-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

HMS ANSON 1781 by albert - 1/48 - 64 guns

Jack H replied to albert's topic in - Build logs for subjects built 1751 - 1800

This will be another great work. -

H.M.S. Atalanta - Drafting my own plans

Jack H replied to Ben752's topic in CAD and 3D Modelling/Drafting Plans with Software

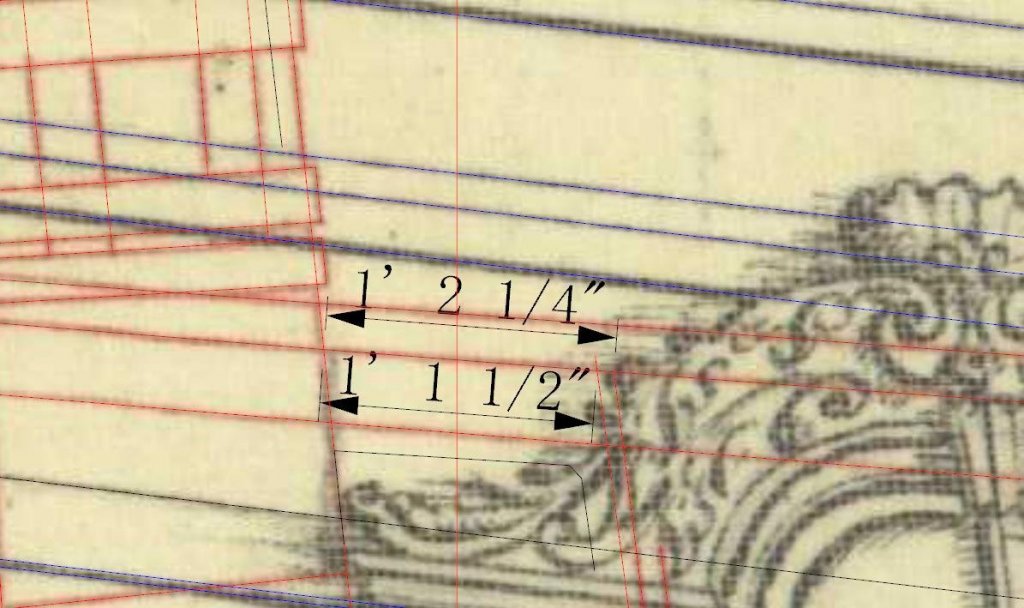

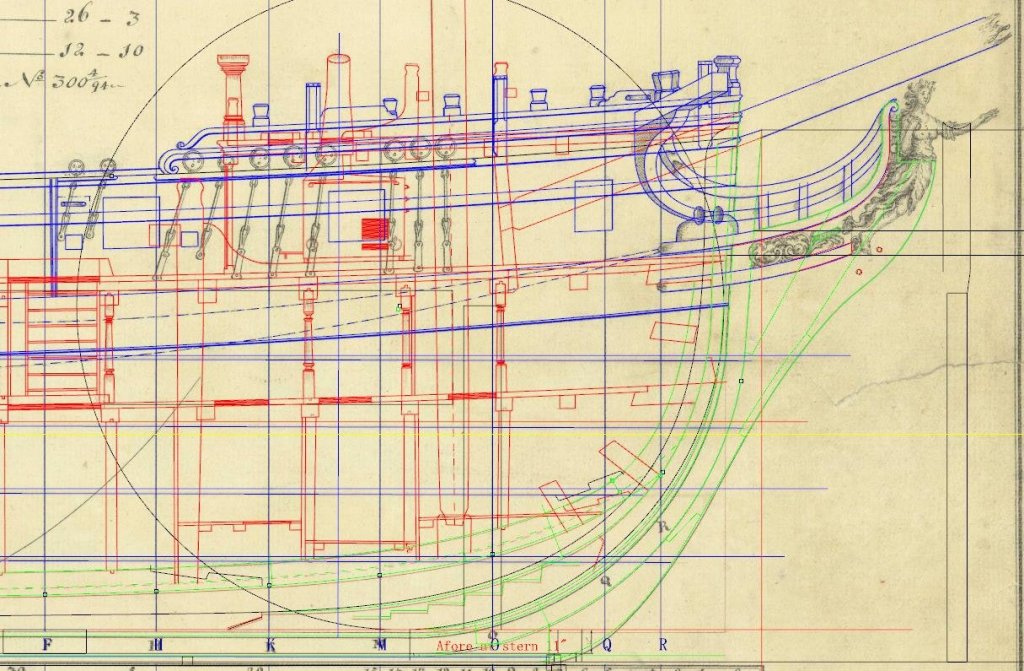

Hi ben752 On NMM original drawing(Atalanta J4428), the head of sternpost is not marked clearly(maybe), if it happens to be under the lower edge of gundeck,see following pic The data of steel' is 1 ' 2",and the 1' 2 1/2 "is the measured value on the graph- to the inside of the" cover ".1’ 1 1/2" is the measured value of the head on graph--But I adopted the extension line, so there will be some deviations.I used 1' 3" because I didn't go deep into it. I suggest you need to prepare a data sheet, Just as Mr. David suggested me before. In addition, I am very curious, how do you determine the center of the arc of the stempost, I found the data in the data sheet about stem center."Above the upper edge of the rabbet"-13' 7 1/2",but I could not locate the horizontal positioning. Thanks. HJX -

Swan class 3D model in progress

Jack H replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

nice rendering!- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Hi Anthony Nice work! I just saw it, a very good reference. Thank you!

- 209 replies

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Jack H replied to albert's topic in - Build logs for subjects built 1751 - 1800

As always, the high level of ship model. -

If a lack of historical pictures or objects, the description of historical documents is a credible way. It's undeniable that the reference picture you sent is very spectacular,but if without the description from NMM, I'm more confident that the figurehead would not be so complicated-except 1st rate or XXX royal .Because of the evolution from 17th to 19th Century,the battleship became more and more concise on sculptures.And it's rarely seen that the limbs will excessive unfold-wing and horse's hoof .It is foreseeable that it will be a beautiful and spectacular figurehead,even I have an impulse to make it.

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Jack H replied to albert's topic in - Build logs for subjects built 1751 - 1800

neat and tidy,nice work Albert! -

Hi Mike Nice work and neatly done.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

CNC fairing from 3D MODEL

Jack H replied to Williamo's topic in CAD and 3D Modelling/Drafting Plans with Software

making full size yachts! good idea!I have visited a Chinese small dockyard who build small wooden ship,and some small dockyard(or workshop) in Europe can been found out on Internet. They bend plank after heating them with steam,and some metal jigs are used.A large CNC milling machine can process such a large size of plank, a friend of mine who has a furniture factory use this kind of machine.I think these machines can fully meet your idea. I think the cost of processing wooden planks may be about the same as that of making furniture.I don't know the cost of processing in the European and American countries. In China, it is very cheap. The processing of large quantities will even be as low as 1.5 US dollars per hour. The price of the machine is from about 4000 (3 axis) to $100000(5 axis). -

ancre Chebece 1750 by Jeronimo - FINISHED

Jack H replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Hi Karl! Nice work and it's a very good reference for me.Do you changed your profile photo? any more introduction to this ship model of 74 gun? Thanks HJX -

CNC fairing from 3D MODEL

Jack H replied to Williamo's topic in CAD and 3D Modelling/Drafting Plans with Software

Yes,It's flat on the bed of the cnc but the strake is curved,so it needs double sides milling. I have some strange and eccentric ideas - but my behavior is normal, for example, in the Chinese forum, when I propose to use CNC to produce an independent figure-head - without any support or "bridge", many members were opposed or thought it's impossible, but I did it by the same machine without any "bridge". Many people question that the plank was so thin that it is impossible to be machined by CNC. But they ignore that i can use a support, the rough stock of strake can be fixed on the surface of a support, then processed it and installed it to the hull? The frames produced by CNC will be very accurate, and the deviation may be within 0.1 or 0.2mm.-But this is not the traditional method of making ship models, there may be a lot of opposition. -

Thanks Mike Y and Gaetan Bordeleau! I carved one again,and I use more fine textured box-wood this time. But still made a mistake-her left hand was broken, and it was a pity for me. Maybe it will be a year later to continue this project, I have to make the drawings of HMS Victory 1765 first, so maybe it's the last update this year. The purpose of making this project is to verify some strange ideas in my mind. Maybe you will think it's incredible or impossible. For example, I use 3D and CNC technology to planking.Yes,planking! Once i told a friend of mine that I didn't use a saw (manual or power-saw) to make frame of ship model. He asked me, am I crazy?Maybe that's me, and I like to do it in my own way.

-

CNC fairing from 3D MODEL

Jack H replied to Williamo's topic in CAD and 3D Modelling/Drafting Plans with Software

And my fancy is to planking on a substitute of hull (NC machining), and then transfer it to the actual hull, but strake was processed directly by CNC-I have done the experiment in this step. -

CNC fairing from 3D MODEL

Jack H replied to Williamo's topic in CAD and 3D Modelling/Drafting Plans with Software

Hello Williamo I have seen AlexBaranov made shipmodel by this way(Or close to your idea).You can search the keywords "cumberland"/"hms cumberland", he introduced the method in his buildlog. -

I'm quite agree with Mark,the planking is really great!-Mark's Bellona is great, too,that is another style like following. HMS Valiant 1790,Science Museum. As to planking,I think it needs good experience and skill.So I think about an inexperienced builder like me how to do it accurately and aesthetically.Although it sounds unconventional,But it's just a way of planking.i make the strake by cnc directly... The benefits are accurate, and any wood can be used.-(But this is my first experiment, version 1, and it doesn't look good enough.)I want to deal with the steps of strakes by this way. But there is a problem in version1.0 that the wood grain does not bend the direction of strake.So,I'm going to use version 2.0.The rough stock was bent first, and then the NC machining is done-this can also save the material. It's a pity that my wife does not agree with me to make ship model.I don't have workroom. She forbids me to make ship model in the office, so I just do some experiments.

-

Desktop CNC Router, Engraver, Mill

Jack H replied to pompey2's topic in Modeling tools and Workshop Equipment

Hi nick He didn't sell products on eBay yet, and he can't speak English. He said he had exported a number of machines through the agent,he can not provide after-sales service to customers.A cast steel engraving machine with a weight of more than 120kg. Secondly, Machines with electric motors are difficult to express or send by mail. (customs formalities are very tedious),perhaps the European voltage is 110V, but 220V in china ...so I suggest you buy it locally. Even if I send you the Chinese website of their company, Chinese is also an obstacle to you. I suggest that you'd better buy a cast steel engraving machine. Secondly, I suggest you buy 4 axis engraving machine. The 4 axis engraving machine can make almost all of the shipmodel parts, even the metal cannon with relief (except for sails). -

Swan class 3D model in progress

Jack H replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Hi Denis Your idea is super cool-wondful. I remember that a member used to use a game engine to make a ship model before, but the effect was not very good at that time. Today, UE4 has an amazing real time effect. It can achieve the effect you imagine.And the software is free (last year). I wanted to do it at first, but I had a crush on CNC, I want to get the true model, so I "over the wall" From the affirmation and expectation of so many members to your work,nice work you have done!- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Swan class 3D model in progress

Jack H replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Nice work Greg,and it is a good idea to separate the design of the ship model from the rendering.As you have such a detailed 3D model, the file will be very large in the end, I estimate at least 1G, unless the model is optimized. Simplify the model and restore the details with a normal map(use alfa map),this is a common technique at present. But it takes a lot of time(to do it ), and maybe it's another choice to improve the performance of the computer. In any case, this will be a grand project. CAD and virtual simulation intervention ship model making, as well as more applications of CNC, may be used by more and more people in model making -- just like many power tools used to replace some manual works.- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Desktop CNC Router, Engraver, Mill

Jack H replied to pompey2's topic in Modeling tools and Workshop Equipment

I use 4 Axis carving machine,3040-Actual processing area 26x36cm. It's my carving machine,the product is being processed and has not been cleaned yet. It doesn't include computer and any software, costs me about $1200 ,equivalent to 8000RMB. This is made by my friend's factory.It is made of cast steel and can engrave the metal and stone such as jade and copper. The precision is +-0.02mm,1500w,water-cooling. He also has a 6090 machine, the table is aluminum alloy. The price of 3 axis's is 7000RMB this year(excluding computers and software),about $1000. -

Hi Gray! After a month's waiting, I received the first book.Building The Wooden Fighting Ship.It's easy to understand and very useful to me( used to develop the 18th Century British 3rd rate ship model from NMM original drawing.) Can you recommend some more books on British 1st or 2nd rate ship in 18th Century? Thanks so much for your helping. HJX

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.fe43da9d2ffe4a8f81178e29ee71e64e.jpg)