-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

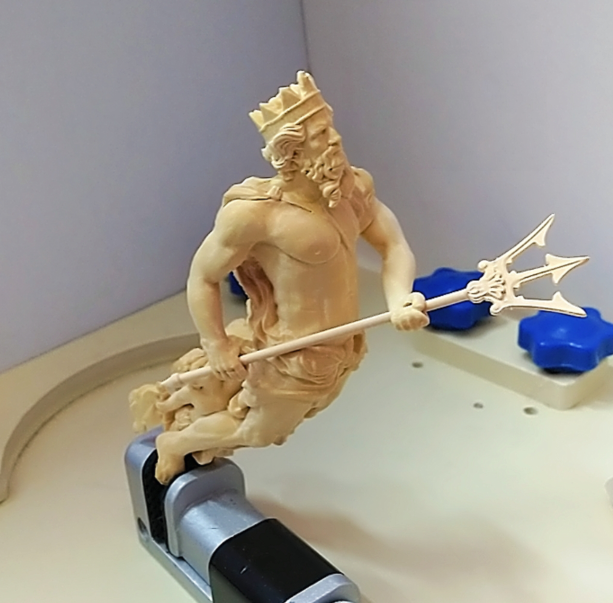

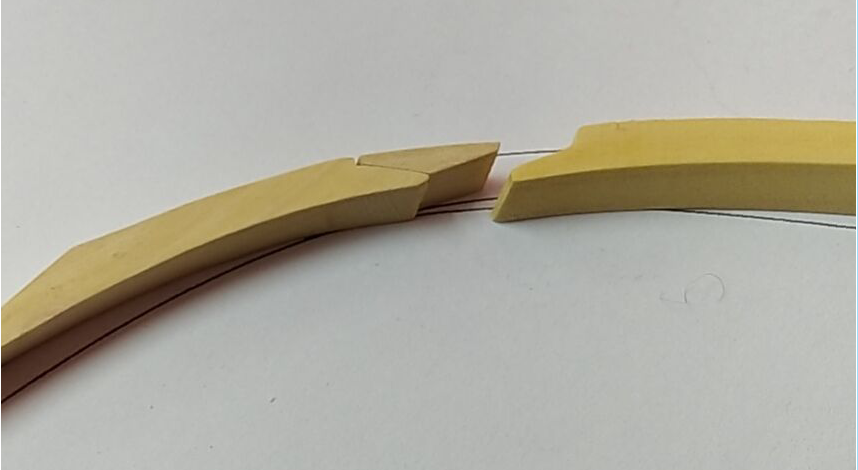

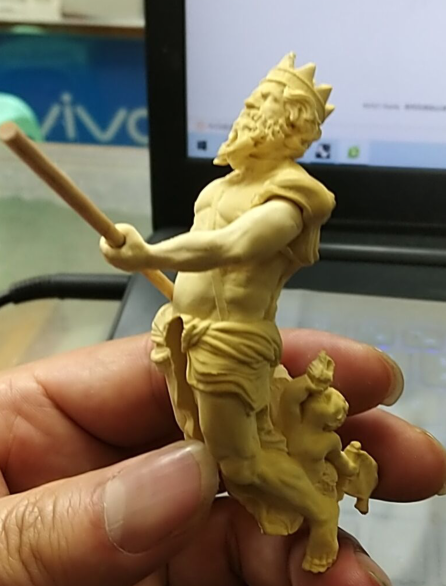

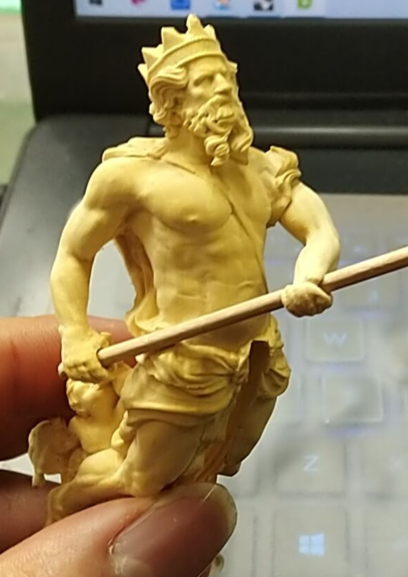

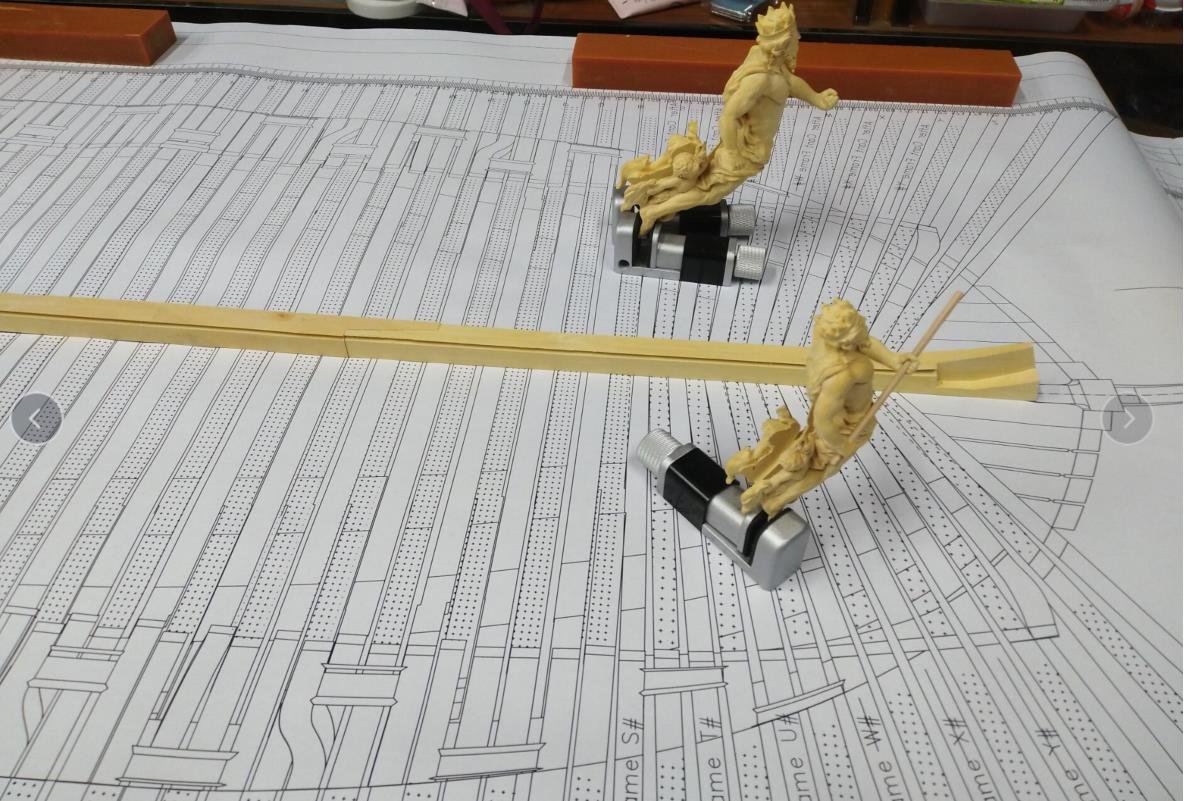

This is the 1:48 and 1:36 Trident, boxwood, Chinese and English versions.The trident of boxwood is just to show the effect at present. There will be Trident made of copper in the future. I have also designed some molds for batch processing, and I will release the parts for batch processing these days. Jack

-

This can not be said to be a bad idea Sailor1234567890!LOL...I have such an idea, I used to be obsessed with the ship model Museum, about 15 years ago, so at that time I tried to do my business, hoping to invest in a hotel in the seaside( tourist area), where many ship models were displayed... But my several failed businesses blocked my plan. These two photos were sent to me by my friends. I don't know who the original author was. If there is any offence, please tell me that I will delete them immediately. I'm just saying that someone does build a 1:12 model... Maybe, sometimes dreams become reality...These are the big machines I mentioned which can process huge parts. Container transportation is a feasible way.😁 Jack

-

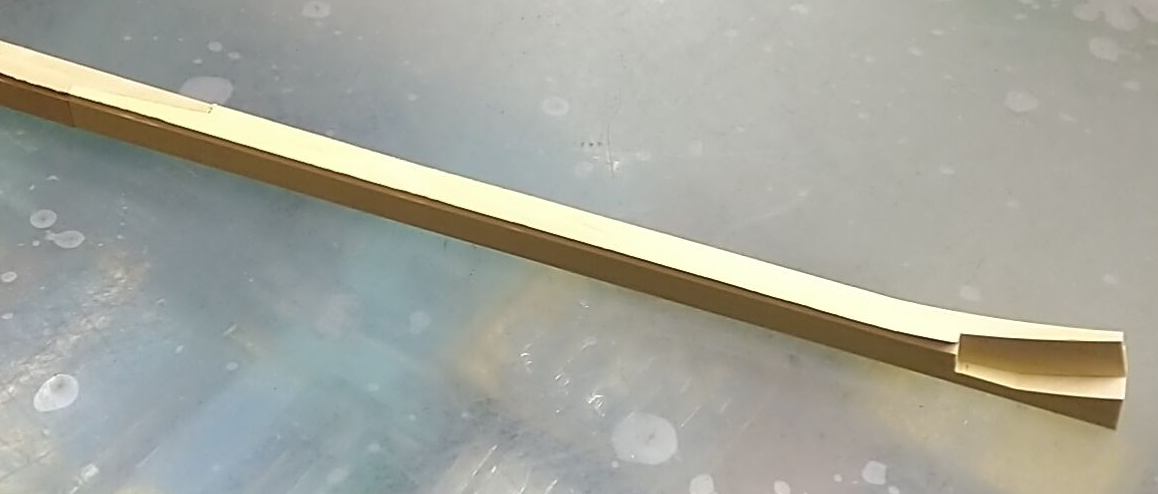

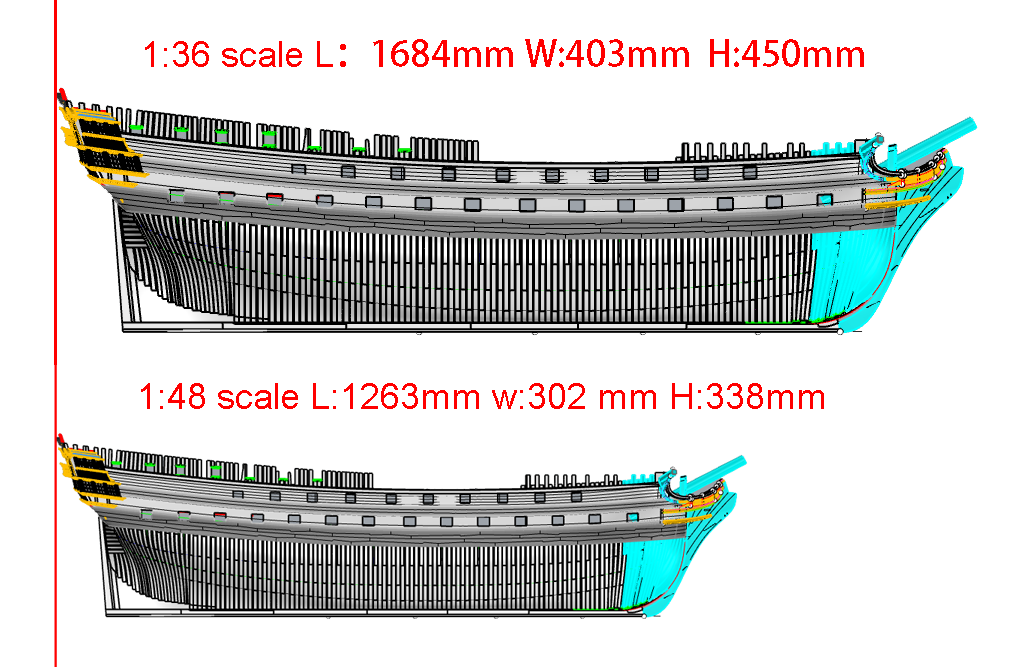

Thank you Sailor1234567890, the batch products should be 1:64 and 1:48. By the way,say something more...we have taken it into account for transportation and price (which also involves tariffs), as well as the size of the final model, which is designed for display. Because many members have more than one model at home, so we are considering 1:64 or even 72, 1: 64 will be about a meter long, equivalent to frigate at 1:48 scale , and then with a length of about 840 mm at 1:72,for a small scale kit, I consider using boxwood. Because of the huge hull, it is inevitable that it will be expensive. As a matter of fact, 1:36 Cumberland is customized by a fanatical model enthusiast. He agrees to participate in the verification of this model. In addition, I don't think there will be any more orders, so I don't intend to release the 1:36 kit, but we can accept the customization, and the price will exceed $3000. So the real batch products should be 1:64 and 1:48. I wrote 1:36 in the title just for display, but now there is a 1:36 buyer indeed.Of course, if any lunatic needs 1:24, we can customize it, because we have made Cumberland 3D model. I think the limit of our production is 1:12, that is to say, the maximum size of a single part is 1200 mm long, the required board thickness is 8 cm-10 cm, and the total length of the model should be 5.2 meters,our CNC equipment for furniture production is competent for this kind of work. As for the modeler those only needs a bow section, I'm considering a large proportion one, which will only be used for display after completion. The maximum size of the figure head we can carve is about 60 cm. Jack

-

Thank you Mike,I'm sorry, I don't have any plans for Hms Bellona. CAF is developing that project. I mentioned HMS Victory 1765 and HMS Princess Royal 1773. If I can get their licenses from NMM, I will continue those projects. I did OEM a (another) 5th rate project carvings (except Winchelsea),as long as any project is legally licensed. Jack

-

Thank you Thomas,😃 Thank you JJ! I'll let you know as soon as I finish some more parts and preparations. Many thanks to MSW and Chuck. In fact, Cumberland used to be the background map of MSW's website. This project was proposed by me and was supported by Chuck immediately. I followed his suggestion. This project will cooperate with MSW for promotion, so more information will be released--when we(True Image model) finish the negotiation with MSW on some details.I need to follow MSW's rules about business content. Jack

-

By the way, we will provide high quality boxwood, jujube and pear wood, as well as fine machined parts. We can provide parts all made by boxwood- Yes, all parts are processed by high quality boxwood. Figurehead made by boxwood, Asian boxwood has a good appearance, very delicate, moderate hardness, density and fineness are more than pear wood, thick wood is very rare. High quality jujube wood, which surpasses the density and hardness of boxwood, is similar to the fineness and color of boxwood. Entry level products will use pear wood. Jack

-

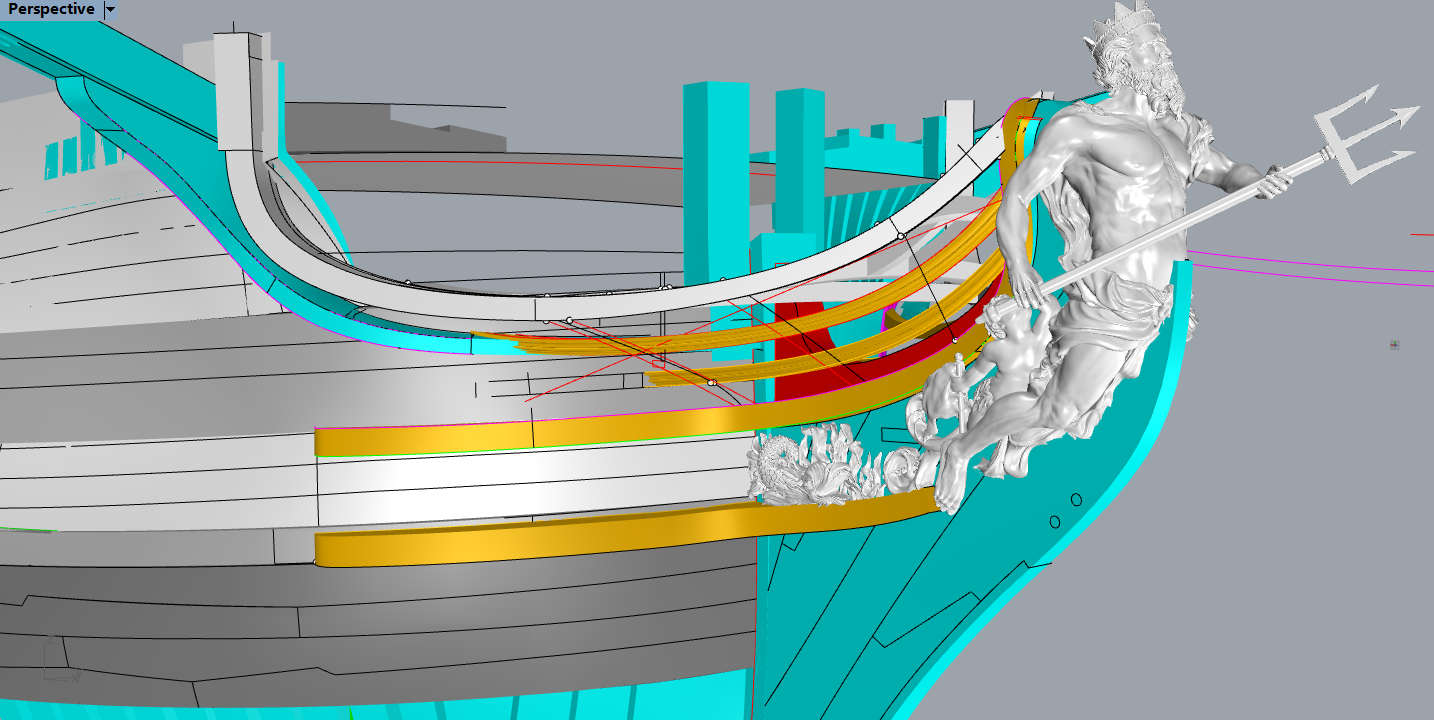

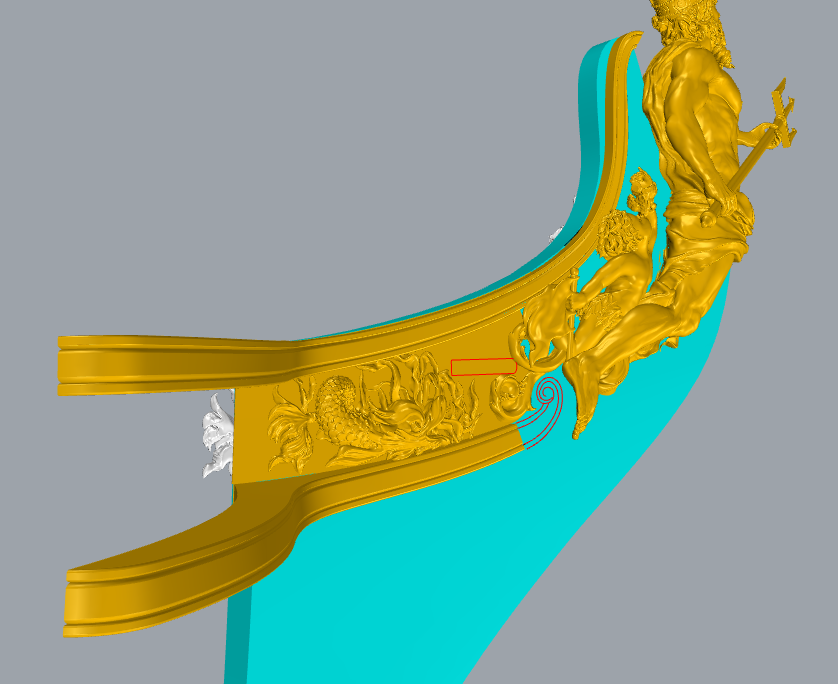

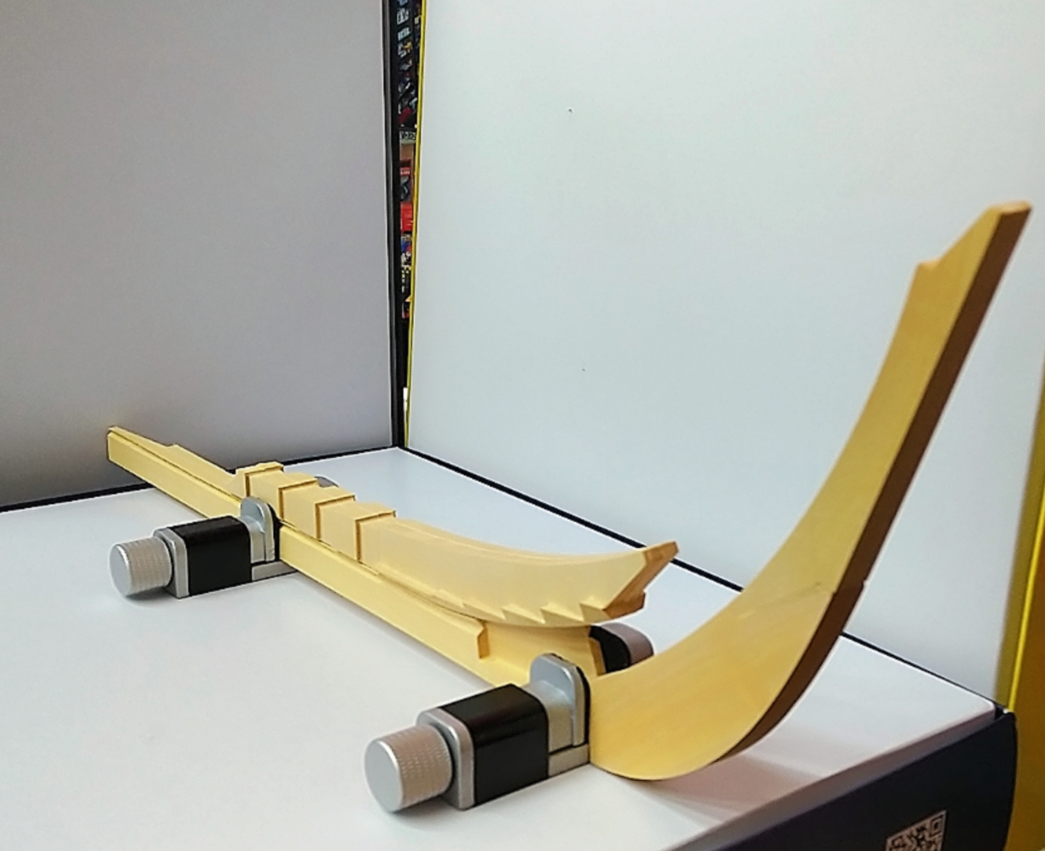

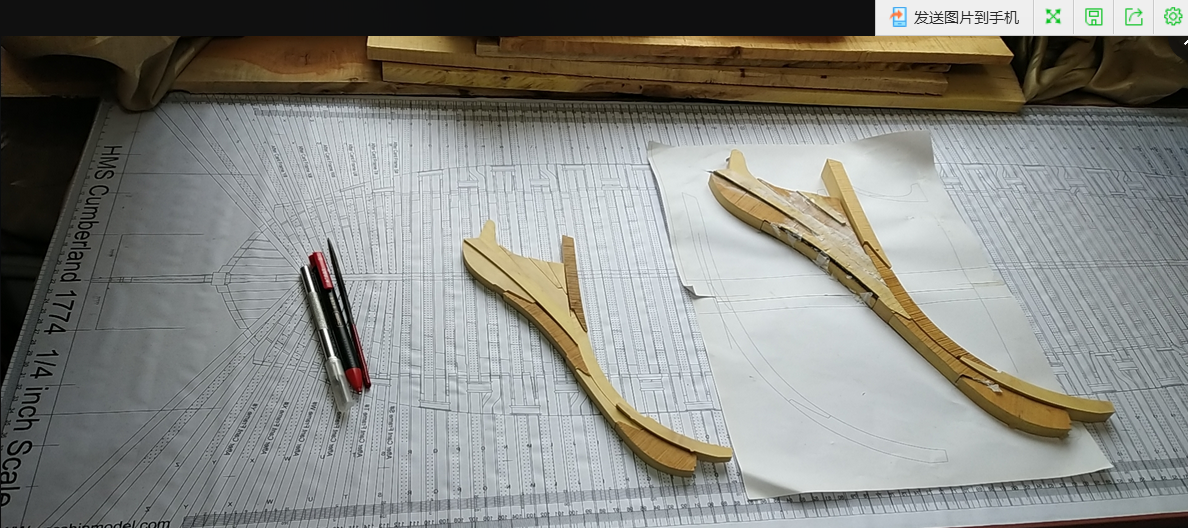

Thank you Sailor1234567890,It's true that the 1:36 model has a huge hull. Here's an approximate outline comparison. Now there are two modelers working on 1:36 and 1:48 models, and maybe more people will be involved.I will also do some verification work myself, and my UK partner will write instructions in English. He said he would make this model, too. The blue part will be the bow section kit. Maybe it will be longer. We will accept customers' requests for customization. Jack

-

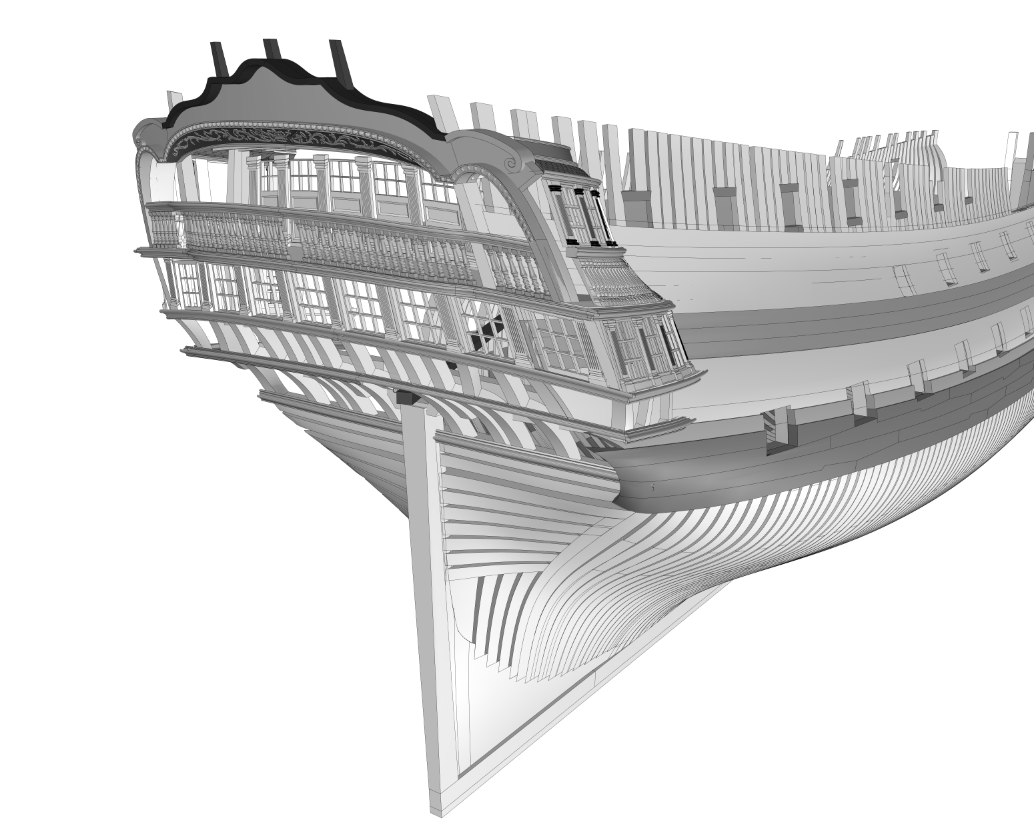

As for the development cycle, I will finish the project all the time. In order to speed up the development progress, I invited two ModelBuilders to verify the model, and I only focused on the processing of components. Secondly, the UK partner also agreed to develop the bow section first, and I expect that the work of the bow section may be completed in the second half of the year. One idea is to release the bow section first, then stern section and midsection, so that the folks won't wait too long. Then, all these section kits can become independent models or assemble four sections into a complete hull. However, if you want to make a traditional and complete POF model, you should follow the traditional Chapters method. Once it can be sold, 'True Image' will provide a sponsor link in MSW immediately. All sales outside China will be handled by 'True Image', and I will provide after-sales service. Jack

-

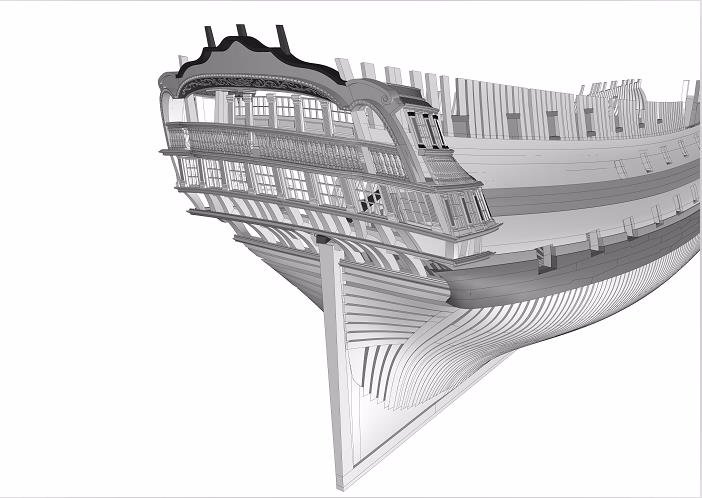

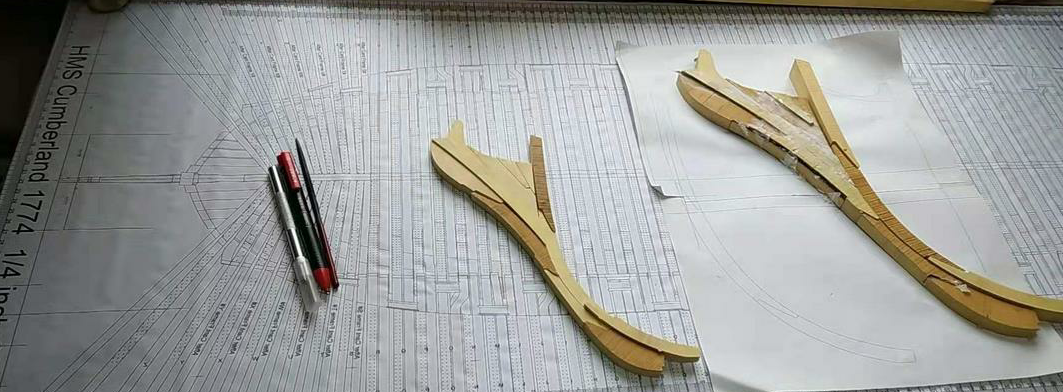

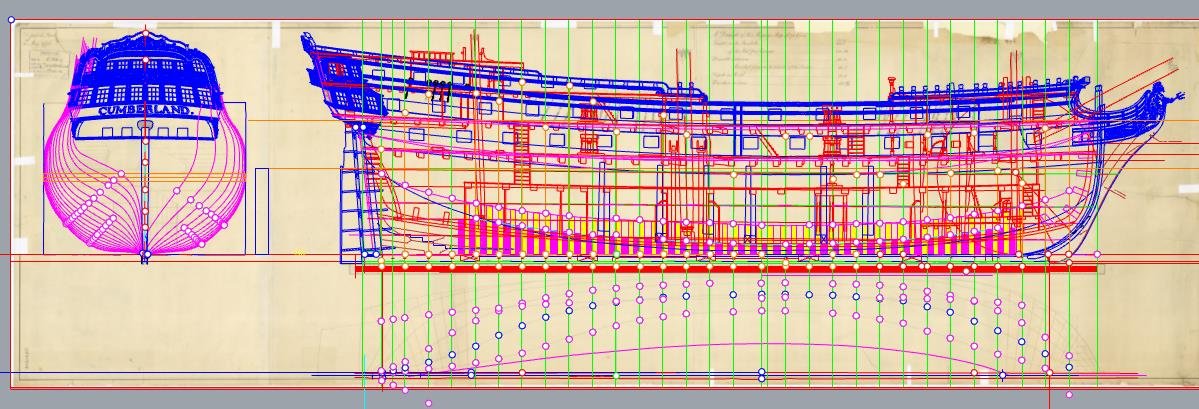

Hi, This is a validation model for kit development, and the work of hull part will begin soon. About 70% of the design has been completed. My partners will make 1:36, 1:48 and bow section respectively. All the photos from their buildlog are authorized for me to release in MSW. This project started from NMM's original draught, True Image Model, a ship model studio from UK, which obtained a commercial kit license from NMM. Now there are three modelers involved in the model validation. We will complete the bow section kit first, because it is relatively simple. The wood used in kit is boxwood / pear wood. Welcome to pay attention to our follow-up progress. Jack

-

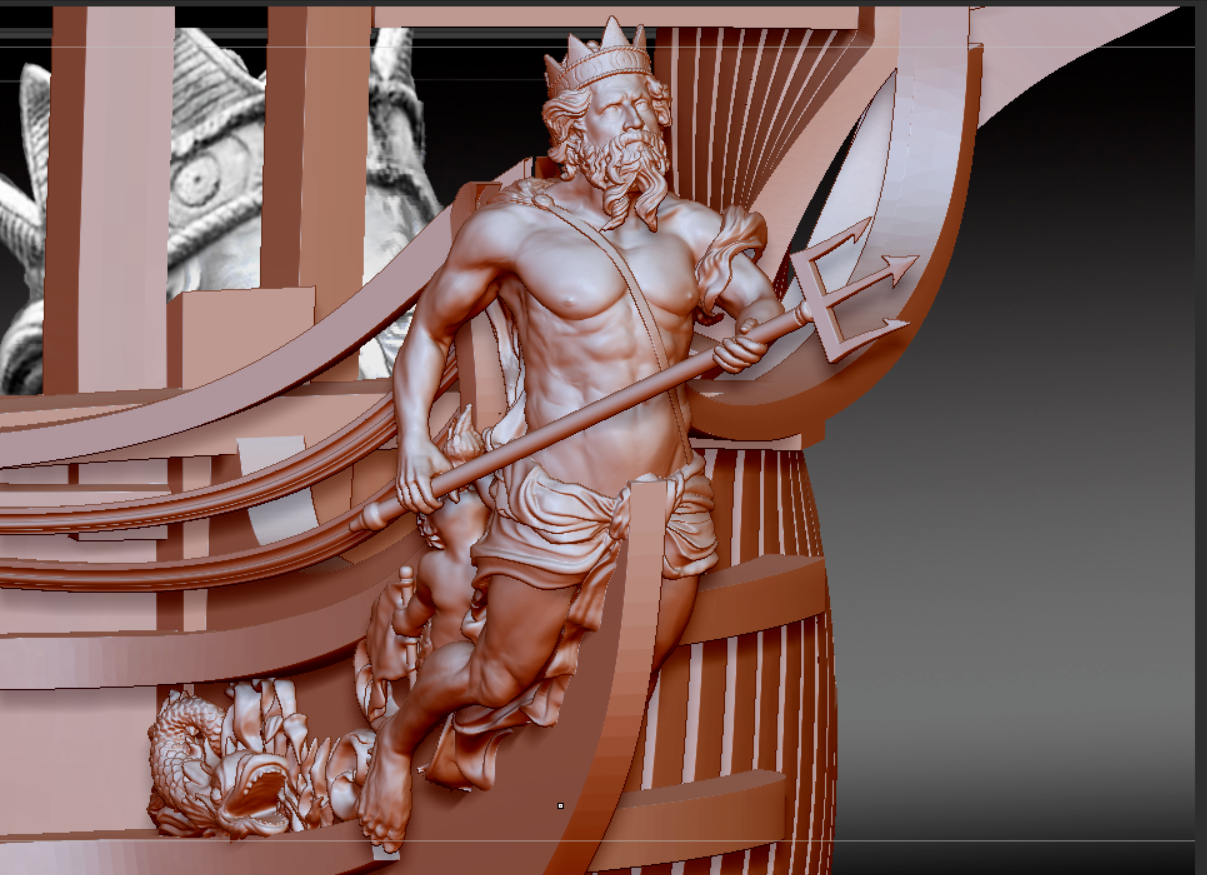

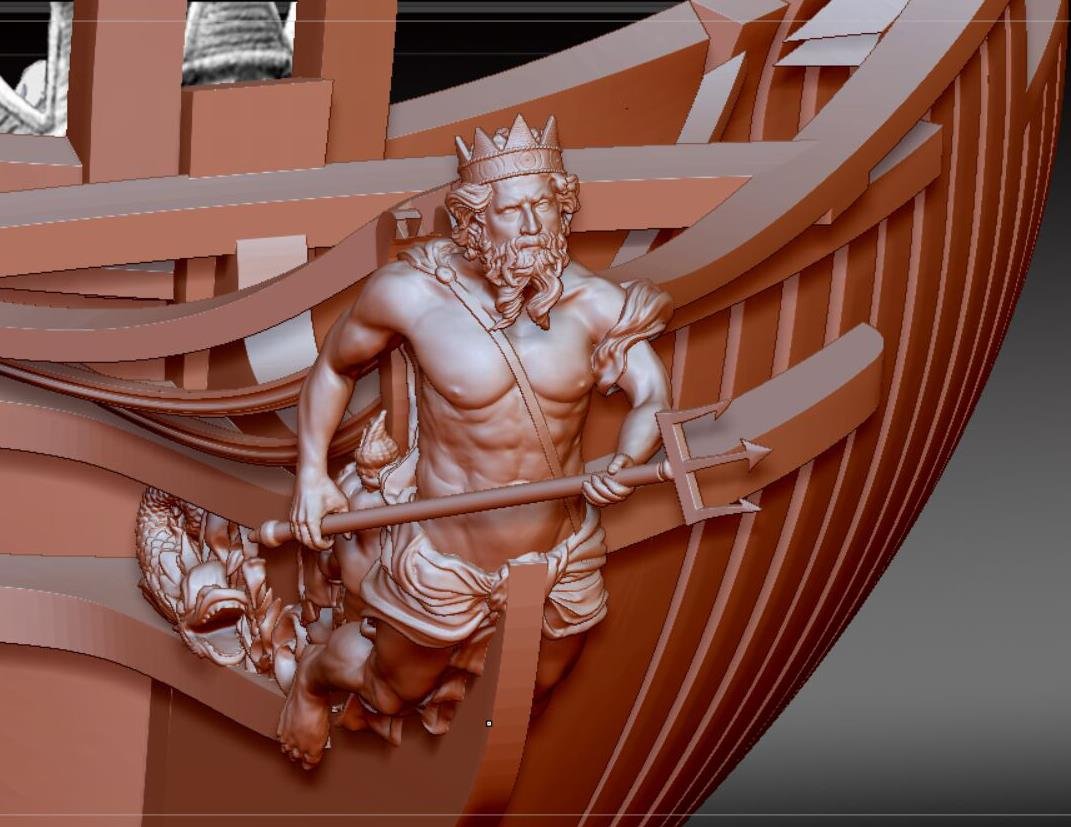

Thank you JJ! Maybe it's not suitable to publish Cumberland in the buildlog of Artesien. I think it's the last time release photos of Cumberland here. I'll create a new buildlog to introduce HMS Cumberland 1774. As the left arm will interfere with the processing of the body, I will carve the left arm separately and hide the splicing line in the robe. Although the real figure head's arms will not do this, but as a model, I will hide the splicing line. Jack

-

Thank you Gaetan,JJ and all the "likes", I think I will help Dahai release his subsequent buildlog, or a new buildlog releasd by himself,L'Artesien's figurehead will after Cumberland's,I'm working on Cumberland's figurehead these days. By the way, due to the epidemic situation, European friends participating in the model validation need to wait until March to may, China's modelers will test this model(Cumberland) earlier.

-

Hello everyone, I'm sorry that due to the pressure of my family, my wife doesn't agree with me to continue the non-commercial ship model project, so I stopped (or suspended) all personal non-commercial projects. Of course, L'Artesien is non-commercial, because it's very difficult for me to obtain the license from Ancre - the probability that I obtain the license from Ancre is less than 0.0001%,i think. I would like to thank all the enthusiastic members who have followed this project. My friend Dahai, who is also my partner, will use his method to make La Artesien.This is the model he's working on. So I will continue the carving parts of this project, including figure head,but I'm busy with the Cunmberland 1774 project right now, so it will be in a few months. My friend helped me remake the head using sculpture clay. I made some modifications with the software myself, So this carving set will be reborn in another way. By the way, I'll give you a preview of my new project, HMS Cumberland 1774, which I'm starting to validate. Currently, the scale of 1:48 and 1:36 is being verified. This is designed based on the original draught of NMM. My UK partner obtained (purchased) the license for the commercial kit development of this project in 2018.All the software used in the design, CNC programming and processing of this project has purchased commercial license. (rhino6, rhinocam 2018, silo2.5, ZBrush 2018...) includes plug-ins for ZB, and other software... Thank you! Jack

-

Hi Chuck! Same as you, I'm designing the head platform. It's true that the upper and lower check are a bit complicated, then the main rail is a little better. After all, from the top view, they are straight, not curved, and then they are actually stitched together. I don't know as a kit project, the whole one will be easier to make? Then when you have finished a sample, can you consider casting with resin? I saw in the previous buildlog that the resin parts can be properly deformed to fit the hull. However, it is much more difficult for me, because I am also considering how to use CNC to process such complex parts, and I also have to consider the deviation of each model. Fortunately, I'm behind you. I can refer to your method, but I can't copy yours..., which will make you angry😝

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS VICTORY 1765 by albert - 1/48

Jack H replied to albert's topic in - Build logs for subjects built 1751 - 1800

Hi Albert! Looking forward to this great model, she will be a legend again! -

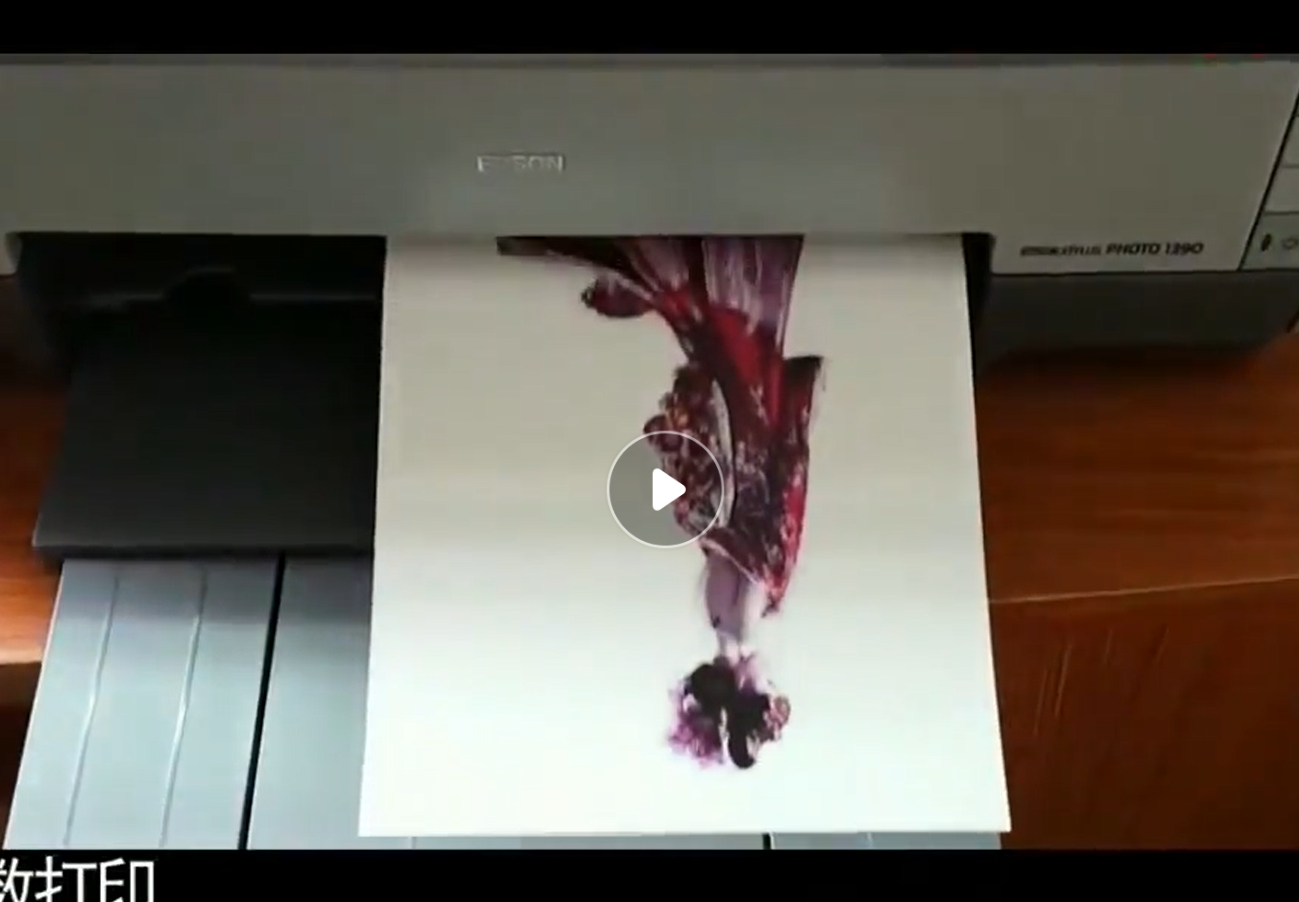

Print the frieze,good idea, this time I saw Mr. Chuck's method of making the frieze. I accidentally saw a video of using a printer to make patterns and then transfer them to other objects. With his permission, he agreed that I use screenshots to introduce his methods to members in forum. 1. 2.Spray a protective film, which he also provided. 3. 4. 4.Put in water for 30-60 seconds, the bottom film will separate. 6.Transfer to the surface of another object. 7.According to him, it takes 15 minutes at 80-100 degrees Celsius. Indeed, this step is some troublesome, I will do some experiments next month. . Jack

-

First of all, thank you very much, Mr. Passaro. You have made it a reality. More importantly, you have not only given me, but also given all members the opportunity to participate in this project. You have taught everyone the skills of making the whole project, so that the fans not only enjoy in making(this model), but also learn the knowledge of ship model. I really enjoyed the process. I would also like to thank the enthusiastic members who participated in this group project together, and many members provided valuable modifications (design of the carvings), and thank MSW for this communication platform. Thanks, Jack

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi garyshipwright, I'm so sorry I misunderstood your needs....If you want to buy CNC engraving machine, the cheapest one(Desktop level) that can process products in batches, it will be over $1200 in China. I see the price on eBay seems to be more expensive. Machines below this price may have some problems, such as durability and accuracy. There is a very cheap machine, estimated to be only about $600, which has become a "toy machine" in China, which is not good enough for processing products. If it's industrial grade, for example, the machines used in furniture factories will be more than 10,000 US dollars, and the CNC milling machines used in furniture factories of my friend's will all cost more than 15,000 US dollars. -This kind of machine is only a "cheap industrial machine" made in China. Using these machines requires CAD software, at least 2D graphics files. If you need to carve relief, you need 3D models. What's important is that CNC engraving machine doesn't come with software, especially CNC programming software, which is very expensive. The cheapest software I use, rhinocam professional version, costs 2500 dollars, rhino6 needs 999 dollars, and zbrush2018 for relief needs about 980 dollars... But the CAD software has a free version. If you've never learned to program, it's very difficult to program 3-axis or 4-axis or even 5-axis machining, except for 2D cutting. By contrast, the laser cutting opportunity is much simpler. The laser cutting machine only needs 2D graphics files. In China, the price of this kind of machine is $700-2000/3000 , and there is processing software attached. If you need to cut a thick board, such as 8mm or more, you need to choose a machine with high power. The power of laser tube needs to be more than 100 / 130W. The high-end machine is just priceless. I just mentioned by the way that a person I know, his laser cutting machine is in the nitrogen container, and the wood cut by his machine has no burning trace. He said that his machine can easily cut 2-3cm wood board, and there is no trace of carbonization. He "bragged" to me that his machine is worth $1,000,000. Jack

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.png.0afdaedf1c9d14098898e9ec0ce8270e.png)

.thumb.jpg.6f3cddb01e6712f99730e0544d752987.jpg)

.thumb.jpg.433963e43f636d10104a754c93daca4d.jpg)

.png.c3fd02022df3bdf7117401be6aca2574.png)