John Murray

Members-

Posts

100 -

Joined

-

Last visited

-

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

FrankWouts reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

Greg M reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

Greg M reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

westwood reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

westwood reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

Matt D reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

Matt D reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

Tossedman reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

Tossedman reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

Tossedman reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

Tossedman reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

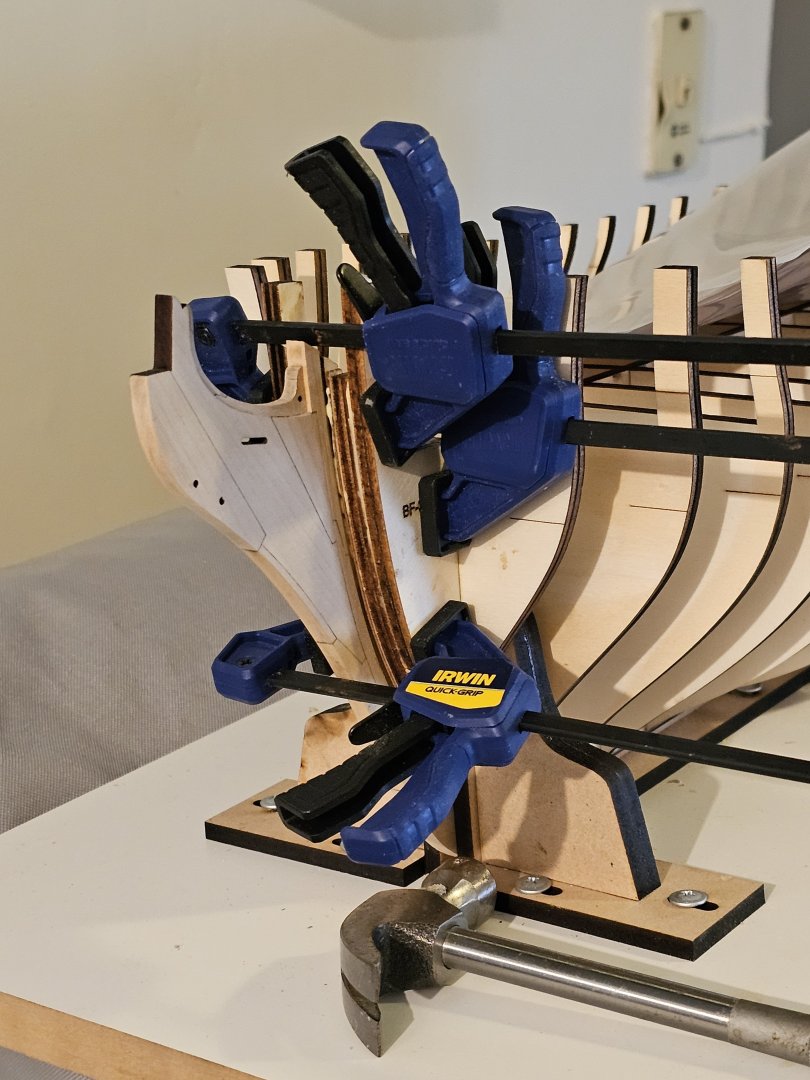

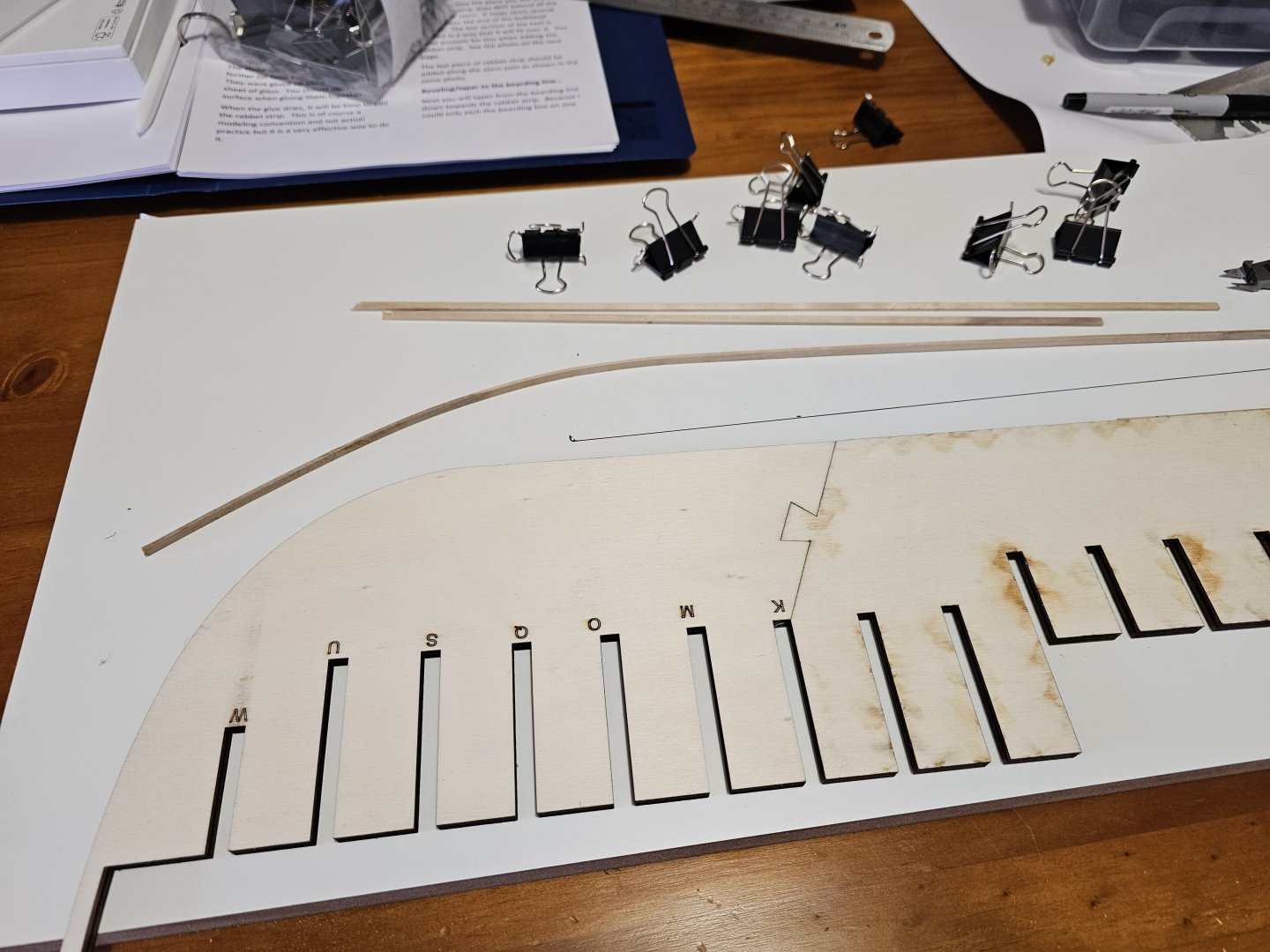

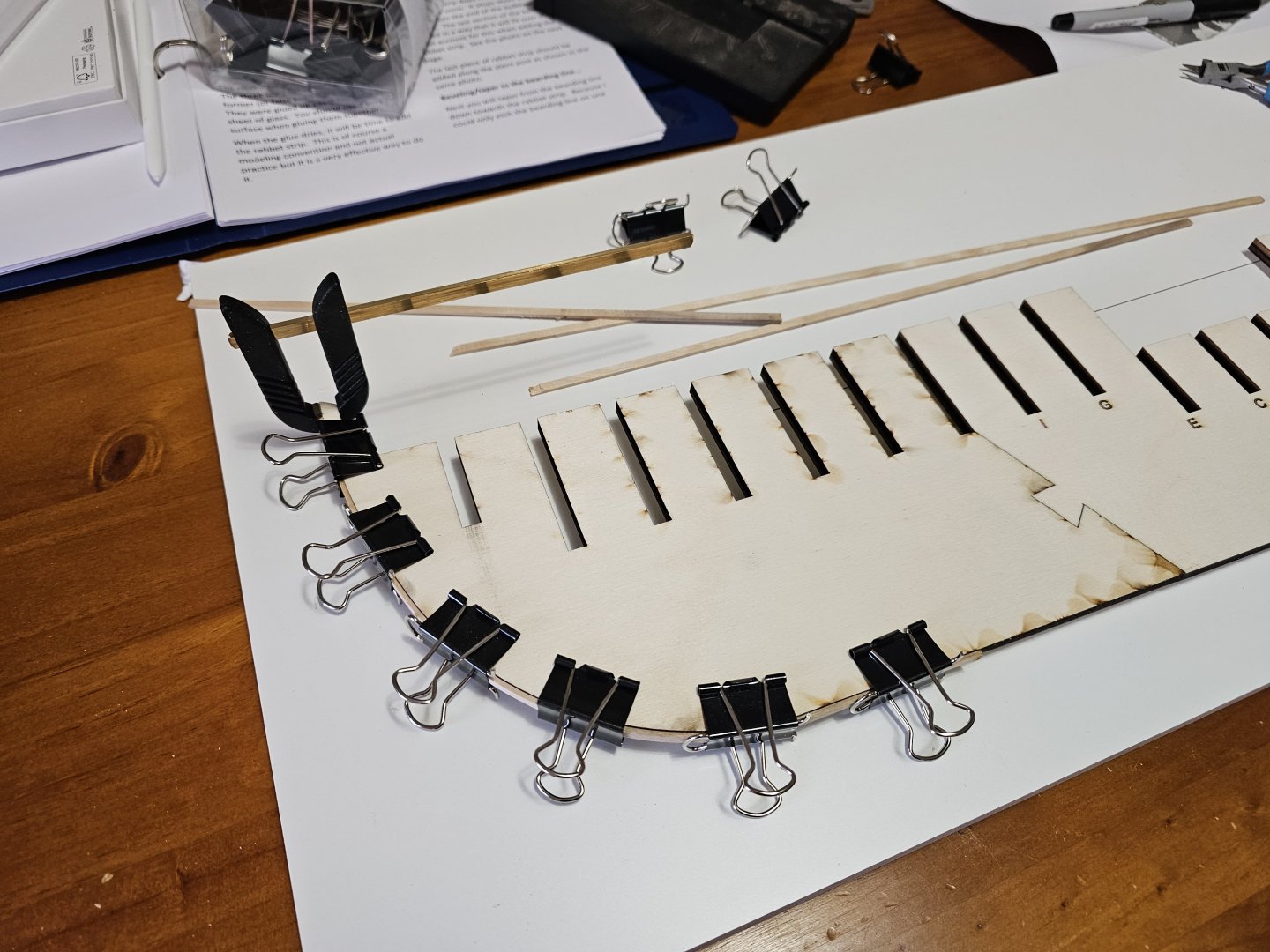

Today I spent some time using corner brackets and foldable clips to protect the bulkhead extensions as suggested in the chapter 1 instructions. Naturally, after placing the last one, I snapped off one of the rear extensions after a slight bump whilst placing it into the building board after making adjustments. Luckily, the broken piece fitted into one place only so was easy to glue into the correct place with Titebond II. It has a bracket to align it vertically and two foldable clips to keep pressure on it whilst the glue cures. This demonstrated to me how much care will be needed fairing the hull.

-

John Murray reacted to a post in a topic:

Using biarc approximation for frame representation of ship lines

John Murray reacted to a post in a topic:

Using biarc approximation for frame representation of ship lines

-

John Murray reacted to a post in a topic:

Using biarc approximation for frame representation of ship lines

John Murray reacted to a post in a topic:

Using biarc approximation for frame representation of ship lines

-

John Murray reacted to a post in a topic:

Chris Watton interview

John Murray reacted to a post in a topic:

Chris Watton interview

-

John Murray reacted to a post in a topic:

Chris Watton interview

John Murray reacted to a post in a topic:

Chris Watton interview

-

John Murray reacted to a post in a topic:

Chris Watton interview

John Murray reacted to a post in a topic:

Chris Watton interview

-

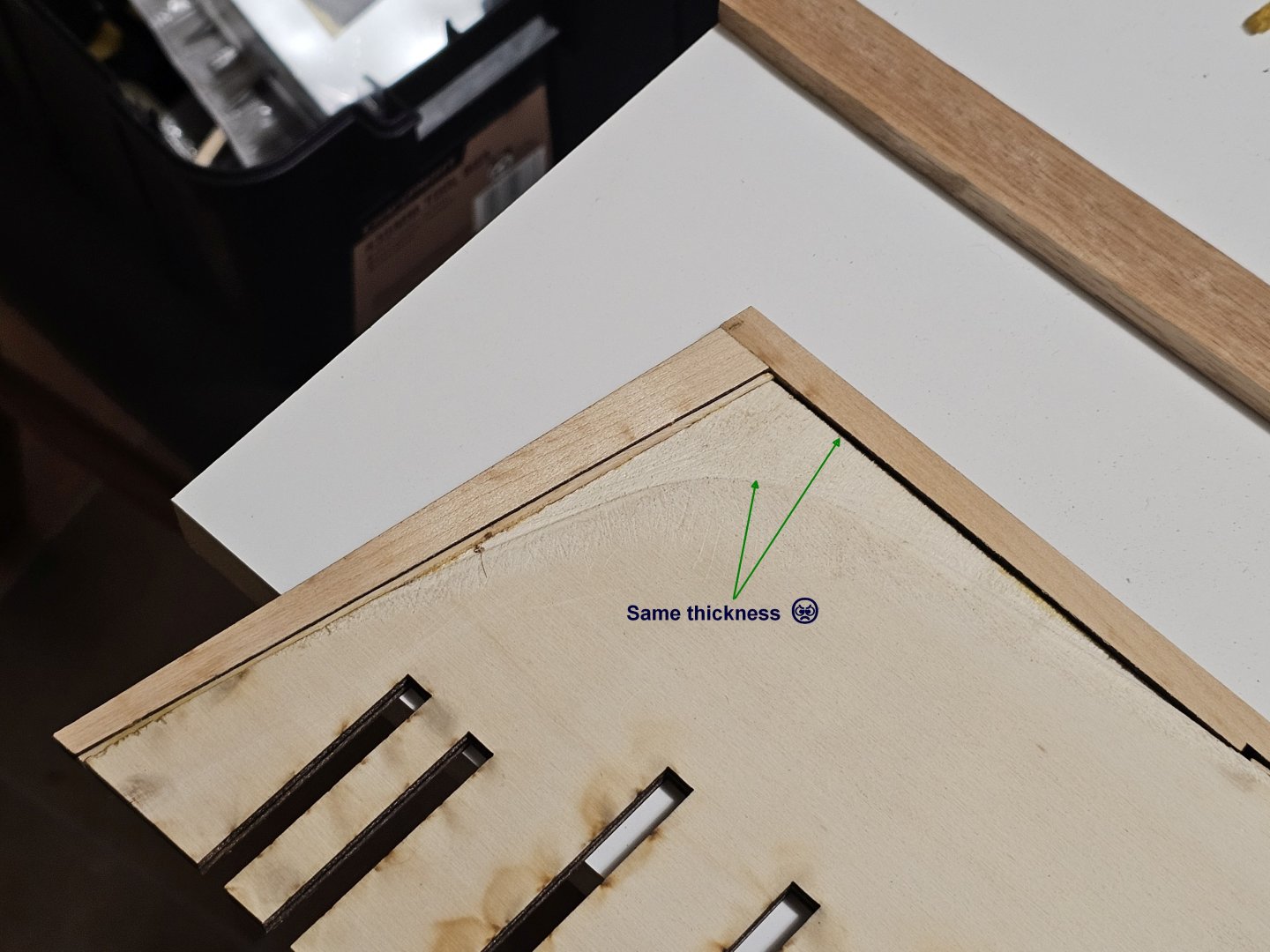

I visited a local specialist timber supplier who had various veneers of different thicknesses. I got 3 pieces of 750mm x 190mm x 0.5mm thick Rock Maple. I cut two of them into 4 pieces just over 300mm long. I then used Titebond II to glue two together giving me 2 final pieces at 300mm x 190mm x 1mm thick. The glue layer will add a touch of thickness I hope. I have them both under a weight of books to keep them flat until fully cured overnight. Checking them this morning I found the veneers had corrugated due to uneven glue thickness when applying it. Bugger. I know why though so that issue won't crop up in future. So, today I went into the makerspace and used the laser to cut 6 of the spacers (I only need 4) from the 0.5mm veneer I had. I glued two of the spacers together which gave me 1.15mm thickness which is close enough. I clamped the two of them between two planks of flat wood for two hrs. Releasing them, I found the laminations were flat, not corrugated. These two final pieces are BF-1. There are two pieces BF-2, and a further two pieces BF-3. 2 stacks comprising in order, BF-1, BF-2, and BF-3 were glued together and placed into the bow of the ship and glued into place. Now they are cured, It is time to start fairing the hull. I anticipate a few days to do this as I am house sitting a dog in their house for the next 10 days. After that, I start assembling the gun ports.

-

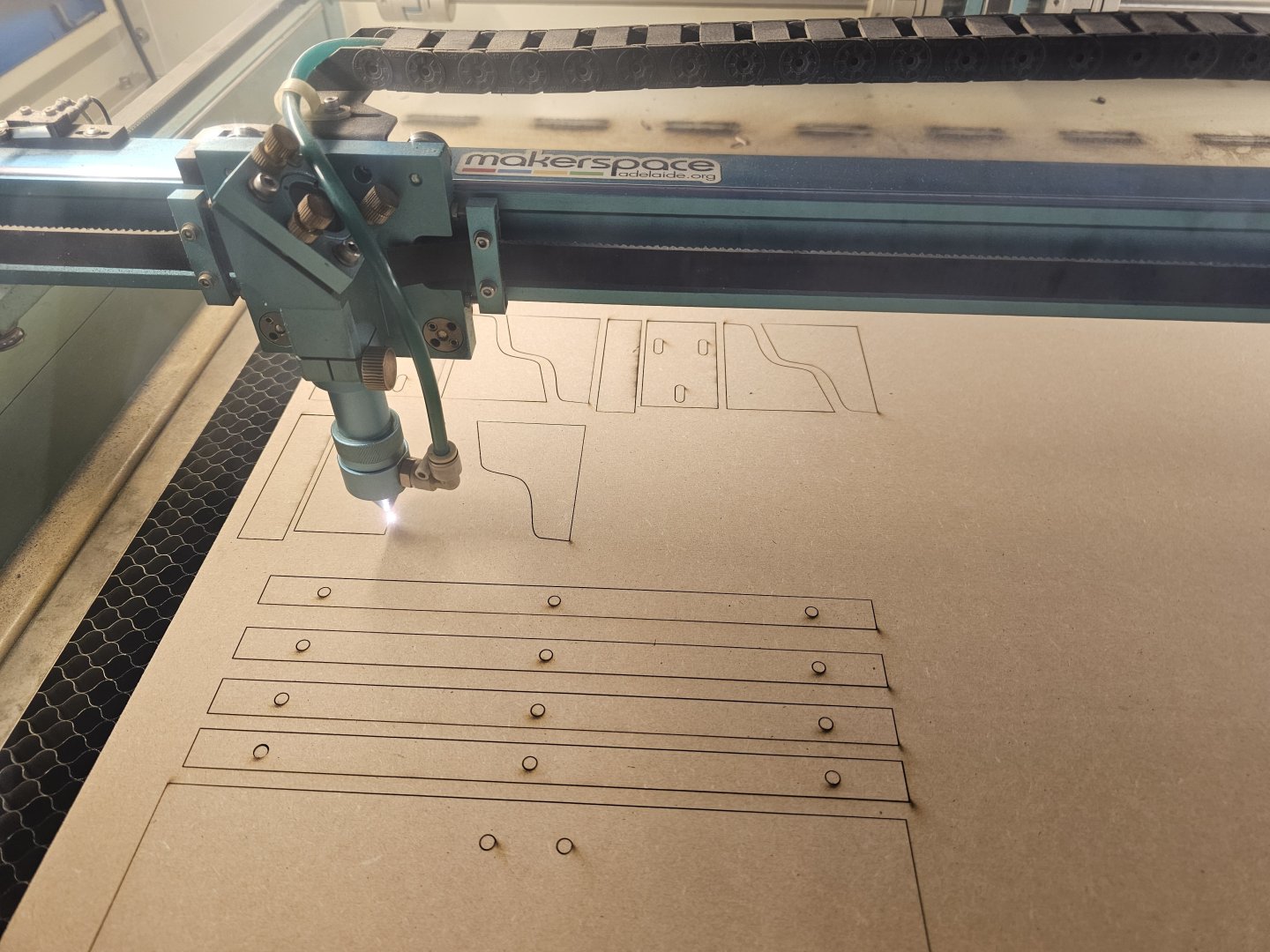

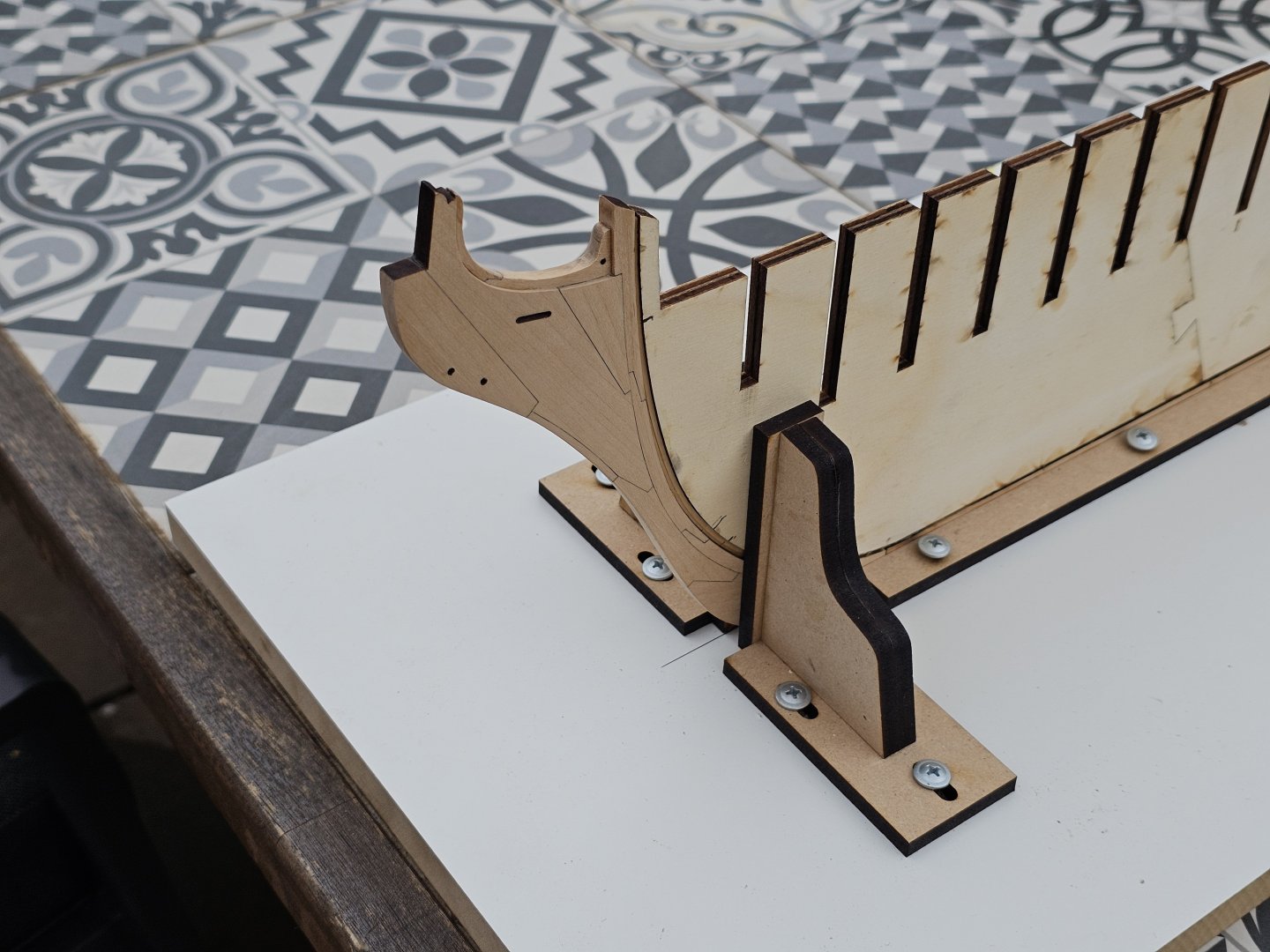

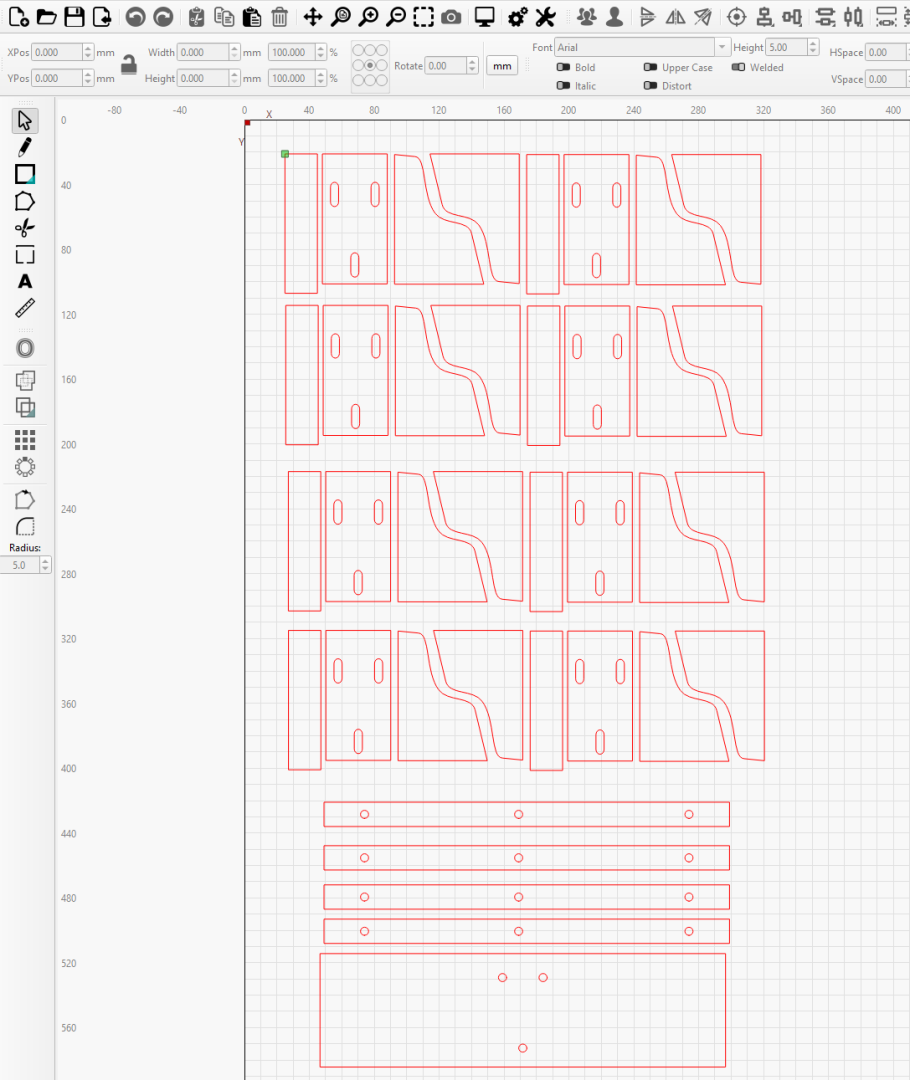

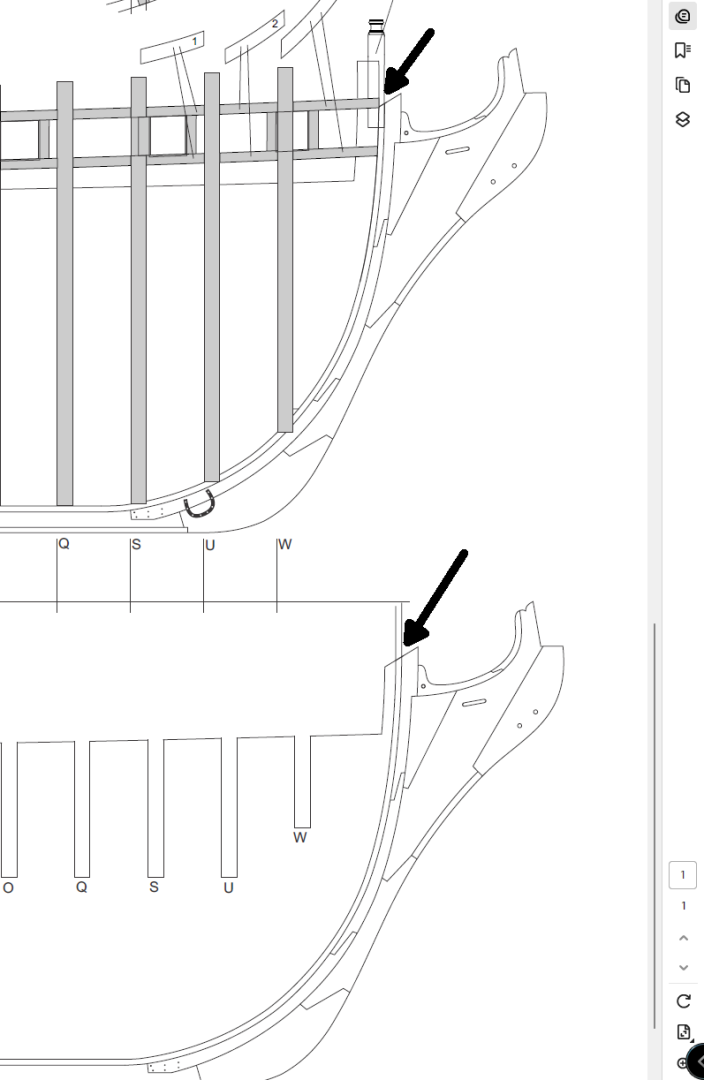

I have been busy with life but have been pottering along on the Winchelsea. Over the last several months I have added the Rabbet, the Keel, and the False Keel. Various small issues were encountered but I tackled them one at a time. After a long layoff, I was eager to get going and screwed up when removing some of the bulkhead former at the stern to allow planks to lay correctly. I did not angle the thinning, i gave no thought and took it down evenly. 😒Some filling will be required. After that, the keel and false keel were added. After cleaning the joins and surface up, attention turned to my building board. In Lightburn, I designed some 6mm MDF supports that needed to be cut by the laser as well as 4 strips of MDF that are straight edges. Yesterday, I used the laser cutter at Adelaide Makerspace to cut a load of sub assemblies from the 6mm MDF. The were assembled into braces that hold the bulkhead former, and the keel straight. A couple of hrs later and I had the building board, supports, and the bulkhead former completed and in place. I then glued in the bulkheads making sure the orientation was correct for the numbered and lettered bulkheads. I then turned my attention to the 3/64th inch pieces for the window spacers, the BF-1 spacer shims and the rear transom. I got 3 veneers, 1 . My Proxxon machines cut to a width of 80mm max. So, how to get a sheet or two of that size (I use mm, so it is 1.2mm sheets needed.) I visited a local specialist timber supplier who had various veneers of different thicknesses. I got 3 pieces of 750mm x 190mm x 0.5mm thick Rock Maple. I cut two of them into 4 pieces just over 300mm long. I then used Titebond II to glue two together giving me 2 final pieces at 300mm x 190mm x 1mm thick. The glue layer will add a touch of thickness I hope. I have them both under a weight of books to keep them flat until fully cured overnight. I will then go into the maker space and use the laser to cut these shapes out. Hopefully my next update won't take as long.

-

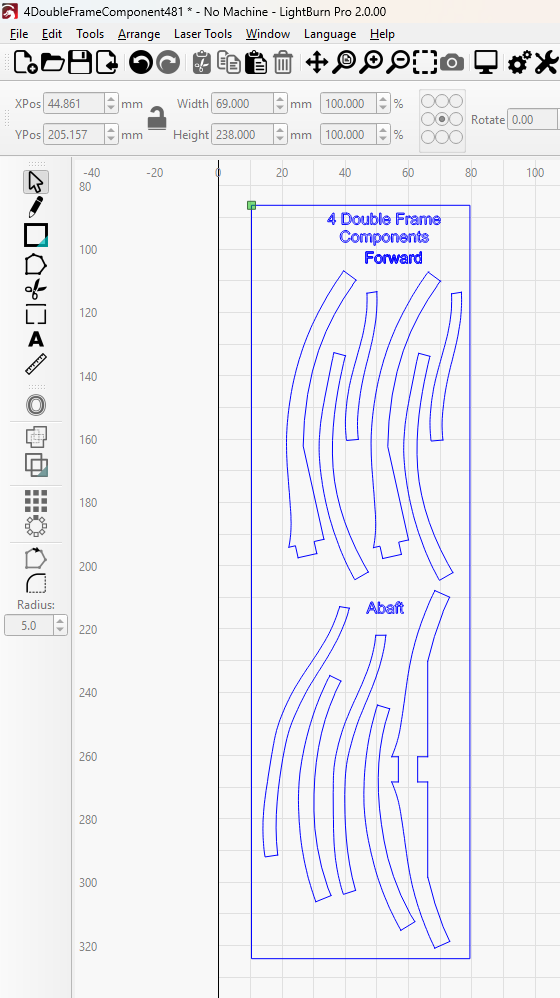

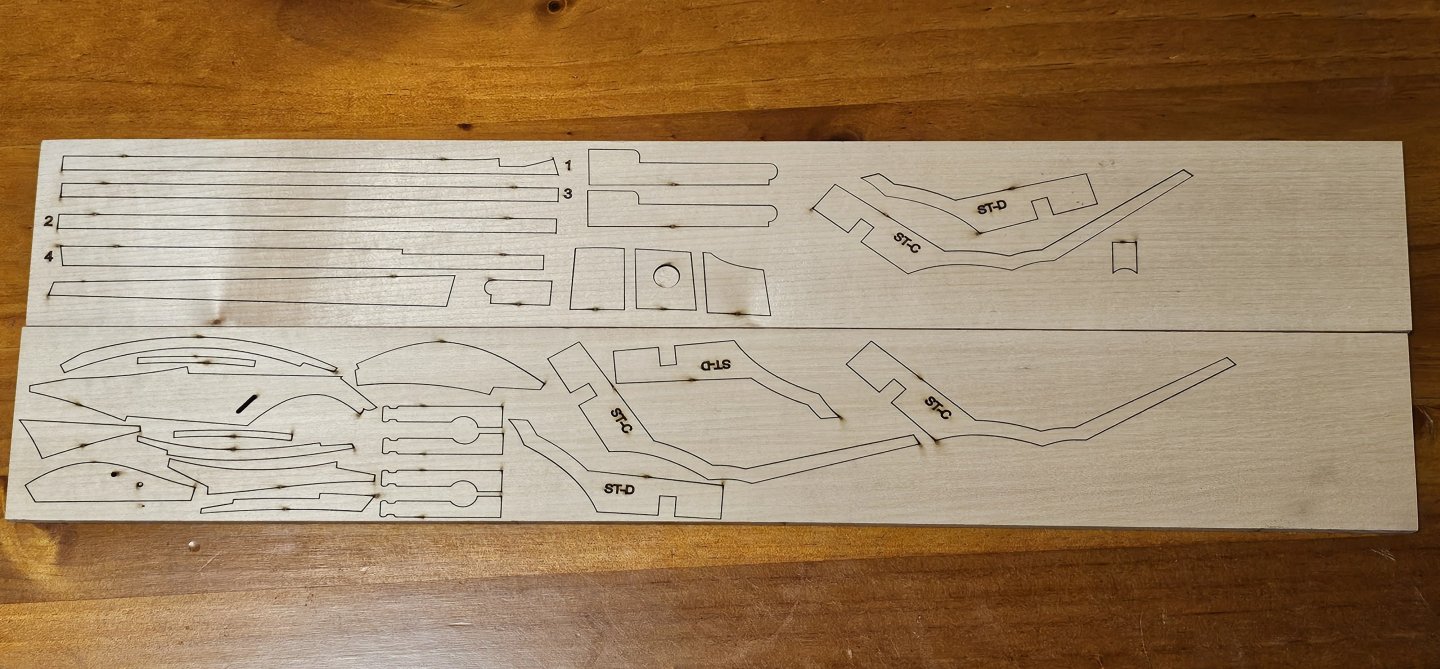

Morning All, I have downloaded all of the files for the Triton build. On my HMS Echo cross section, I used rubber glue to place the paper cutouts on the wood so they could be cut out. I found this not a particularly good solution as the glue would quite often let go.. For this section I have taken the assembly pdfs and imported them into Lightburn to see if I could separate out the frames only and place them onto the Lightburn working area. Shown below are the forward and abaft components for the 4th frame. Since the frames are symmetrical for both sides I only needed to copy the relevant ones for the opposing side. I plan to lightly vector etch the wood. I had considered cutting them on the laser but the charred edges would need cleaning up. Any thoughts pro or con for doing that? I am combing the pdfs and the wood sections. Best I can make out is that all timbers on each frame are the same thickness at 5mm thickness.

-

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

John Murray reacted to a post in a topic:

HMS Winchelsea 1764 by John Murray - 1:48

-

One further question I have is that I have just discovered a local supplier to me able to supply sheets and strips of Limewood, Mahogany, and Walnut in the lengths and thicknesses I will require. This would be a better option for me if the woods are suitable. The Walnut and Mahogany are darker though and my preference would be a lighter coloured wood such as the Limewood. Searching the wood forum here did not assist in the decision. Not being a woodworker, I am not familiar with the advantages and disadvantages of these woods.

-

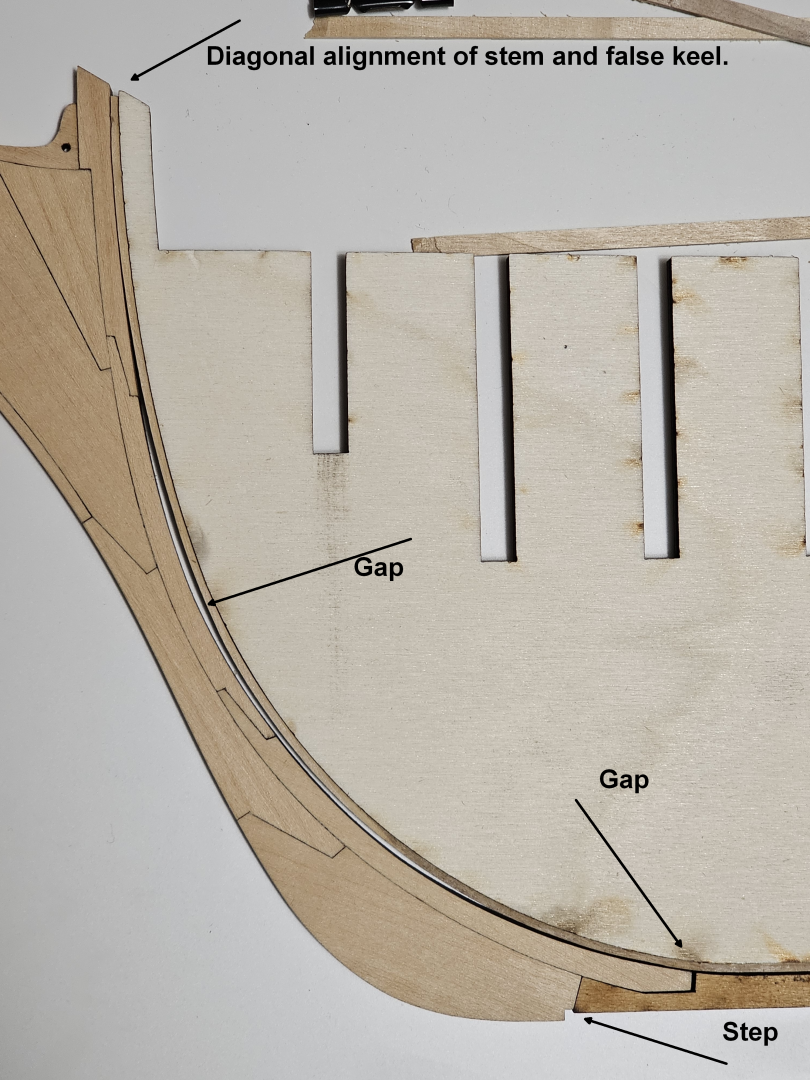

Morning all, Work slowly progressed the last few days. I have gotten myself a melamine building board and have started to glue the rabbet onto the false keel. I used my Byrnes table saw and Proxxon thicknesser to make the 4mm x 1.56mm (5/32nd x 1/16th) strips for the rabbet. The rabbet eventually came out to 1.53mm thickness. I used an Iron to heat the strip and clamped in place whilst it cooled and set with a curve. With the rabbet in place, I positioned the stem and the keel piece #1in position to check for fit. As can be seen in the 1st image, both ends of the stem are in contact but there is a roughly 0.8mm gap (perhaps more) in the centre. My question then is how to rectify this? 1) Do I remove wood from the top of the stem allowing the bottom to act as the pivot? 2) Do I remove equally from the top and bottom realising that this will affect the stem to Keel #1 piece. If you look carefully at the stem to keel #1 joint, you will see there is a flush fit everywhere bar the stern most vertical joint where there is a 0.8mm gap. Also note the false keel step on the stem and keel #1 piece joint. Thoughts on how to proceed would be appreciated.

-

All of the joins were as supplied in the files. I calibrated the cut power as best I could. I have not yet investigated the kerf or taper of the laser. The machine though apparently has a 0.15mm kerf. The 11 pieces of the stem fit together snugly after cleaning the tabs that hold the pieces in place after cutting. I am now in the process of assembling the keel and frames. I hope to have an update here soon.

-

I have assembled my 3rd version of the stem after having issues with the laser using too much power.. I used some Sassafras that I had and thicknessed 3 300mm x 80mm x 6.35mm planks with my Proxxon DH40 thicknesser. I used one plank to calibrate the lasers power to the material and then cut the pieces out on the 2 remaining planks. I had taken the original files and used acrobat and illustrator to make new cut files that would fit the plank sizes I had. I may use this as the final version of the stem.

-

G'day Frank, Thank you for that. I have joined a makers space nearby that has woodworking, metalworking, 3d printing, and 2 laser cutters in the space that I can use. The two laser cutters are 1 ) Trotec Q500 running Ruby with a bed size of 1,300mm x 900mm and a 120 watt laser. 2) Thunder Laser Nova 35 running Lightburn with a bed size of 900mm x 600mm and an 80 watt laser. I have used both. I found the Nova 35 running Lightburn much easier to use due to the Lightburn software. I need to be inducted though in 2 weeks time before I can do it myself. Currently, I need someone over my shoulder supervising. My plan is to use Poplar 900mm x 600mm 6mm ply that I can source locally for the bulkheads and other things requiring 6mm ply. For the 1/4" stem etc I plan to use either Poplar or Huon pine slabs that I can rip to thinner boards with their bandsaw. Once that is done, I will run each boards large face flat on the planer. Once they are all done, I shall then flip them all and run each board through the thicknesser to get to 1/4" thickness. I have downloaded the full Creative suite. I split the bulkheads into individual pdfs. Then, in Illustrator I created 2 documents sized 900mm x 600mm. The first document has the 3 keel pieces and the first 14 bulkheads all fitted into the document. The 2nd document has the remaining bulkheads. In Chapter 1, all of the 1/4" pieces were placed into a new document sized to minimise the waste of the Polar or Huon. The MDF 6mm cuts were ok, some slight scorching on the rear. Having talked to a few users in the makerspace I get the feeling they use just the material defaults in Lightburn and are happy with the results. Me though, I have looked into the software and there is a lot of tweaking that can finetune the laser to the particular material and thickness. Once I am inducted, I shall do some calibration tests for the 1"4 Huon or Poplar and 6mm Poplar ply so that I will get good, consistent cuts by the laser. I will also be checking to see if the laser is set to allow for the kerf of the laser. Once that is done, I will then run the final 1/4" and 6mm pieces through the machine. Everything I am doing so far is to build my experience with the software and to eliminate as much waste as I can. I will do things myself only to eliminate the issue you raised or buy things I need that I cannot manufacture myself off Chuck. .

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.