honest as possible, I have tossed about 7 models into the trash because they had clinkers, huge gaps and just plain did not work. I 'suspended operations' and turned to solid hull models and have done very well with about 9 of them. So now I am asking for advice as to what would be a good model to again start planking lessons. There is no hurry for an answer as I am currently working (and enjoying) the Essex cross section model. Also, when planking, is it easier to use shorter planks or planks that are as long as the model itself? Appreciate your opinions. Chuck

-

Video of a serving machine being used

achuck49 replied to achuck49's topic in Masting, rigging and sails

Now I fully understand. Thanks to all. Chuck -

Good morning, I am wondering if there is a video of a serving machine being used? I have seen several that only show how to assemble the thing, but not being used. I am not at all certain what this machine does (bring me coffee about now?) and being a visual learner to actually see it in use would be very helpful. Thanks so much Chuck

-

Super job...I have one in the box that I should start. It is a bit late in the build for this question, however, when planking the ship, did you use 'shorter' pieces or one long piece of wood. From studying your photos it looks like short cut lengths. Chuck A.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

The wisdom on this site stuns me. When I finish two boats in bottles I will get back to something larger and try these techniques out. Thanks

-

This question will get me banned for life, but I have been bounced out of any number of places by very angry fathers. So many model makers send thread that looks like the attached photo. I used to try to salvage it, because of incorrect reasoning concerning "supposed to be this way"; now I toss it out. Is there a way to untangle this mess or is donating it to the land fill the proper battle plan? Chuck

-

This question is in conjunction with my question concerning drilling holes into dowels. When I study build logs, all of the blocks attached to the masts and spars look so clean and neat. I 'think' this means that a hole was drilled, thread inserted and glued, to give this appearance. Most of the instructions for various models are not clear how this should be done. I do state that there are cases where a block is extended for a certain distance, at the end of a spar for example. How is this type of block attached? Should I just wrap some thread around a few times and glue it in place? Should I use some type of glue that has some flex to it? I have one more question of the truly absurd type. Chuck

-

Greetings My steady stream of questions never seem to end. I study build logs many times a week as well as the other forums to learn all that I can. One problem that I have and must have missed the solution is how to drill straight holes through dowels, in particular the sides. I make a lot of ships in a bottles (these are very thin dowels) for grand-kids and silent auctions at charity groups. When working on any scale ship, accurate placement of mast or spar holes is essential. I have created "V's" out of wood to cradle the dowel and help to center it, but then the very thin drill bits will often bend and roll off target. I have filed a flat spot to try to help stay on target, but it does not mean that there will be consistent results across all of the stock of dowels. I have a Dremel with work station, push drill, and hand drill that I turn manually so there is no shortage of tools or bits. Any suggestions for consistent results??? Chuck

-

This site is full of great people. Progress is better...I found an alligator clip which I placed into a vise. I then put some glue on the string and quickly wrap it around the block. This works 'most' of the time. The string sometimes is slightly off the groove on the back side of the block. I then get it in place and tie it off. This reduces the time from 8 to 2 minutes per block. I believe that a major part of the problem is the thread that I am using is synthetic instead of natural. I studied the pictures that were sent and noticed that a more natural thread was used in all of the illustrations. Lesson learned. I will finish this model (not at all happy with the results) and give it to some very young nephews who think that I am a true master. Thanks again to everyone.

-

super fast responses! I have tried the clips, and vises with out much luck. However, I have not tried them by first putting some CA into the small grooves first. I am going to try to blend the given ideas with the CA in the grooves. Thanks so much Chuck ... wanting to just finish, learn and try again

-

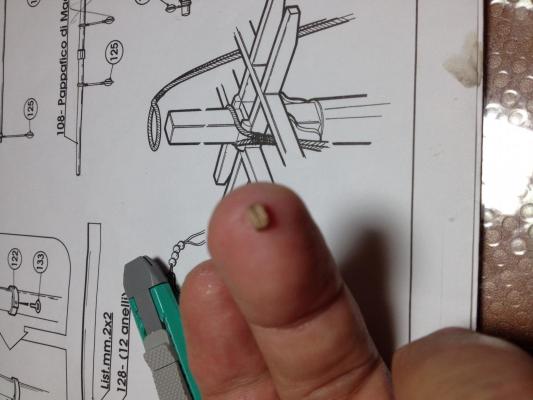

I am nearly finished with the Dominica from Amati and have run into a 'painful' process that is common to all of the models that I have worked on. How to wrap cord/string/thread around blocks that are as small as shown in the attached photo. I have put pins in them and attached to cork boards, but when it comes time to place thread around the outside, into the grooves, the thread will move off the block, or the block will twist in circles. Placing it between my fingers is the only solution that I have come up with. However, this is not a great way to do it either. They are so small that I cannot see it when trying to capture with thread. When I finally get it right, I end up dumping glue all over myself and this often removes the thread when I separate my fingers. I have tried tieing loops and any other methods that I can think of to no avail. any ideas will be so welcomed. Chuck

-

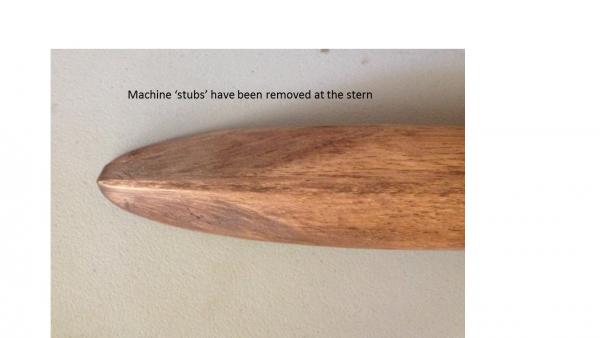

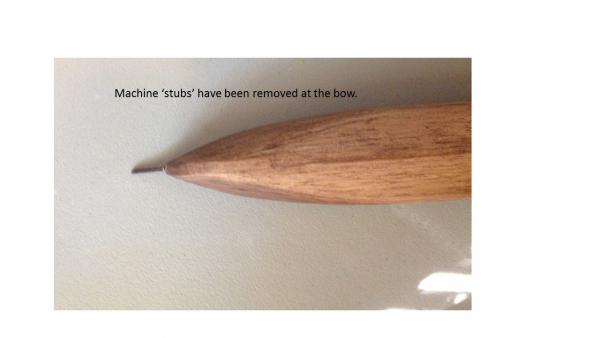

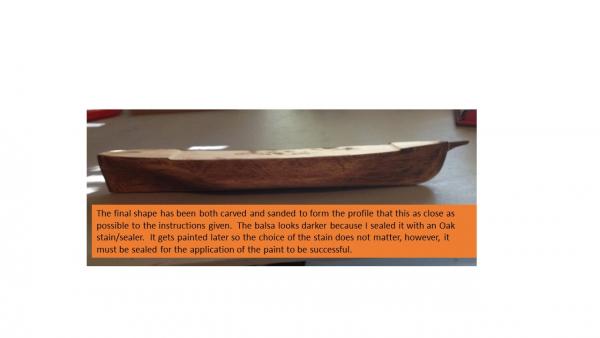

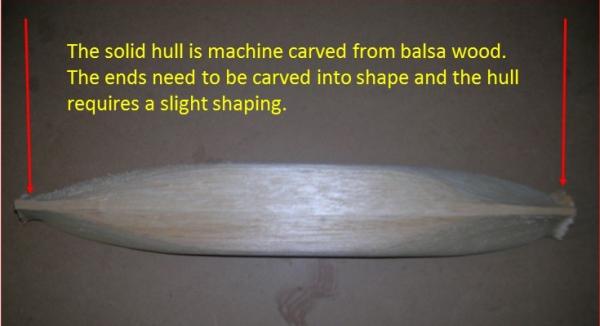

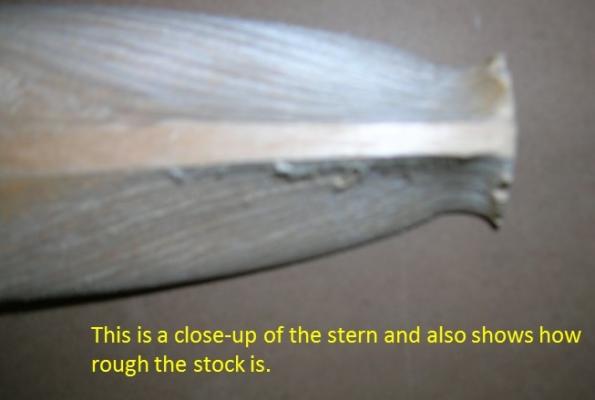

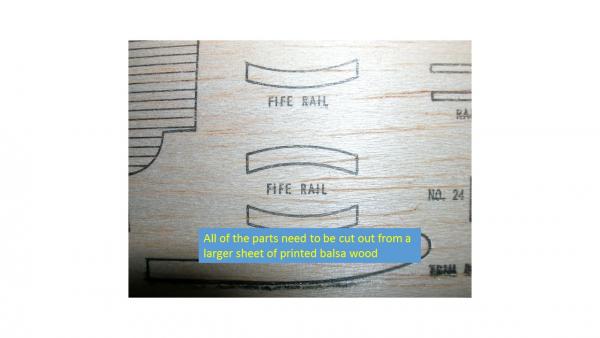

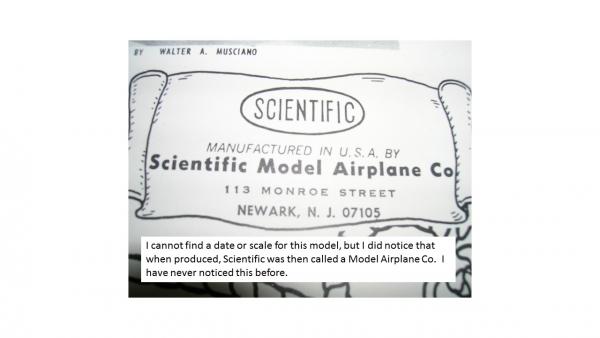

I am still placing 'stuff' on the hull of the Santa Maria, however, when I have the granddaughter over I will not use glues and other sharp objects around her. So I decided to also start a solid hull version of the Cutty Sark by Scientific. I started one other model from this company a few months ago, but sat on a box of parts and sort of brought that project to an end. This is an old model, and that means no laser cut parts or other nice to have helps. I will do my best to make this a very detailed account of how grandfathers used to assemble their museum masterpieces.

-

Thanks I will build one and at least have it

-

The directions for my current model recommended that I use a bow sander for uniformly shaping the bow and even fairing the hull. Is this something I should have in my rucksack and don't? Does one buy this or make it? Changeable sanding grades I would suppose. If it looks good and fits good something else is wrong

-

Sorry for not posting sooner but 3 year old granddaughter had a bad ear infection and the Sooners lost to TCU. I did work on Maria and discovered some problems that I had not anticipated. The ribs making up the false hull were too tight. I was very concerned about making the fit too large so I spent two days carefully sanding everything to fit. I lightly sanded all areas to be glued but the glue would only work in spots. What is shown in the photo is mostly plywood. Initially I used Tightbond woos glue as I have many times. The glue would hold very well for half an inch but fail for three. This was regardless of degree of stress, amount of 'bite', or anything else. I broke out the super glue and had similar results. Tiny nails and a new nailer finally worked. After some cleaning up I will put the first planking layer on. The instructions and photos clearly state that a few full length planks are all that is needed because the rest will be filled in with stealers. If fits well and looks good, there is a problem elsewhere

-

I just ruined a Constructo model so tomorrow I will start a build log of a 1976 model of old Connie. Stand by for questions. Chuck

-

Thanks I have not seen such a build and was wondering. Chuck

-

hello group In a week or two I will start work on a Bi-Centennial version of the Constitution produced by Scientific. It is a solid hull model. It is my plan to construct it as closely as possible in the same manner as would a builder would have then. Is a solid hull worthy of hard drive space? Thanks for your consideration. Chuck

-

wow Thanks!!!!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.