-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

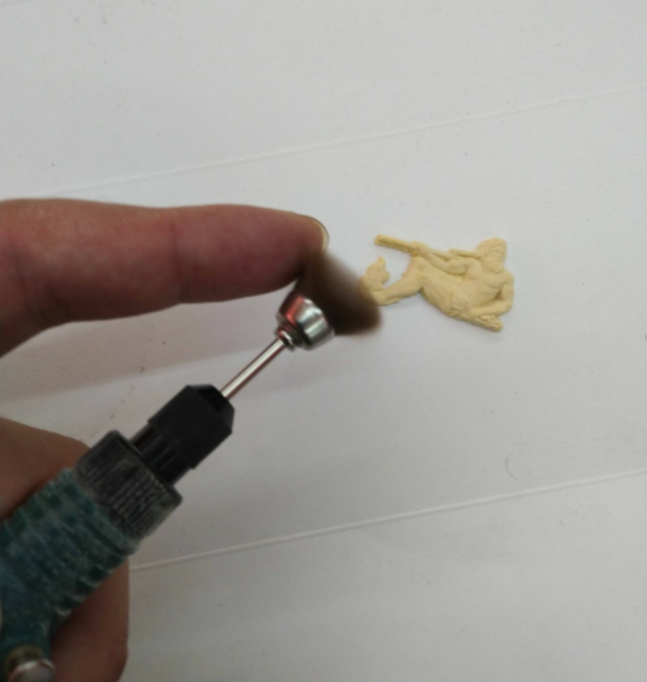

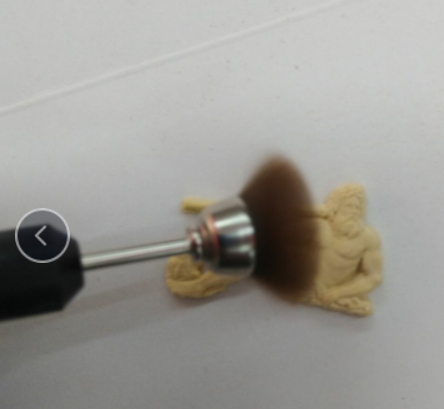

Hello, everyone. I will introduce the cleaning and polishing of boxwood/Jujube wood carvings.These operations apply to all of my carvings (include figurehead). 1.Don't use sandpaper or a file to clean or polish carving, because my carving is so fine that you can see his/her eyes (or even eyeballs).Otherwise, some details will be lost. But you can modify the back or edge of carving with a file. 2.All the members who ordered and eventually purchased this set of carvings,I will send him a set of special polishing/cleaning brushes free of charge. Let me show you how to use it. This is the carving of the newly carved ,it still looks a little rough,but it's not polished or cleaned at all.In fact, he is very smooth, just because the sawdust on the surface has not been cleaned. Install it on your Dremel (or mini-miller), turn on the switch, and the brush spins fast, but it's very soft, just like your pet cat touches your hand. After a simple cleaning, about a minute. It looks a lot cleaner. In this way, you can polish carvings without losing details.I'm sorry my camera is not good enough. You can refer to Mr. Chuck's figurehead. After further polishing, the surface will have the unique oily effect of boxwood, you can also wax him. You can also glue the relief onto the model and polish it. The brush won't damage your model. Please note that before sticking to the model, do not wax it, if so glue is difficult to stick. Many modelbuilders are so helpless to make models dirty. Models dirty only depend on polishing. Fine relief or figure head can easily lose details in the polishing process. I recommend a simple, inexpensive and practical tool, which is This is ‘finger-cot’,made of latex, it also protects your fingers from paint or glue damage. Thanks Jack

-

Hi Mike, thank you for your message, According to the current statistics, I will arrange the first batch of production. When I finish the first batch of carving, I will inform every member to start ordering, you can choose to order or give up. As for how to order, it's quite easy. Payment by paypal, you will receive an international express package. I have sent it to America and Europe several times without any loss. If the package is missing but not for your reasons, I will send you a new one. If you give up the order, you can either give up permanently or reorder, but if you reorder after giving up, you will be placed in the next batch. I'm registering for a website called CNCShipmodel, but I haven't finished it yet. I hope to become a sponsor of MSW, where you can check and order carvings in the future. Jack

-

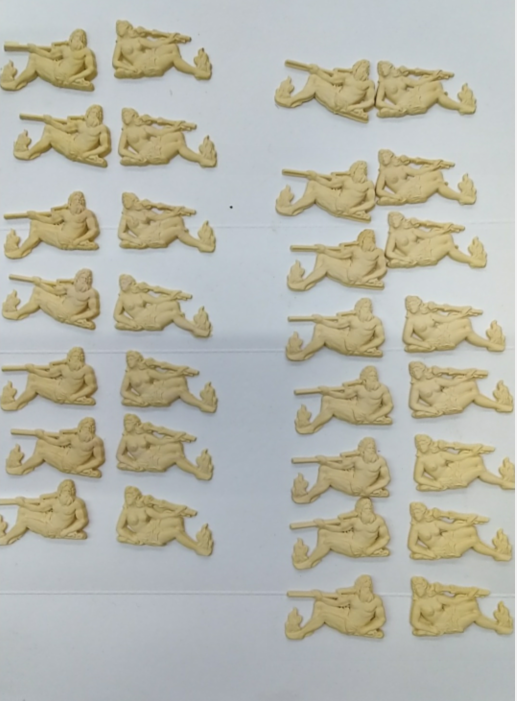

Hi everyone! Thank you so much for your attention and reply to this post ! Thank you so much for telling me your thoughts and sending me useful message...and now I'll talk about the production cycle of boxwood and Jujube wood's carvings.It's the topic of concern to all. As you can see, when I get an approximate demand, I will produce it in sequence. Now I know the approximate amount of demand and most people tend to buy boxwood sets, so I will produce 20 boxwood sets and 5 Jujube wood sets in the first batch. I estimate it will take about two months to complete 25 sets of carvings.Express delivery to the United States and Europe is almost 5-10 days, usually five working days. Payment is Paypal, very fast and convenient.Both products are all free shipping. I will keep releasing progress information (pictures). Thanks! Jack

-

Thank you Jim Rogers! Column should be in laser carving KITs, although I can provide it (CNC one), but it is up to Mr. Chuck to make the decision. I think you will get a reply from Mr. Chuck tomorrow morning. As for whether you can buy the figurehead of resin and the carvings of jujube, I need to wait for Mr. Chuck's decision, including how to calculate the price. It doesn't matter. When I finish the first batch of products, you can finally decide whether you need to buy them or not. Thank you for telling me your thoughts. Jack

-

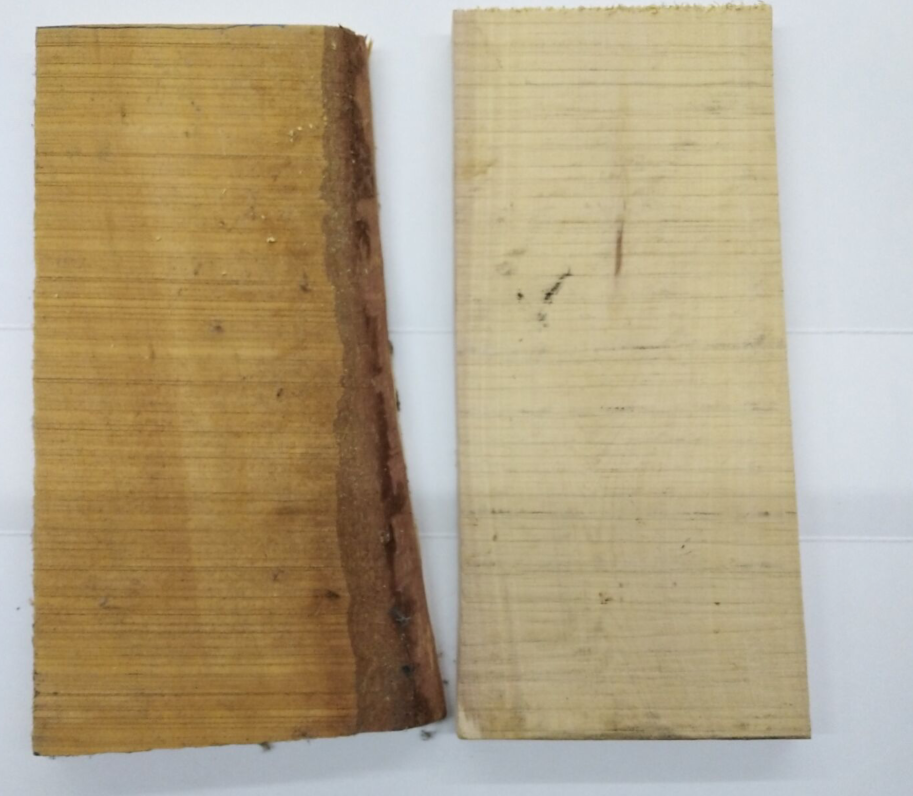

Thank you very much Mr. Passaro. I am very glad to be able to participate in this project. I am also very happy to offer every member Boxwood and Asian jujube wood sculptures. I will introduce the sculpture in detail and answer your questions. An important purpose of starting this topic is to find out how many members are interested in boxwood or Jujubewood sculptures. I will start to produce according to the quantity needed. Whether it is one set or 20 sets, I will try my best to provide you with good products. All members interested in buying boxwood/Jujubewood sculptures can express his wishes in replies. I will make a preliminary statistics. I will know how many people need this set of wood sculptures. Then I will produce sculptures according to this statistics. If you don't want to publicly express your purchase intention, you can also send me PM. Ultimately, before selling, I think I will become a sponsor of MSW first, because I'm still preparing my studio named CNC Shipmodel. Usually I will produce 10 sets, unless more than 10 people need it, then I will continue to show you the completed carvings until all are completed, then i will accept the order. I will give priority to those who reply to the purchase wish. Almost forgot to say that I only accept orders from members(or modelbuilder) who have purchased Kit of Winchelsea from SYREN company, but not from anyone who have not purchased that KIT!!! I solemnly assure you that all the software I use for this sculpture, whether for design or NC processing, I have purchased commercial licenses. Before developing and making these sculptures, I have sent all the purchase certificates to Mr. Chuck. All the software I use is purchased by myself. The authorized person is myself, not my company or anyone else. All 3D models are based on Mr. Chuck's drawings, and originally designed with Mr. Chuck's permission. All the 3D models were made by myself, and all the NC programs were written by myself, so these sculptures were made according to Mr. Chuck's drawings originally. First of all, I would like to introduce the difference between Asian box wood and Asian jujube. Because of the reasons I mentioned earlier, the price of this set of sculptures is not cheap, so Mr. Chuck has provided you with Resin-Cast sculptures. Mr. Chuck wants me to continue making some boxwood sculptures, because Winchelsea is really a beautiful project, and maybe many members will need years to make her. Moreover, Mr. Chuck has devoted a lot of energy and years to providing you with high quality KIT. Perhaps many members want to use the boxwood sculpture to complete the project. Mr. Chuck also wanted me to offer a relatively inexpensive but good version, so I chose Asian jujube wood. Judging from the previous pictures, it is estimated that many people find it difficult to distinguish the two kinds of wood. Undoubtedly, boxwood is almost the best wood for ship model or sculpture, while Asian jujube has a hard and dense character, and its color is similar to that of boxwood. Because of the high price of box wood, many people use pear wood (Swiss pear wood) to make ship models. Compared with Swiss pear wood, Asian jujube wood is not as delicate as pear wood, but jujube wood has similar color and performance to box wood. Because jujube wood is too hard, it is not suitable for manual carving, but it is very suitable for CNC. There are yellow and reddish brown, but I only provided yellow one this time. Asian jujube (left) and Asian box wood (right). Because jujube wood is more easily oxidized, the color of jujube wood tends to be more golden, but the color of jujube wood and boxwood is very similar when they are just finished processing. If you need the best one, then box wood is your choice. If you want to use wood sculpture, but you want to have a relatively cheap price, you can consider jujube wood. Secondly, I would like to introduce the processing technology of this set of sculptures. Thanks to the precise 3D modeling, although I can't communicate and modify the sculpture face to face with Mr. Chuck, when Mr. Chuck received the sculpture, I think it fits well with KIT, because Mr. Chuck didn't ask me to modify the size, including the figurehead.Unlike many other carvings, I use complex composite processing technology, that is, relatively complex NC programming, so you can get separated sculpture, while many others are single-sided sculpture and the precision is relatively low, which requires quite a bit of work on polishing and refining. I used a variety of milling cutters mixed processing, and the use of composite processing technology, so that the sculpture looks like polished, and has been separated from the board, as long as you do some polishing and decoration, you can get very delicate carving.They are taken directly from the machine tool, after simple cleaning, without polishing and embossing, that is to say, what you get is what you see now. Jack

-

Good idea, Mr. Chuck always has some unique ideas... For example, the ribs assembly method of his cross-section KIT last time.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

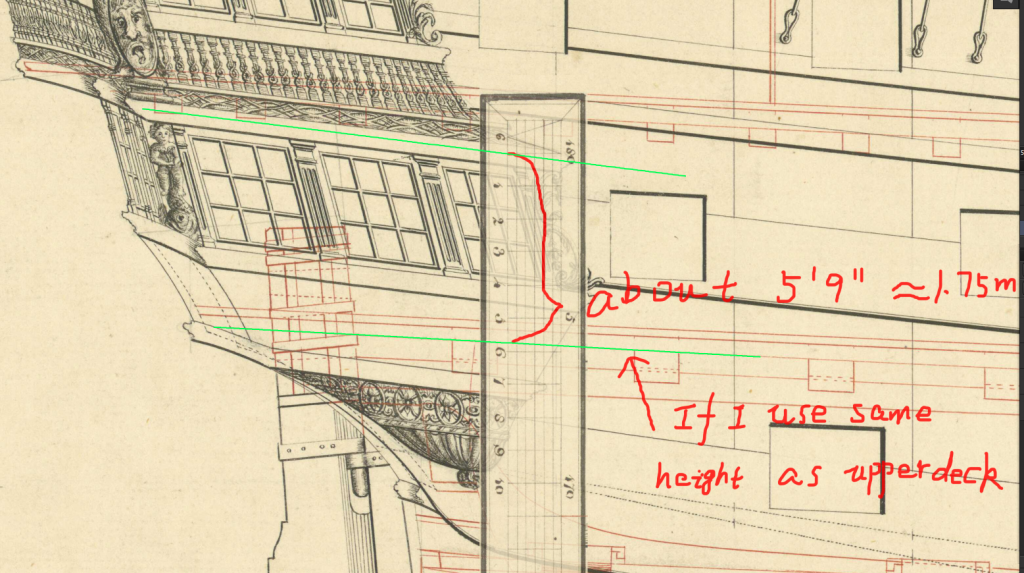

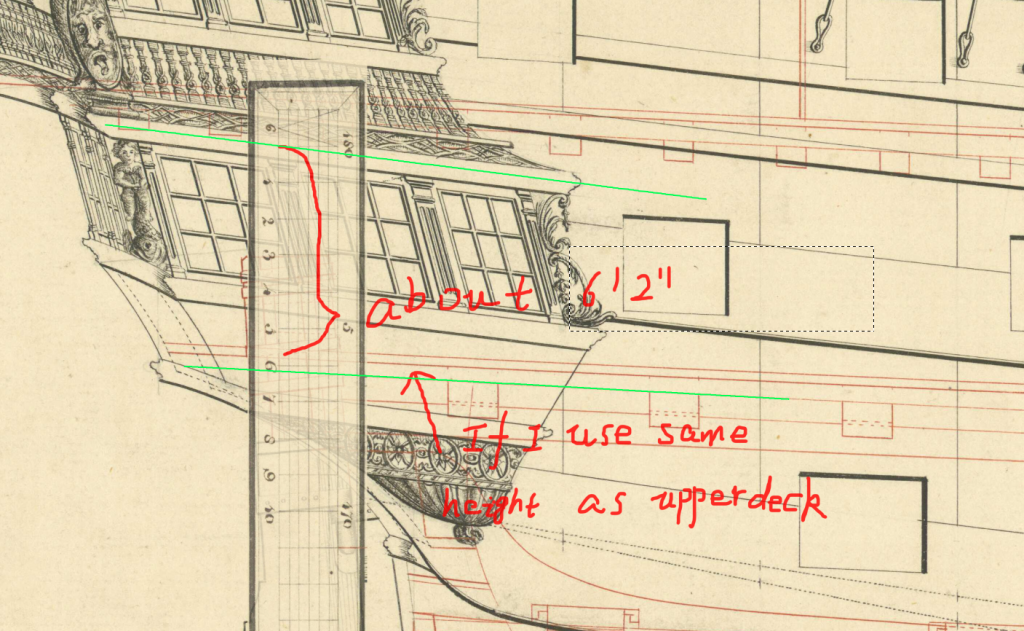

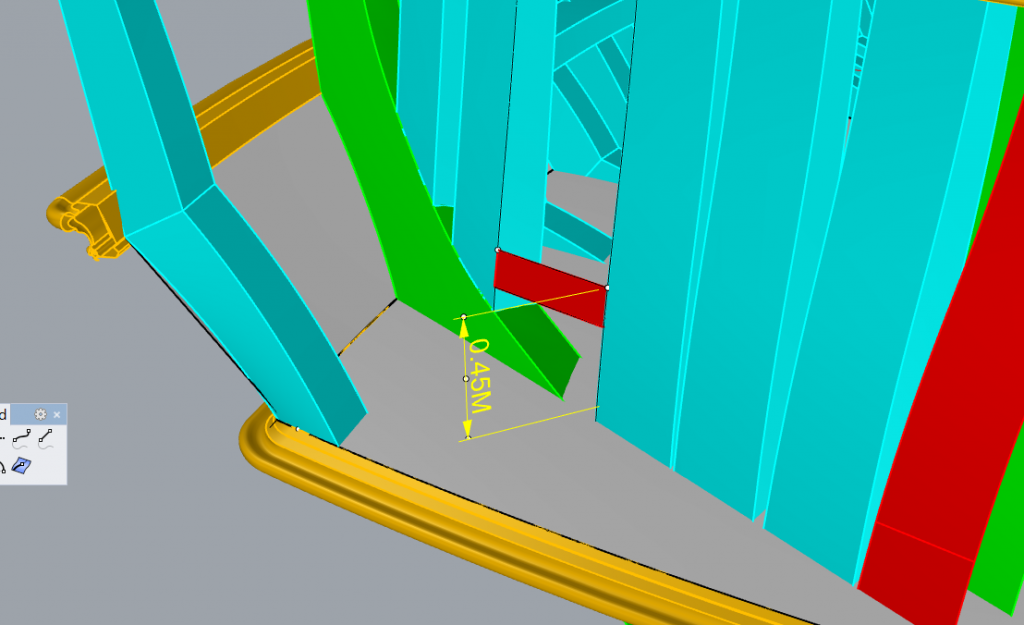

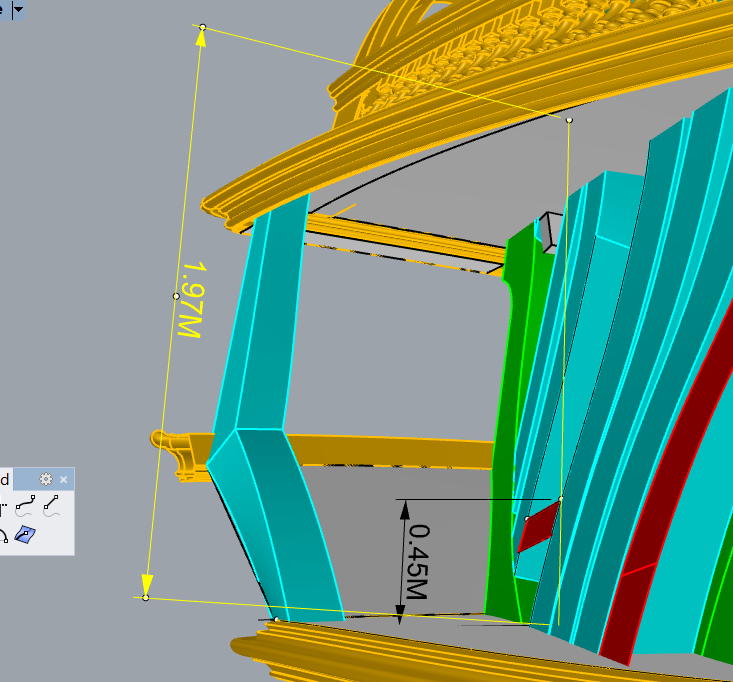

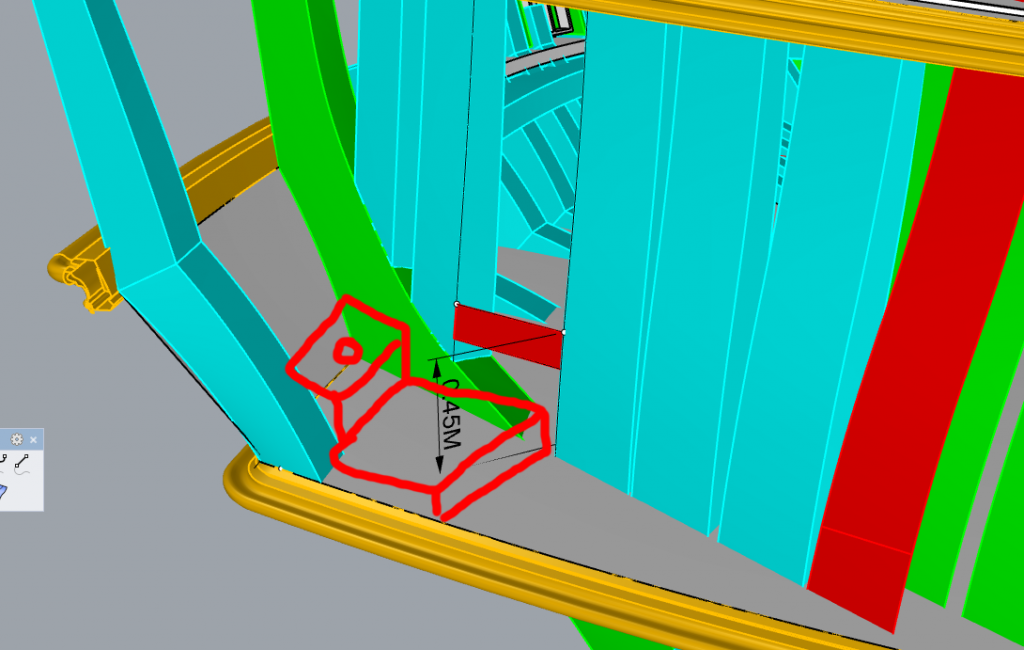

Hi Siggi52 ! Your last sketch is more accurate than mine,thank you! I overlooked one detail, the position of rail on the other side. But according to your sketch, the floor of stool will be more higher, especially in the rear. I used your method to measure the height by scale, but she's Hms warrior because I didn't have the draught of Alfred.I think this height can satisfy the average person, although it's quite uncomfortable.. But my personal idea is that the floor of stool will be a little lower than the upper deck. If i move to it's port,it will be 6' 2". I checked out Mr. Goodwin's book. If i follow his structure, the height of my 74gun project is 0.45m, I think maybe I need a step or simplify it, just like Franklin's model. The internal space height 1.97M-2 1/2",it's about 1.9M. Although I have this idea personally-see below figure ,but it has no any basis,so i think i will simplify it. HJX

-

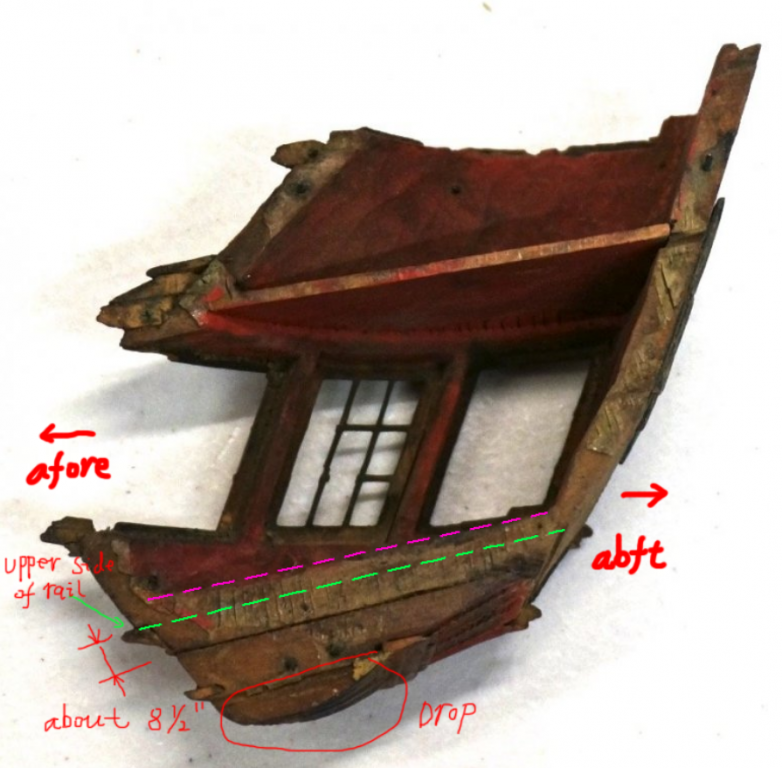

Hi Siggi52 Thank you for providing these good photos of NMM model. However, as far as we can see, the position which you marked of the 'floor-line' is not accurate. Referring to the position of rail, the floor of the lower stool is indeed higher than the rail, considering that the beam will a little dropped from middle- line to it's end, the floor near frame will more higher than the rail. And don't worry about the internal space is not high enough, because the floor of the upper stool is also raised, and you can see that the floor is very thin,it's looks only 2" or 2 1/2". I personally think that the floor of the lower stool is higher than the rail, may be same as the upper deck, or it may be slightly lower than the upper deck, but it is as high as the upper deck at the rear rail. Also, I think the model's has been simplified. I don't believe that it will be carved out of a whole piece of wood,except Drop, the floor will be planked. HJX

-

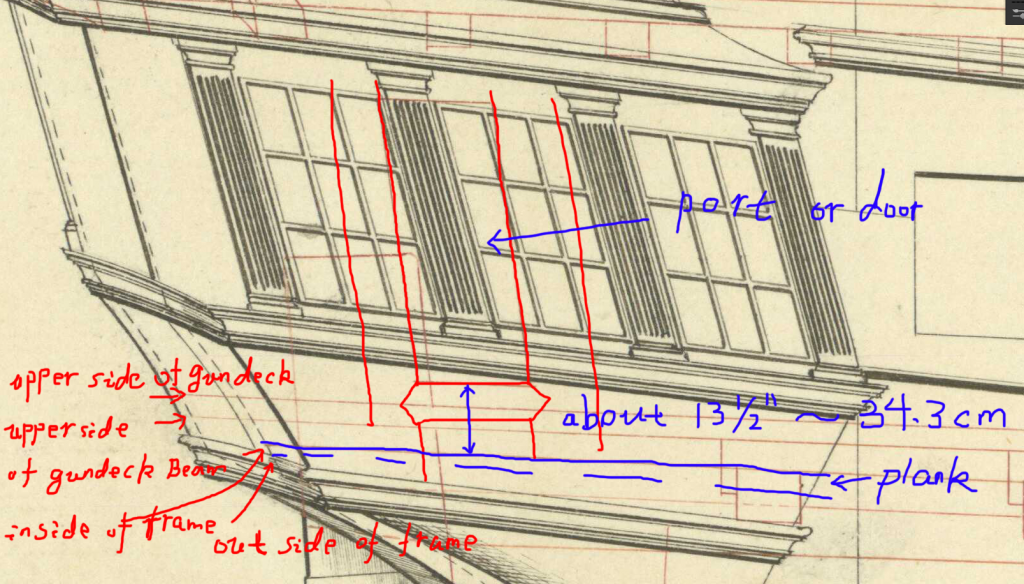

Hi everyone! Maybe garyshipwright is referring to this? I found a draught of 3rd rate 64gun. The minimum measurement of this height is about 13 1/2", which is almost 34.3cm. It really needs a step or ladder to ensure safety. It's a tricky problem,there seems to be no model or book ever mentioned here with steps or ladders... I will refer to Franklin's model to simplify this part - the so-called 'gray-zone'. HJX

-

It's really great, high quality resin castings are what many modelers expect,can't wait to see hull's planking in next step. Jack

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

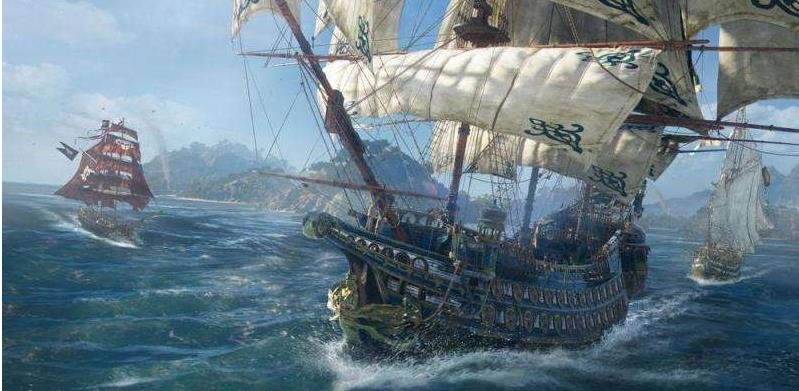

Nice work Martes. Seeing your work, I recall that a few years ago, I was very obsessed with 3D modeling and game engine, especially the following real-time naval game scenarios. Some screenshots from game, very gorgeous scenes... I used to use Unity or UE4 engines to simulate the 18th century frigate naval battles.However, many aspects beyond my ability, especially C language and dynamic seawater (sea water plus special effects), need professional learning, so I can only give up later, now I focus on 3D modeling and CNC programming and processing, because for me, making naval games seems to be a dream, but 3D modeling and CNC programming / processing seems more realistic. HJX

-

I'm also looking forward to appreciating high-quality planking.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It looks very delicate and beautiful.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

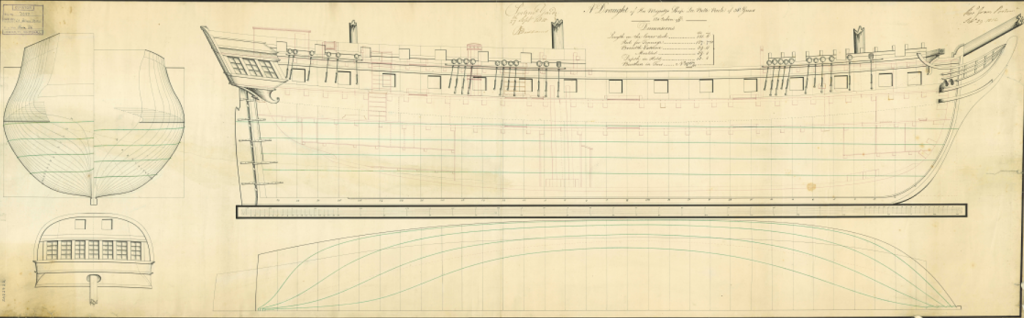

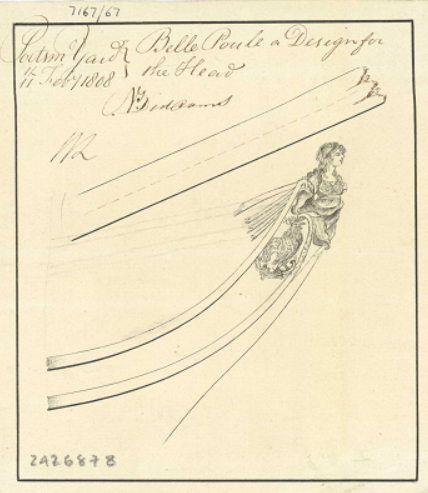

Hello I remember you have studied Belle Poule in another post? Of course you have good drawings of Ancre now. I happened to see a draught of NMM, the text of ' 1810 ...As taken off...' was marked on it. I don't know if it means that the drawing was drawn in 1810, but it was when she was captured. Jack

-

Hi every one! I'm glad that Mr. Chuck allowed me to participate in his KIT development, and thank you so much for the helpful advice from so many enthusiastic members...I'm really working with British model companies, which have obtained written licenses of commercial development from NMM . I can tell you a little more that there are two projects under development, one is the 50gun in the 17th century, the other is the 74gun in the 18th century, both of which are British ships, NMM style. At present, one project has entered the stage of 3D modeling. When I complete the modeling of this model, it will enter the validation of the actual model immediately. Several ship model experts participate in the design of this project, and there will be ship model masters to participate in the validation of the actual model. The design software used in the design process, as well as 3D sculpture software, and CNC programming software(CAM) are legal and obtain commercial license. Thank you again, MSW Forum and Mr. Chuck. Jack

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS VICTORY 1765 by albert - 1/48

Jack H replied to albert's topic in - Build logs for subjects built 1751 - 1800

Hi Albert Great victory, great project, deep respect and best wishes for you! HJX -

Indeed, it would be tempting to buy a CNC/Laser Engraving/3d Printing Multifunctional Machine for just $299. I once wanted to buy a similar machine. The cheapest CNC engraving machine in China is only $70, and the cheapest laser engraving machine is about $42. I know you've been focusing on CNC equipment... My personal experience is that for making ship models or other models, , there (in China)will be at least about $700 -Does not include any software and computers.. Compared with ebay's , it will cost about $950, only three axes,800w motors.And this kind of machine can not be used for high-intensity processing, such as for Kit production.

-

In my experience, this kind of machine is only toy-level, or just for "Study", which is not suitable for model making. 3D printing is OK, laser can not cut more than 0.5mm, that is to say, can only leave a marking line on the board, but can not cut the board. The function of CNC is very weak. Can not cut more than 5 mm board, and the accuracy and stability is not enough, in Chinese website known as the "toy engraving machine".

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.