AdamA

Members-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AdamA

-

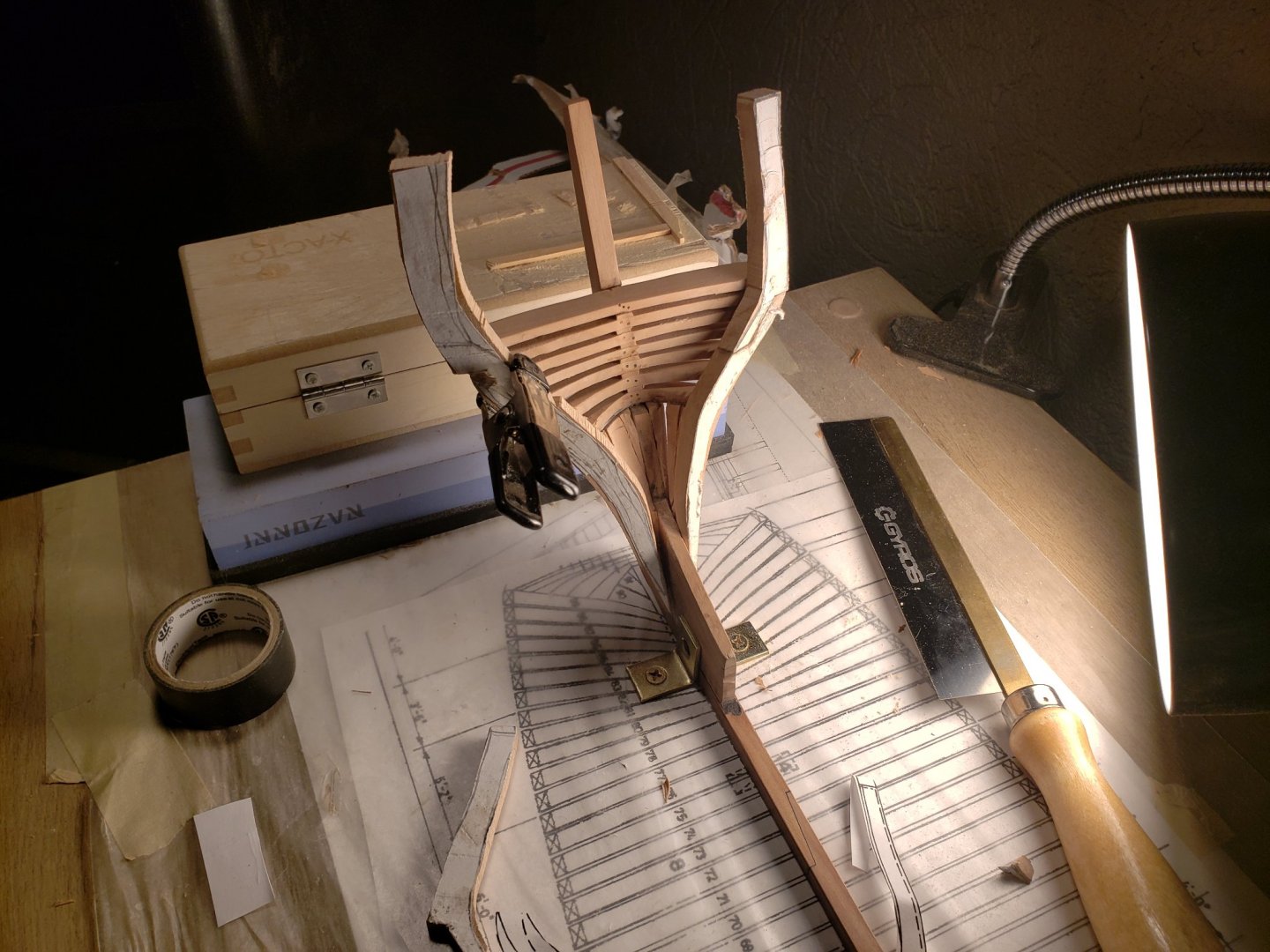

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

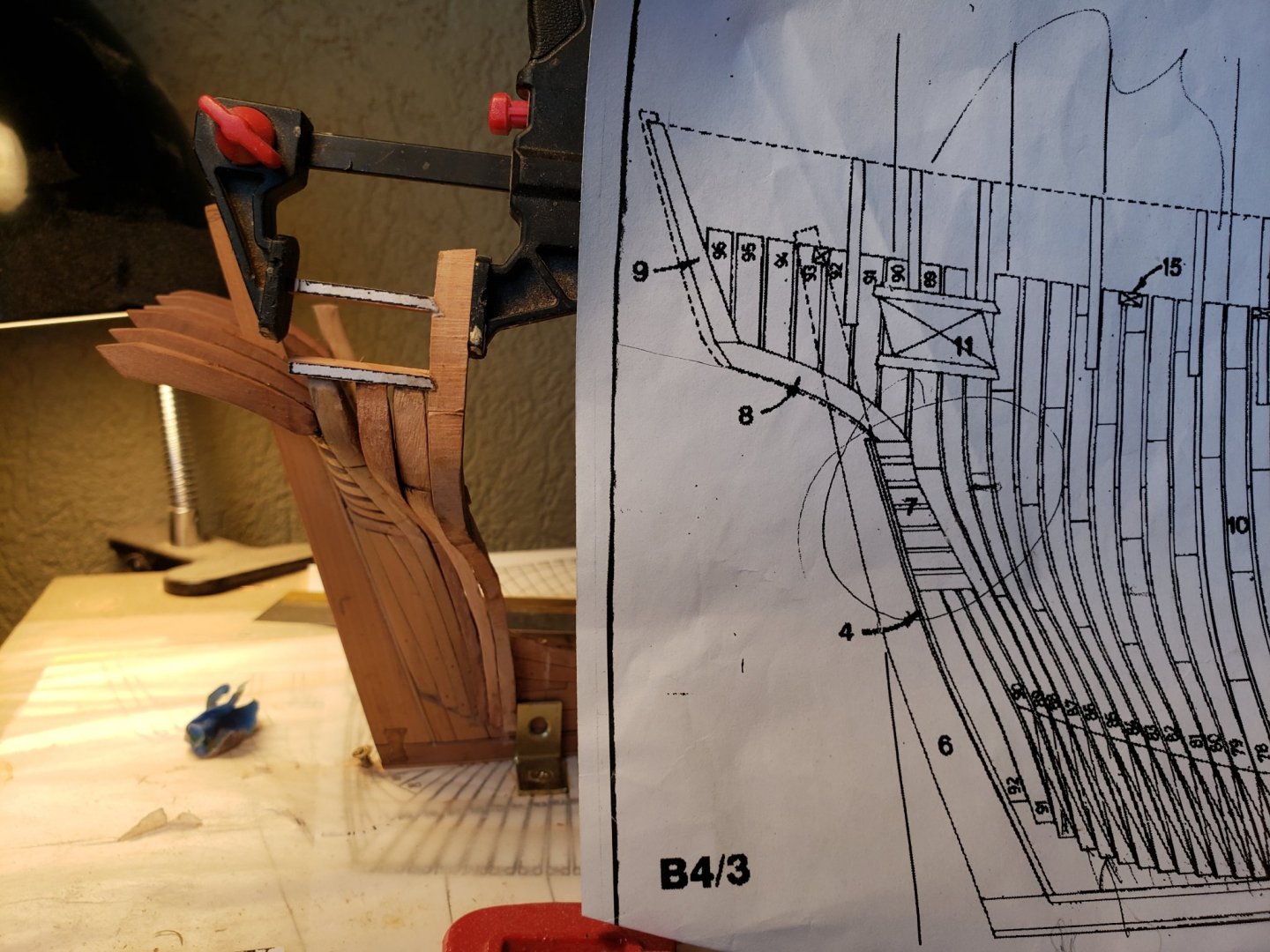

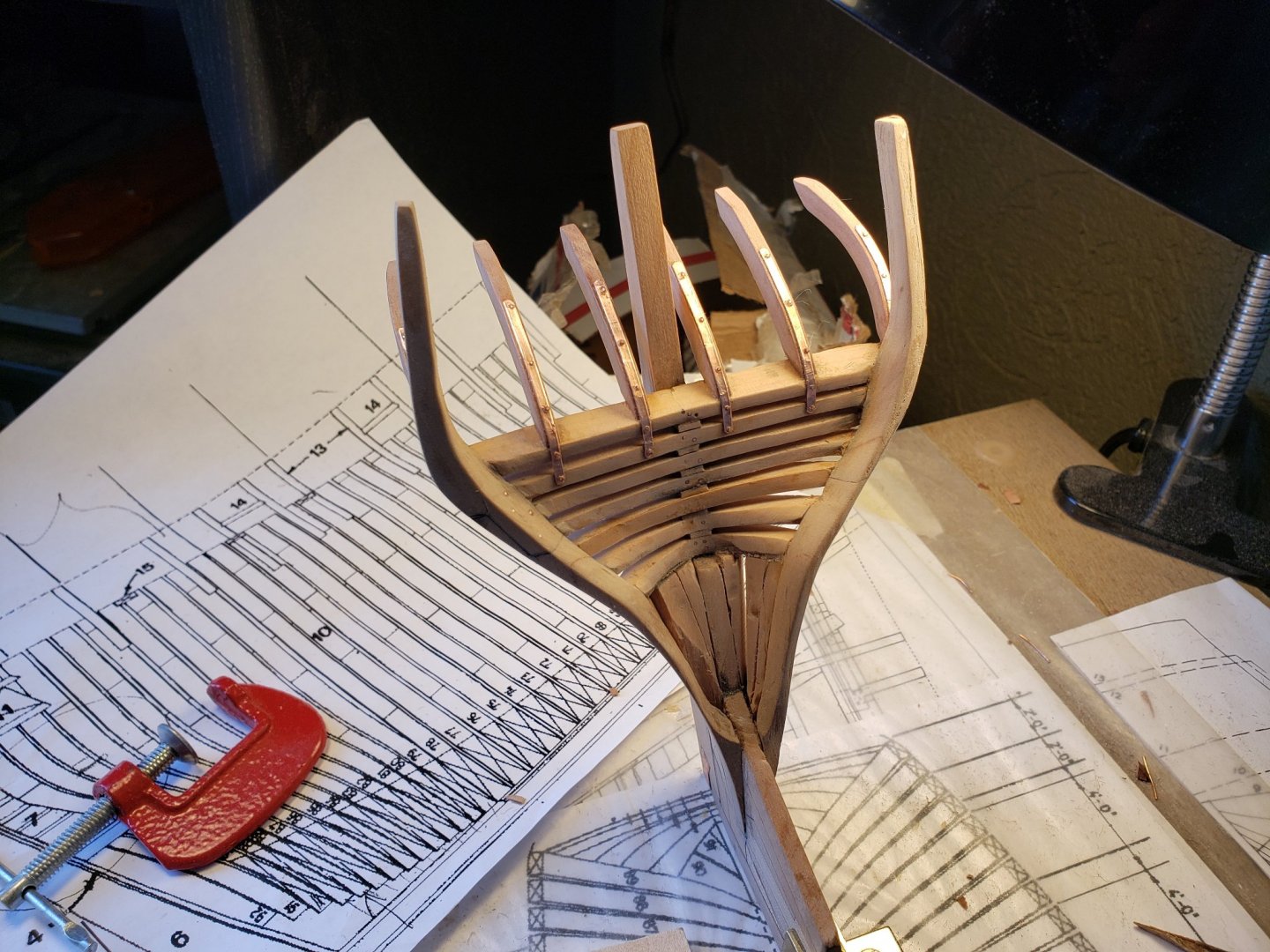

I put copper bolts through the counter timber and into the aftmost cant frame because I really don't want it to move. The "bolt" is 24 gauge wire pushed into a 0.5 mm hole with super glue. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

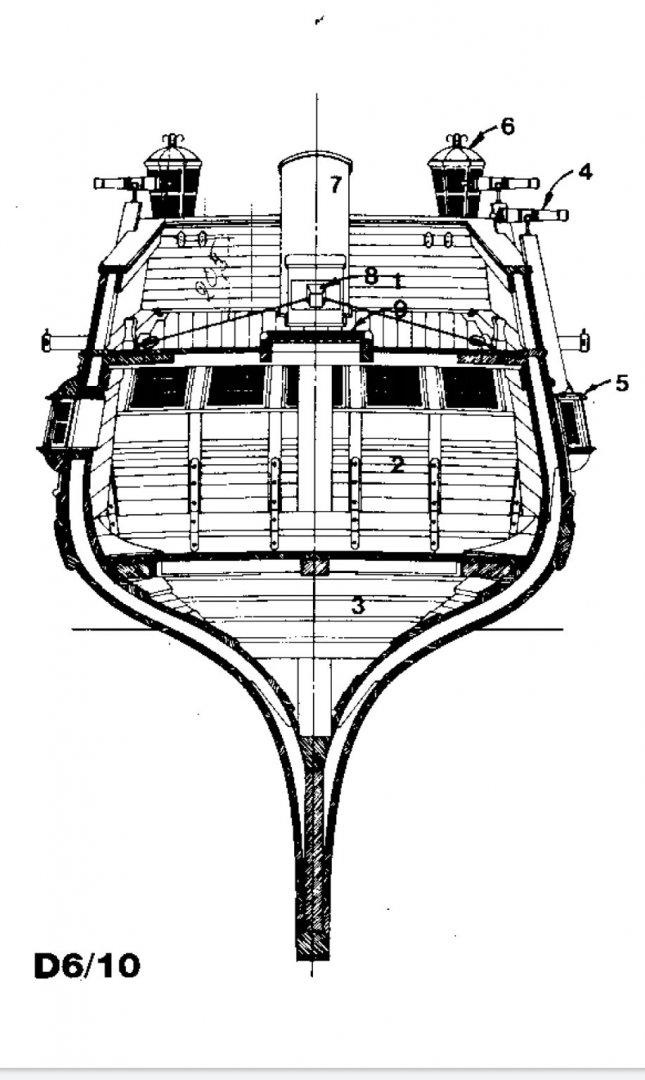

I used the pictures from McKay for the stern. You already have those I believe. Hahn's stern has fewer if I recall correctly. Your boat is looking good. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

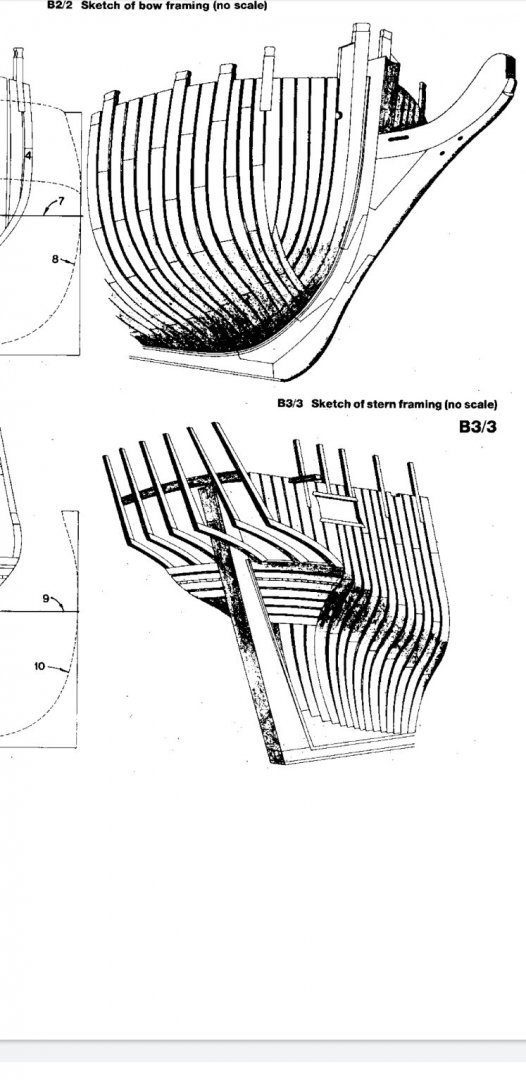

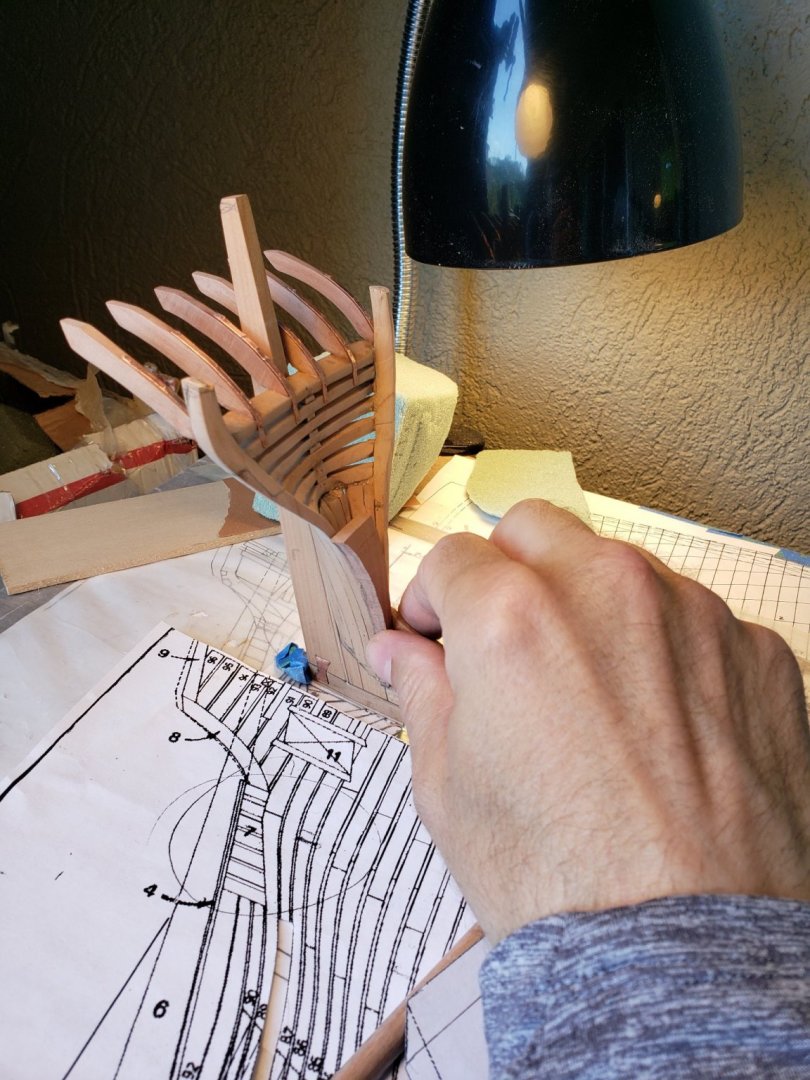

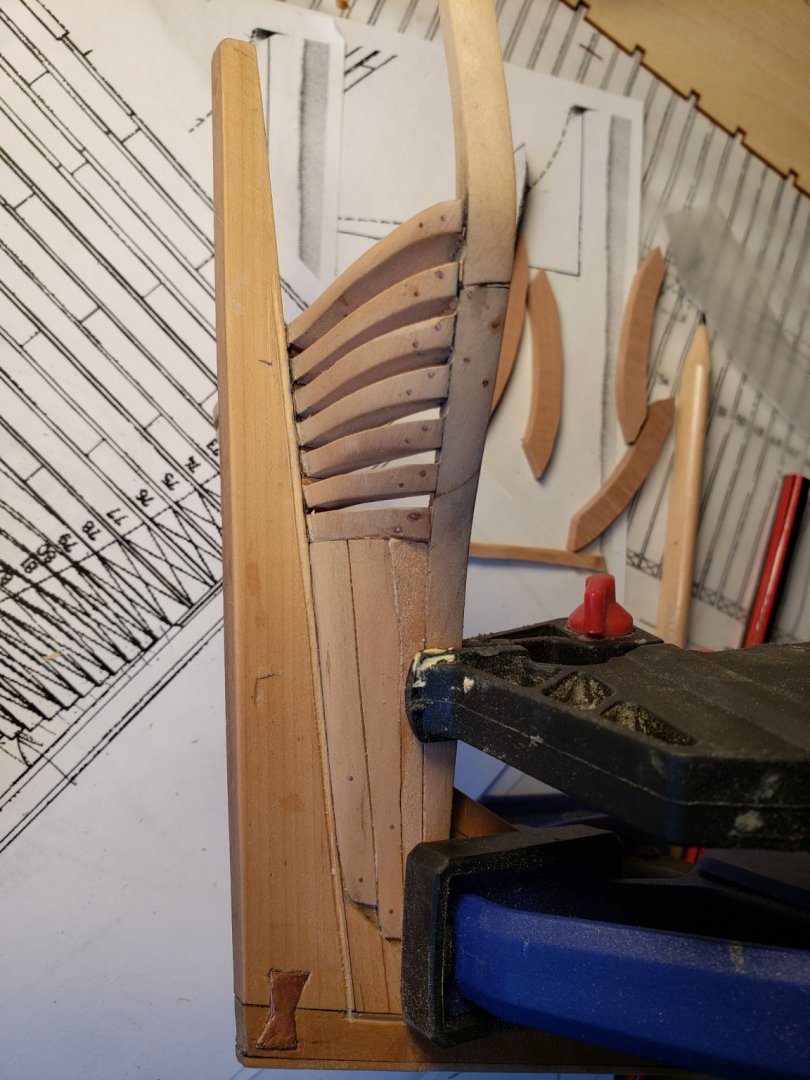

Its good to see the hull beginning to take shape. There's some variation in the color of Swiss pear I purchased thats evident from the three frames roughed in. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

I have the book to pull the images from. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

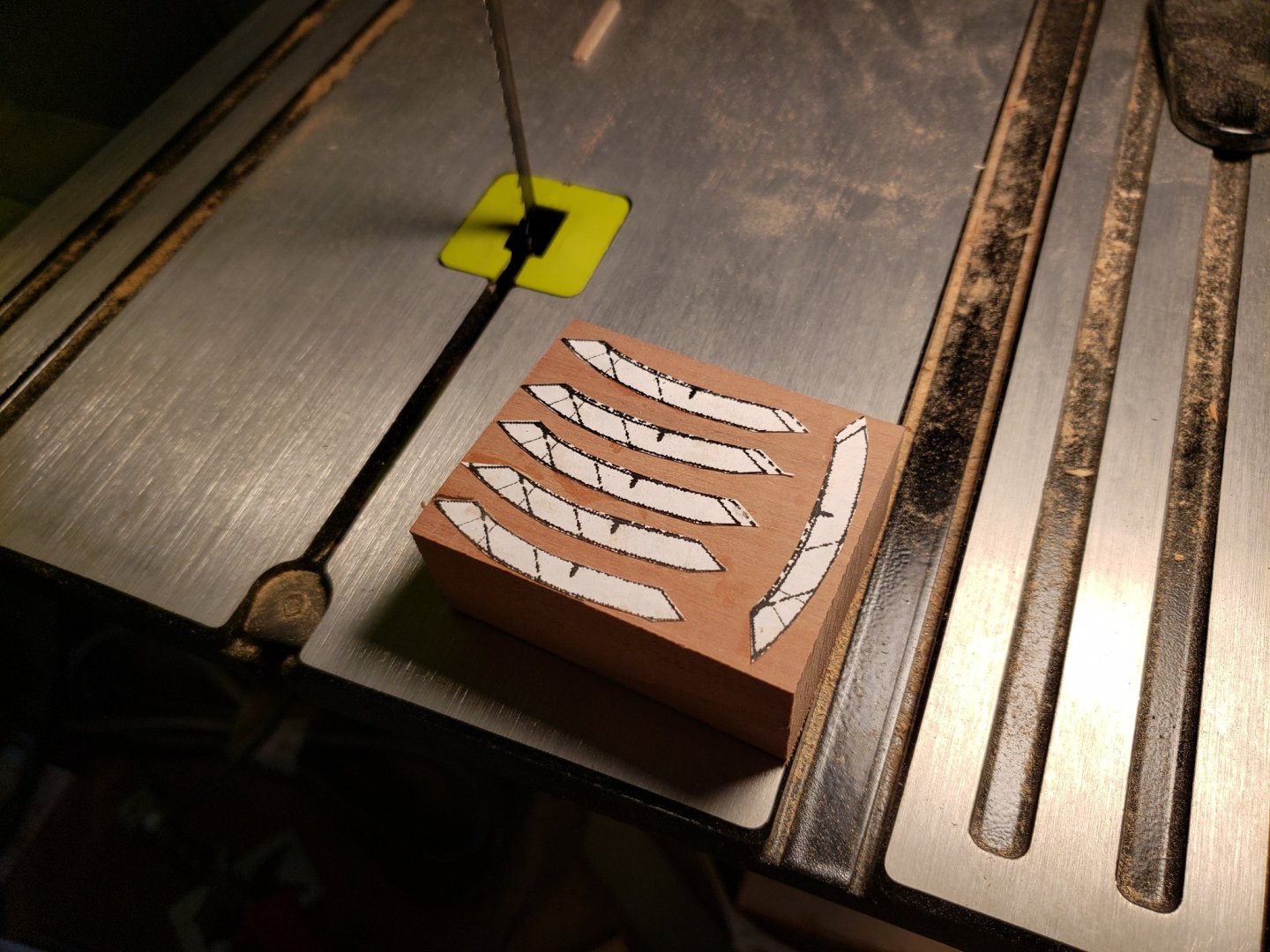

I don’t know how to use software to lift and loft these frames so, for now, I'm gluing the profile for each piece onto the wood and cutting them out on the bandsaw, careful to ensure each piece is wide enough to account for the frame's shape. I'm sure that's clear as mud -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

If anyone else has come across these straps let me know how you handled them. These are made from three layers of copper tape with 24 gauge copper wire for the bolts. All CA glued down. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

I noticed these six straps connecting the stern timbers to the top two transom pieces in the pic below. They aren't labeled and they are missing in all the other pictures so I'm not sure what they were made from. Considering the Bounty had to have all its iron fittings replaced by brass or copper when it was coppered by the royal navy (something they did apparently to keep the iron fittings from reacting with the copper plates, I'm going to use copper for them and for the five bolts in each. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

I cut a piece to fit into the hole. Its thin enough to twist along the curve where the original piece was. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

More surgery was needed. When I added bolts to this fashion piece I noticed it was shredded along its aft length. It must have happened when I originally cut it to shape. The shredded area was waiting for me to sand it down then it said "hello." I chiseled it out and will replace it before I move on. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

-

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

Welp. I learned a hard lesson about transoms. They like to wander off if you're not paying attention. I'm realigning them lol. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

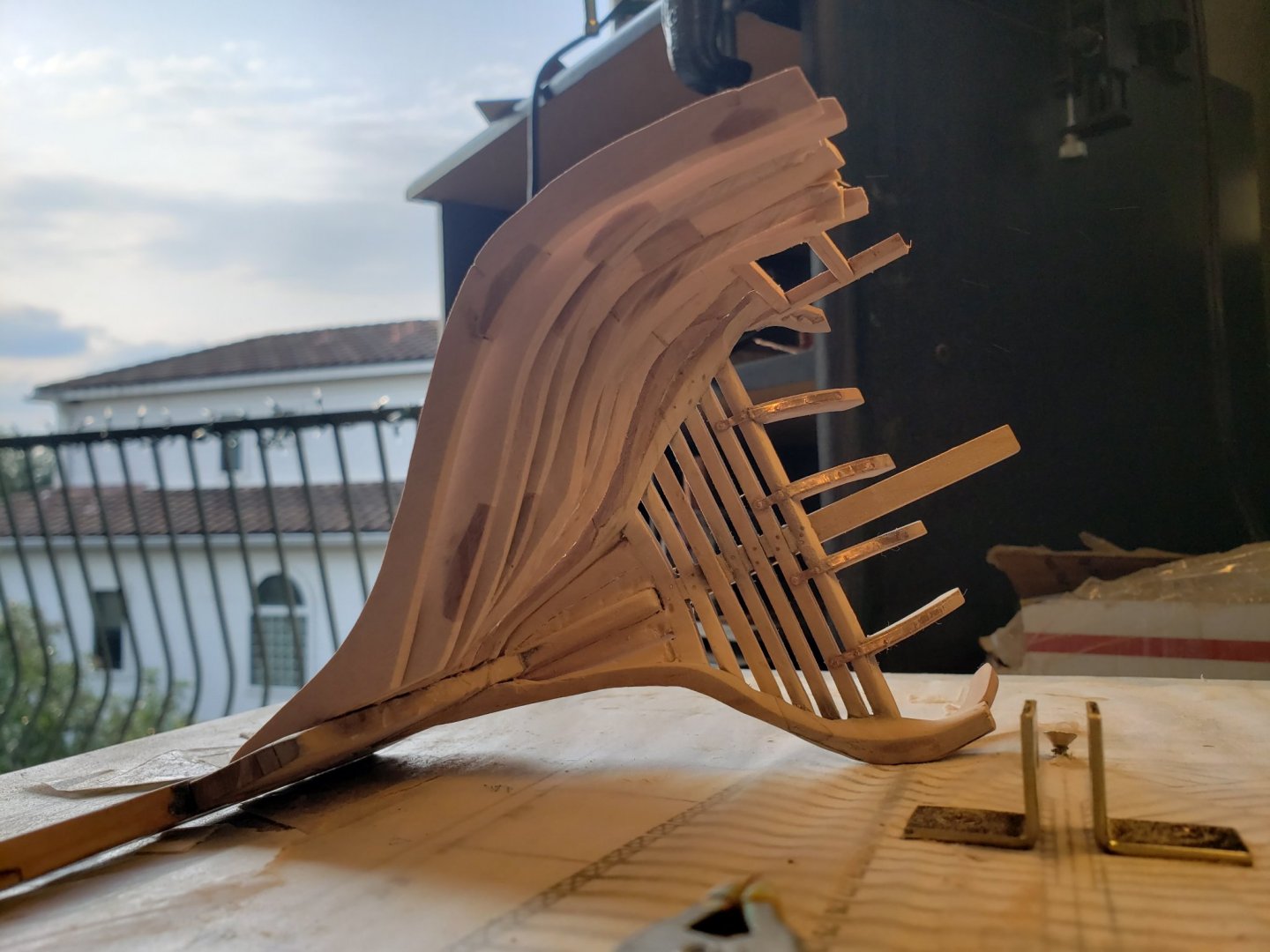

Ok. I had to remove the lower halves of the most aft cant frames so I could cut the scarph joints. Then I had to remove and recut them a second time. Here is the very rough draft of that frame: -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

On second thought I'm going to cut those scarph joints. I just cut the first one and I'm feeling good about the ease of doing them using a paper template. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

Ok I may have underestimated the amount of work that McKay's drawings entailed. He has scarph joints in every joint in the frames. No chocks. No overlapping single angled joints. All scarphs... I may make an executive decision to use chocks for all the frames. -

HMS Bounty by AdamA - 1:48

AdamA replied to AdamA's topic in - Build logs for subjects built 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.