AdamA

Members-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AdamA

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

The difference between "Pear" and "Swiss Pear" if anyone else was about to make the same mistake I made. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

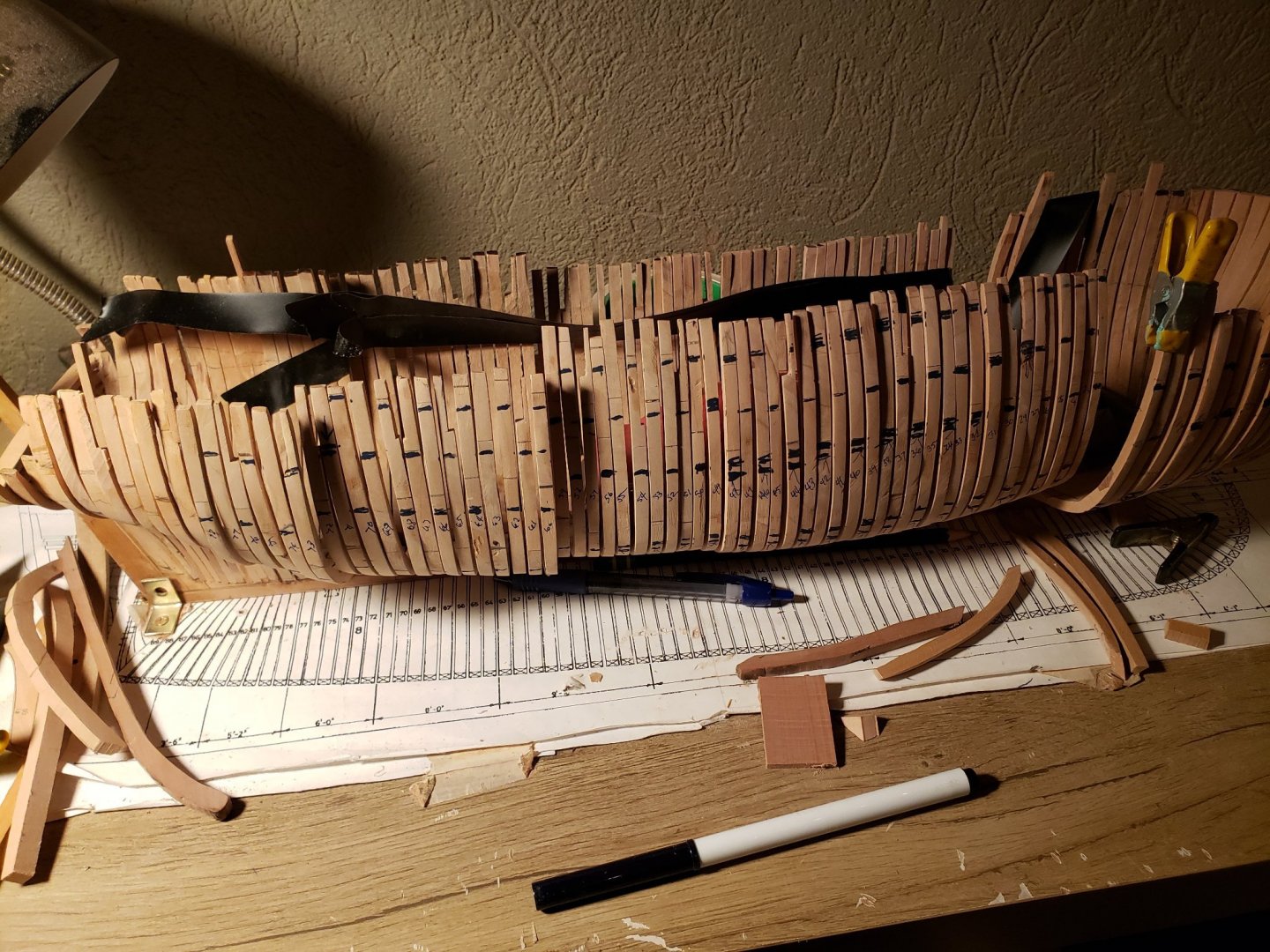

I am also going to have all these frames lined up correctly this time. I am pretty happy with how this disaster is going. I used a marker to indicate the meeting places on these [now template] frames. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

Ok... I realize this looks bad but hear me out... I found some kind of mite trails through out most of the frames. I also found out that I was not using Swiss Pear for a lot of these frames so when I looked at the whole ship it was two different colors: a drab brown for the parts that were the wrong wood. So I'm going to rebuild the frames entirely from Swiss Pear. It'll be much faster this time because I have already faired all these so I will be able to cut out the parts almost exactly correct. (OMG) -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

Sanding is 220-->320-->00 Steel Wool-->000 Steel Wool-->0000 Steel Wool It gives the Swiss Pear a nice polish. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

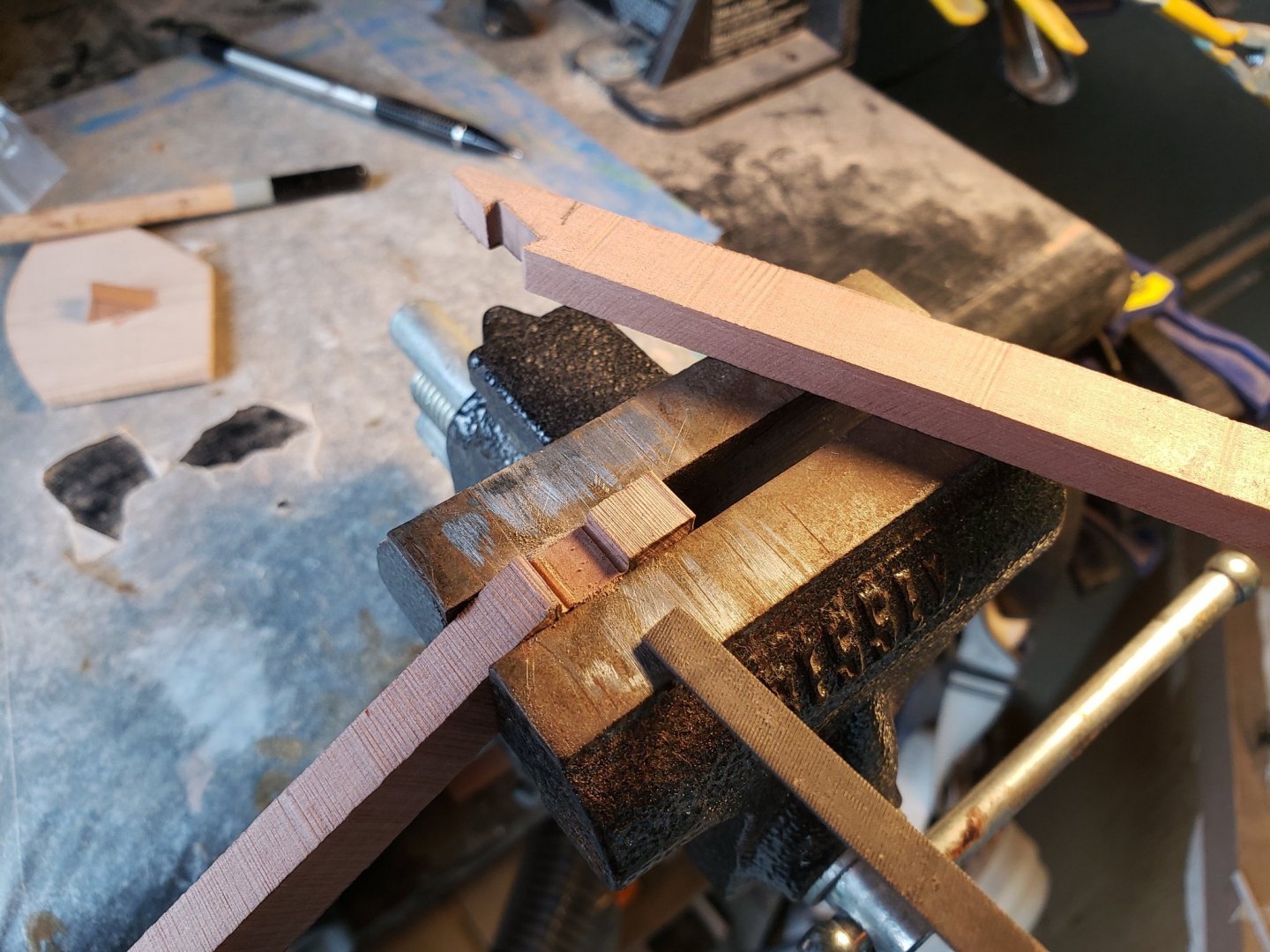

There are four of these along the keelson. I rough cut them with the band saw then use a file on them while they're in the vice. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

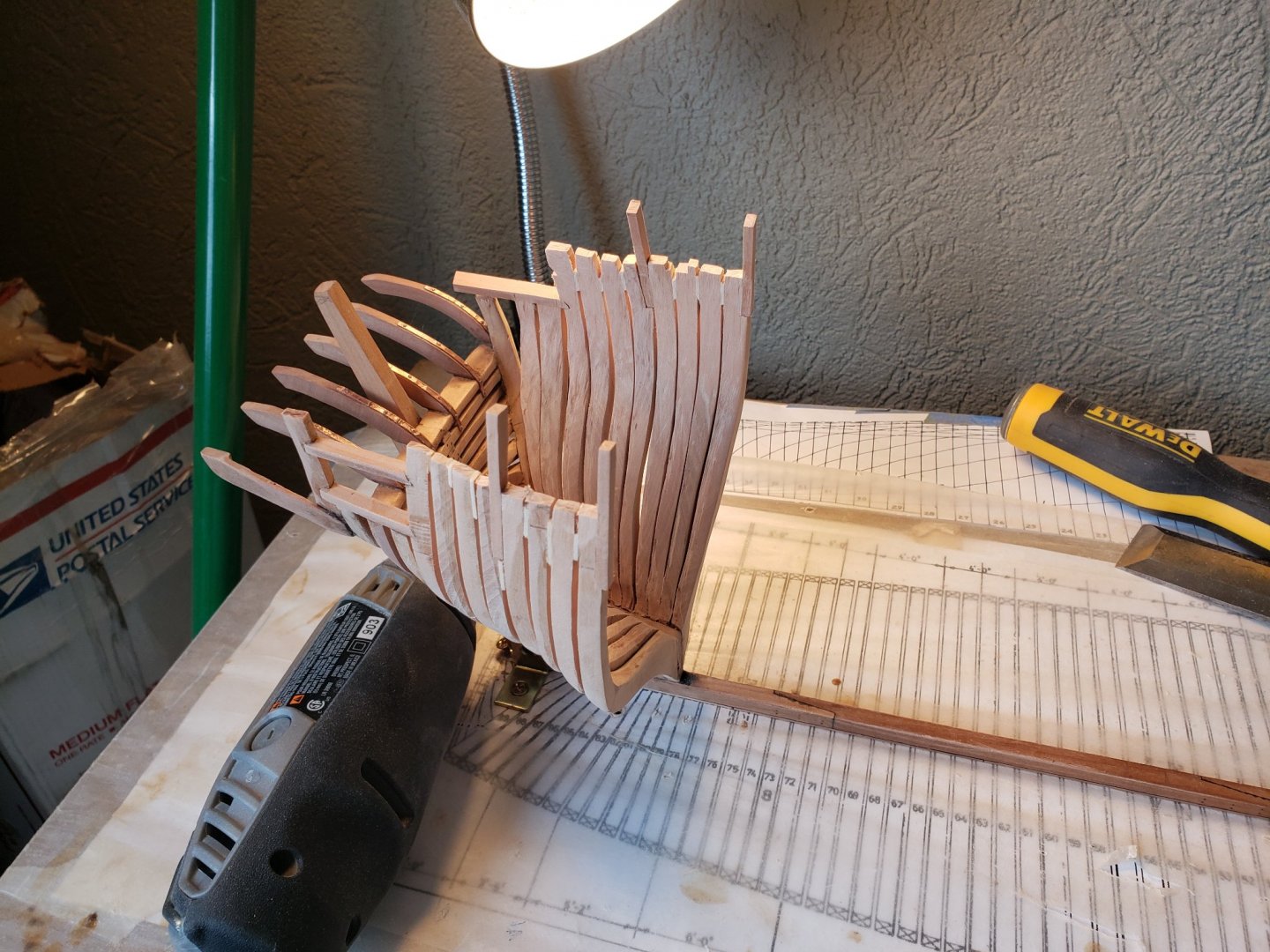

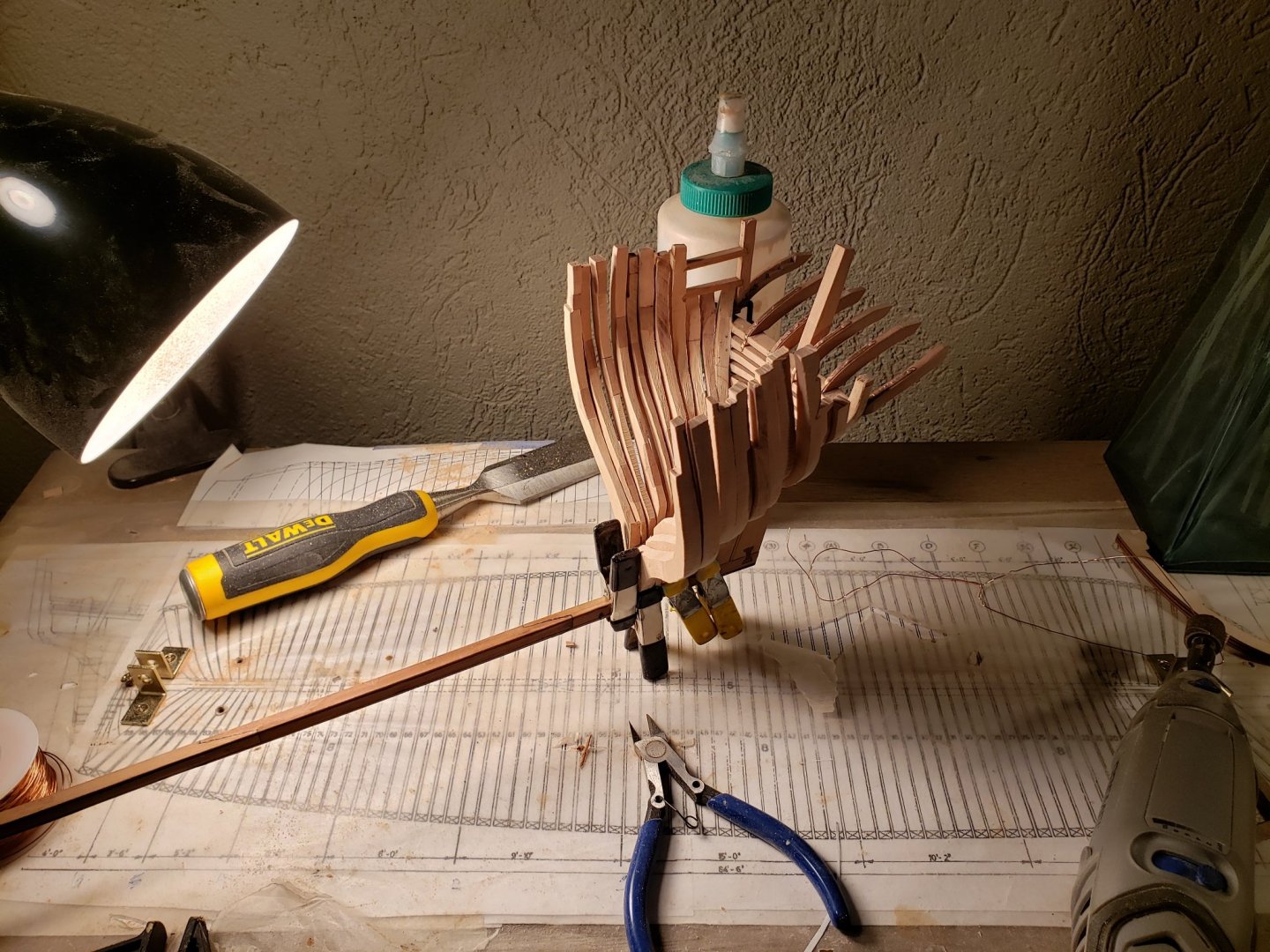

I'm going to put the keelson in so I can have a bit more stability for rebuilding and sanding frames. The frames are fairly shifty without it even with the copper bolts into the keel. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

I put in a temporary deck to support the frames so I can sand the outside of the frames with mini belt sander (also pictured) to the correct thickness. I feel like this method of getting a good shape is cheating, but here we are. when I build the next one I'll attempt to get the frames the final shape before I attach them to the keel. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

I put copper bolts through the frames and into the keel using CA. The drill bit is .5 mm and the copper is 24 gauge so its the same width as the holes -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

These lower deck templates will keep the hull at its widest point while I'm sanding the outside to the correct depth. I made them out of some leftover pine we used for baseboards on a new wall downstairs. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

I used a small round file and a razor saw to make this detail on the top of the first forward cant frame. Only 25 to go! -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.