-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

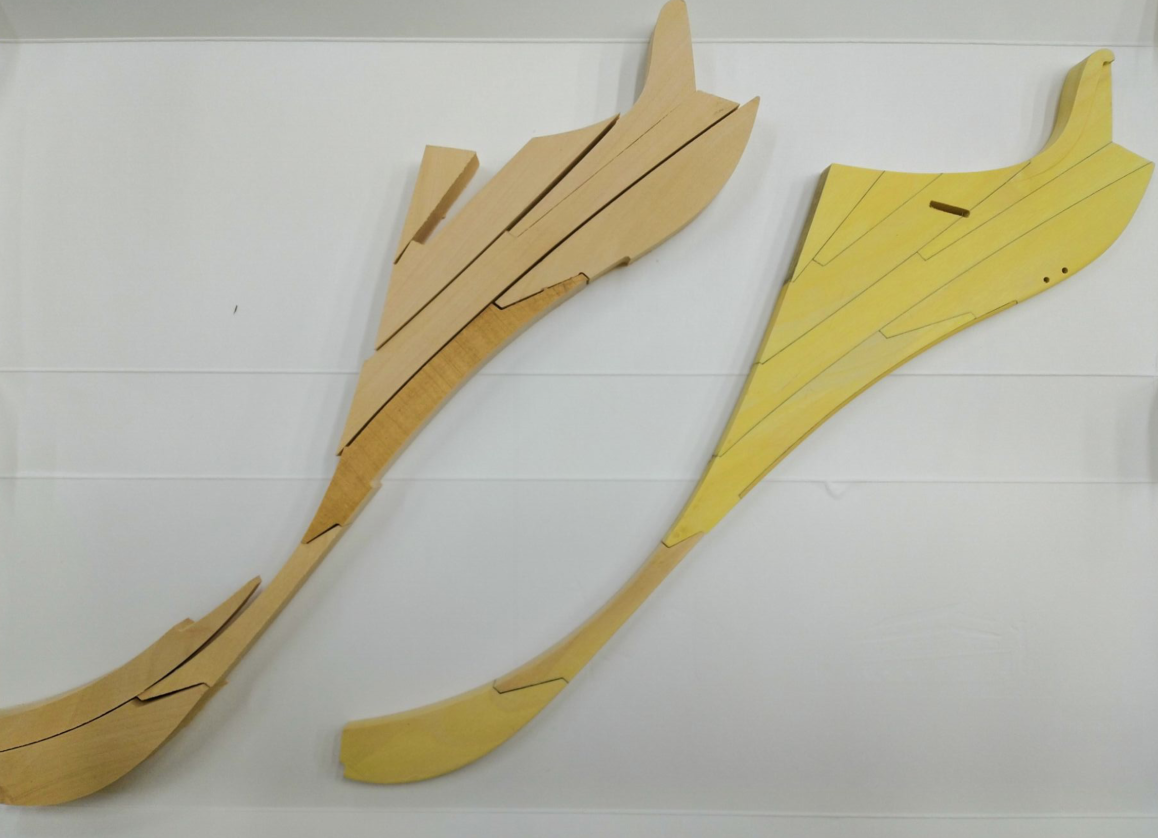

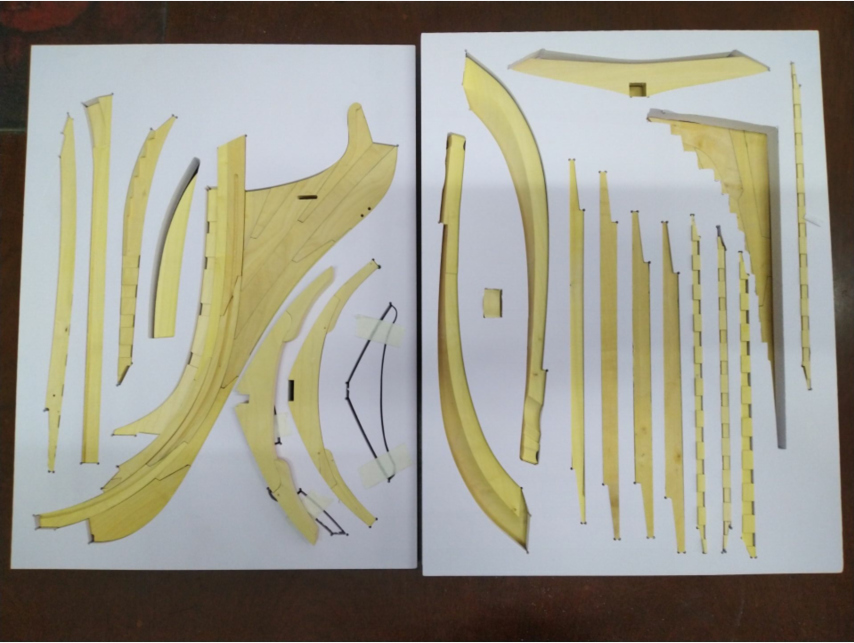

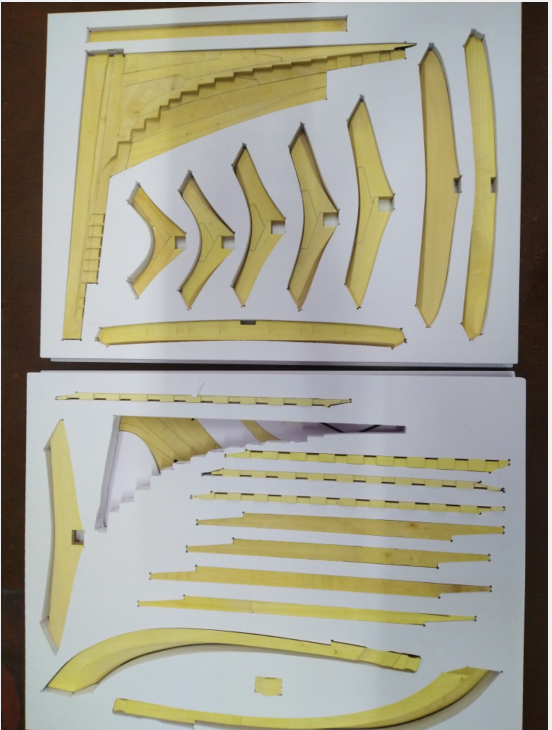

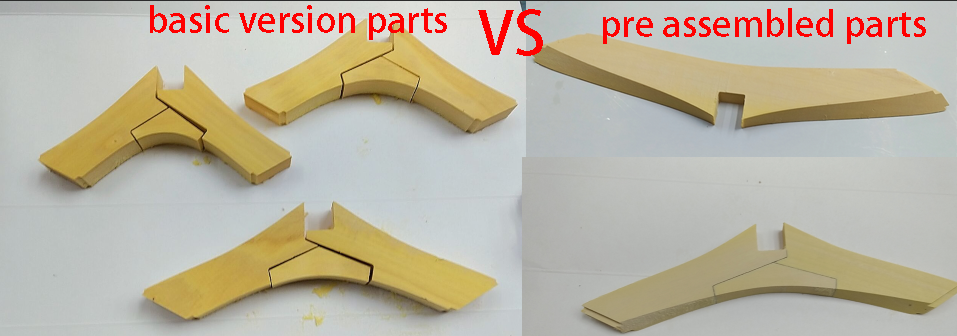

Yes,that's basically the first chapter. And then I went on to process the 1:48 parts, and I started to make this model in a real sense, I want to show you my idea, that is, how to simplify a complex POF model into several large parts by machine and hands, so that modelers with common skills and no professional tools can make this complex model. This is the first step. Let's take a look at the basic parts of pear wood and the pre assembled parts of jujube wood on the right.I will process a set of Asian boxwood samples at the same time.Maybe you are tired of looking at those model parts all the time. Indeed, I am too busy. I have to go to work during the day, and then design and process the ship model in my spare time. Maybe I only have a few hours of spare time every day. However, my classmate's processing factory can process these parts in batch ,I insist on testing these parts myself in the hope of finding more mistakes and modifying them. On the left is Chinese pear wood, and on the right is jujube wood. Asian boxwood and jujube wood look similar, but undoubtedly boxwood is the best, more delicate than pear wood, and has good color. In the future, I will release about 3-10 full boxwood kits, if anyone likes them.

-

No, it's not the final product. I mean the parts I'm going to send out, but it's the first chapter of my plan. I need to finish at least the hull part, which means that I have to complete all the design and prototype of carving set. Secondly, in addition to the first chapter you have seen, there are also need all cant and square frames, then decide whether I can release chapter one. As for those "β parts" ,there are very anxious modelers who are willing to take the risk of project failure and willing buy β Version to participate in the verification of this project, I promise them that if the project fails, I will return all the payment to them.But we don't accept such orders now. My German friend will participate in the second batch of prototypes,if everything goes well, my UK partner will probably make this model in the third batch because he is very busy now. The final English version, including instructions and components, needs to be determined by him--He also owns the copyright for the project and owns 'True Image Models'. We are looking for cooperation with MSW. It will take time to determine many details. In order to reduce tariffs and freight, I am considering whether we can process some parts in the United States. Similarly, I am also considering processing some parts in Germany or UK.But all these need to be accounted for before the final decision can be made. If really can't reduce the expensive price , I will consider the concept of "basic parts". I only process a small number of parts, such as steps, hawse pieces, can frame... and carving set,--i call it ‘plans+basic parts’ or 'semi-kit', which are difficult to be made by hand. The rest are made by modeler himself, which can reduce the cost greatly.You guys can tell us any your suggestions and ideas. Thank you! Jack

-

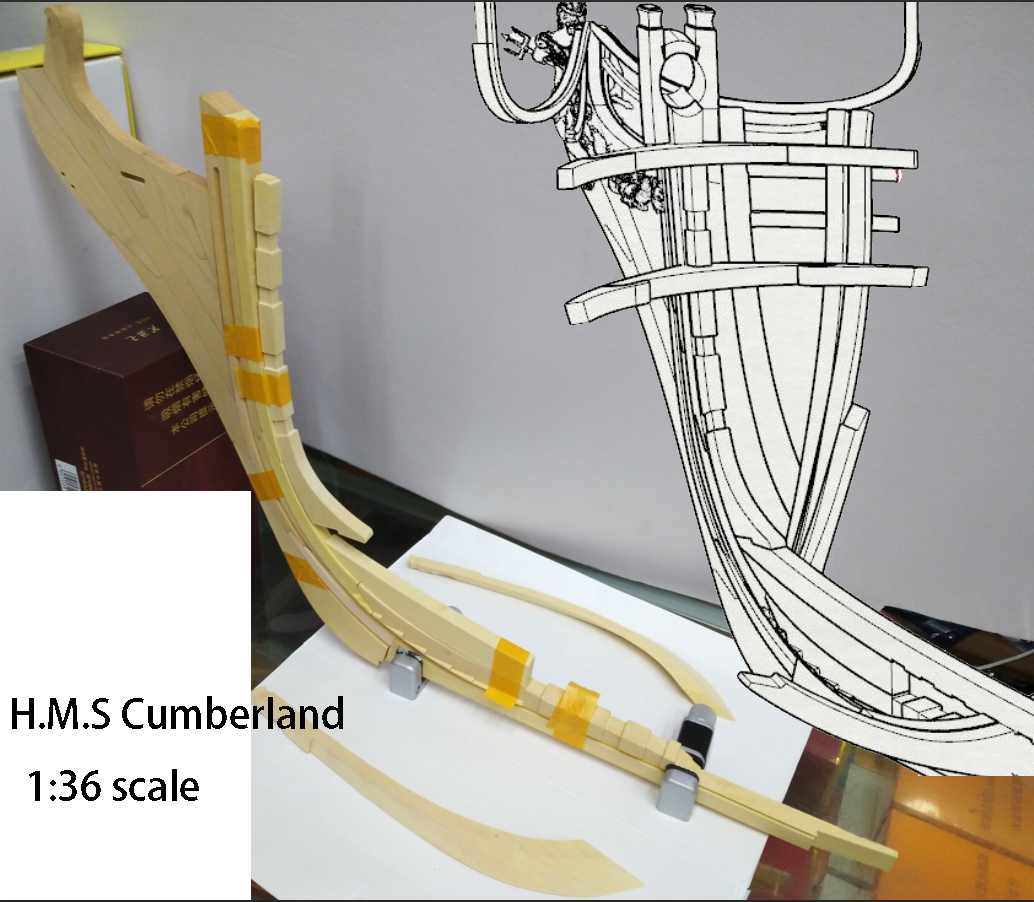

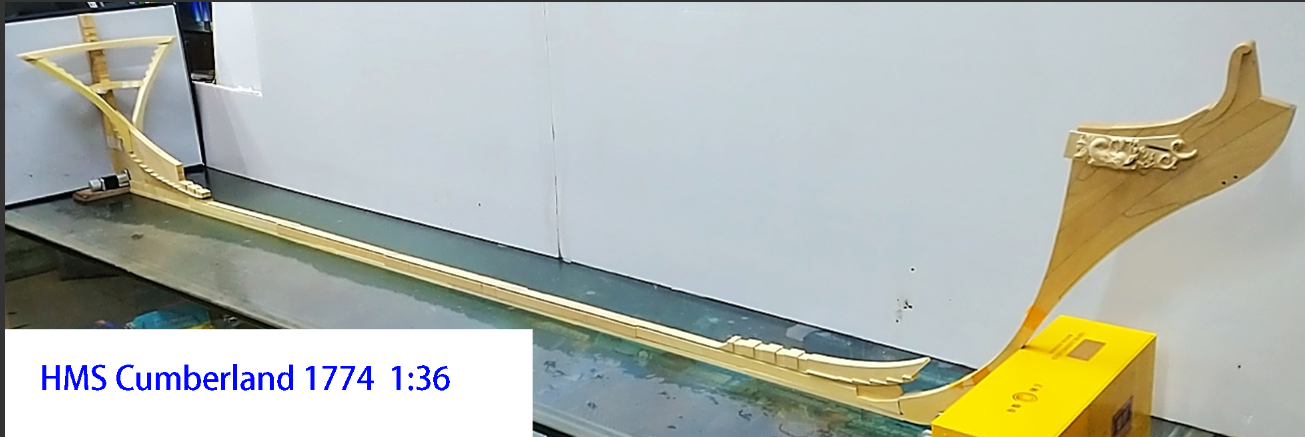

Hi! Maybe I'm processing 1:36 and 1:48 pear wood and boxwood parts at the same time, so it seems a bit messy,but I'll mark the scale of prototype. 1: 36 is a customized model, I can only verify the 1:48 version of pear wood and boxwood myself. Pear wood will be the basic version. I should release the parts of the basic version immediately. As mentioned earlier, the basic version is equivalent to the parts of laser cutting. The difference is that the laser has black carbon , but the CNC has no black carbon . Because the thickness of the laser cutting board will not be too thick, the kit scale for laser cutting is generally small, such as 1:72 or 64. The first chapter parts (1:36)will be sent out soon, and then I will process 1:48 parts of pear and boxwood, you will see the material and color of pear wood more intuitively. Jack

-

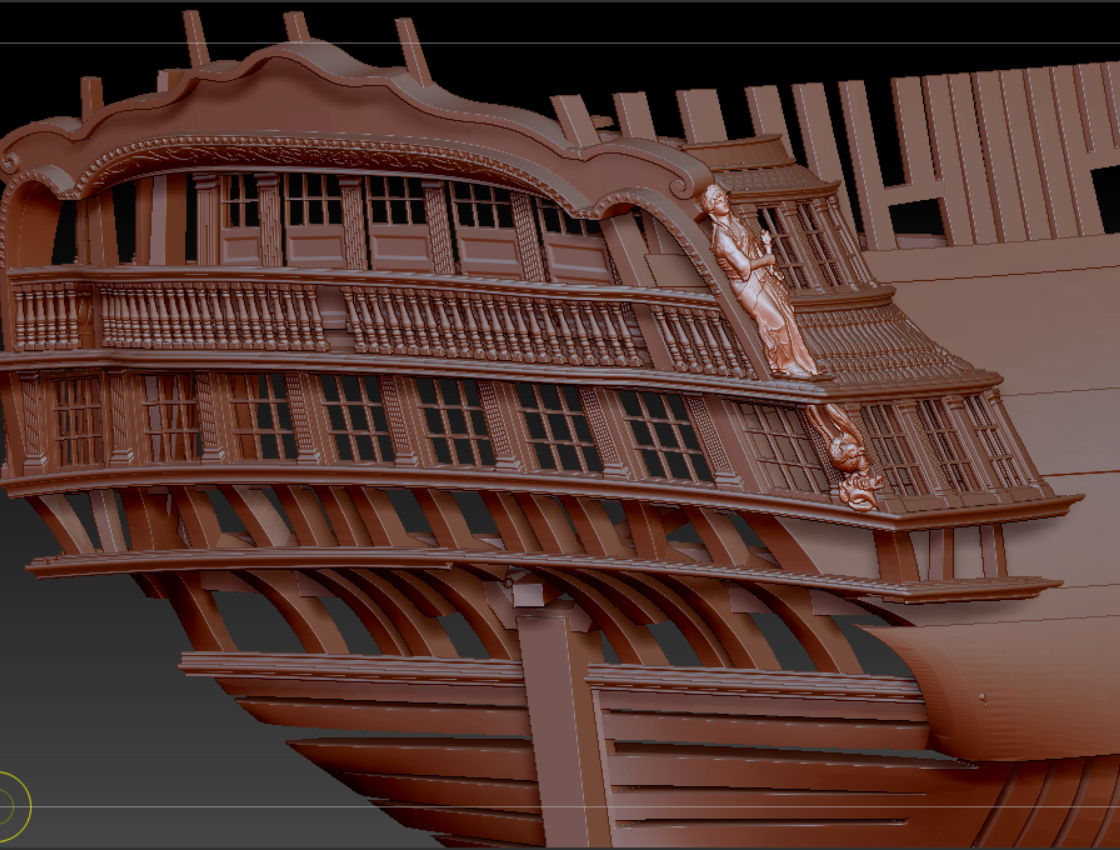

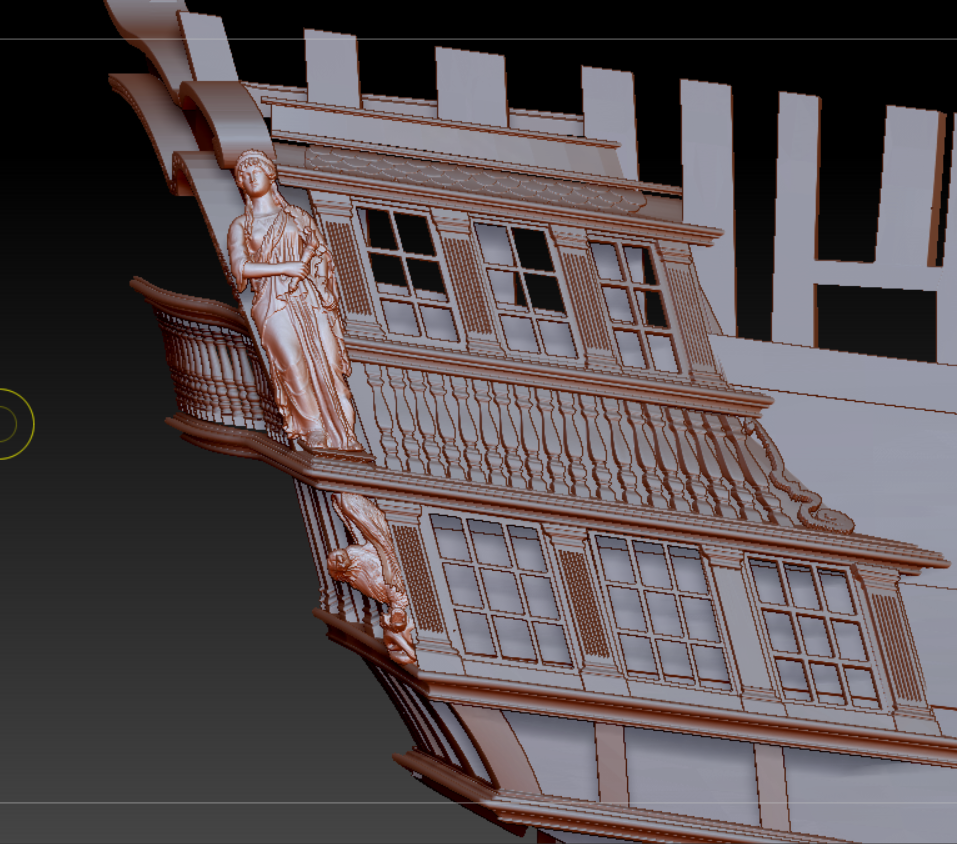

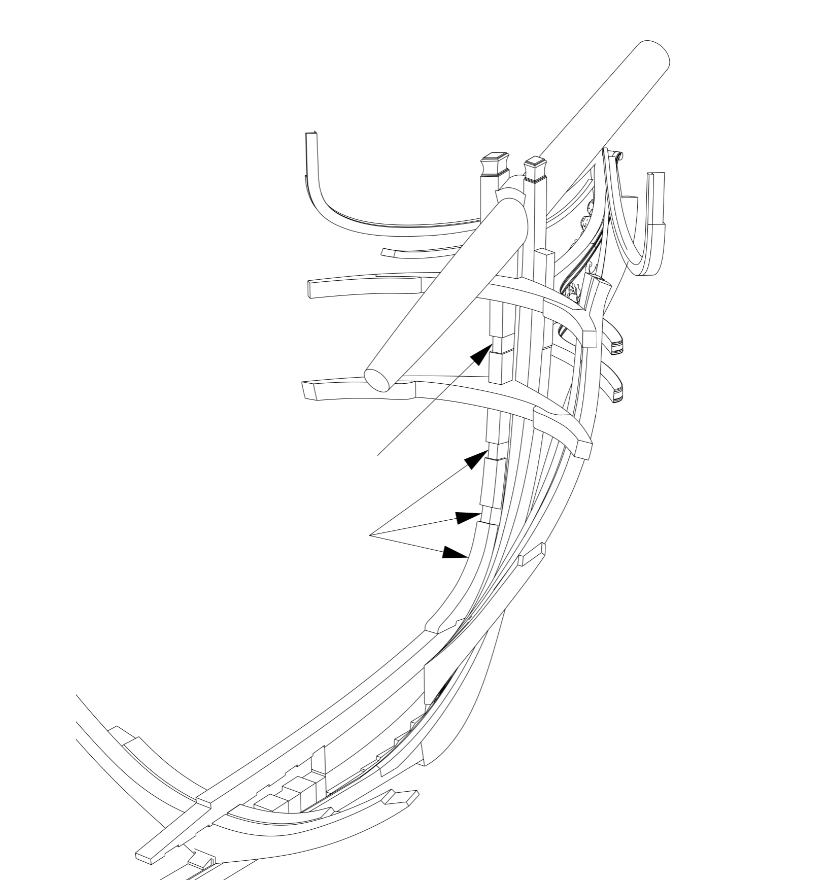

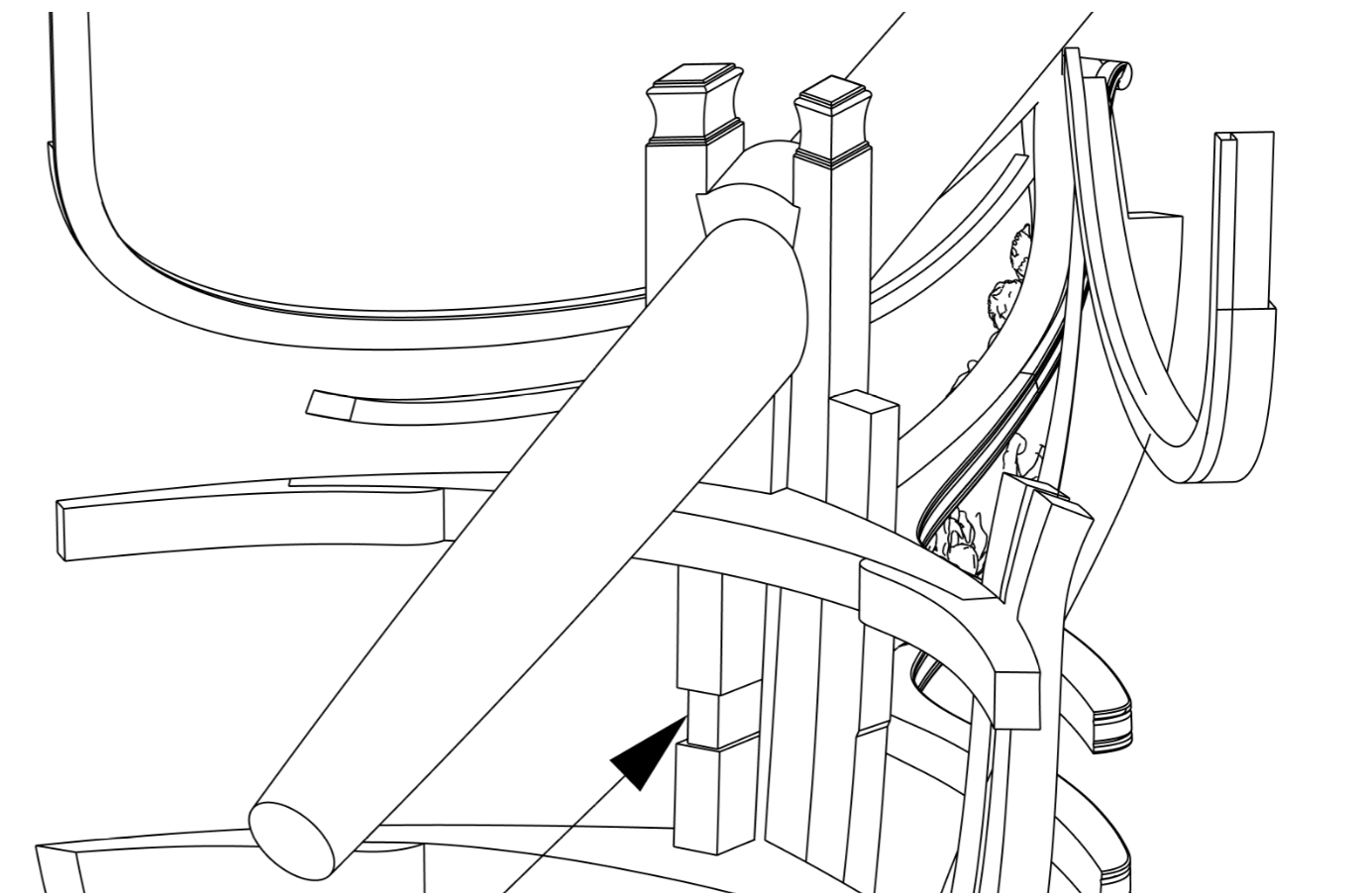

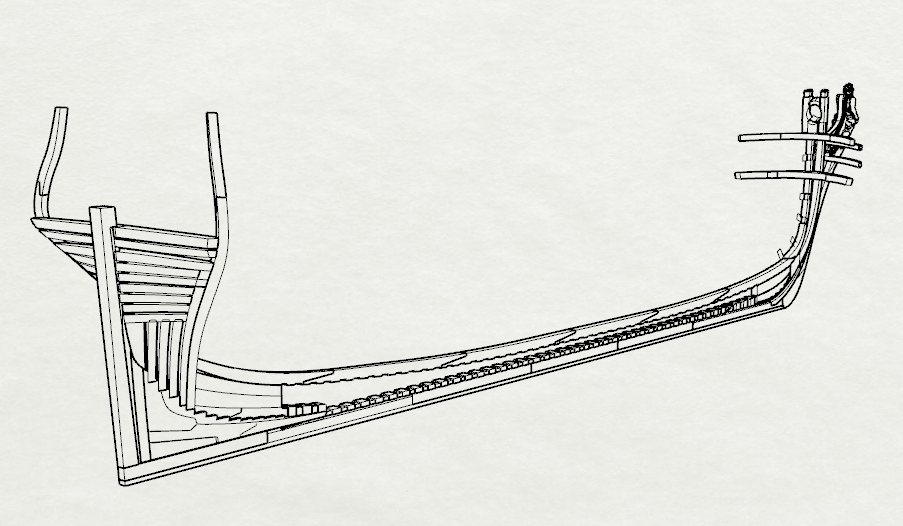

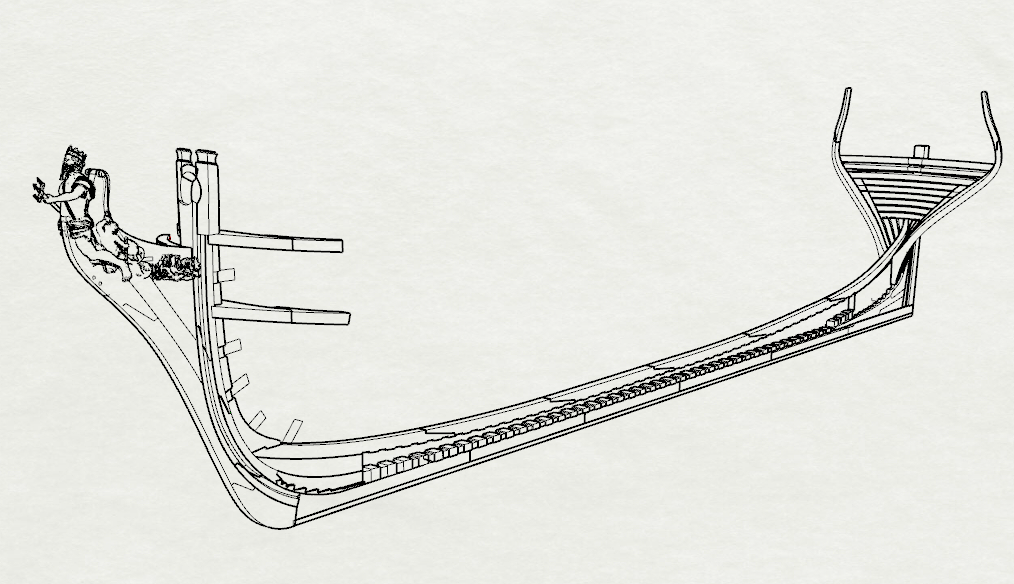

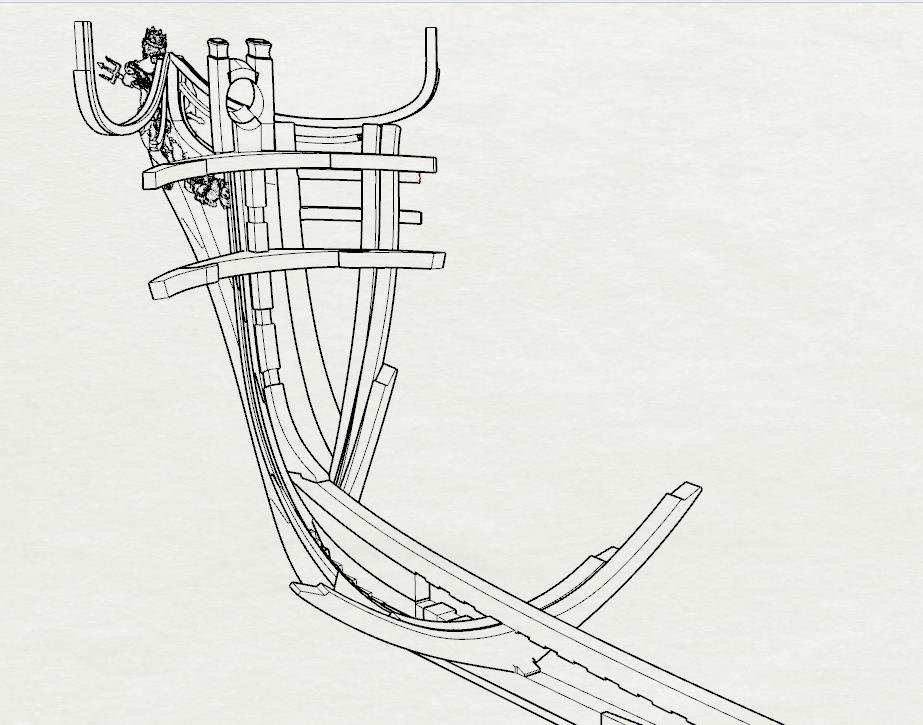

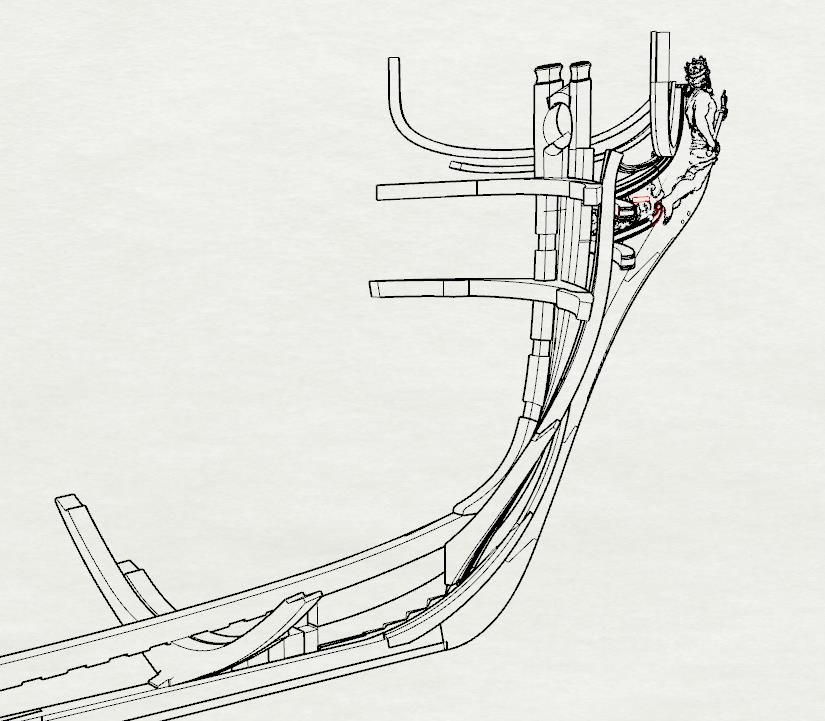

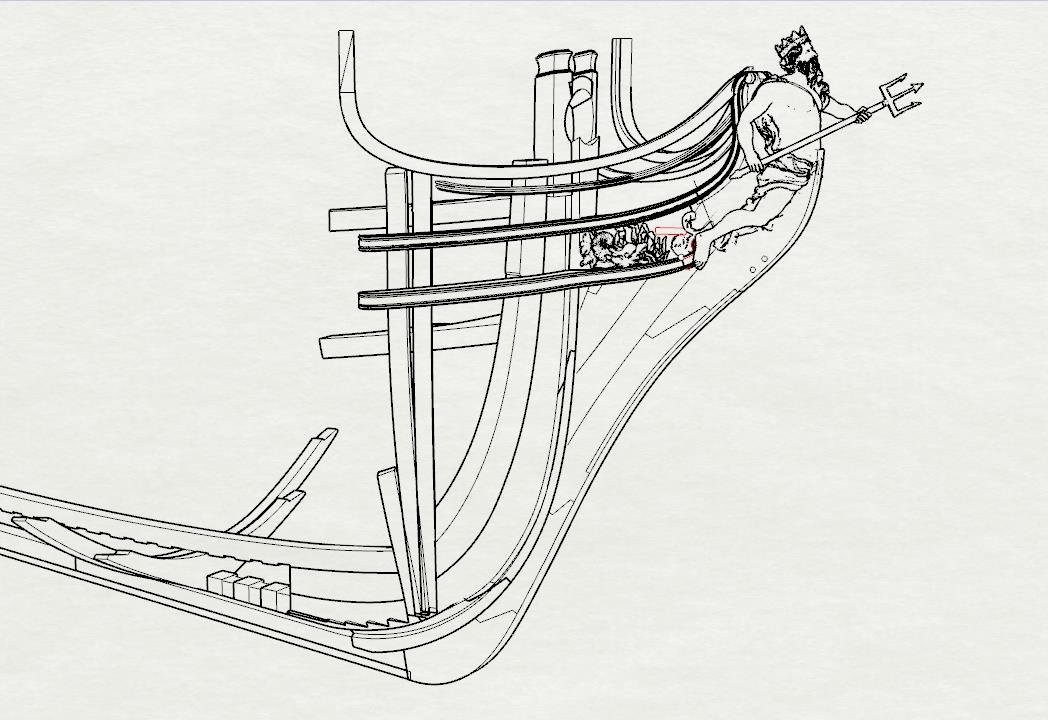

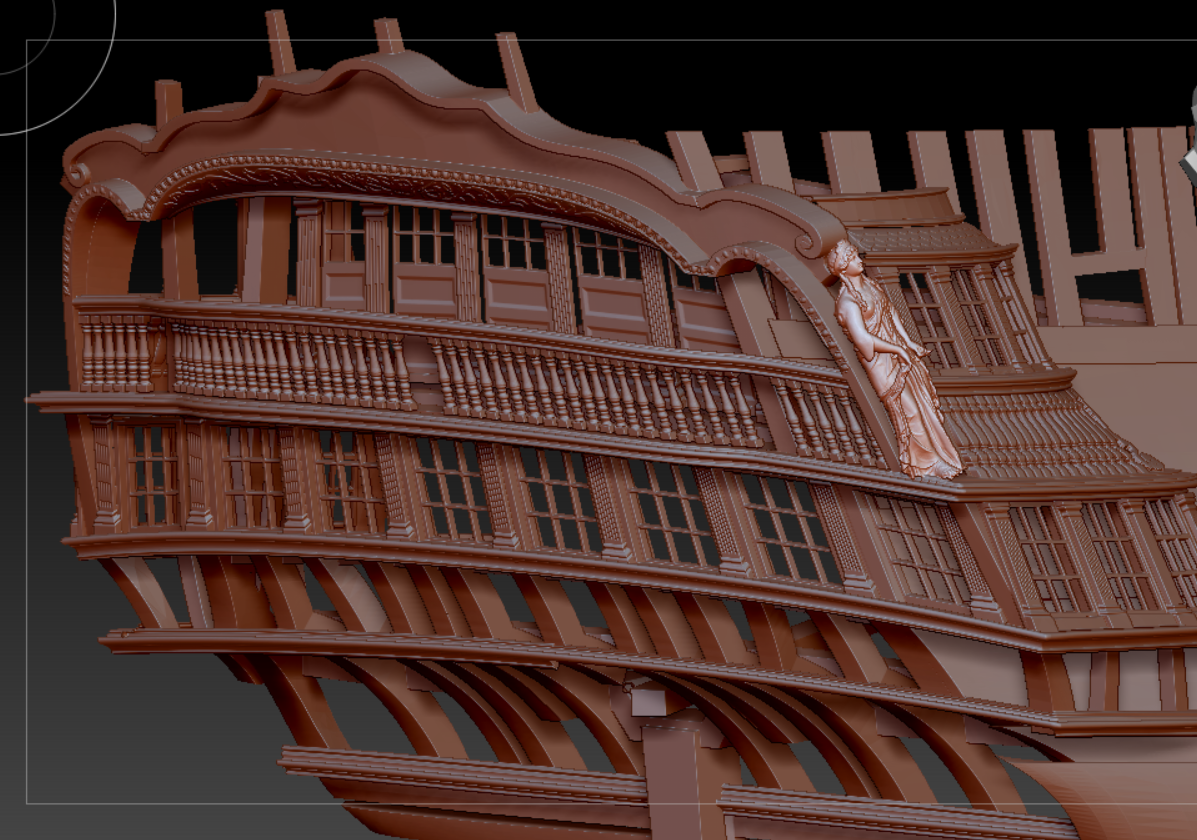

Now I'm not sure about the length of the bowsection, but at least she will contain a lower deck and an upper deck's gun ports, By the way, I'd like to show the "3D structure diagram". These black and white line diagrams can enhance the understanding of the structure. There will be such a structure diagram in the assembly instructions in the future.

-

Hi JJ, Now I'm not sure about the exact release time, but I can make a general plan public. As my area is now in the rainy season for more than two months, and then from July to December is relatively dry season, so from July to September I will process the first batch of 20-30 sets of basic version, using pear wood. I'm testing the parts of pear wood, and I'll release the photos of the parts in the next few days.Then I will process some pre assembled parts properly. But the official sale, or booking, needs to wait until the prototype is completed. For the English version, I prefer the chapters mode of bow / mid / mid / stern section, so that even if you are not willing to continue to make the remaining chapters, the previous chapter can also become a separate model. If you can finish four chapters, you can also assemble a complete hull.I think the bow section will be released more quickly, but if you stick to the traditional Chapter mode, I think it may need to wait until next year. If I have completed at least 10 sets of basic parts from September to December, we allow 1-2 experienced and skilled members to participate in beta kit (testing kit). It needs to be emphasized that in MSW forum, non-sponsors can not publish commercial information, but I am a "de facto sponsor". Because we (true image models) have not been able to prepare the website, and for some other reasons, we have not officially published the links of sponsors. Jack

-

Thank you. I agree with you. In fact, the basic version of kit is the most realistic. It saves complicated processing and costs. Modeler can decide whether to choose pre assembled parts according to its own needs, that's why I've introduced the two versions in detail .Secondly, this kind of face-to-face communication can let me know more about modeler's feedback and process kit that suits most people's needs.

-

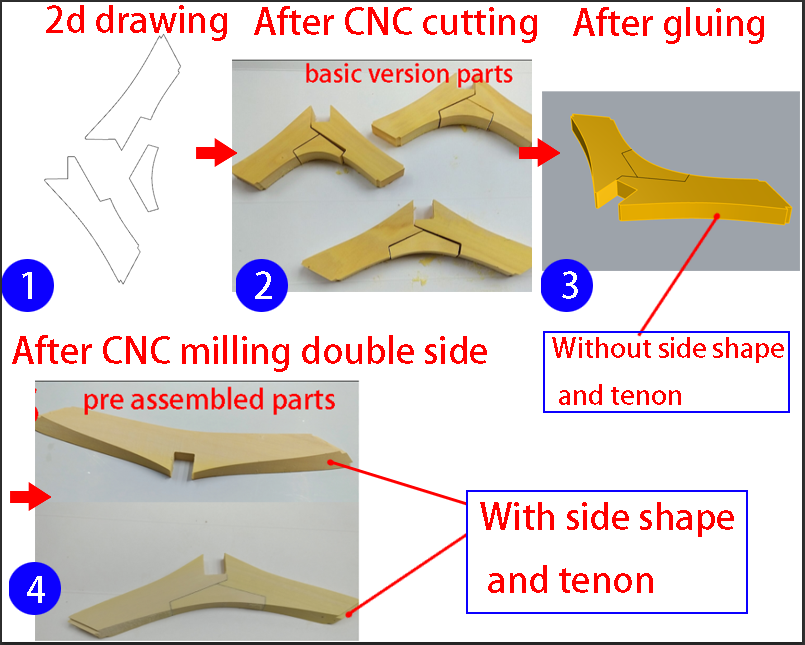

Hi JJ, Maybe this picture can help me explain the difference between the two versions,they are all precision cnc cut ,the basic version is equivalent to the second step, and the follow-up needs to be completed by yourself (whether it is traditional manual grinding or power tools).It takes a lot of time and some skill, but it can save money. Pre assembled parts can save a lot of time, which may reduce the time from 5-10 years to 1-2 years (maybe). But the high-end version does not mean that all parts are finished. That is unreasonable. The high-end version will pre assemble and process many parts that are difficult to make by hand. Other relatively simple parts are still equivalent to the second step. “Are you actually going to offer and ship pre assembled sections of the model in the kit”,We are experimenting with this plan. We can at least provide the kit for the second step. As for pre assembled parts, we need to find a balance between convenience and price, that is, we will control the proportion of pre assembled parts Thank you! Jack

-

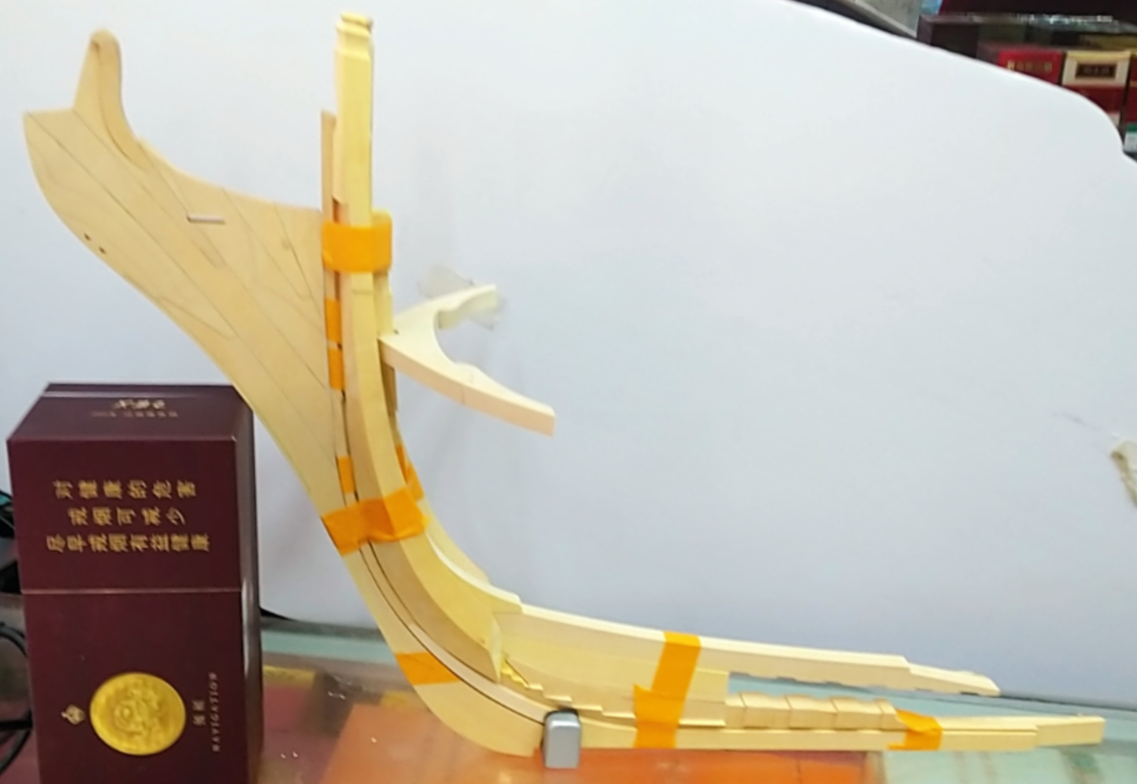

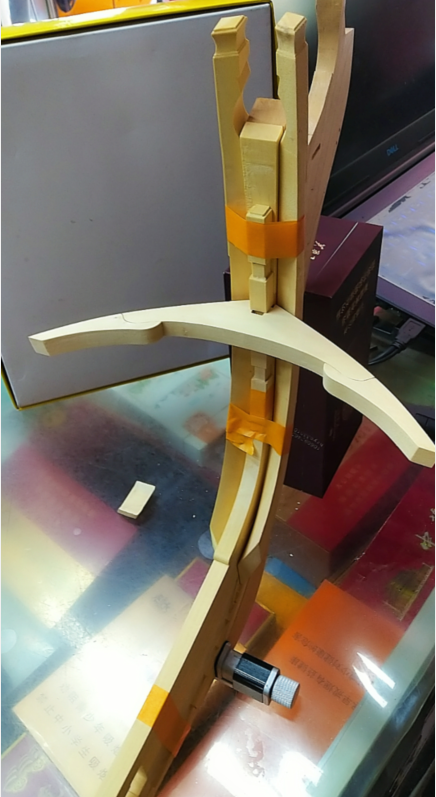

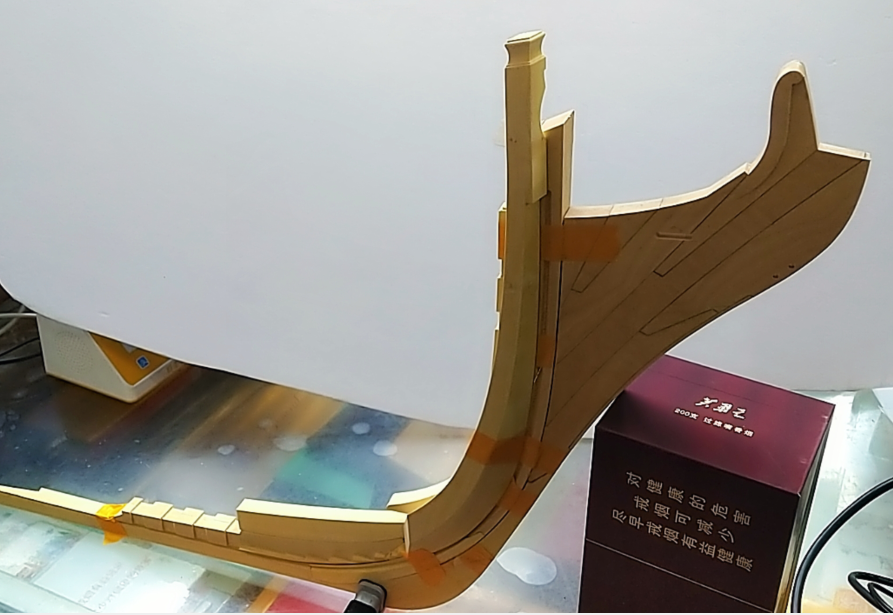

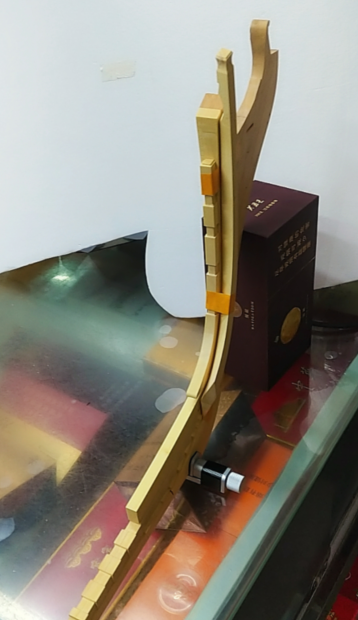

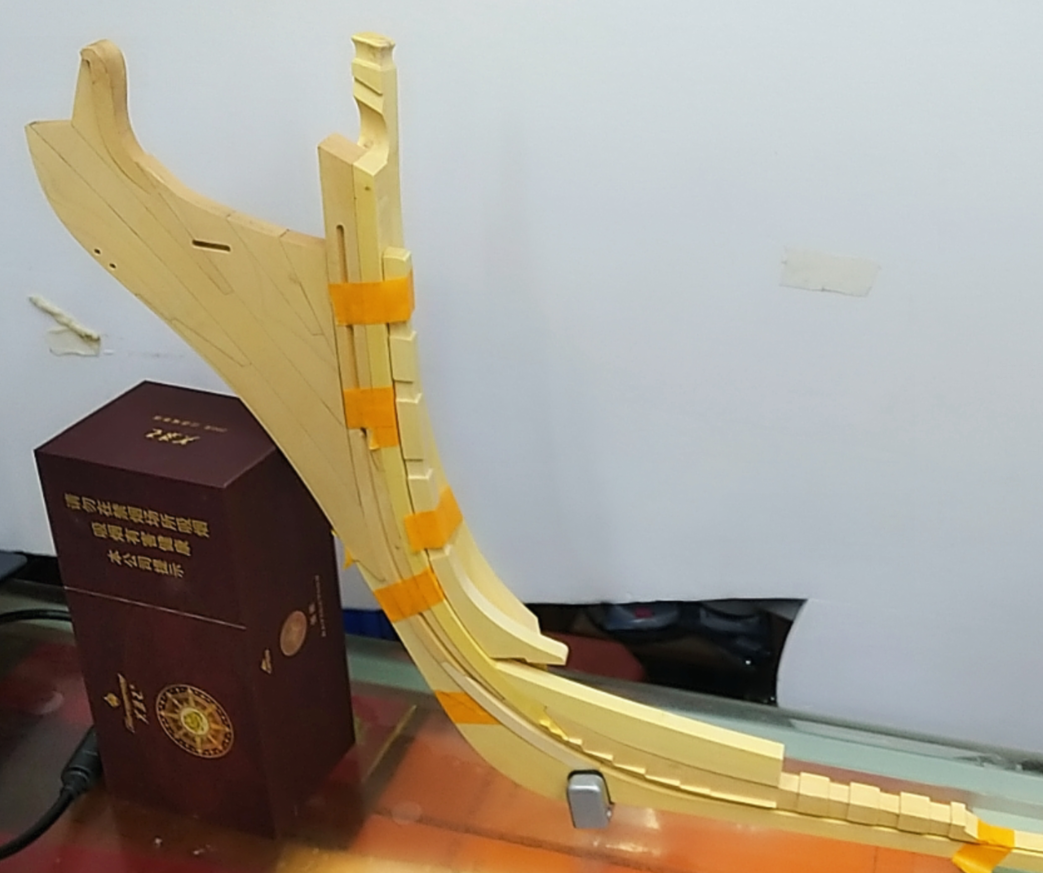

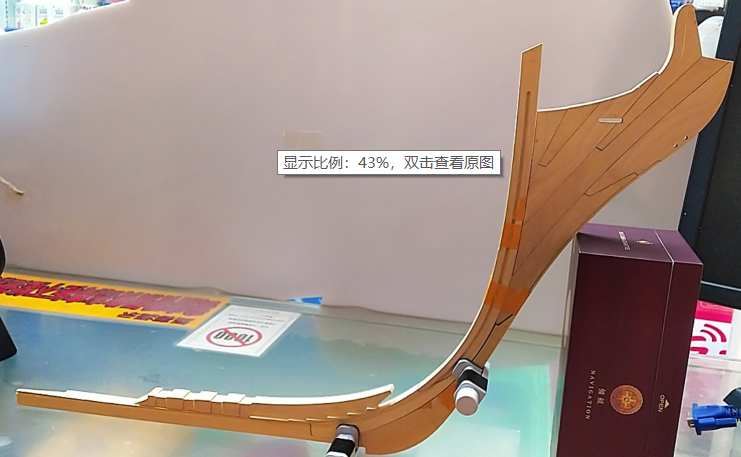

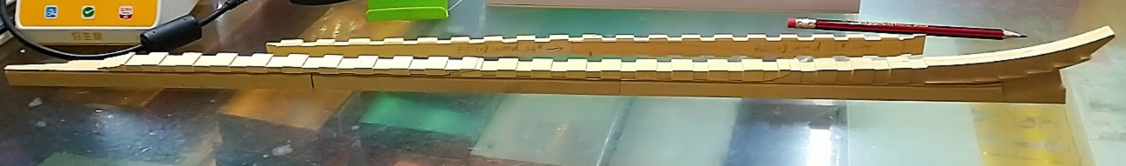

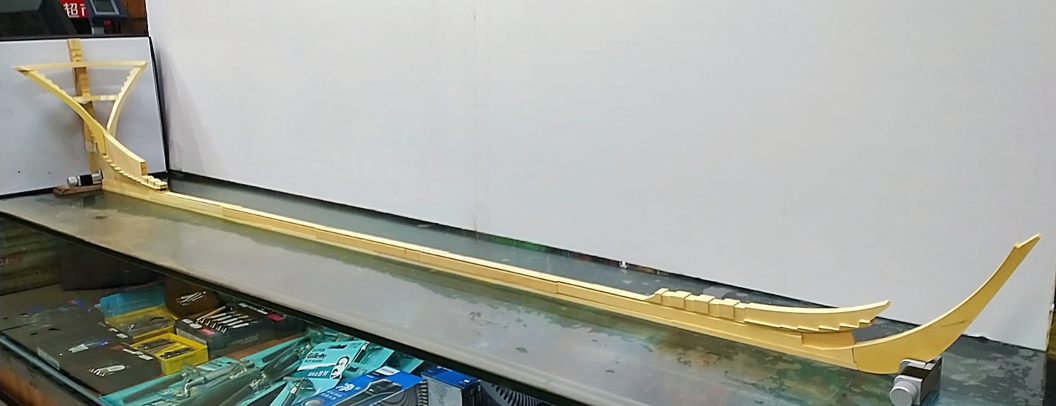

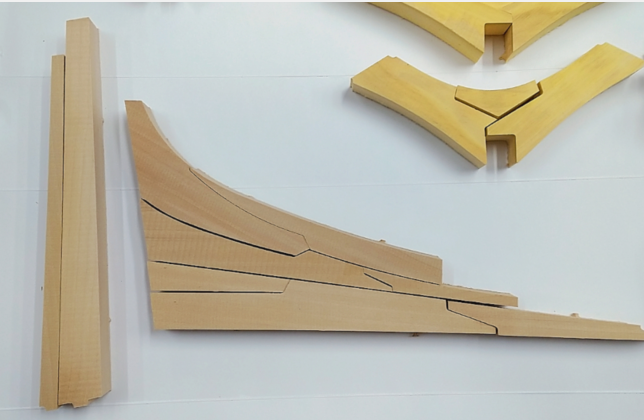

Hello everyone,haven't updated for a long time for busying with other things. Just as stern post and dead wood, fashion pieces and transoms are processed, I will talk about some of my ideas. POF or fully framed model because of its complex structure, it is difficult for ordinary modelers to process these parts by hand. Even modelers with high skills need a lot of time to complete these complex parts. I use CNC to process these parts, which is simple and fast, and can save a lot of time for you. This is just a commercial kit. My goal is to make a POF model that only a high skilled modeler can do before, without taking 5-10 years for a modeler with ordinary skills.The following two figures show the pre assembled parts (deadwood) and the pre machined parts (transoms, fashion pieces, after fashion pieces). 1:36 Cumberland 1774 However, there is no doubt that this kind of pre assembled parts will increase the cost, and the price will be much higher than the basic version. 1:36 Cumberland 1:48 Cumberland 1:36 Cumberland basic parts,peer wood The basic version only has 'basic parts', almost no pre assembly and processing parts. It is suitable for modelers with high skills, and the price will be cheaper. The high-end version is relatively expensive, which is suitable for modelers who want to make models quickly and easily I don't hide my idea. My goal is to enable modeler to make "high quality" models ,But I won't copy or imitate the master's model. My UK partner and I calculated all the parts according to the historical data (contract) and Navy principles, referring to the original draughts of NMM. All the parts you see above have not been polished or hand polished. In other words, these are the parts provided by kit. After your own fine polishing and waxing, you can get very good results. Jack

-

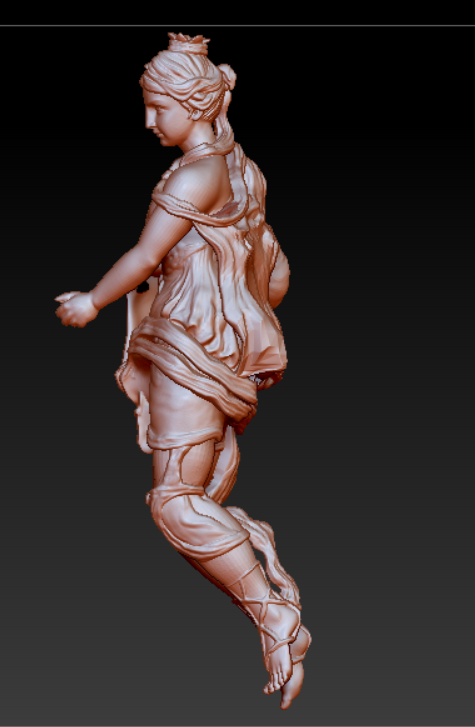

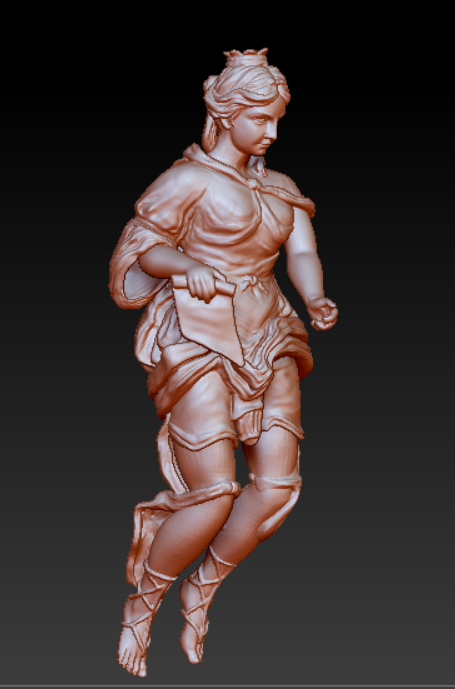

Hi Allan! 3D models can be roughly divided into two categories, one is similar to mechanical parts of the model, the other is similar to human or animal and flowers, etc., the second is not suitable for CAD modeling, or even suitable for display in CAD software. So my suggestion for those who have no modeling experience is to enlarge the drawing, such as one or two times, or the proportion you think is appropriate, and then use clay. Be careful not to use black one. Then you can carve clay by hand and modify its details. Large scale carvings of clay are very easy to make and modify.Then you can get satisfactory results after 3D scanning, you can reduce the scale ( any scale by software) . Finally, you can get better details through 3D printing or CNC. In my opinion, 3D modeling is very difficult to learn, especially the human body (or animal). Jack

-

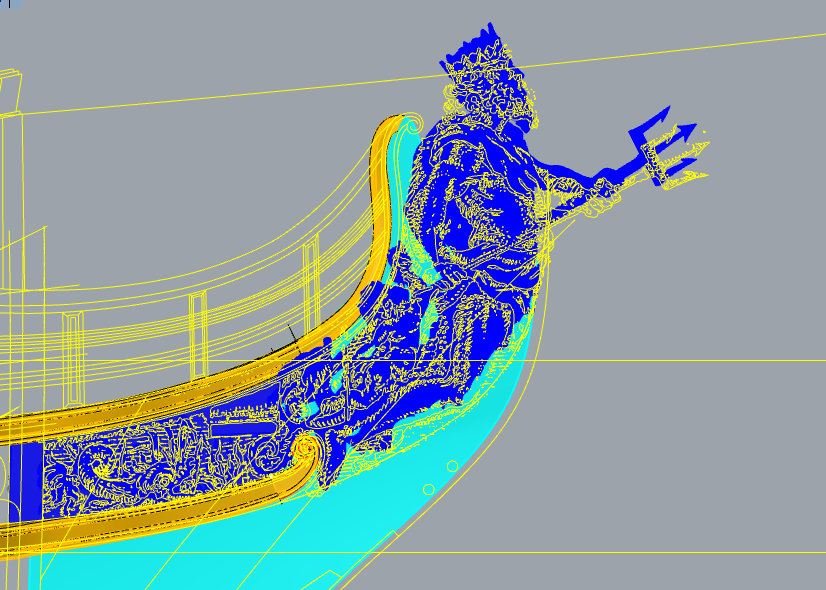

Thank you Greg! As for that gap, it's a result of unfinished drafting work now, I'll test sample of scroll,in next step, Compared with the original draught, I made some modifications to the head of Neptune,especially the neck, the head posture in the original design is a little strange,it may be intentional to leave enough space with bowsprit.. Personally, I prefer the heroic posture...And his robe, because I need to use the robe to cover the connection of the left arm, I use 4-axis processing, so the left arm will hinder me from processing his body.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.