-

Posts

305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Auger

-

Of course. Have you ever experienced something of the like without a decent crowd? Especially when the company has gone long with repairs and upgrades. Everyone bites at the VIP cruise, it’s good for business. The weather is getting better, people are feeling good… This is what I want to convey with my model.

-

Very nice! Way better than my cardboard box spray booth.

-

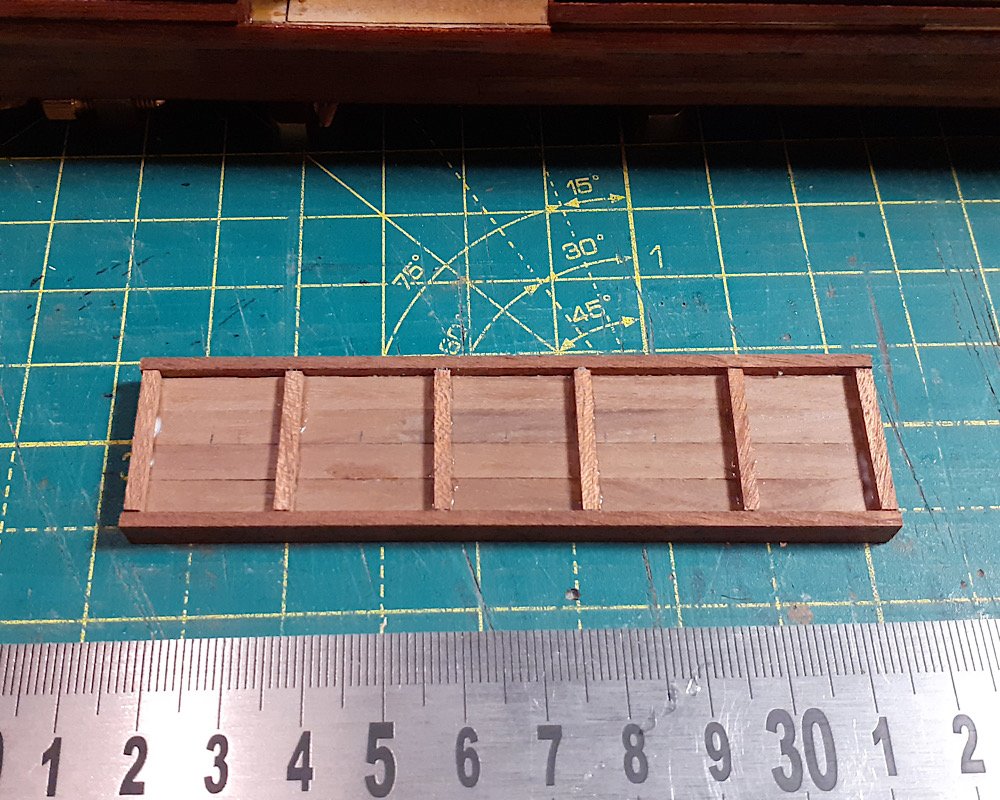

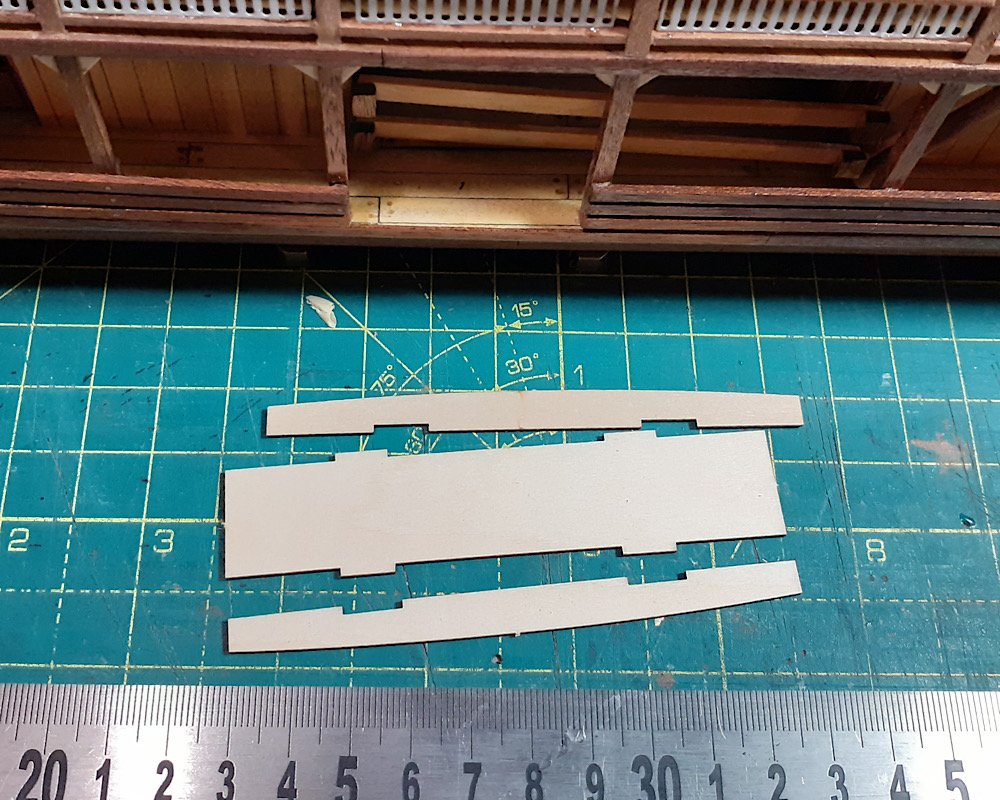

(spoiler) So, the trained eye will notice that I’ve been using 2mm x 2mm sapele wood in place of the 1.5mm x 3mm (about) kit laser cut wood for the rail bends. It’s what I have on hand so it’s what I’ve used. The layman generally won’t know the difference which sets you all apart. Why? (Maybe I’ve said it before) The kit laser cut parts came up short in certain areas, so I abandoned the laser cut railing sheet all together early on. If you want the laser cut parts to work for you, don’t follow the instruction book in order, page by page. Work the railing posts from the top deck down in respect to the larger railing plan. I followed the instruction book page by page and found the flaw afterwards. Cut-out and lay the upper deck plan onto your upper deck build once entirely built and mark the railing posts from there-down. Then, work the railing posts top-down and outward from there (bumpers, etc.) Not bottom-up like in the booklet. Trust me. Ignore the railing posts in the book until you reach the top deck. Then work backwards top-down from there. I really hope this helps someone. This is based upon the 20505 version. The 20515 version may be different.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.