-

Posts

2,516 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Rustyj

-

-

Hi Pete, That is a great way of doing it and was done very nicely. Well done.

-

Everything is looking very good. Well done!

-

Looks like some really nice wood. Can't wait to see it used.

-

Hi Martin, if they bother you now they will drive you nuts later.

Like you said it's best to redo them.

Get well.

-

The grating redo, although I didn't think it was needed, is an improvement.

The rope work is impressive too. Thanks for sharing.Your're doing a great job.

-

Thanks Pete, Mark, Paddy, Martin, Bob, Ben and Grant.

Thanks Russ, I was hoping the colors would look good and was pleased with the results.

Thanks Chris. Sounds like a good way to do them and I’ll try it next time.

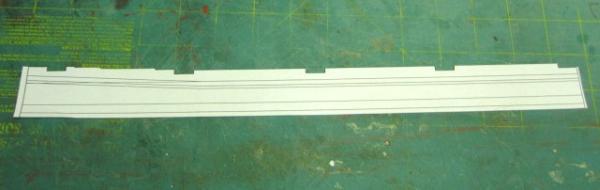

Here they are the hatches just set in place.

And here I have glued them in place and started the deck planking. I'm continuing to use

Holly planks with black paper for the caulking

I'm off to continue the planking and will use boxwood for the tree nails like on the lower deck.

- Mcdood, fatih79 and sonicmcdude

-

3

3

-

Great job Bob. It sure is a lot more fun planking these!

-

Hi Marius,

Everything is looking very good. You may not have xacto blades but your wood is great.

One thing with doing the fake treenails, I’ve done the same. I’ve been told that you should

use a filler that dries hard. Some filler is firm to start and is wax like but never hardens.

Keep up the great work!

-

Ow Martin. I've sliced and diced a few fingers over the years but never got a tendon.

I hope all goes well and you make a full recovery. My best to you and good luck.

-

Well I’ve had to spend the weekend before building a deck for one daughter and t

hen went on a little 4 day vacation and just got back. Here is an update on what I

had done but didn’t have time to post. Also there is a whole lot posts I have to catch

up on. Wow you all have been busy.

Thank you Shannon, the Byrnes saw makes all the difference.

Hi Bob, I do like the color. Of course I got it from Hobby Mill.

Hi Joe, It has been quite a while now hasn’t it? Great to hear from you.

Hi Ben, Yes it is hard. Might even be harder then Boxwood. As I said it’s the saw.

Now that you have one I expect you to practice and be able to do it too.

Thanks Wayne.

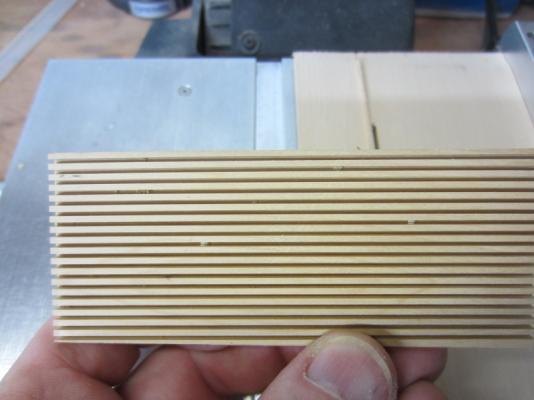

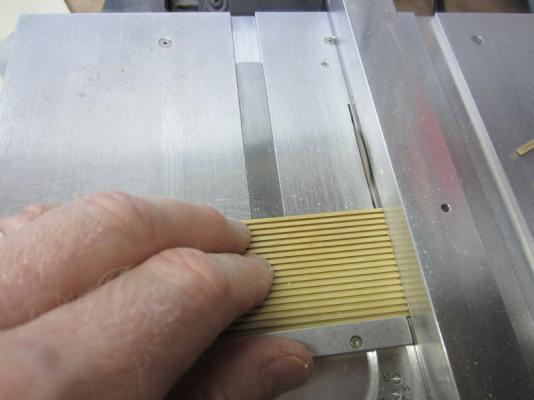

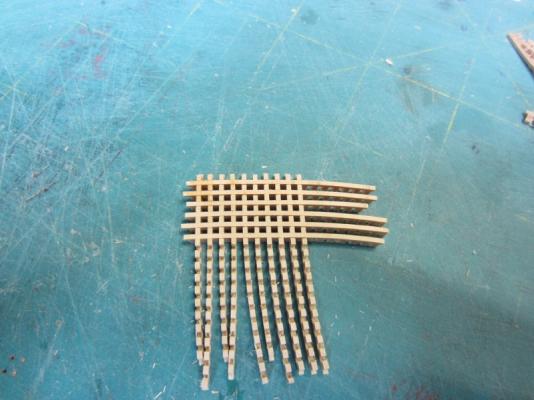

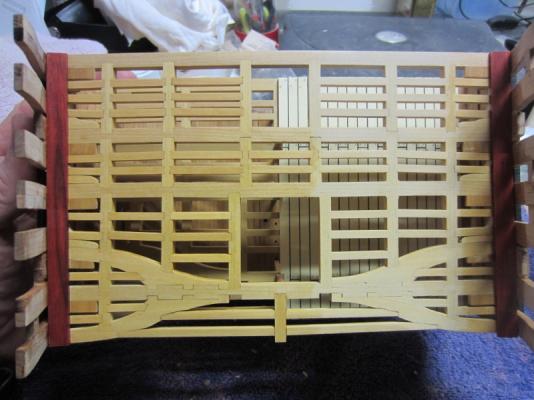

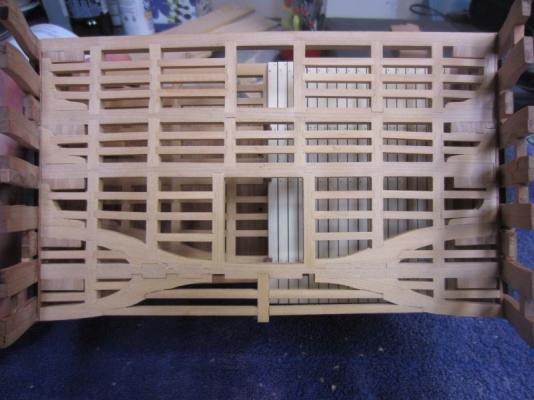

I’ve made the hatch grate using a technique I copied here. I’ll try to explain it in case

others haven’t seen it.

I used 1/8” boxwood and a saw blade that is .040” thick.

First I used a piece of scrap basswood to make the jig, I cut a channel in the basswood

the width of the saw blade. I then cut a strip of wood the same thickness as the blade and

inserted it into the channel so that 1/16” showed. I then clamped it to the top of the Byrnes

table saw making sure that the blade was the 0.40” away from the channel.

Next using the jig I cut a series of slots in the underside of the boxwood board,

and then sliced the board into strips on the table saw using a fine tooth blade.

The strips were cut the same thickness as the blade. (0.40”).

I then assembled the gratings like we do when we buy them precut.

I hope that makes sense

-

Hi Roger, Frontwards, backwards who cares.

It's just great to be able to see your build pictures again.

-

Hi Chris, Great to see you back.

I’ve been wondering how you and your family were doing.

I’ve been wondering how you and your family were doing. I’m glad to hear all is well and you will start back on the Confederacy. I know grabbing time

will be tough but we know you can do it!

-

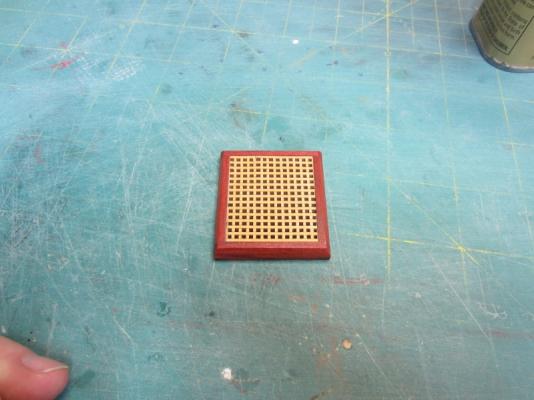

Thanks Russ, Joss, Grant and Pete.

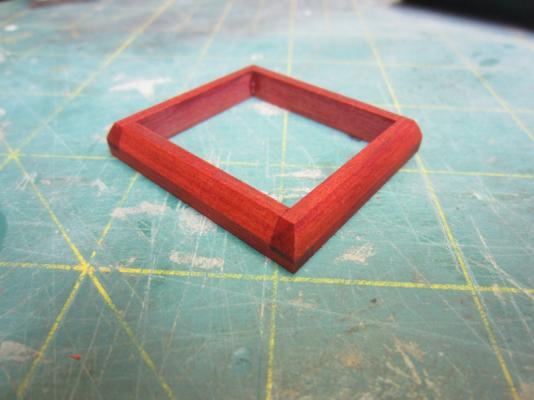

Grant. You can see the difference between the earlier picture and the close up

of the completed one. The completed one is the color with a coat of wipe on poly

applied. No touch up. It’s that red.

Paddy. One thing they say is the Red Heart can fade some over time especially if

exposed to sunlight. This is some I have had on hand for a couple of years and it

hasn’t faded. Also I plan on keeping it out of direct sunlight once completed.

Daniel. Nope not Blood wood but Red Heart. Blood wood is a deeper darker red. I

have used it in the past but I didn’t have enough for this so I couldn’t use it now.

Again thank you all!

-

Just to confuse you more I went half way between the two.

-

Hi all. Thanks for the kind words. I hope it works for you as well as it did for me.

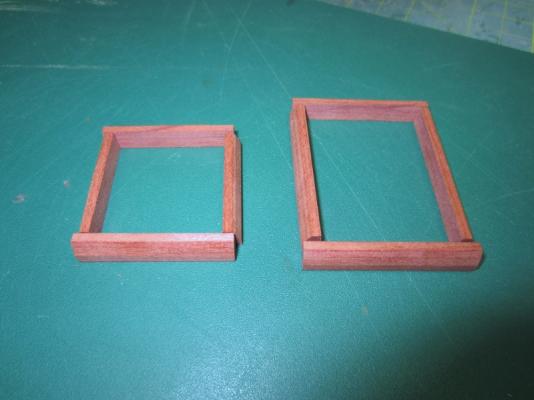

Here I’ve added the waterway and have started on the hatches. Both are being cut from red heart.

Here the sides are cut to length with the bevel cut into them.

Here they are notched for assembly.

And here it is assembled.

Are here they are set in place but not yet glued down.

Next I'm going to make my first attempt at making my own hatch gratings.

- fatih79, mtaylor, aykutansin and 2 others

-

5

5

-

Hi Ben,

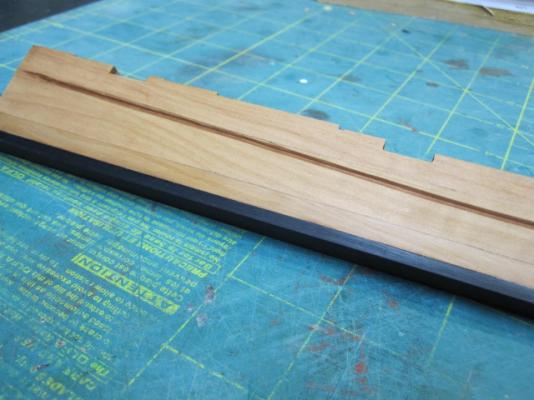

That’s great you’ll love it! The wood is swiss pear and the false keel

is ebony. I have a little left and figured it was a good place to use it.

After gluing the two sections together I cut out the pattern that shows the

rabbet location, transferred it to the keel and then cut it out using a V grove chisel.

-

Belated Happy Birthday and well done on the frames.

Ummmm that cake sure looks good too!

-

Hi Bob, Boy they sure look nice to me! Well done.

-

Hi olphart, nice to see your progressing along nicely.

Good luck on redoing the limber boards.

-

Very nice Pete. Travel safely.

-

-

Hi all and thank you for your kind words.

Hi Daniel I used the following sizes. Ledges 1/8” x 1/8” and carlings 3/16” x 3/16”.

Not sure if they are 100% accurate but they worked for me.

The way I used for cutting the mortises is what worked for me. Experiment and

see what works best for you. We all add our unique touch to how we do things.

Well here it is with all of the carlings and ledges in place. Now to sand it all smooth

then next up will be adding the waterways and decking.

-

Well done Paddy. It sure does feel nice when you raise that first one!

-

Grants Triton - FINISHED

in Cross Section Build Logs for HMS TRITON

Posted

Great work as always. Very nice way of doing the blocks. Gotta remember that!