-

Posts

345 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack H

-

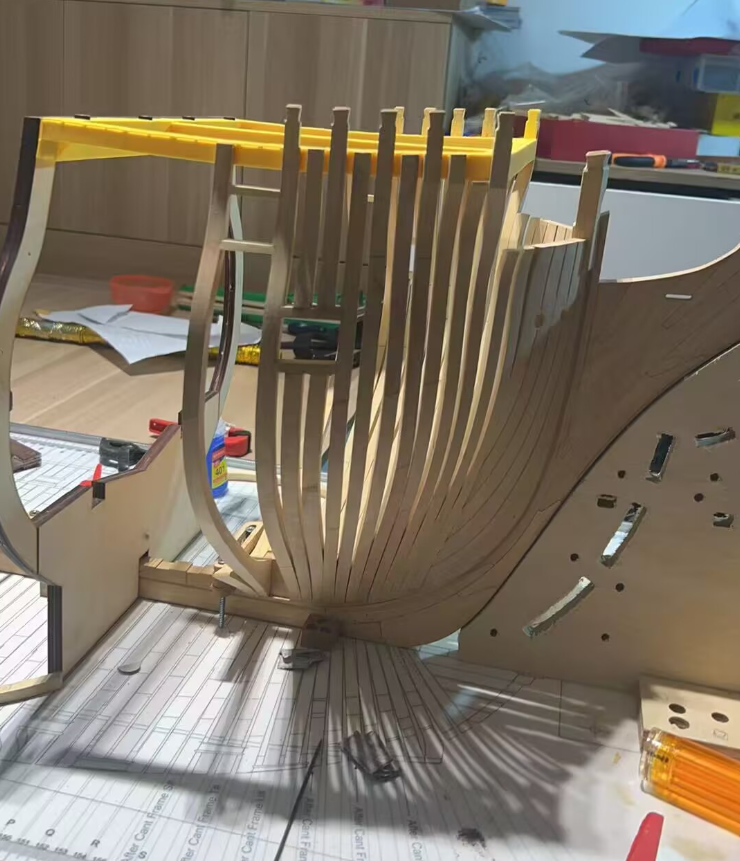

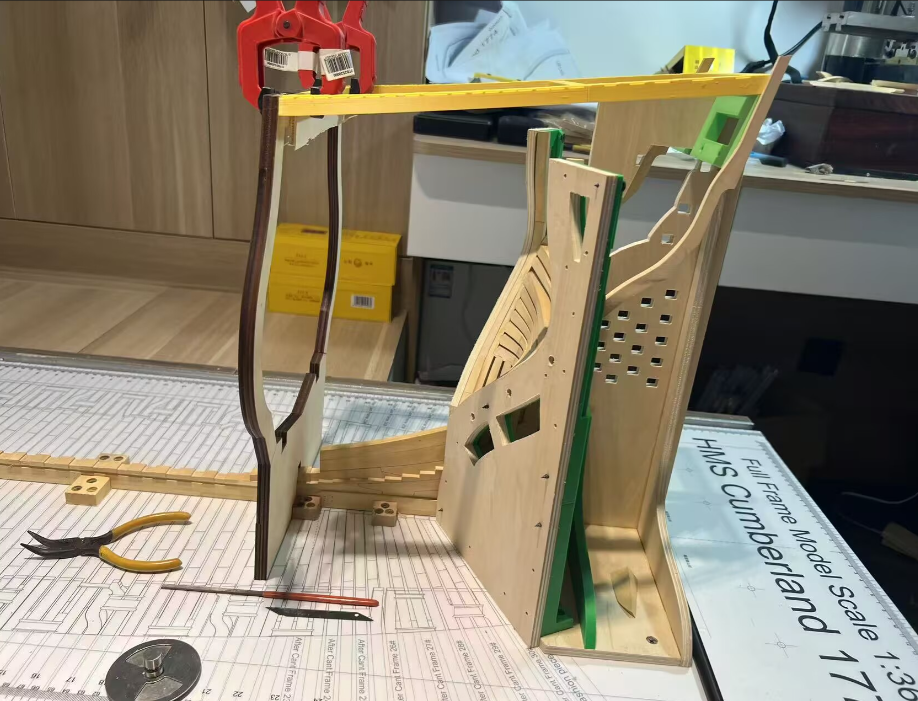

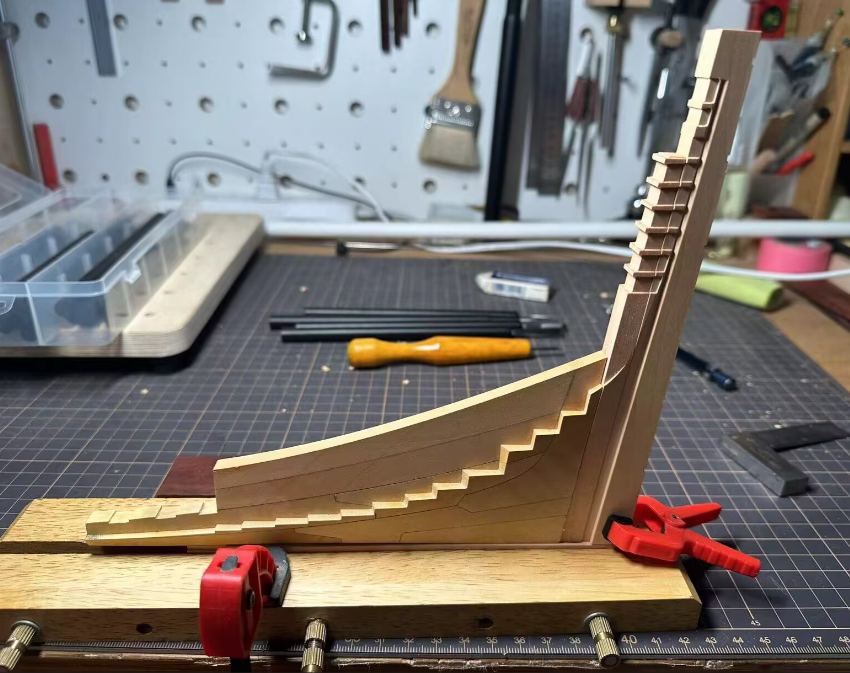

A tiny bit of progress, As you can see, using some new technologies makes this complex POF ship model relatively simple. Even if you’re a beginner, with just a little practice, you can assemble a decent complex model by yourself. And if you’re an experienced builder, it will save you a lot of time—maybe even years. I’m moving all my equipment from the garage to a new space, so I’ll pause updates for about two weeks. This’ll be my new studio, but it’s still a woodworking shop right now. I think this will help me develop some projects better.

-

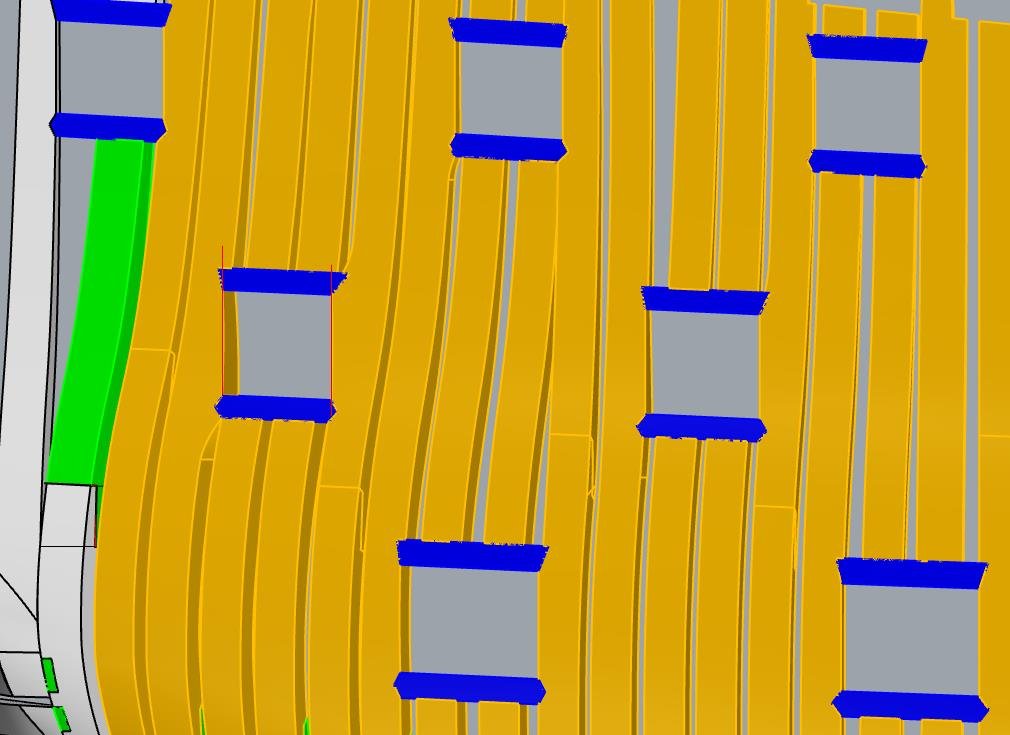

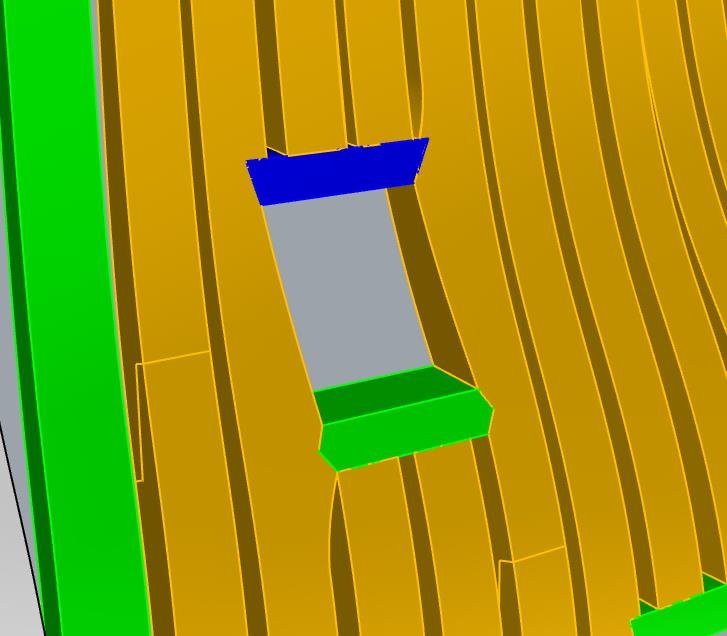

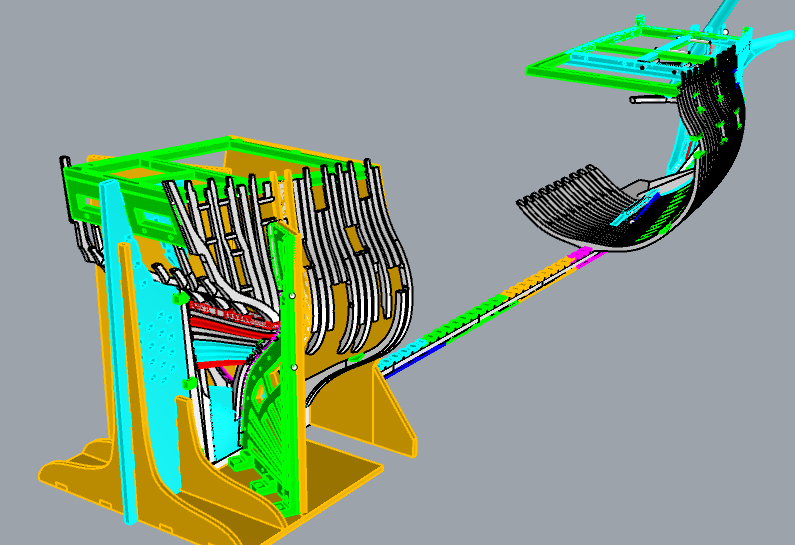

Thank you Matthias, I've also noticed your question. From the right view of the design, this GunPort is indeed vertical, but from many perspectives, it appears slanted.Regarding the size, especially the height and width of the GunPort, they seem disproportionate. This is likely due to the perspective. Please refer to the 3D simulation diagram.

-

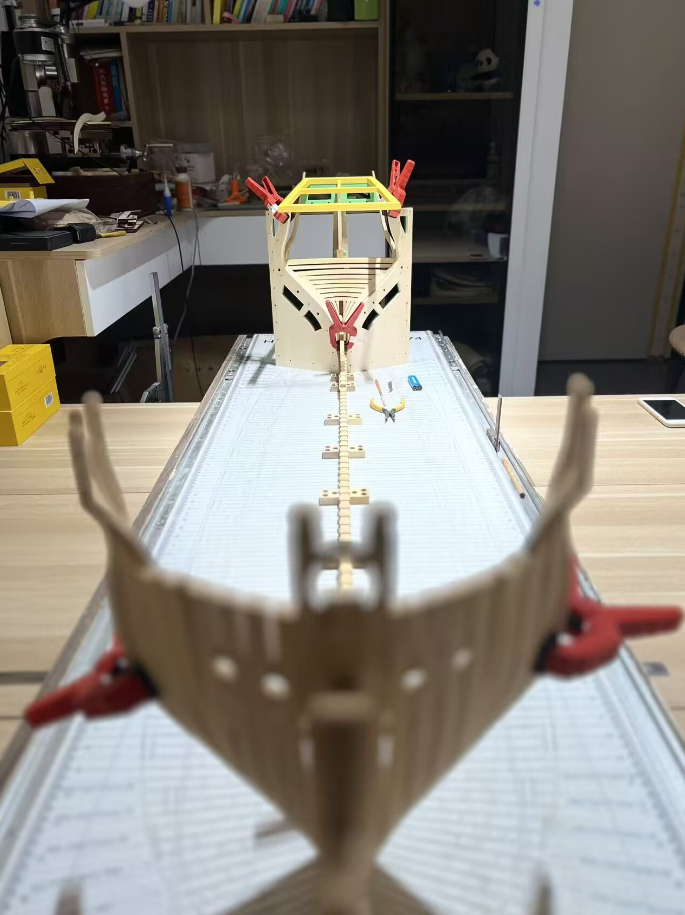

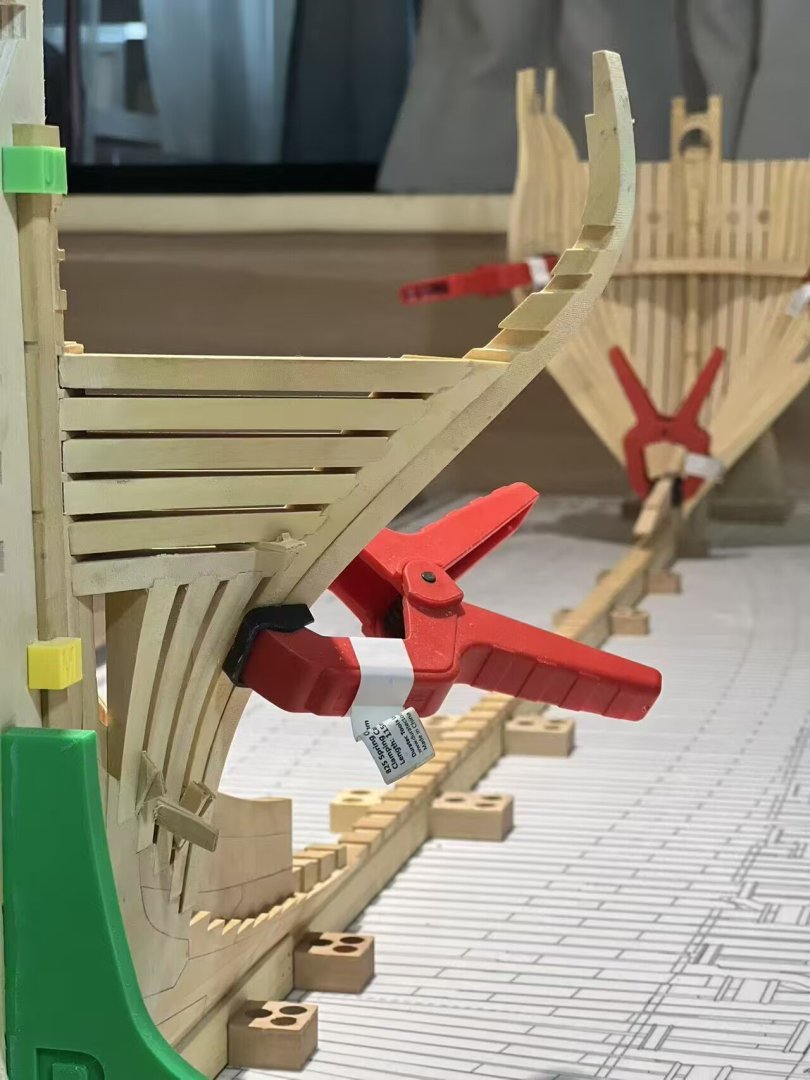

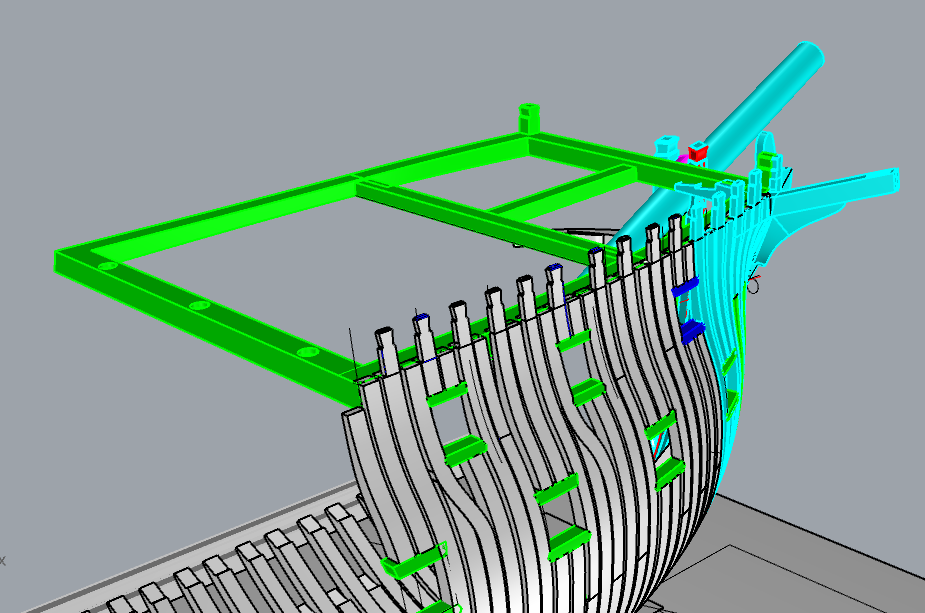

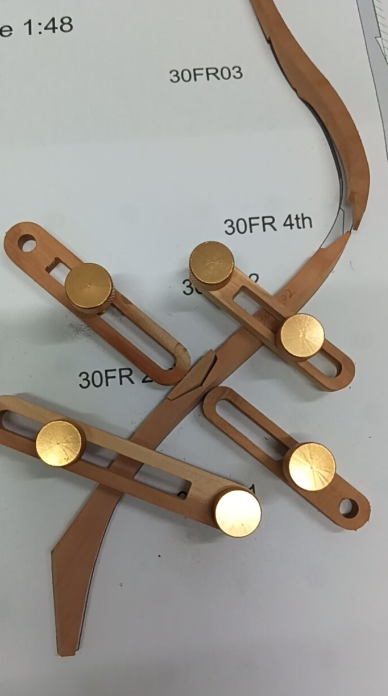

Hi, Liu has started assembling the cantframes. I suggested that he assemble the adjacent main frames first , then adjust the filling frame, and by the way, assemble the port cills too. This might be a completely new assembly method, or rather, a new sequence. Such an assembly sequence is based on the characteristics of CNC-machined components. Of course, with such components, even an average modeler could finish assembling such a complex POF model after a little practice. Anchor chock and port cills are supplied as finished products. However, I’ve also been working on a few ideas for jigs – specifically, using 3D-printed composite jigs that would let modelers sand square frames by hand quickly yet with minimal effort. This would make the processing costs much lower, thereby significantly reducing the price of the kit. As for the false keel, it’s true that 74-gun ships of that era should have had a double layer. But back then, I thought that overly thin components would be prone to deformation – especially horizontal deformation – which would be catastrophic. Maybe I’ll offer a suggestion: if needed, one can modify it to a double layer themselves.

-

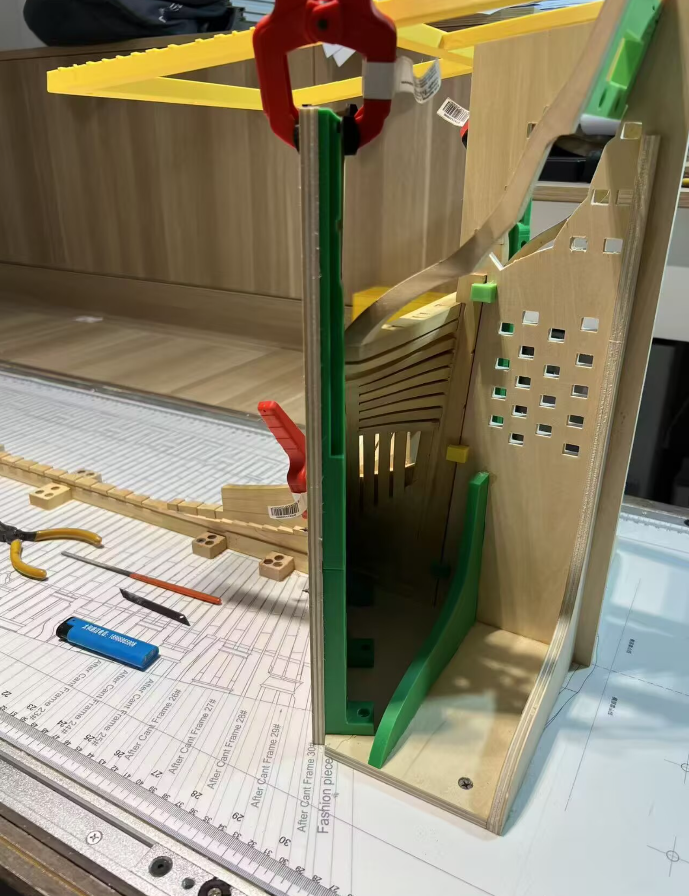

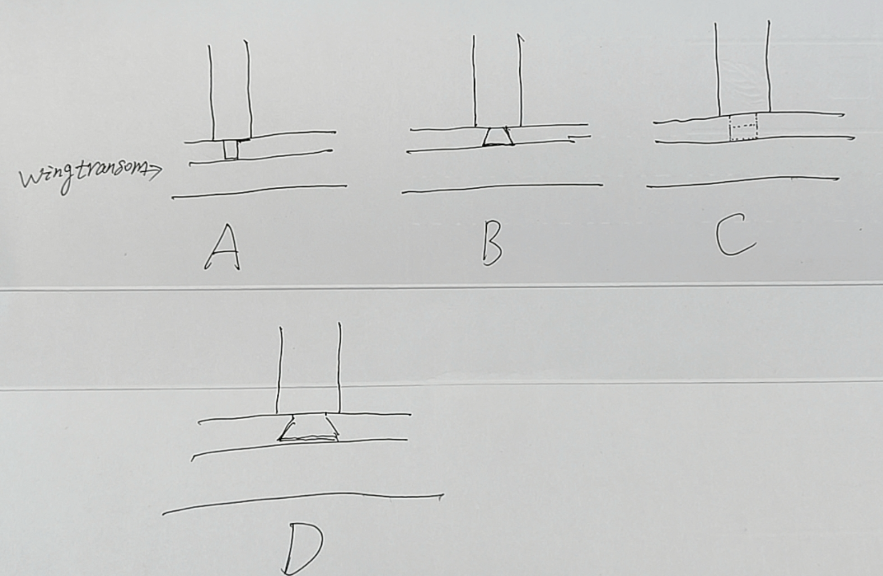

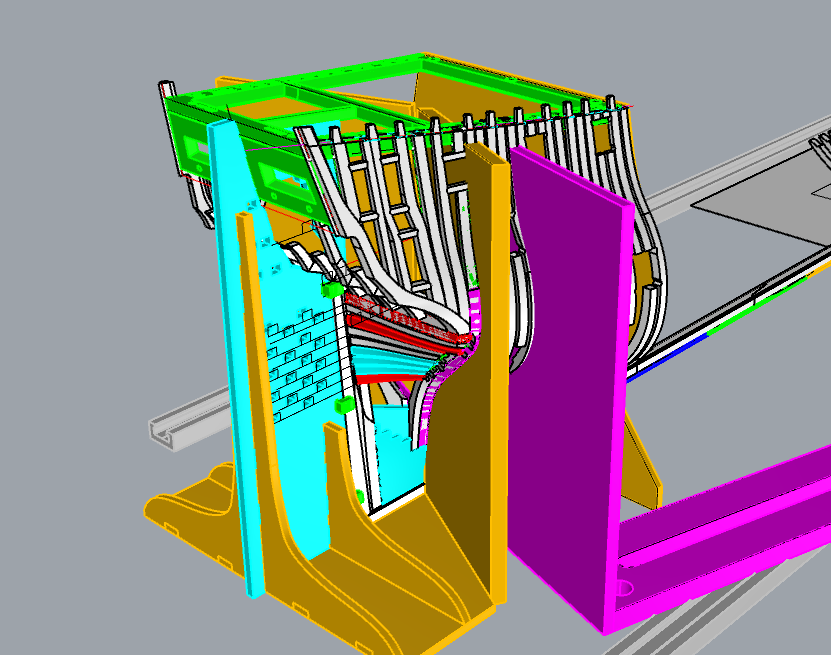

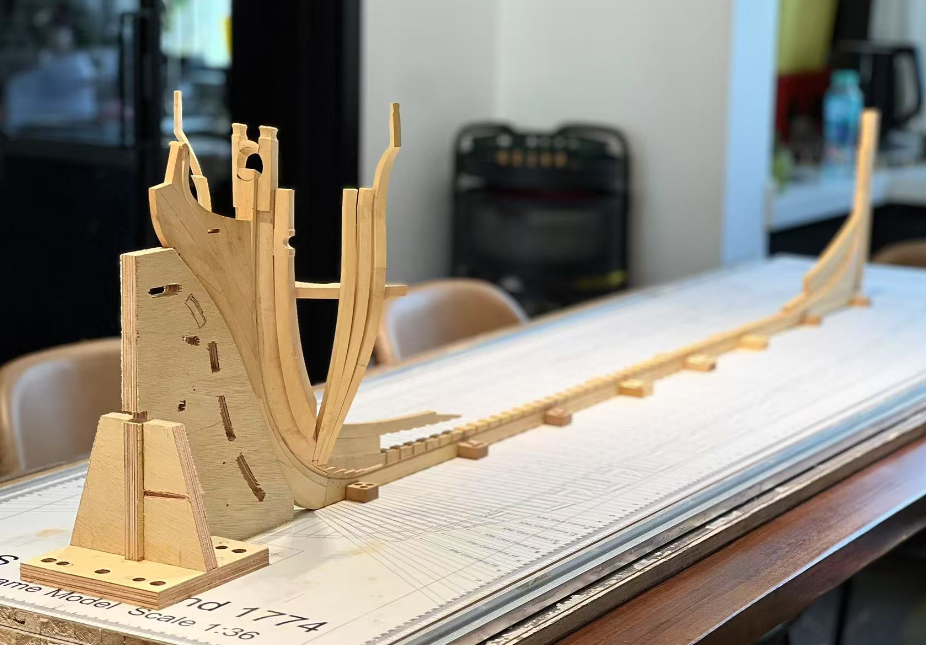

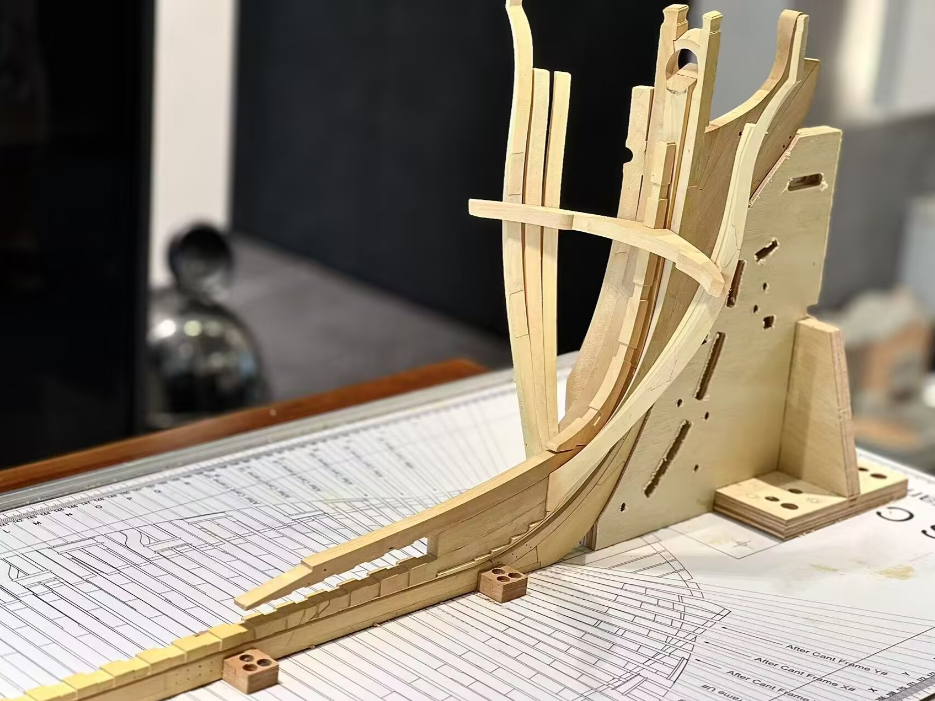

Hi everyone, Liu has completed the assembly of the wing transom, fashion pieces, and filling/deck transoms. Perhaps due to the bulkiness of the hull, he hasn't provided photos of the rear-facing perspective. However, I expect he will offer close-ups of this angle once the fashion pieces jig is removed. He used his own skills to assemble this structure, and his feedback is that the jig has a slight deviation and needs to be calibrated according to the drawings, while the wooden components have minor warping that requires on-site adjustments. I only made a 0.7mm allowance for the key transoms components. Next, he will finish assembling the top jig, after which he will start assembling the cant frames. Regarding the dovetail grooves on the upper surface of the wing transom, I adopted a simplified version of David White's "let down" method, though I first came across a comparative introduction to it in David Antcherl's book. Personally, I don't think the straight tenon of Type A is logical. When using real tenon techniques, one should either employ dovetail tenons or simplify them into hidden dummy tenons. The dovetail tenon of Type B is probably the more widely accepted structure, but my teacher's idea is similar to Type D. That is to say, it's not a direct dovetail tenon—since sharp corners are prone to damage, there might be a small section of straight tenon followed by a dovetail tenon. Given this, as someone obsessed with museum models, I opted for the simplified "let down" dummy tenon. Complete the support for the TOP Jig.

-

Liu started assembling the transoms at the stern, using his own methods and sequence. I didn't offer too many opinions, just reminded him to check the drawings and ensure symmetry and verticality. I have been worried about the accuracy of the assembly of the wing-transom, deck transom and fashion pieces, but now we can only wait for his next step of work. This process seems to be a test of whether the design and processing techniques I have adopted can enable an ordinary modeler without professional training to complete the assembly of such a complex tenoned structure, as well as the final result. Liu had previously completed a POB kit, but he had no experience in assembling POF. However, so far, it looks pretty good. The reason why I am so concerned about this key structure is that when I communicated with an excellent Chinese modeler a few years ago, he expressed doubts about this kind of structure of mine. He adopted Edward's method, which is a good scratch build method that has been repeated by many people. However, in order to avoid copyright issues or plagiarizing other developers, I need to design an entirely new jigs, processing techniques and assembly methods. Now I am also waiting to see if this new method works. My idea is to enable more ordinary modelers to complete such complex structures without requiring highly professional skills.

-

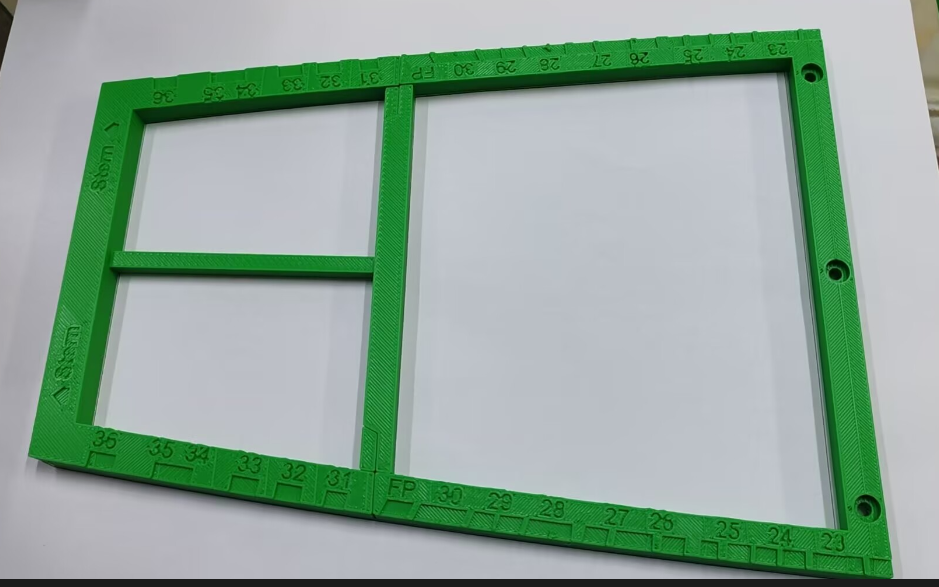

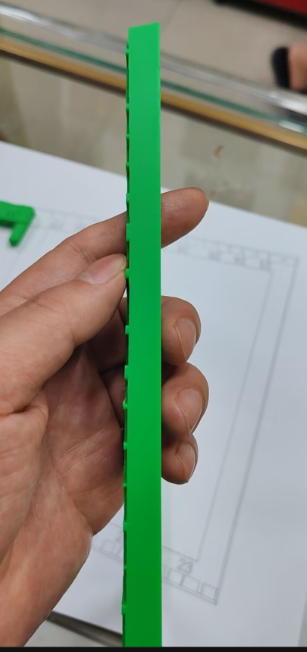

To better fit the structure of the kit, I have modified the fashion pieces jig and adopted a composite structure of plywood and 3D printing.The 3D-printed structure can well match the curvature of the frame's outer surface i think. Today, I have sent the complete set of frame jig to Liu, and he will provide his usage experience soon.

-

Hi! The first prototype of the frame jig, which combines 3D printing and plywood, will be sent to Liu immediately. He has been waiting for these components to complete his subsequent assembly work, and this will also serve as a good opportunity to verify the set of jigs. He will provide me with feedback afterwards. And stern.

-

Thank you for your attention; I think this project will eventually be released, whether it's a kit, full or semi-kit/ basic kit, or the drawings. However, first, this prototype needs to be completed, with the unreasonable designs addressed and the errors corrected. I know that it's impossible to avoid all mistakes; I can only try my best to do better.Secondly, my teacher, who has also participated in some of the design work, and I will discuss when and how to handle the drawings . In general, this project will definitely be presented to everyone once it's completed.

-

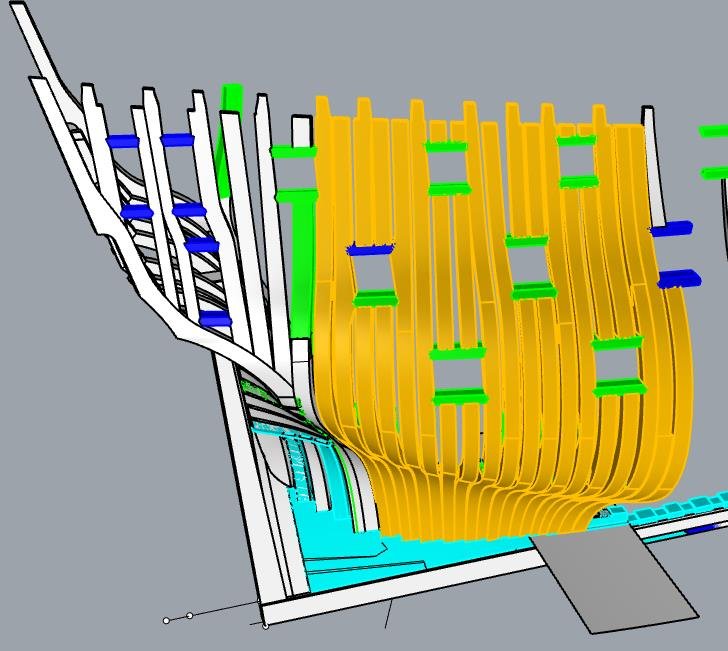

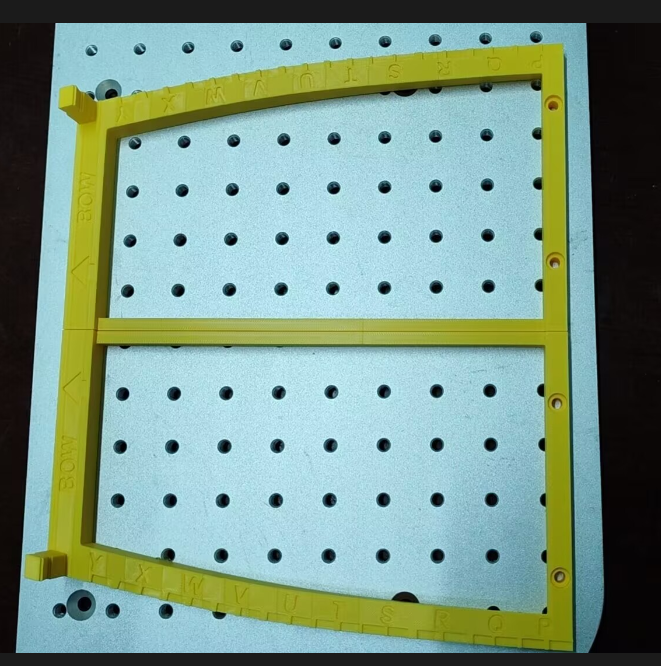

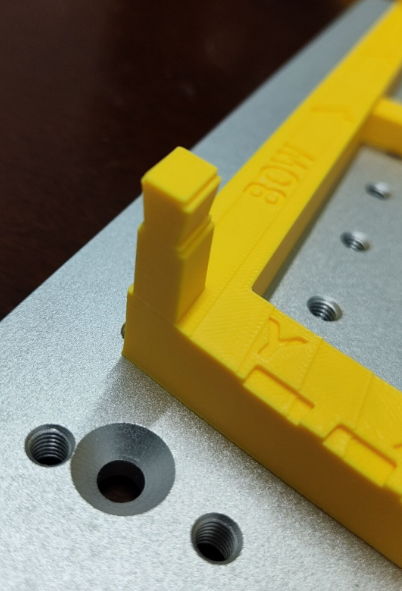

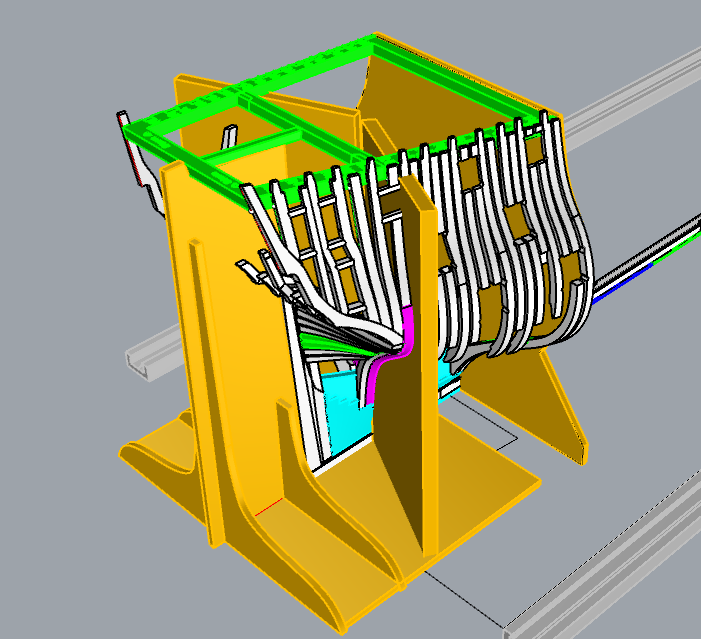

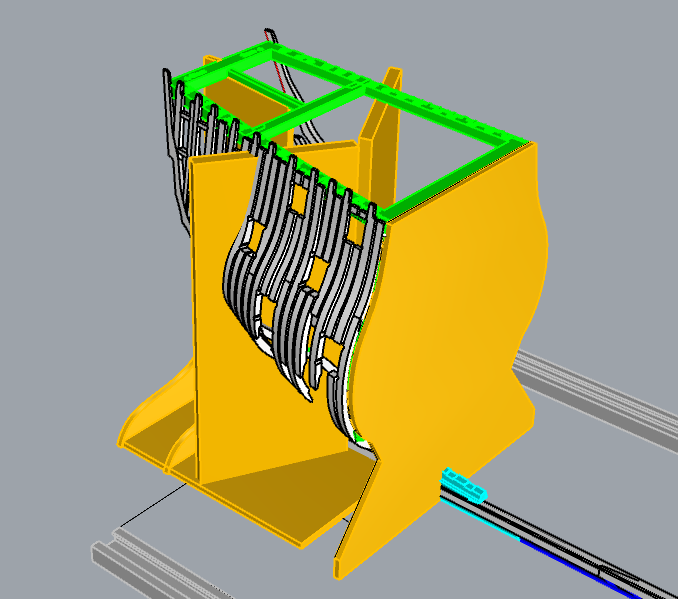

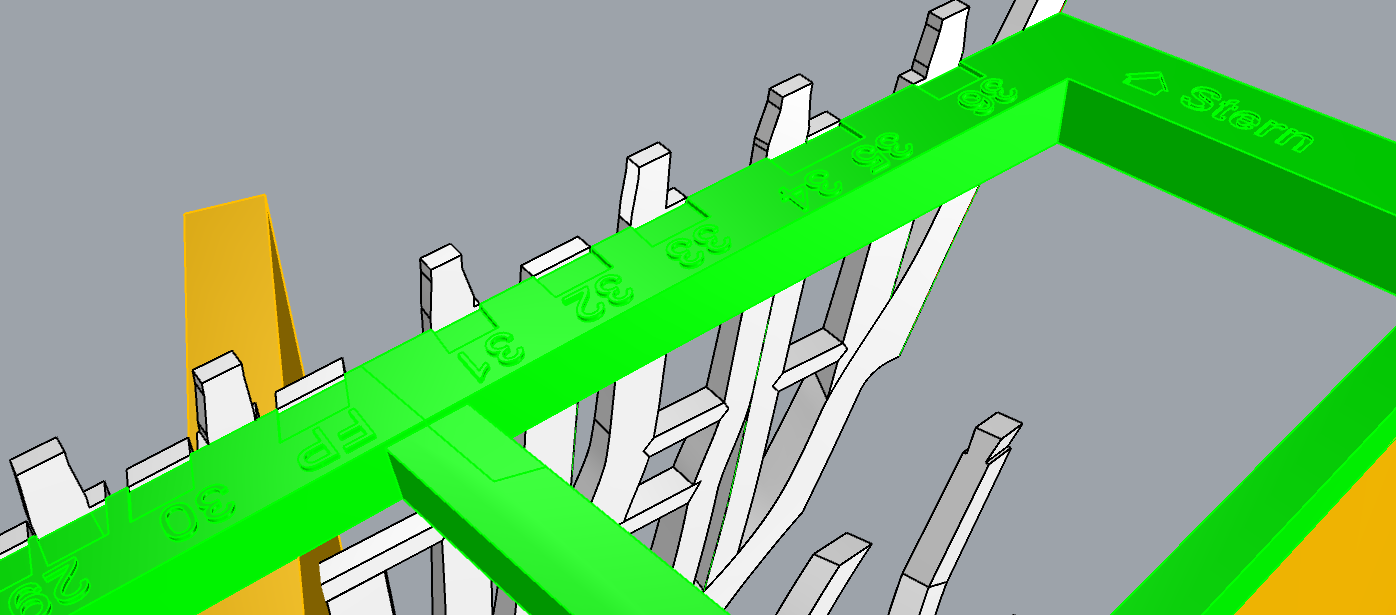

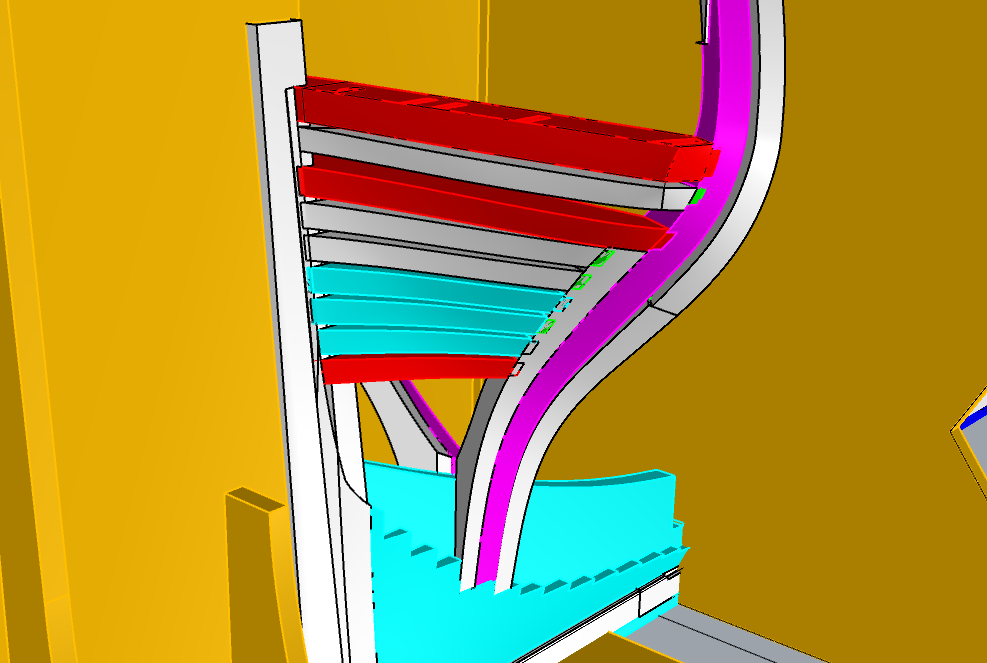

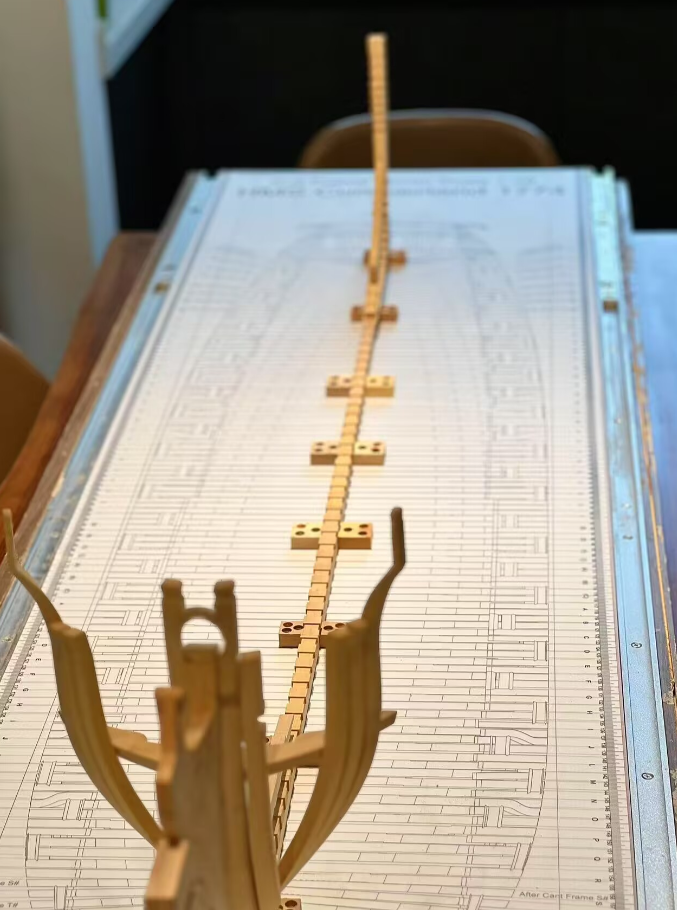

Hi! My 3D printer arrived yesterday. This is the schematic diagram of what I call the "TOP Frame Jig". The yellow part is 7mm plywood, and 7mm is chosen so that it only occupies the position of one frame. The green part is 3D printed, which I call "Frame jig". There are scale lines and numbers on its upper surface. It's really quite rushed right now. Liu will give me feedback, including whether the expansion components for transoms assembly are needed. I once suggested that he eliminate some tenons and mortises, which would greatly reduce the difficulty. However, he wants to take on the highest level of difficulty, so let's wait and see. In my design, the red transoms require precise positioning for assembly. For the gray ones, I have added allowances to facilitate corrections. As for the blue ones, I have disassembled them to make it easier to adjust their positions during assembly, especially the positions of the tenons. This is an assembly method designed by my friend DaHai and me. With an aluminum alloy platform and a wooden pressure plate, after being tightened with screws, the horizontal resistance can reach more than 1-2 kg (estimated value, static pressure). If you try to push it by hand, it can hardly move. The three components of the transoms shown in blue in the diagram will be glued together only during assembly. This way, the splicing gaps will be left on the inner side, ensuring the best possible finish on the outer side. However, Liu may have his own ideas, and I can't stifle his creativity, so I'll wait for his results. I also used another type of metal jig, which is widely used in the CNC machining industry. Its current price is already very low. Previously, it cost more than $15, and that was even the price for a cheap second-hand product. The horizontal resistance of this jig may exceed 5 kg. It can almost correct any deformation—if I may put it a bit exaggeratingly—and can precisely adjust the displacement.

-

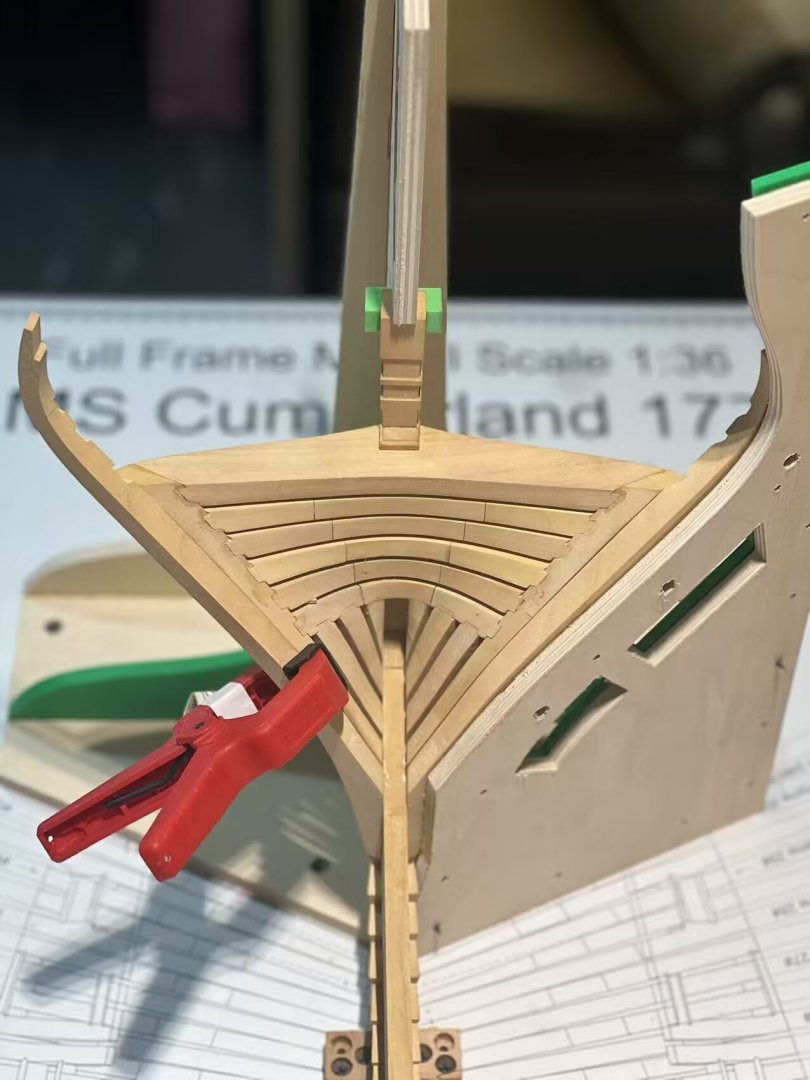

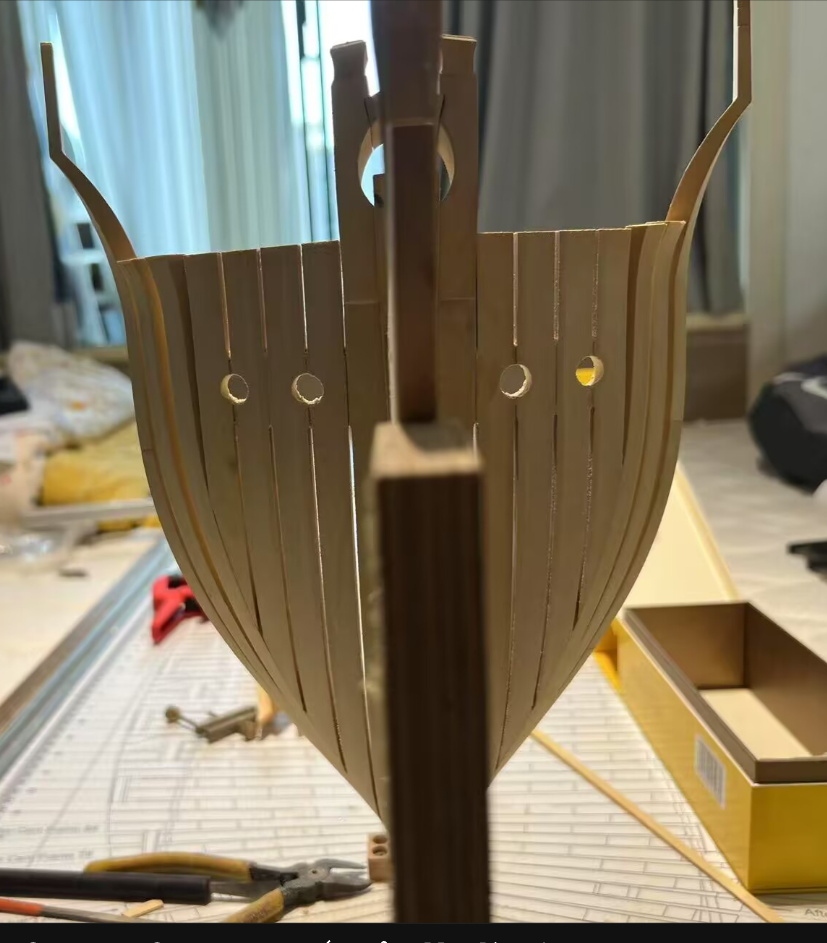

Liu started assembling the cant frames at the bow because I haven't sent him the stern jig yet. I agree with Greg that the stern structure requires skill and is quite challenging. Several years ago, I discussed the assembly of the stern components with BiTao, who is an excellent modeler with great skills. I watched him assemble the stern,same method as Edward's—using a significant amount of allowance. I conducted tests on the wing transom, stern post, and fashion piece. After finishing the processing of these components, I left most of them exposed on my office desk without any wrapping for over a year. Then I put them in a box for about two years. During this period, they went through several seasons. In my city, spring is a rainy season with high humidity that lasts for 2-3 months, followed by a hot summer and a dry winter. Finally, after testing, it was found that the deformation of the wing transom was approximately 0.7mm.So when I processed the filling transom, I only allowed a 0.7mm allowance, but Liu insisted that I shouldn't leave any allowance. Another batch of components, which is what you see being assembled, was mostly processed 4 years ago and then sent to Xi'an, a city in northwest China where Liu is located. After several years, that city is relatively dry. Having been transported from the southern part of China, which is humid, to the dry northwest region, these components have gone through about 4 full years. There is indeed some deformation, and in the coming days, Liu will show us the effect of reassembling these components that have been stored for 4 years. I will introduce some tools I designed myself to correct the deformation of the wood, which should be used at some point in the future if Liu finds that the deformation of the components exceeds the allowable range. The main reason for using CNC to process ship model components is to simplify the assembly difficulty and let the machine handle the tedious polishing work.

-

Thank you everyone,thank you Greg,the hawse piece, stemson, and the breast hook you mentioned are not fully fixed. You can see clearly that the hawse piece is not in the correct position and there is a large gap. Liu only used "a drop of glue" to temporarily fix it. He temporarily used the breast hook as a jig to position the hawse pieces. Actually, this is my fault because I failed to provide him with the frame jig in time. In my plan, the bow jig has a reserved expansion interface for the installation of the outer contour jig. However, I don't like the outer jig because it will interfere with the assembly of components. But I once designed an inner jig (frame jig) in another project. Nevertheless, I told Liu that Albert completed the assembly using only curved wooden strips without a jig, so I asked him to use the breast hook as a temporary jig, as you might have guessed. Your experience will be of great guiding significance to this project. After all, 3D design still falls into the category of theory. Personally, I have no objection to 3D printing; it's just that in this project, they require me to use all solid wood components. I haven't completed the design of any other jigs so far. I need to make sure that my design avoids being the same as those by other designers, but the inner frame jig is quite simple.To facilitate their assembly, I need to provide them with the 3D-printed frame jig as soon as possible.

-

Hi all, My partner Liu has decided to continue with the 1:36 prototype, and several model builders are preparing pear-wood version in 1/4" scale as well as another two sets of pear wood version in 1/3" (1:36) scale.So I'm continuing to develop this project, even though it has been on hold for 4 years – that's way too long,say so sorry.

-

I'm sorry I forgot to reply to you. I saw your question at that time, but I was busy with other things. Later, I forgot. I saw this post today one more time accidentally ... I use rhino6, silo2.5 ,zbrush2018, and then program machining with rhinocam 2018. The commercial licenses of these software are relatively cheap. I mean, compared with expensive software such as Solidworks + solidcam, 3DMAX, UG, PowerMILL .... But personal use of these software(rhino/cam,zb...) is still a big expense. I spent about $4900 at that time.The price of SolidWorks + solidcam in China is $11,500, from Chinese agent in 2018. Jack

-

Thank you JJ ,Allan,and all your "likes". For some reasons in my business, it may be another few months before this project continues. Also, due to the pandemic, one of my partners, who made prototype of 1:36 in scale, he wanted to pause for a while.so I needed to restart working on the 1:48 prototype. Thank you all for your attention. Jack

-

If it's just a bow section, 1:36 may have better details, but as the full kit of the first POF project, I think 1:48 can be considered because many modelers will put her and winchelea side by side, the same scale is better. Moreover, POF projects are very complex, smaller projects are undoubtedly a wise choice (they can be developed faster). In addition, if I am lucky enough to cooperate with Chuck one more time, I hope do better than last time.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.