-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

Hi garyshipwright! If you can carve a figure head with sculpture mud by yourself, then convert it into 3Dmodel with 3D scanning, and then.... then ....if you are willing to pay for the express delivery from China to the United States - about 30 dollars, I can carve a boxwood one for you free, Why use sculpture mud instead of wood? Because you can modify her, and you can carve a large one, such as 30cm high, which will be easier and get more details. I will help you modify this 3D model until it matches your ship model - scale and posture. Then reduce it to a ratio of 1:48, and use NC technology to restore your own works. But if you don't have time and you are willing to pay for the sculptor, I can help you find a professional sculptor. He can carve a figure head according to your sketch or reference photos, and then I will carve one for you free. Jack

-

Hi, You can click and view this post, Jack

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes, I sent the first six sets to the agent yesterday. The agent has received them this morning and sent them to the United States from DHL this afternoon. It happens that the first six members are all in U.S.A. I have sent the second batch to the agent this afternoon. Tomorrow, the agent will send the second batch to DHL for sending out. merry Christmas to every one in advance! Jack

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

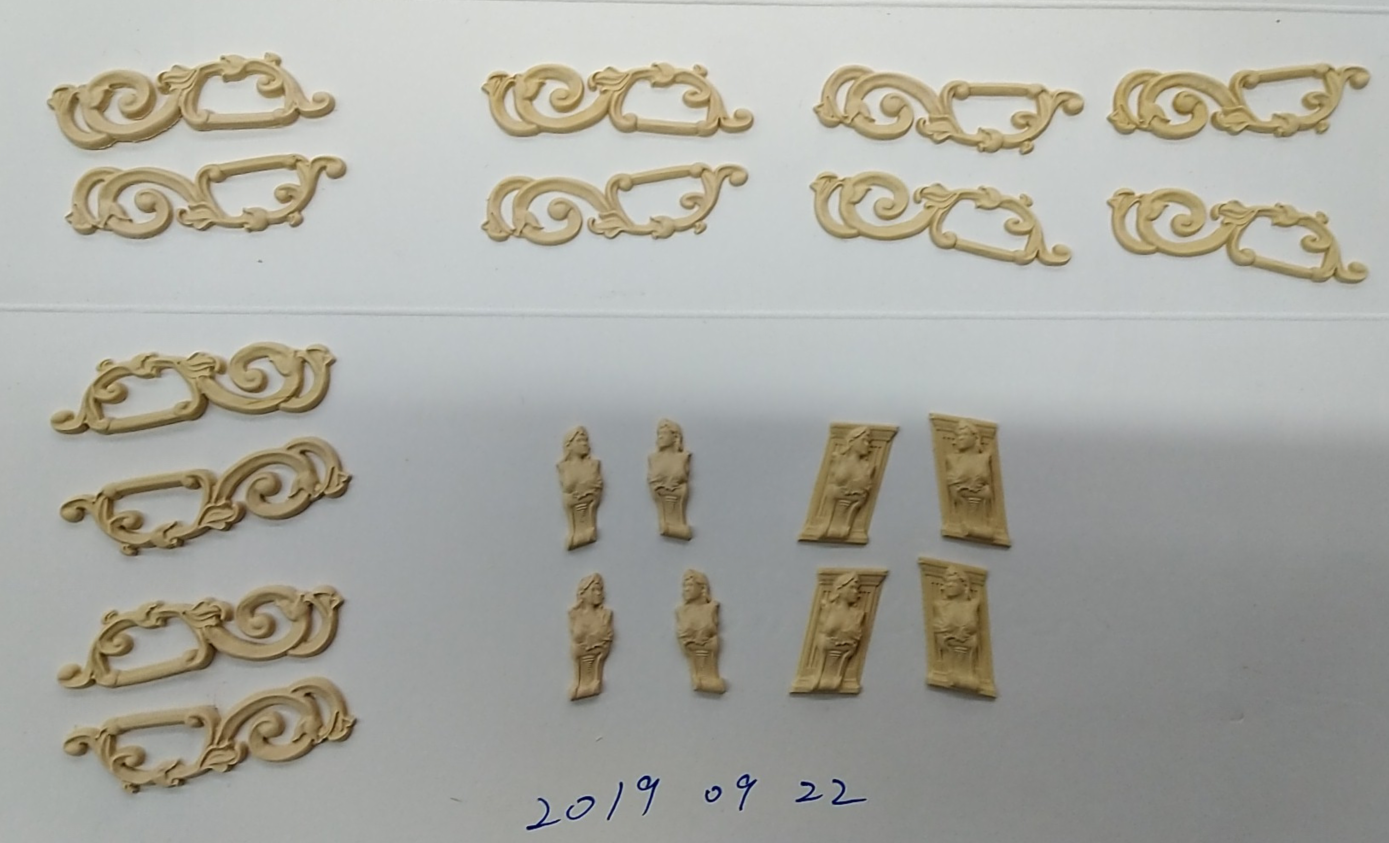

Thank you verymuch for your kind words Mr.Chris Watton,and thank you very one! First of all,many thanks to Mr.Passaro and MSW,thank you for your support and help. The carving sets are available and ready for sale now.I will send PM to every member who participates in the reservation purchase.For technical reasons, my sponsor link will have to wait a few more days, but this does not affect your order.This is a complete set. On the left is the packaged look. On the right is all the carvings and the Gifts of polishing brushes & latex finger covers. Jack

-

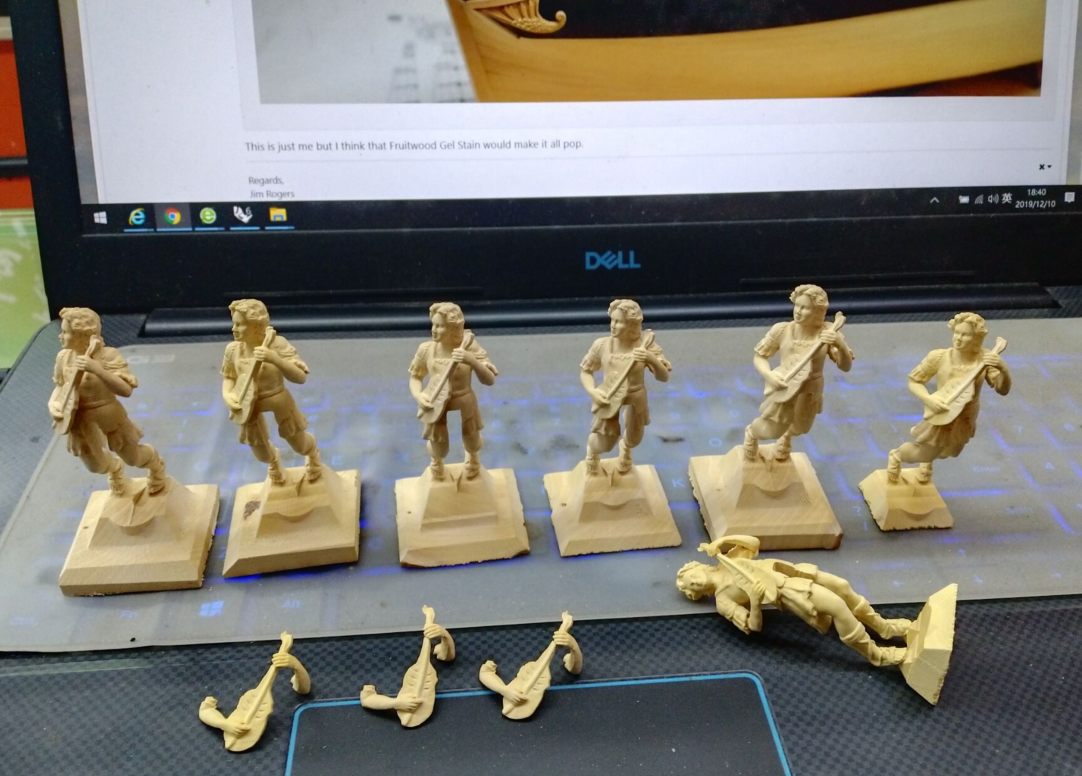

Hi every one! I have finished 10 sets arm-parts. This time, I redesigned the fixture and optimized the processing procedure. So this batch of products is very successful. Except for the first three test products, the last 10 are all excellent products with almost no defects. And I'll finish the remaining 10 sets soon. Unlike Mr. Chuck's figurehead, the arms of all members' figurehead have been glued with German glue. I have also made some simple polishing for everyone, and I will remove the base for your folks. I use a strong plastic box for packing, and each carving will use a breathable bag for packing one more time, so as to prevent moisture and It has some compressive strength. I promise that if it is lost in transit, and if it is not caused by your own reasons, I will resend one set to you free of charge. I will complete the application of MSW's sponsor in these days, and then it will be released officially . I will inform every member according to the previous pre-order. You can buy them or give up. Natural wood has natural texture. I have scrapped all carvings with black spots, but natural texture cannot be avoided. If you can't accept these carvings with color difference and wood grain, you can consider purchasing resin casting sets. Thank you! Jack

-

I think this discussion is very good, because I have been thinking that using CNC machining parts will make all models look the same, which will make the model making become a boring thing? That's going to take away the "soul" of model making. When I see so many opinions, I think it's very good.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The postage for my express delivery from China to the United States is $26, which is the price obtained through the freight forwarder, including the agent's customs clearance fee, but this is the price of 500g, more than this weight, $6 per 500g. Then I have to send the package to the agent. The total price is $30. It's hard for me to imagine that the kit costs only $13.14 and includes postage. There used to be a micro model kit in China's market, but it's only a cross-section model. The price is about $26, but the postage in China will not exceed $1.50. So....

-

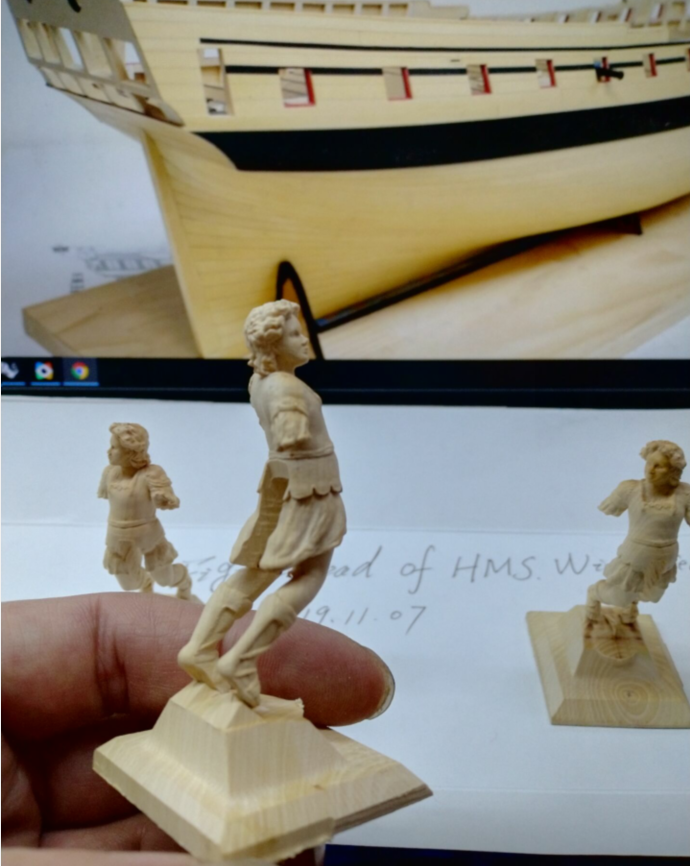

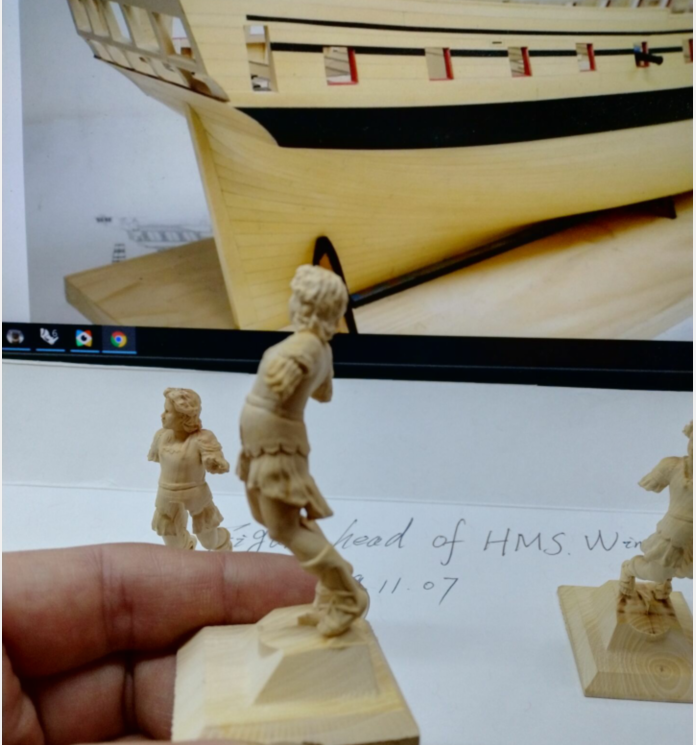

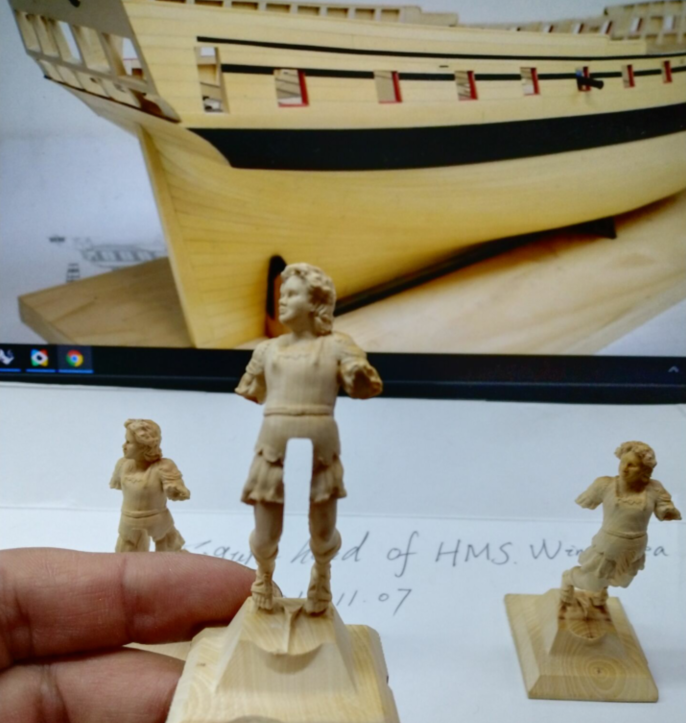

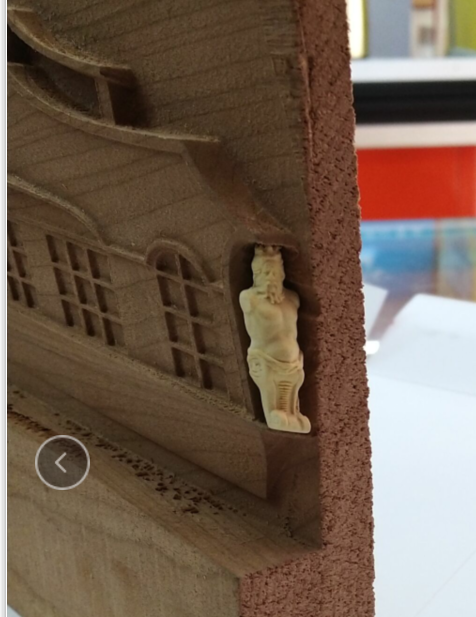

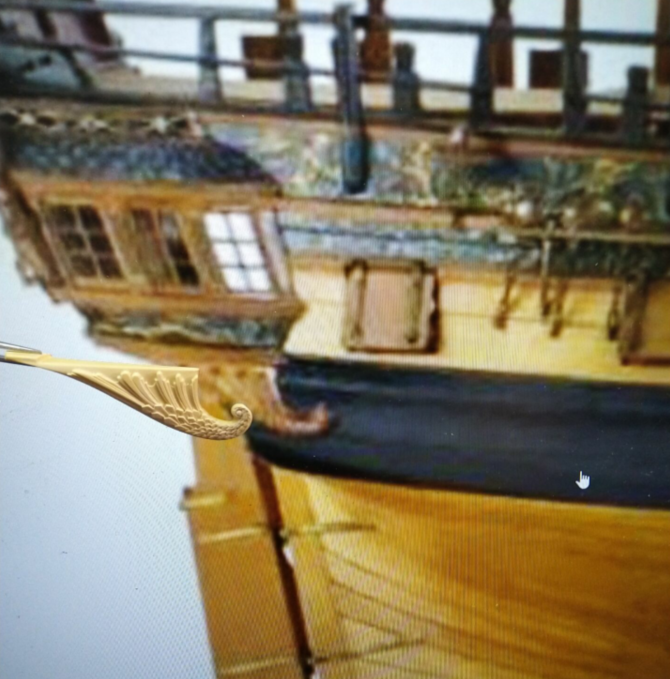

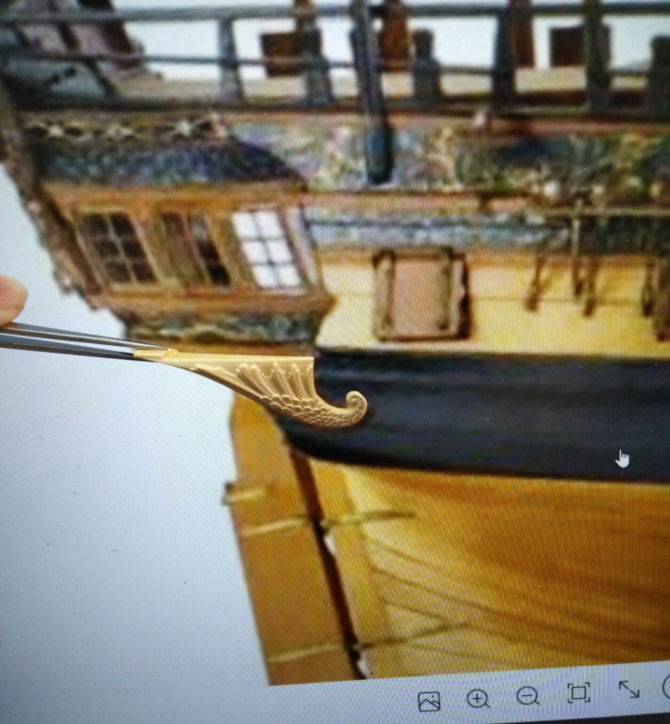

Hi everyone! Today, I am very happy to see that Mr. Chuck released his photos of drop and figure soldiers assembled on the quarter Gallery, because this is my biggest concern. With 3D simulation, it can match the actual model without face-to-face communication and modification. In fact, Mr. Chuck didn't give me any detailed bodyplan. He asked me to calculate it from the original draught... This is the body part of all the figure heads in the first batch. And the first one of arm part made today. Jack

-

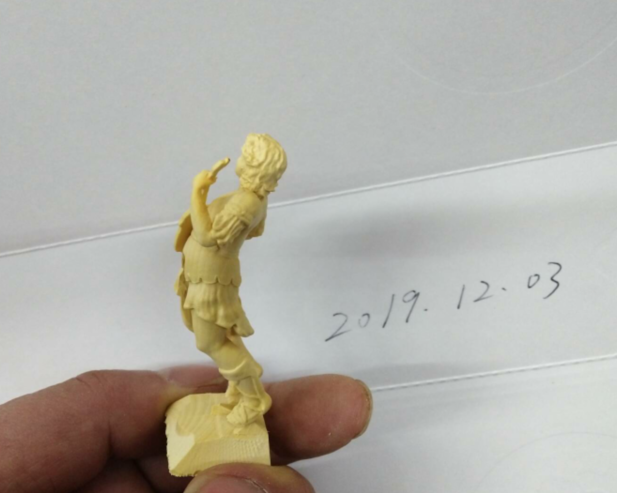

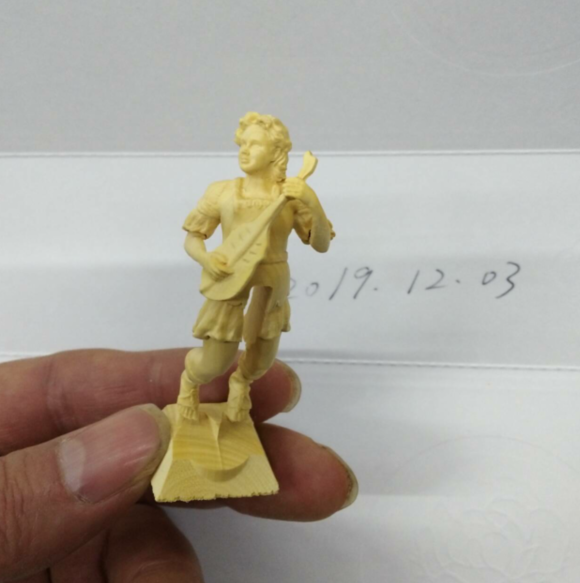

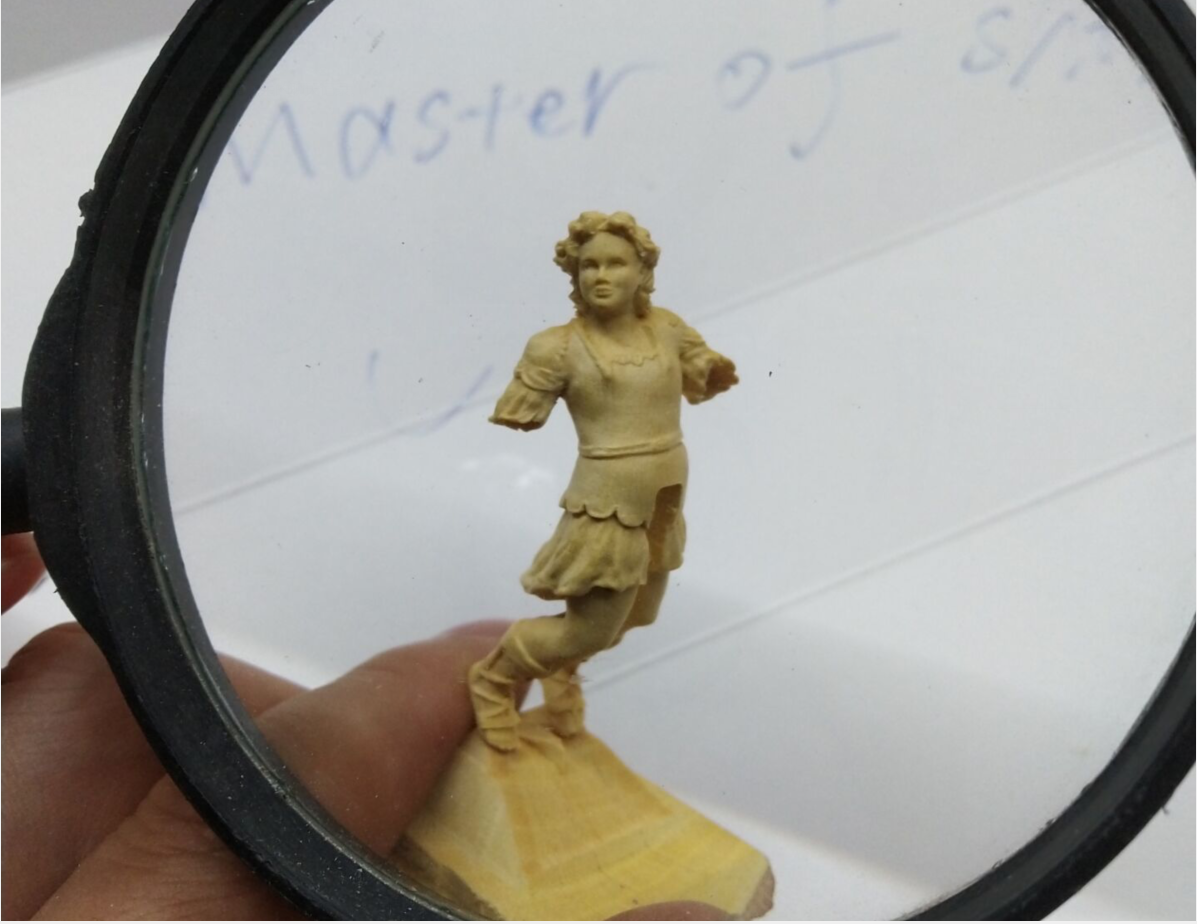

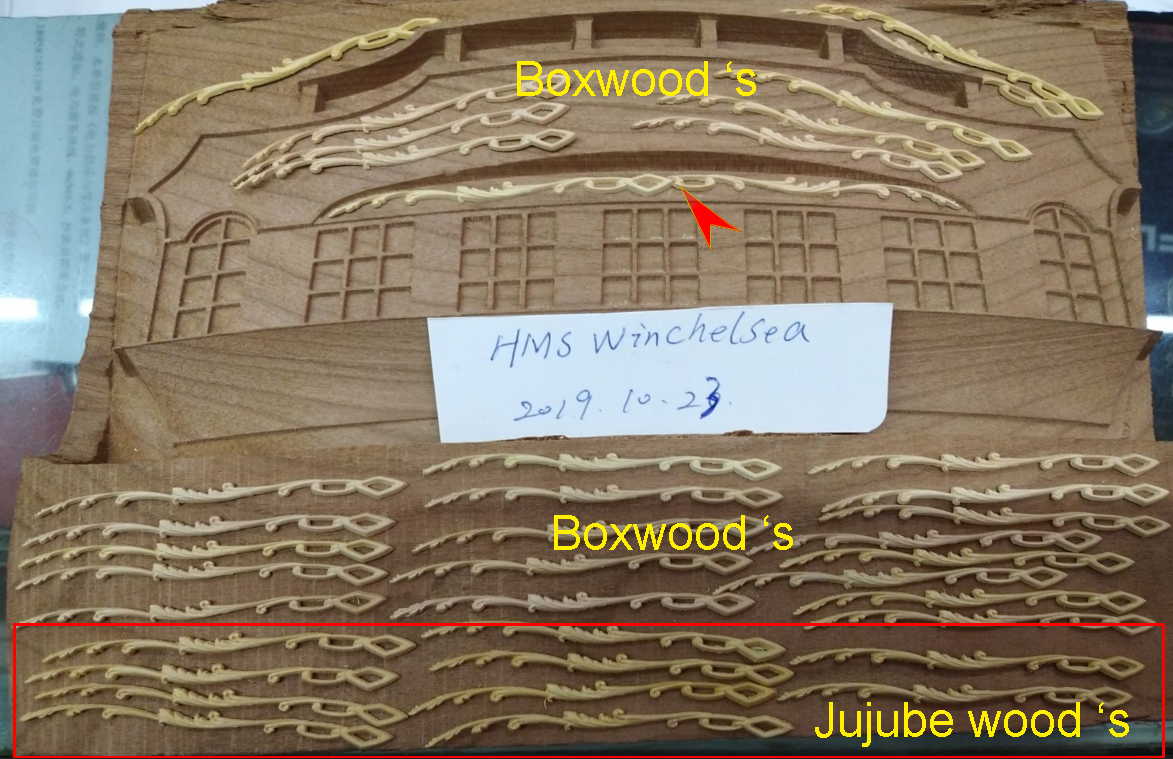

Hi all After using the magnifying glass, I was able to shoot the figurehead of jujubewood clearly .But it still can't catch up with Chuck'sC And the comparison with boxwood. If only judged from the fineness, boxwood will be better than pear wood, and pear wood will be better than jujubewood,but jujubewood is harder than pear wood, and its color is bright yellow. Jack

-

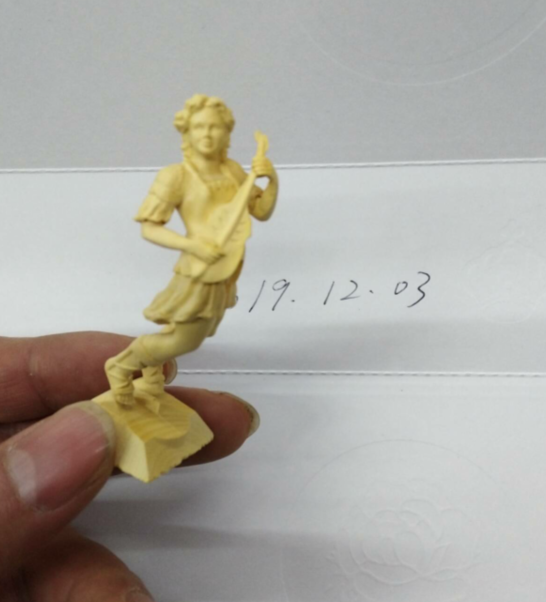

Hi all! The body part of the first batch of figurehead is about to be completed, and I will make the rest ones of jujubewood. If anyone wants to catch up with the first batch, please contact us as soon as possible. As I am about to complete the design of the hull of my 3rd rate, maybe i will spend most of my time on that project. Secondly, I can determine the release time, which should be next month. In addition, if there is any member who does not want to buy carving sets now but have pre-ordered, please send me a PM , thank you so much for your message. Thanks! Jack

-

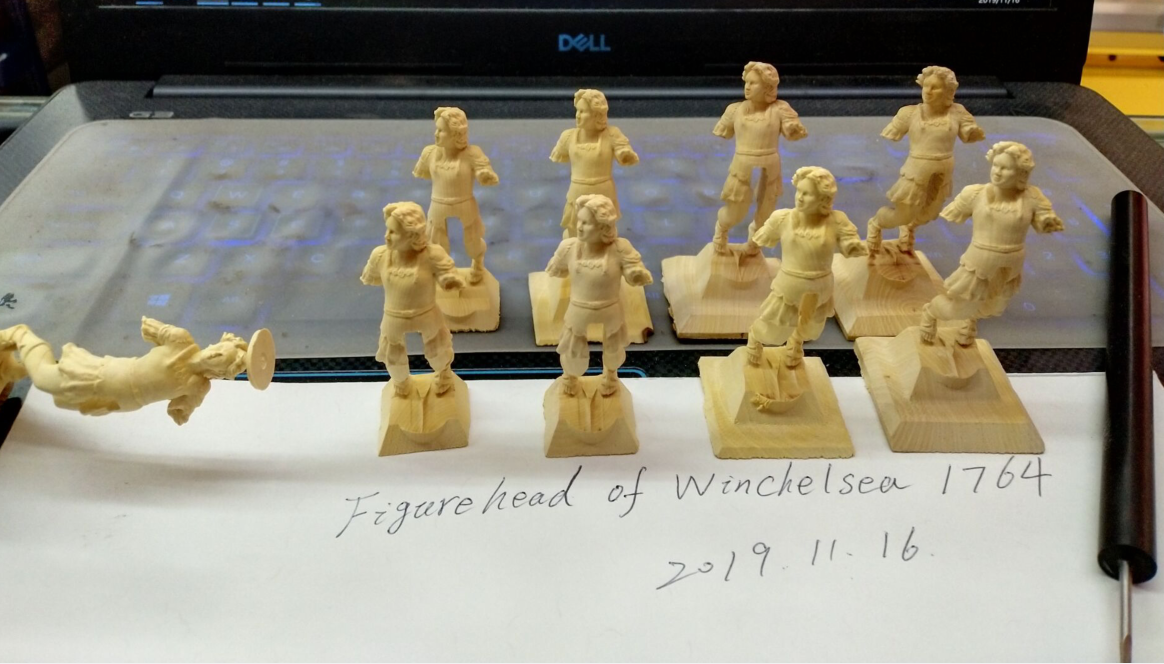

Thank you verymuch Waldemar! Because I have made several more sets, you can catch up with the first batch of carving sets. Once they are ready, I will inform you as soon as possible. And this is the current progress. Several ones have been scrapped due to my mistakes or obvious wood grain defects,I will provide our members with excellent products. I estimate that I can complete all the body parts this month. If I am more prepared, it should be safe to start selling next month. The first batch of subscribers will receive their carvings at the same time.(re-edited on 11/16/2019) Jack

-

Thank you Tim Murphy ,you can pre-orde, but you don't have to pay now. First of all you need to buy the kit of Winchelsea, and then reply here to tell me which one you need-boxwood set or Jujubewood set, from the end of this month to the next month, according to the scheduled order of replies, you can buy them formally. Jack

-

Thank you for your attention and "like". We appreciate and welcome every member's purchase. As this set of carvings is a sub-kit of Winchelsea, it can't be sold separately, but if you have already purchased this kit, you can certainly buy this set of carvings. So I want to know whether you have bought this kit of Winchelsea? If you haven't bought yet, hurry up and you can catch up with the first batch of carvings. If you have, you are very lucky to be listed as the first batch of buyers, because I've made several more sets. Thanks Jack

-

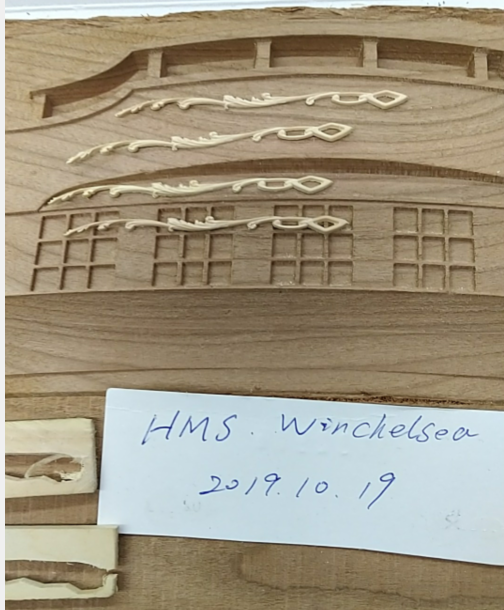

Thanks Mike! It will be available for sale soon.Becaue it has been 8-9 months since the last completion of the sample of figurehead,so i make several minor modifications to the processing program, and now it can be produced stably. It may change a little,that is, I'll finish making all the individual body parts first and then produce the arm parts. Release some photos. ..What the final product looks like this time,certainly,I will remove the base (support). I'm sorry ... my phone doesn't shoot clearly... Jack

-

Thank you KentM! And say hello to every one. Yesterday I finished all the carvings except figurehead, so the next step is to make the last one -Figurehead,since there are still members asking for reservation, I have produced more products, so there are some delays...But I think the first group of reserved members will probably receive carvings this month or next month. As planned before, when I finish half of the figureheads, the members who have pre ordered can place an order for purchase. If the first batch of carvings is sold out, but there are still members who want to buy them, I will arrange them to the next batch of orders, provided that I need to obtain Mr. Chuck's authorization one more time. Today I saw Mr. Chuck finish hull planking. Congratulations and look forward to the next step! Jack

-

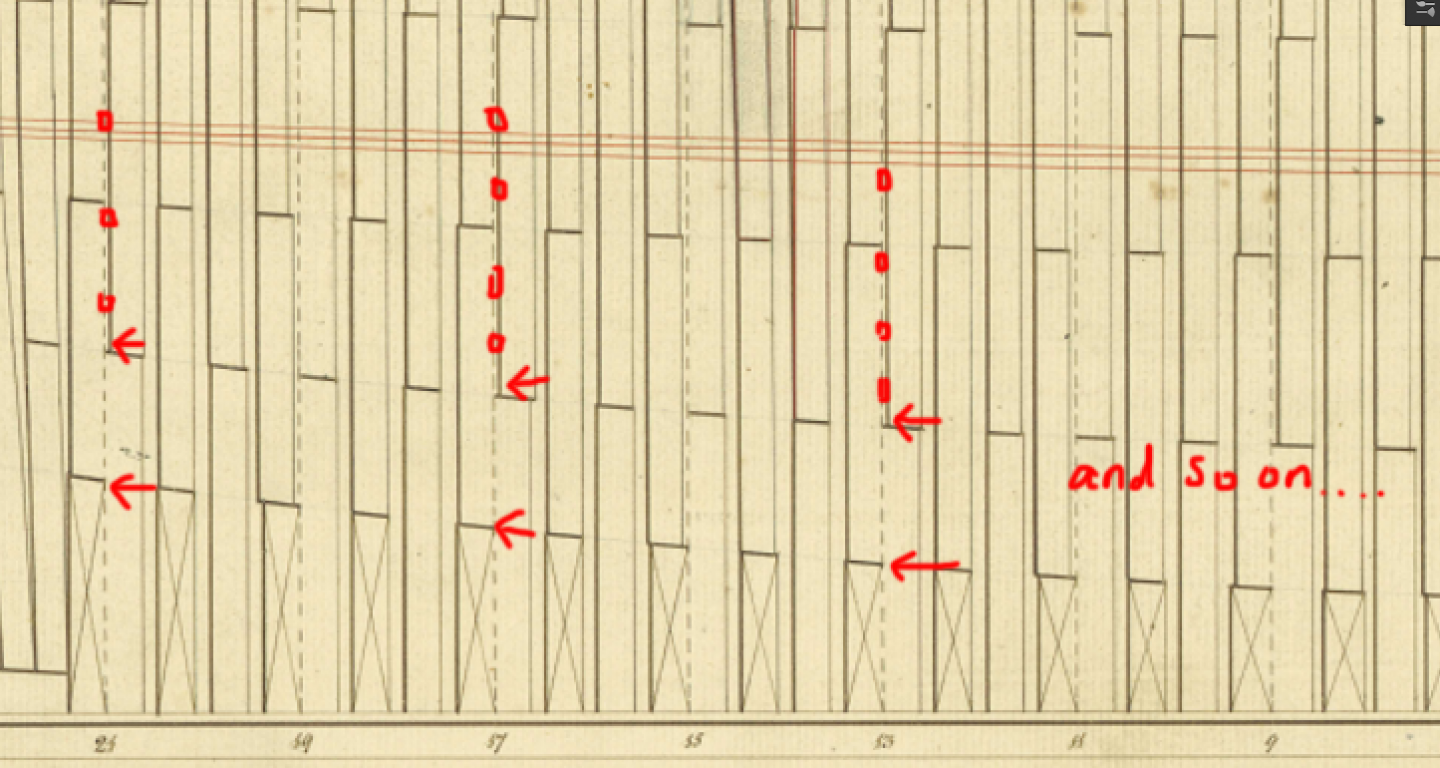

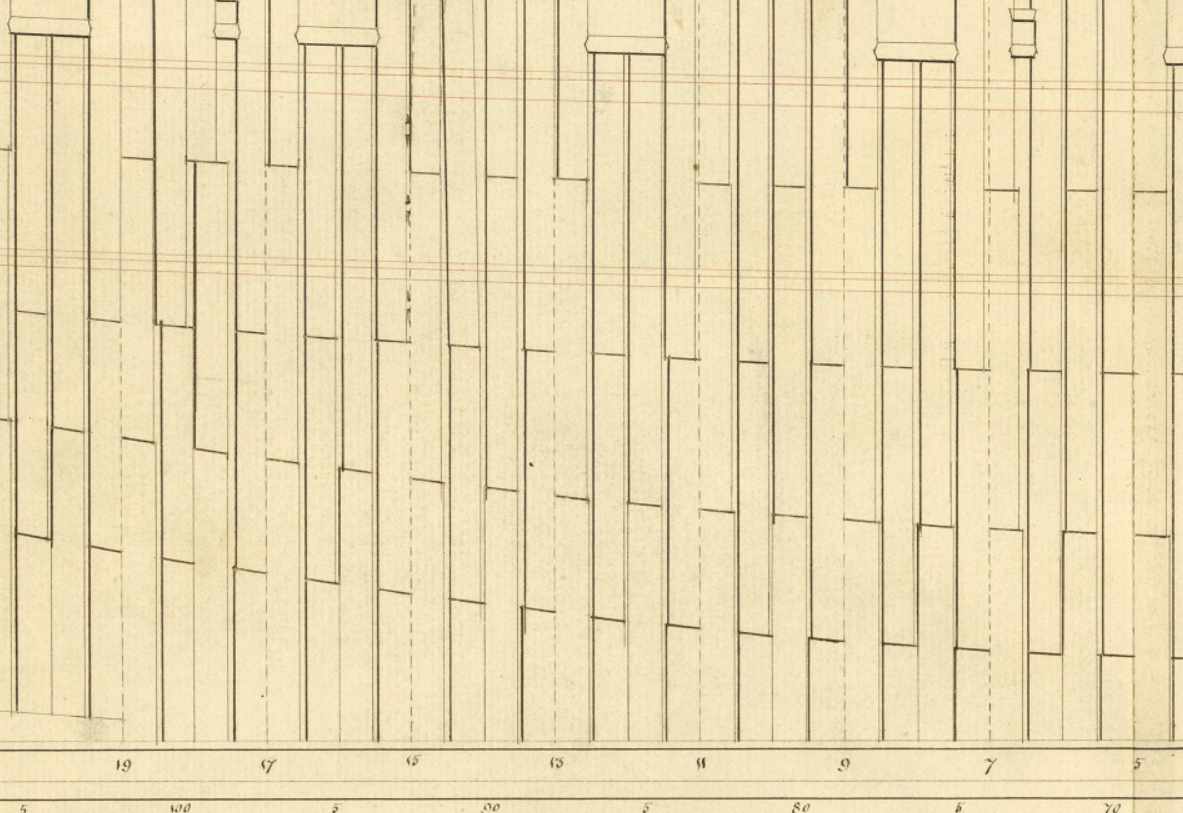

Very good model, very good photos!its also are very useful references for making fullframe model or POF kit. Thank you very much for providing these photos. But I personally think there seems to be a little problem with the main frames.I have no malice or any other attempt. I just want to confirm my personal cognition. I can learn more if some experts refute my opinion. I think it's more like the 6th rate, but obviously it's the 5th rate, as long as you can see from the quarter gallery. And screenshot from another draught... ...... The 6th rate seems to start from the first/foot futtock, so this is neither the 6th rate nor the authentic 5th rate.... My personal opinion is that from first /foot futtock looks not "very orthodox" or "authentic"...Because this should not be a commercial kit, more like a collection model of a museum...I am just from the perspective of knowledge of shipmodel, whether it's right or wrong... Jack

-

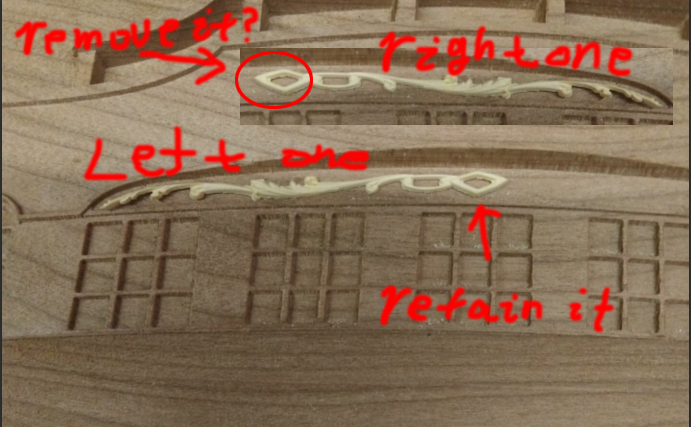

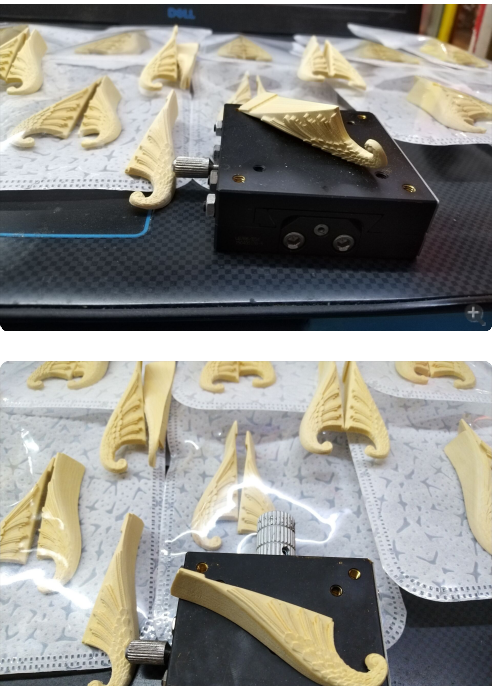

Hi! Inspired by Mr. Chuck's resin casting, I decided to remove the “diamond part" on the right side, so as to reduce the risk of damage during removal. As long as you do a little polishing, it can match the left side well . Because the mold I used for processing is very good-I made two "moulds" same as the Stern's surface, I fixed rough stock on these two moulds directly, and then I could process the carvings that could match the Stern's surface exactly, but this mould could not be reused,so I made more than ten sets by the way so my progress will be delayed, and it is likely to be delayed until next month to complete all the sculptures. Jack

-

Wow!!! it's amazing! Those details can be reproduced perfectly. It's great! I'm curious about the details that even 0.1mm milling cutter can't carve out, how the mold is made? I can only sigh that technology has brought us more and more better products... By the way, your camera is really good, sir. The photos are quite clear! Jack

-

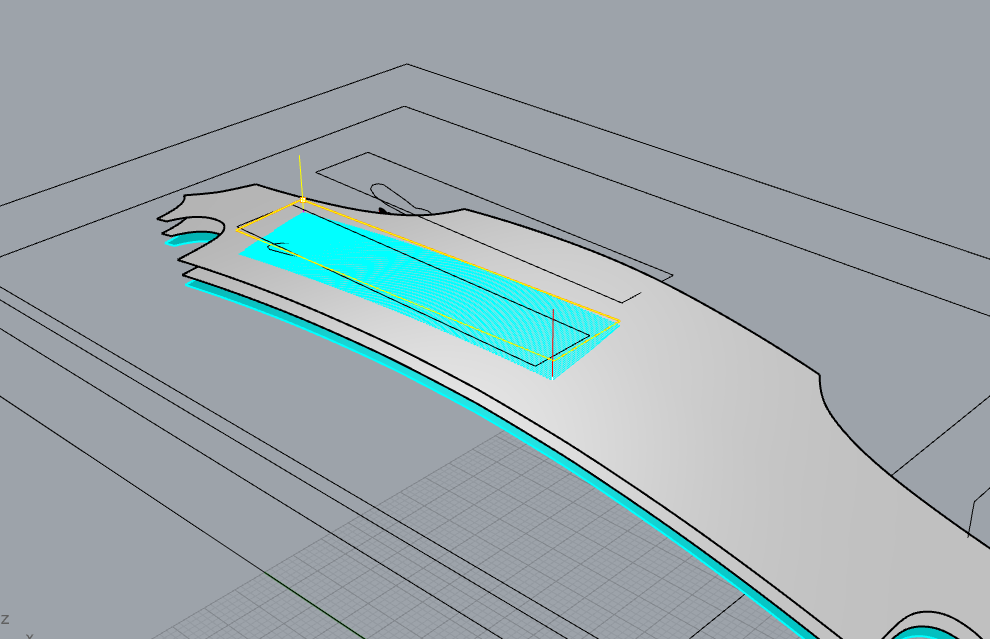

Hi everyone! Today I started the processing of the last relief. Since this is a small batch production, I asked my friend to help me cut boxwood and Jujubewood into thin wood chips. Because the relief is thin and long, and thickness is only 0.5-1mm, it is quite difficult to make... Mr. Chuck asked me to make this part. Fortunately,in the end I found a way to process it .I machined this part directly on the surface, so it can fits well with the surface of the model. As always, this is also a component with high degree of completion, which you can assemble on the model with a simple process.After careful consideration, I decided to keep the ”diamond “ in the right half. You need to decide which side will be removed- the left or right "diamond". As long as you remove the ”diamond part“ carefully, you can splicing it with the other half accurately. Jack

-

Hi everyone! It's almost a month and a half since September 1, I'll finish the production of Jujube wood drops tomorrow. I expect that in another week, I'll finish all the carvings except the figureheads. Then, when I finish about half of the figureheads, that is, at the end of this month or early next month, I can accept the order. Since I didn't make this model, but I built the 3D model of the stern of Winchelsea, I'm glad that Mr. Chuck tested the drops and it matched the actual model 'good'...He told me. Unlike previous ones, this is batch production, so I rewrote the processing program, I used nearly 20 subroutines to process this complex multi-faceted parts (drop), you need only a simple correction and polishing to assemble them on your model. Here again, many thanks to Mr. mark and Alexander for their comments on the modification so that you can get more accurate products. The drop below is made of Jujubewood,not polished and treated, it is very close to boxwood. Indeed, I can only say close but not "the same as...", maybe it's more harder than boxwood, but not so delicate. I will consider using Jujube wood to process POF Kits in the future. Jack

-

Hi scrubbyj427, Wood and resin carvings can be dyed.If you make a cherry or pear version this time, you can dye it. If you choose my carvings, what ever it is jujubewood or boxwood, I can send you a few extra carvings for dyeing experiments,But the carving I gave you is defective. These defective products can not be sold because of the defect of wood grain, but can be used for dyeing experiments.It's better to brush a colorless primer first, otherwise the wood grain will deepen and scrap. Thanks Jack

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.