-

Posts

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Scotty W

-

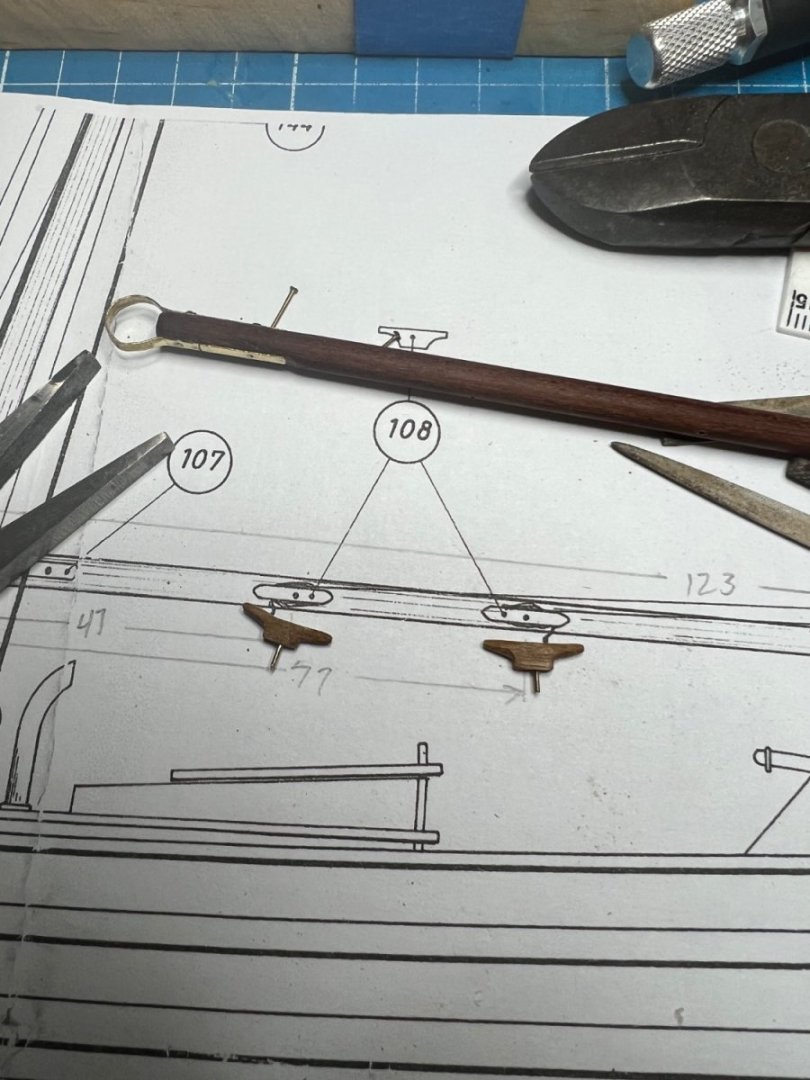

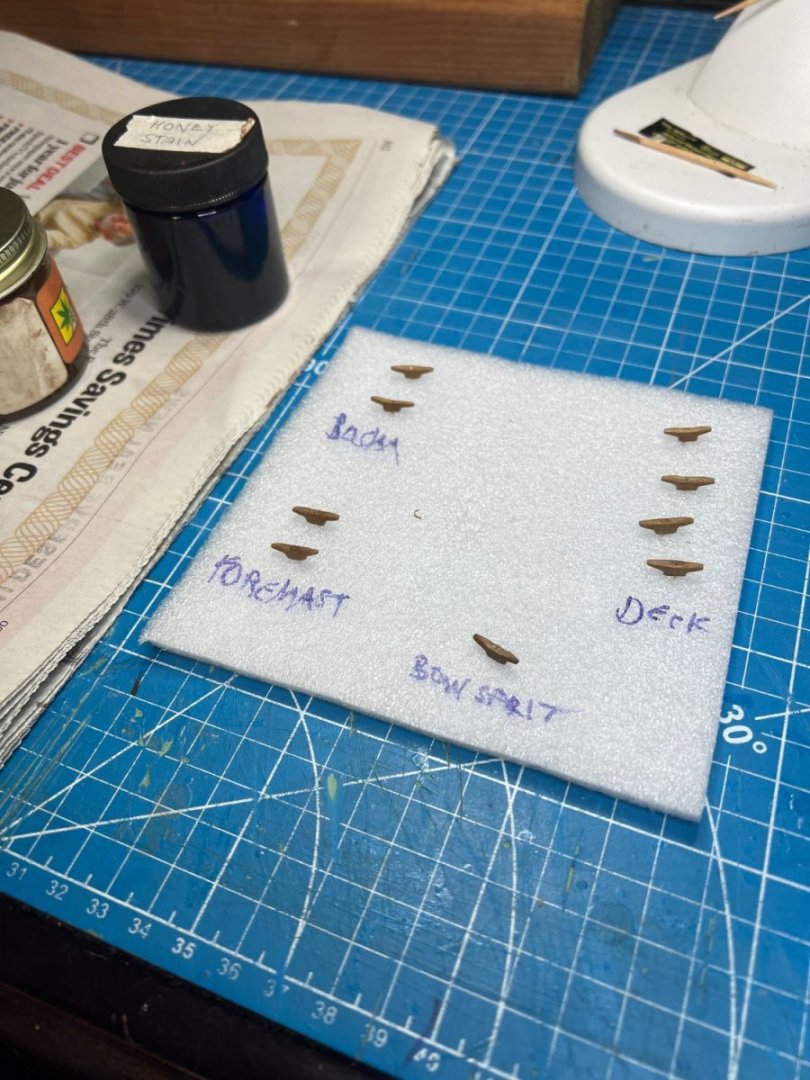

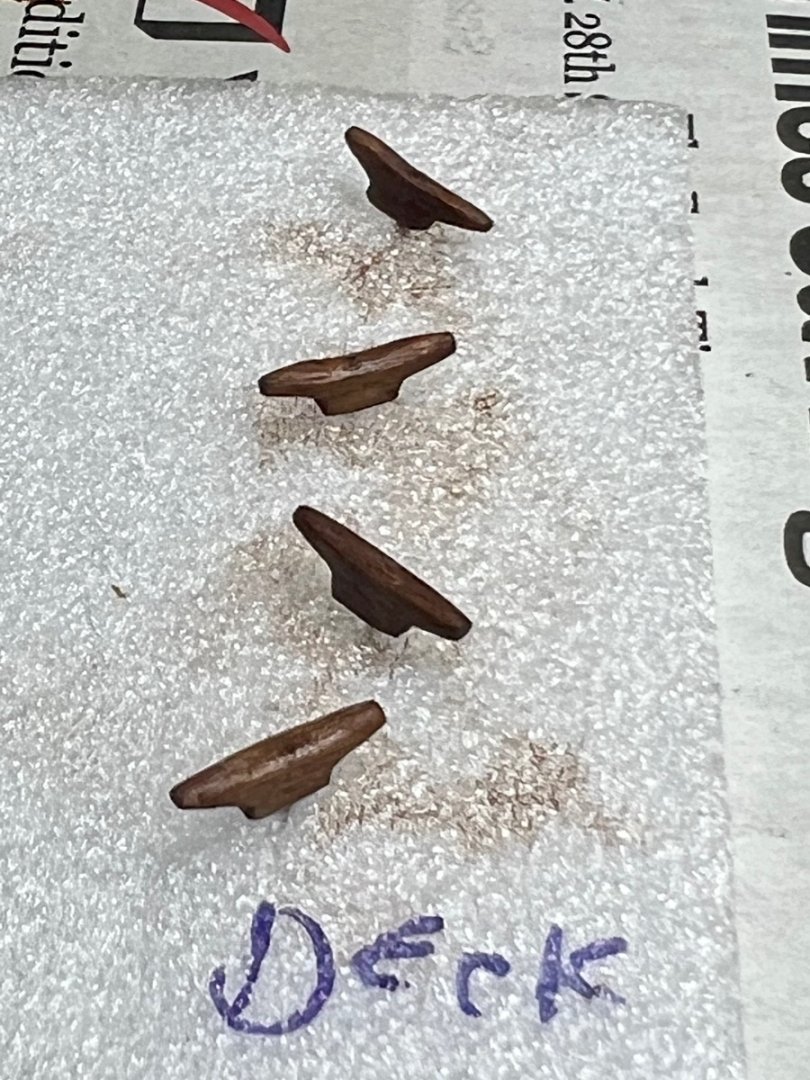

Cleats, oh those blasted cleats. I spent 3 full days working on my nine cleats since 5 of them have a radius on the bottom for foremast, boom and bowsprit mounting. Sanding and drilling those teeny weeny things was a challenge to my physical and patience limitations but I finally decided they were good enough and stained them last night. I’m way ahead of my build log but will try to get caught up when I can. Your hull turned out beautiful.

- 129 replies

-

- Bounty Jolly Boat

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I had the same issue at my transom and read later that builders either this the false keel in the deadwood area by half before planking or don’t plank there at all on the first planking. I just tried to taper from the second planking into my stern post as best I could and write it off to inexperience. The rudder hinges gave me a fit and bad instructions complicated things but I managed albeit if my rudder has limited range of movement but figure nobody is going to in the case trying to come about. lol

- 129 replies

-

- Bounty Jolly Boat

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I drilled pilot holes a wee bit smaller than the diameter of the push pins with my full sized portable drill into the frames next to the plank I was installing which eliminated splitting. It was nerve wracking using that powerful Ryobi drill with such a small bit on my ship but it worked out. I have since aquired a small cordless rotary tool I would use next time for such operations.

- 129 replies

-

- Bounty Jolly Boat

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Quite entertaining! Do you write novels too? lol

- 129 replies

-

- Bounty Jolly Boat

- Artesania Latina

-

(and 1 more)

Tagged with:

-

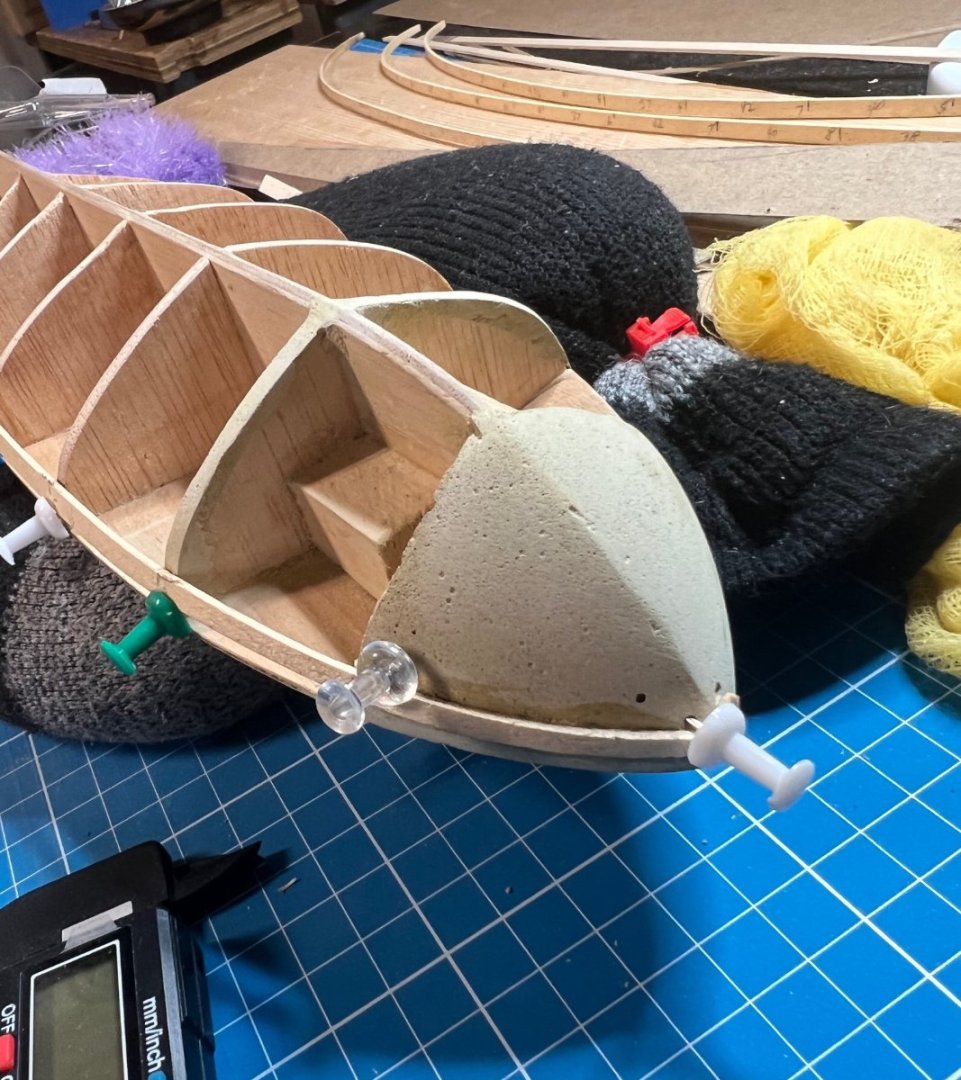

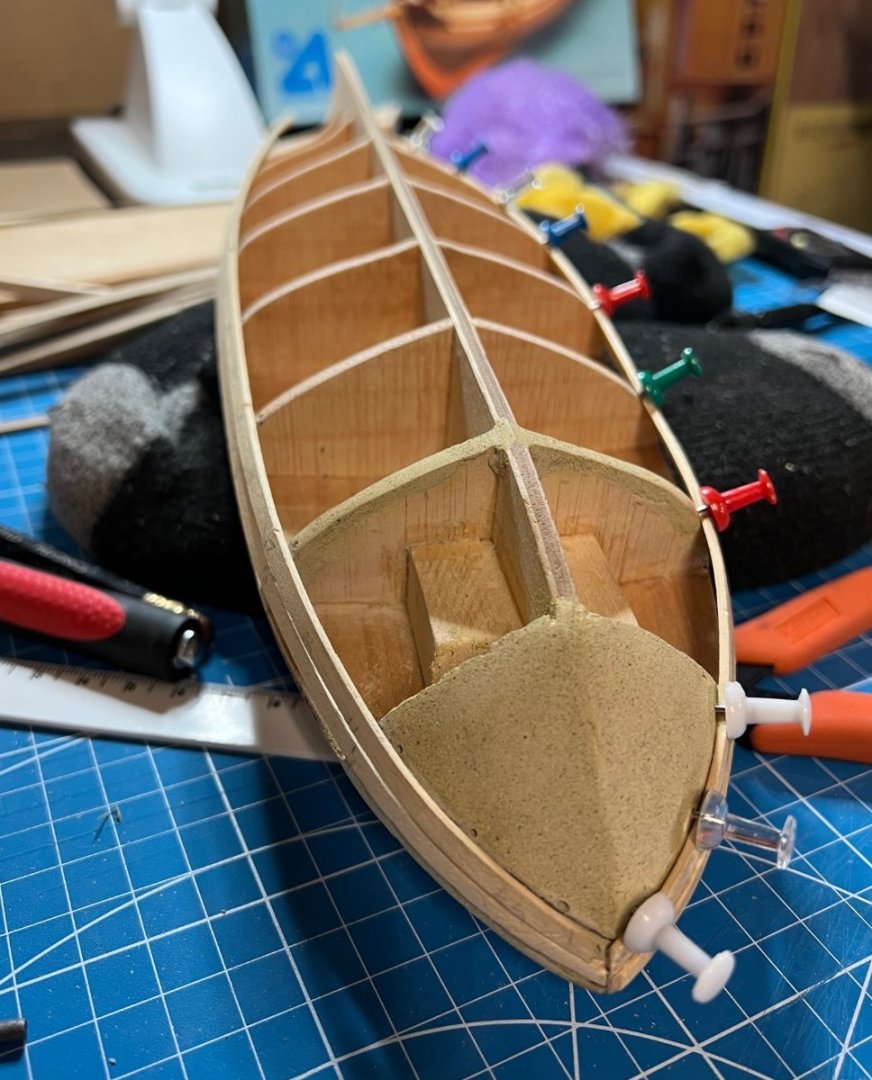

I used the push pins to plank the first layer as well as you saw in my log. I contemplated using pins and removing them but at my state of inexperience I saw the push pins being more in my league for now but might get brave enough to do it like Olha Batchvarov next time, if there is one ha ha. I knew the first layer would be covered by a thin second layer so it was thankfully forgiving for my first time.

- 129 replies

-

- Bounty Jolly Boat

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I really don’t know what the effect of the ammonia is on the wood. Perhaps it softens the cellulose? I didn’t notice any swelling after soaking but that would seem hard to notice given the scale. They may have well been bent using water and a travel iron like you did for all I know. It was my first time edge-bending planks and I decided to try the ammonia and it worked but those fumes, ugh. Funny how the kit cost $40 in 1984 and I’ve probably spent $600 on tools and materials to build it. LOL! Probably have to spend another $600 to finish it! I’m ready to varnish the boat and masts before gluing things on the deck and can’t decide on gloss or satin. Leaning towards satin in a spray can and would appreciate recommendations. I’ll ask in the appropriate forum as well. I’ve got to start stropping (is that the right term?) my blocks to attach at various places soon and I’m nervous and probably don’t have the right ropes (1mm and .2 mm that came with the kit) and probably not enough of it as well so I need to decide on ropes for stays, anchor and halyards and need help with that too. I’m sure you guys will have good recommendations for that. Thanks! I must check out your Jolly Boat now.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I've got just the piece of 2x4 to build that! Thanks Knocklouder! Also thanks VitusBering, I like the pill bottle-tupperware system as well.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

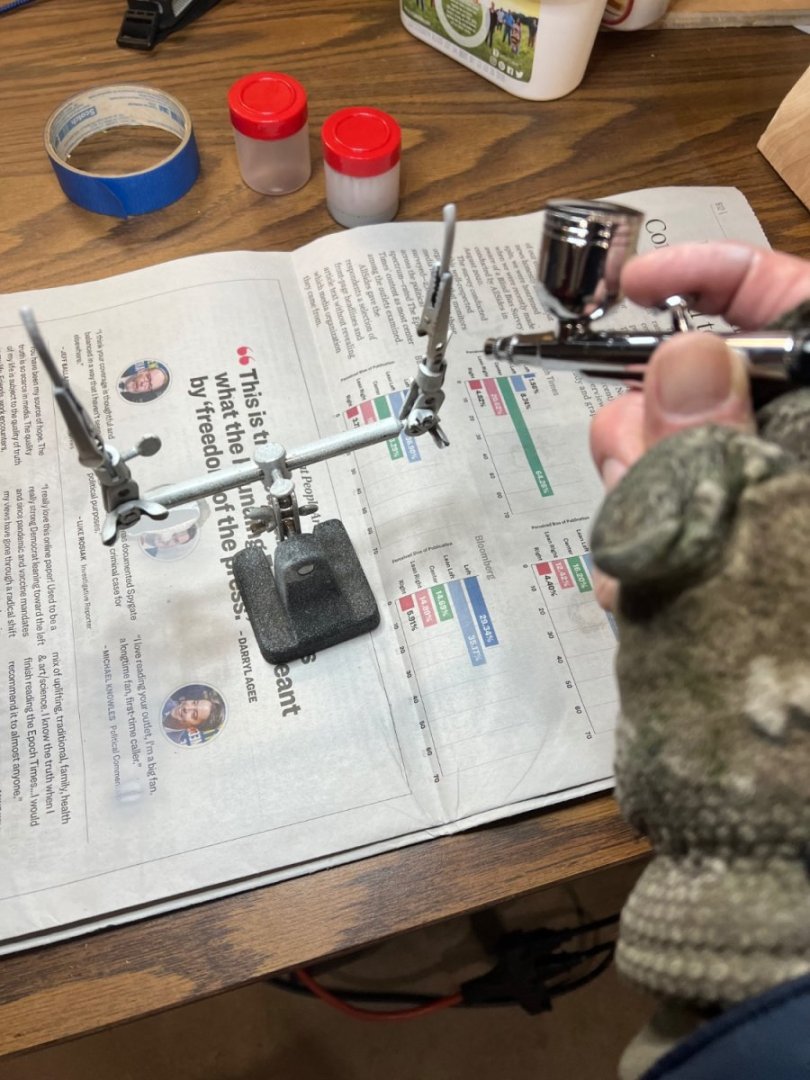

I built a pliers rack out some scrap which turned out good but need a slick way to store all my tweezers. Any suggestions? Also, I got an airbrush for ❤️ day and used it, my first time with one. Priming my scratch made ventilation tubes, don’t know the nautical term for them.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Corridor Ballardin on Youtube gave me the idea first to use ammonia but he used “cloudy ammonia” which I could not find where I live so I used the clear. He soaked his planks in a piece of pvc pipe but my dish worked for me.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

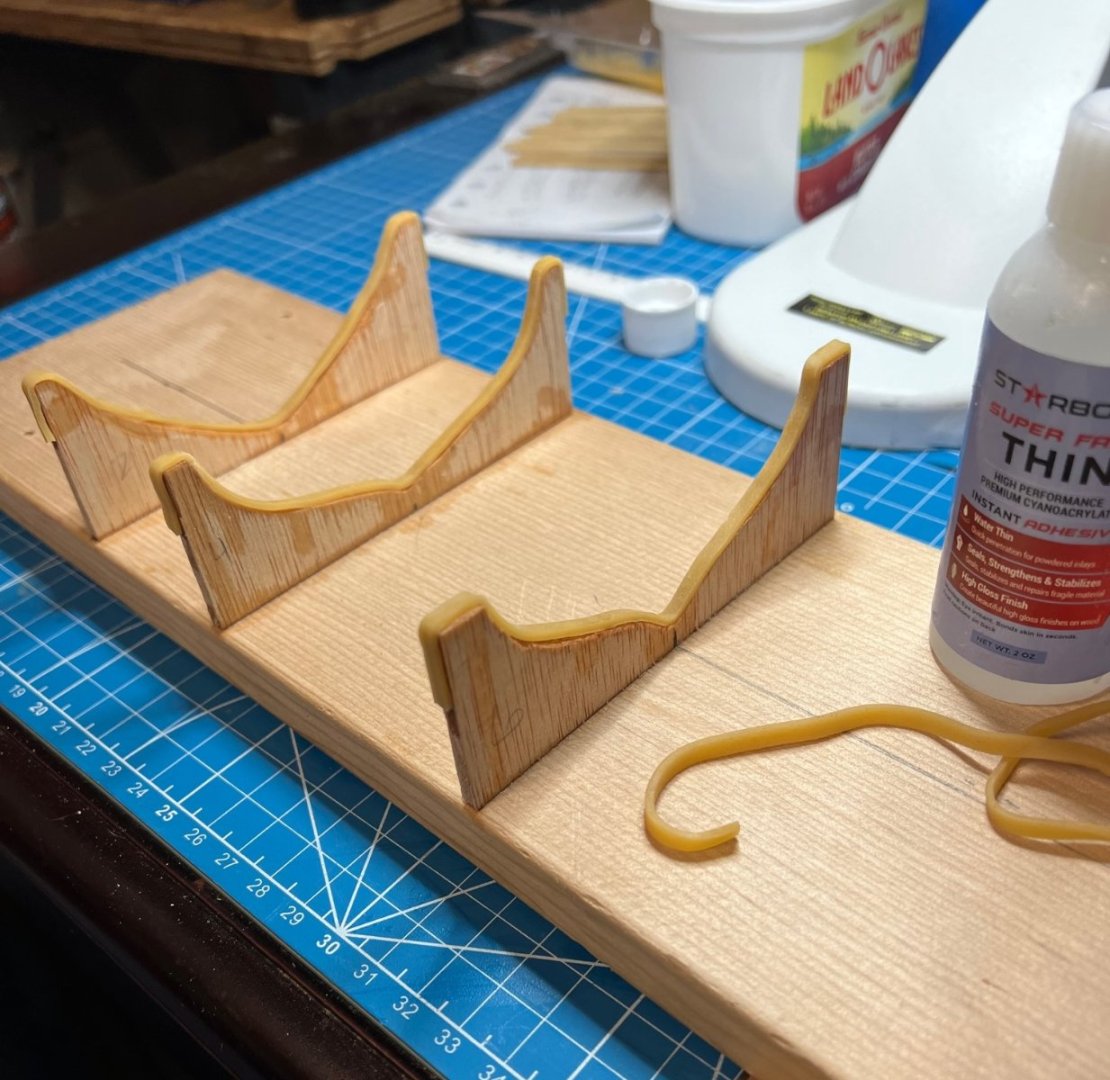

I think I got the jig idea from Olha Batchverov on YouTube, it worked great. The ammonia came after extensive searches on edge-bending planks but only a couple were bending small planks like mine but a few used ammonia. This kit is close to 50 years old and I was afraid of snapping the brittle wood so I let it soak. I covered the dish with a cutting board to contain the fumes better and poured it in a glass jar with a lid to reuse, which I did for the top rail when I got to those. Used the same jig but had to make new clamps because these planks were narrower. Something about the ammonia really softens the wood, just don’t breathe the fumes. I’m learning too.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

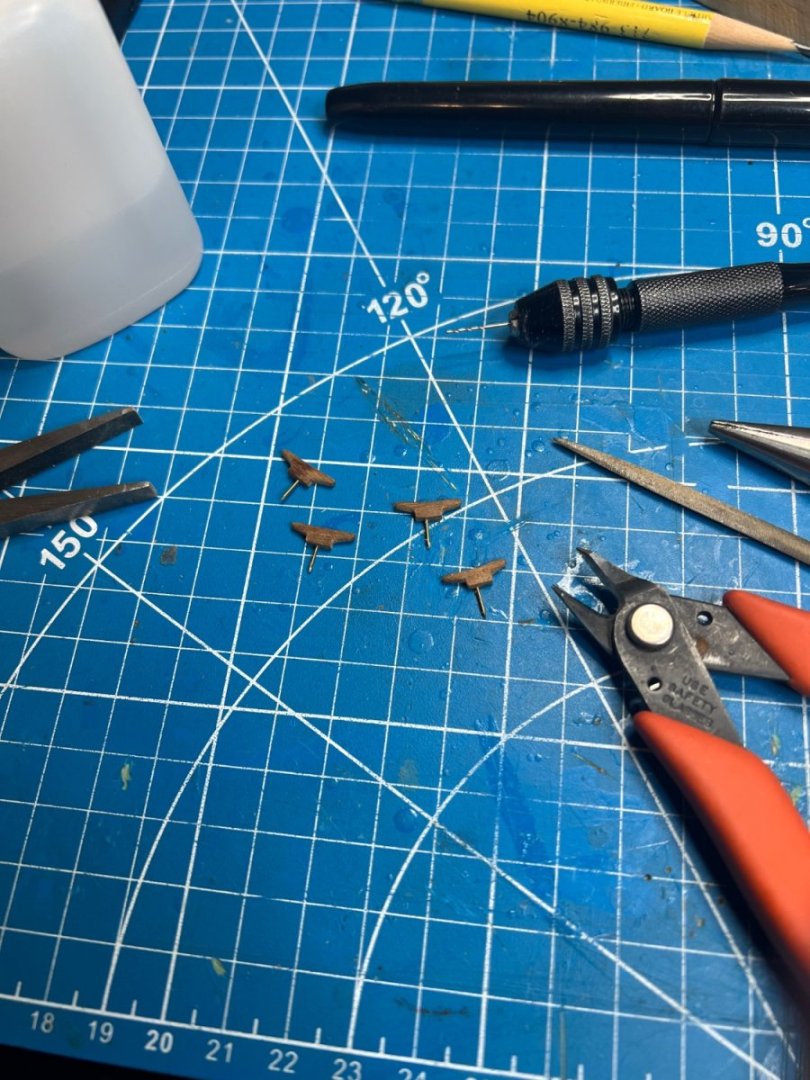

I have a question regarding the 9 cleats I just finished sanding into shape from the rough ones like on the left in the photo. What finish would an 1805 ship have on them? Should they be black or stained to stay wood looking? This is my first ship build and I have no idea what would be appropriate. Also, should I drill them and cut the head off a pin to mount to deck/masts or just glue them in place with no pin? Thanks in advance for any answers you have for me.

-

I am building this old kit now as well and I can relate. My build log is where the 1805 kits would be. Not sure how to link. Keep it coming.

- 3 replies

-

- artesania latina

- Virginia

-

(and 1 more)

Tagged with:

-

Got it! I used a combination of the suggestions so thank you all. I had a little pointed diamond grinding bit which I placed in my drill press. I placed the piece into a slot I cut into some wood then aligned and secured it. I then brought the bit down until it just touched the marked spot I wanted and made the prick. Next I put the .6mm bit in my press and very slowly brought it down and it drilled nicely. Thanks for all the great suggestions!

-

I have already glued the brass ring in place so will look for something to act as drill bushing to put over it or make a center prick from a screw perhaps since they are pretty hard. Thanks for taking the time to help me out.

-

Forgive me if this has already been answered. I'm looking for the best way to drill centered holes through the brass rings shaped around some ends of my boom and other masts on my ship. I'm afraid to try to use a center punch to keep the .6mm bit from walking because it might crush the tiny little piece. How do you guys put perfect holes straight through both sides of the brass and wood? Thanks! Scotty

-

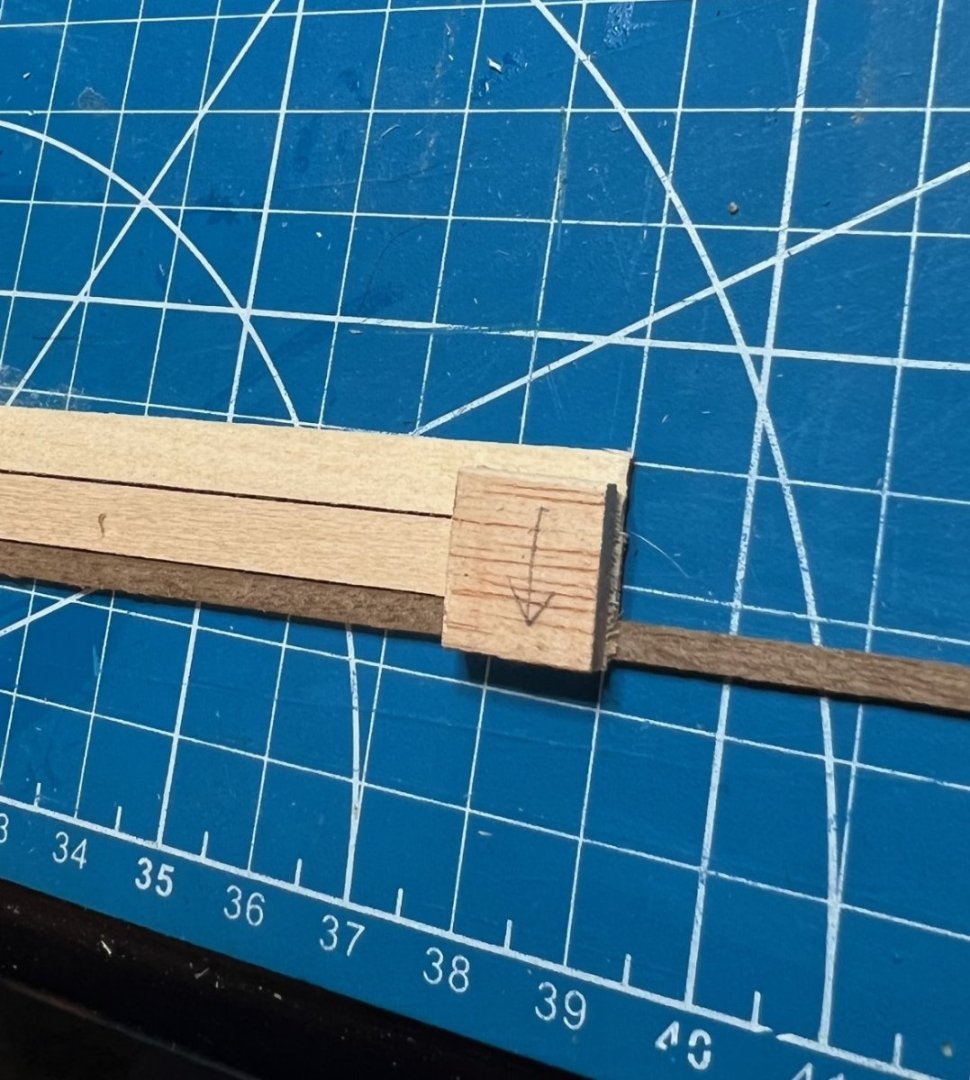

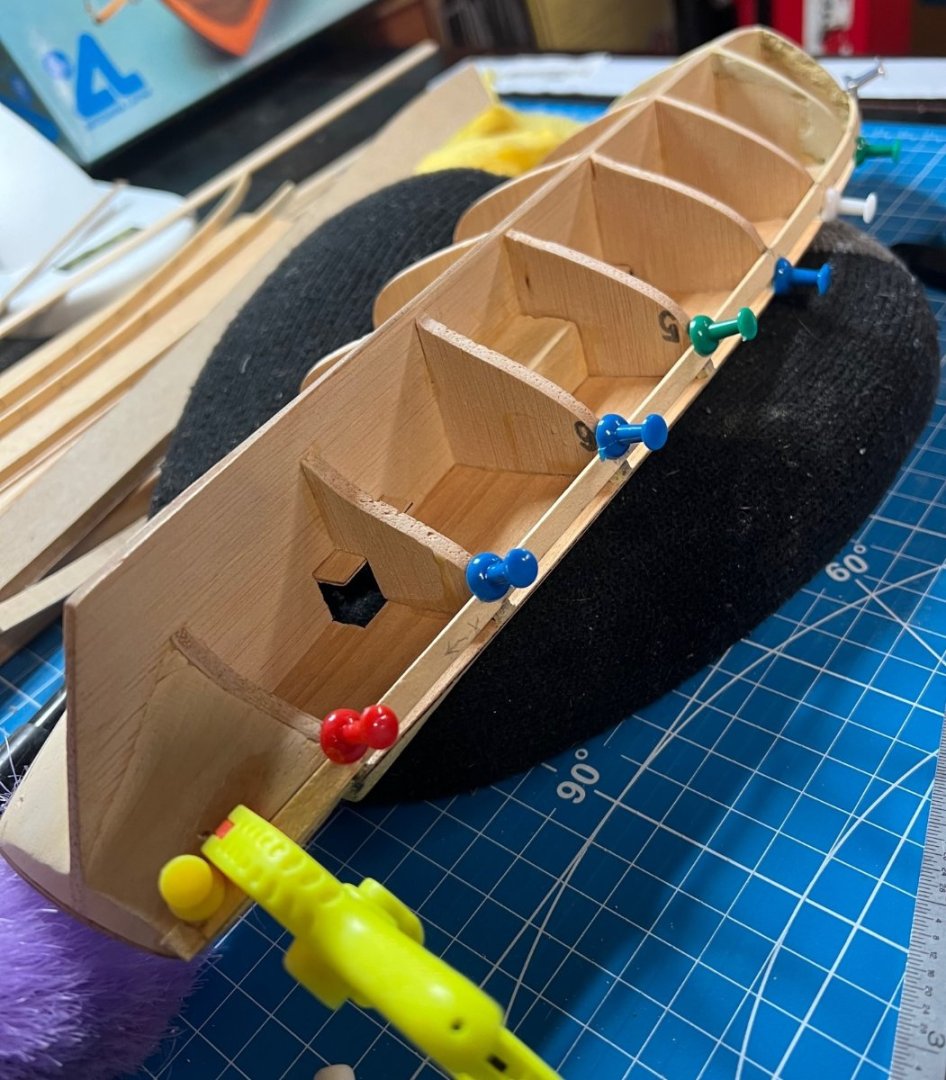

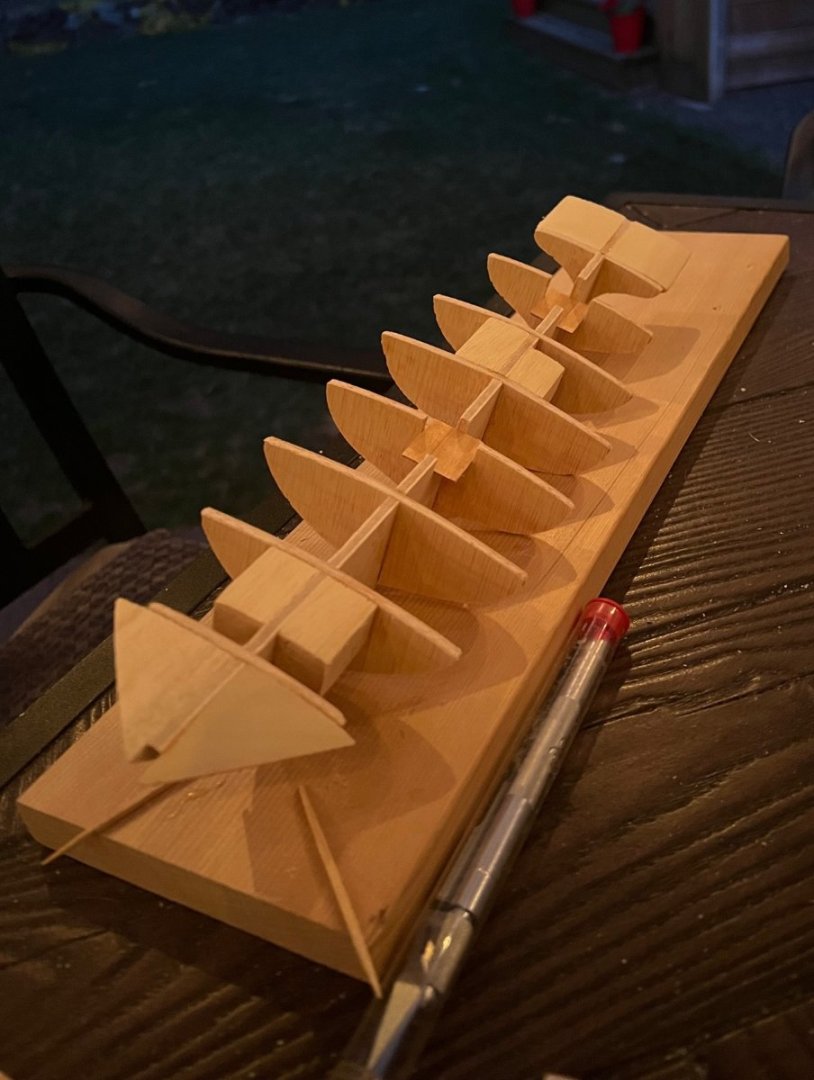

Deck Stringers: Note, the instructions had me put the deck stringers on BEFORE the bulwarks. That turned out bad because of a gap in the bow section after getting the bulwarks on. I would recommend getting the bulwarks installed before the deck stringers so the stringers can be shaped and fit better. Had I followed the instructions for installing the stringers at this point, I would have been searching for replacements for the them and as they surely would have snapped by placing with pins with no pre-bending. I had already bent many planks during the first planking but not 2x5mm bokapi edgewise. Edgewise. That’s a big deal. So before I knew about MSW I checked YouTube and found some ideas. I made a jig out of some leftover plywood by tracing the shape of the deck onto a piece and jig-sawing it out. It then was screwed onto a larger rectangular piece to create the jig. I then made the clamps out of leftover 2x5mm basswood planking by using the stock to determine the width of the gap in the clamp. I cut a couple of dozen clamps out after gluing with CA glue. Next I drilled them to accept a push pin which secured them to the jig with the piece in place. I soaked the piece in clear ammonia for 3 days in a glass cake pan before attempting to bend around the jig. I was pleased how this old wood bent around the jig, one clamp at a time without splitting or snapping. I left them to dry in the jig for a couple of days and removed the clamps. There was some spring back which I expected but was able to easily fit to the sides of the deck. (I really should have waited until after the bulwarks.) The clear ammonia took some color out of the wood as I had to careful now not to mix up my bourbon and the bourbon-colored ammonia. Thanks for reading if you got this far. I have questions for what I’m doing now with the masts and drilling that I need to go the forums for, but I’ll continue soon with the battle of installing the stem, keel and stern. Still can’t believe I got through that struggle. I’m backfilling all this until I catch up with where I’m at in the present. The last pic here is from 11/6/2022 to give you an idea. Thanks for helping me keep my pics oriented by cropping a little if they post wonky. It worked great. Now I got a ship to build, take care.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Great advice! Thanks Kev. I love CA glue because it works so well and I hate CA glue because it works so well. I use both thin and medium. I use medium when I need time to a fit a piece just right and thin when a quick stick will do but only if I can't clamp, otherwise PVA glue and clamps. My clamp collection is growing fast. I'm still learning the forum and the where's, what's and how's. Still don't understand why my pictures posted sideways and upside-down when I uploaded to my build log but whatever. More to come that's already done, just need some time to type and post. Thanks for the warm welcome.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Thank you for the reference. I will study it. My first planking job truly sucked. I knew it would be covered by second planking so wood filler covered my bad spots. The second planking came out pretty nice as you’ll see when I get to it. I have much to learn and retain. Thanks!

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Greetings, new to the site and new to timber ship building.

Scotty W replied to Scotty W's topic in New member Introductions

Brrrrrrr, c’mon Summer! The short 3 months we have of it here near Seattle, not the capitol of Washington. -

Greetings, new to the site and new to timber ship building.

Scotty W replied to Scotty W's topic in New member Introductions

-

Greetings, new to the site and new to timber ship building.

Scotty W replied to Scotty W's topic in New member Introductions

Thank you all and you’re right, it was about 40 degrees F in my garage when I broke that piece. Duh! And I call myself an engineer. Slipping in my old age. I have new brass strips and better tools on the way for bending from MM and will do that work inside out of the cold of the Pacific NW from now on. Just duh, one of many duhs I’ve done and will do before this is done. I started my build log tonight with pics in the section where an 1805 boat would be. Hope to see you there. Thank you all! I’m gonna like it here, I can tell already. Teach me! I’m open to your ideas. -

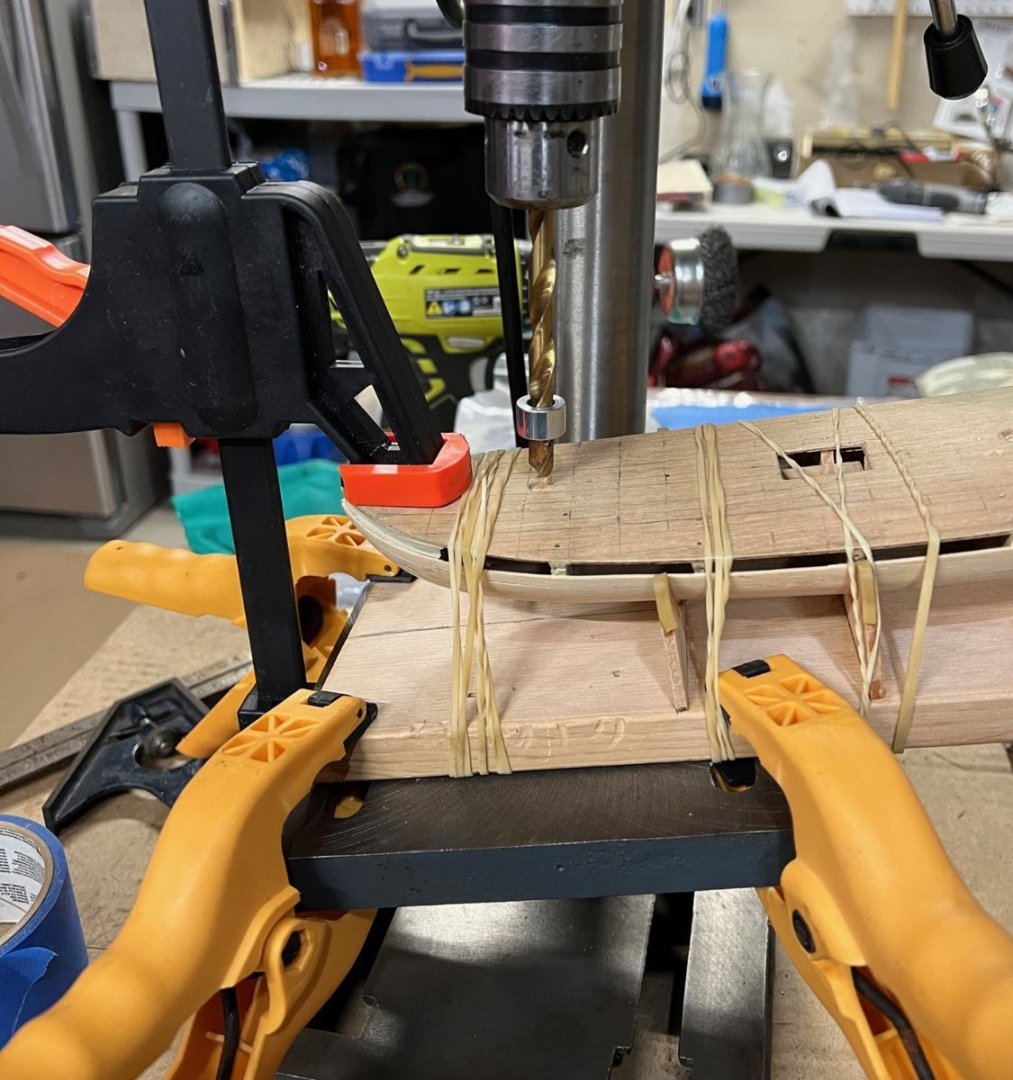

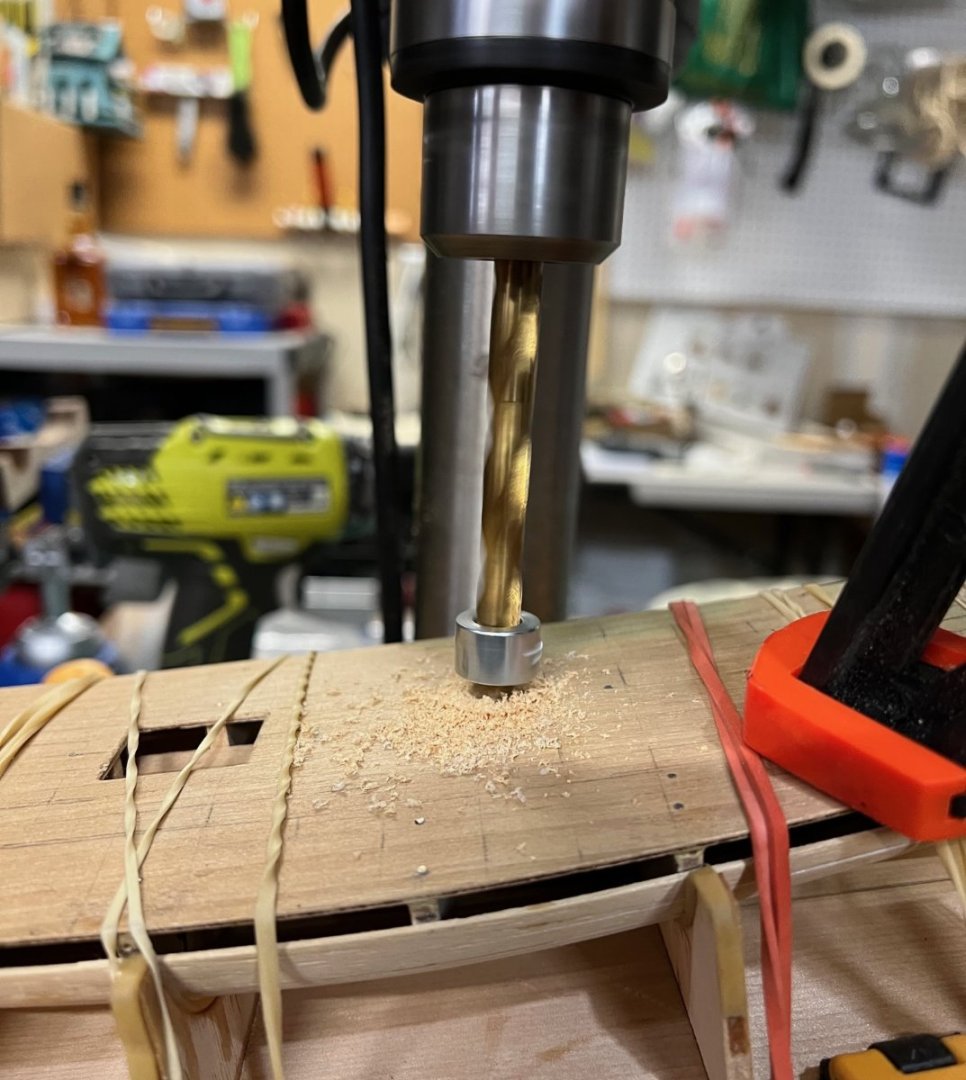

Mast hole drilling and Deck Planking: I asked everyone I knew if they had a drill press I could borrow since the engineer in me knew the mast holes were critical and could not be done with a hand drill and eye balling it. Turns out my next-door neighbor had one he’d forgotten about so I absconded with it, cleaned it up and used it to drill my mast holes. I made a jig from the sprues the frame came in to hold the ship in place during drilling with the help of some clamps and rubber bands. I should have bubble leveled the rig to the table but eyeballed it instead, we’ll see how that goes when I get to installing the masts. I studied installing deck planking and chose a plan. I used pencil around each plank to mimic the caulking as shown in some YouTube videos I watched. It was tedious as hell but looked great. I used CA glue and stuck myself to the ship many times but would get used to that. The deck planking was .6 x 5mm and after marking the positions of the planks in pencil on the deck went well. I used a sharp pencil to put the nails in each end of the planks and stained with a golden oak stain when done. I had to repair a couple of places that the CA glue stuck before I was ready for it to but oh well. I love CA glue but I hate CA glue for the trouble it can give during builds. I am trying to not use it as much as the build progresses but sometimes, it’s the best choice for me if clamping is off the table. Anyway, I think the deck came out fairly well for a first-timer. I screwed up and didn’t stagger my planks on the very back deck but oh well, live and learn.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

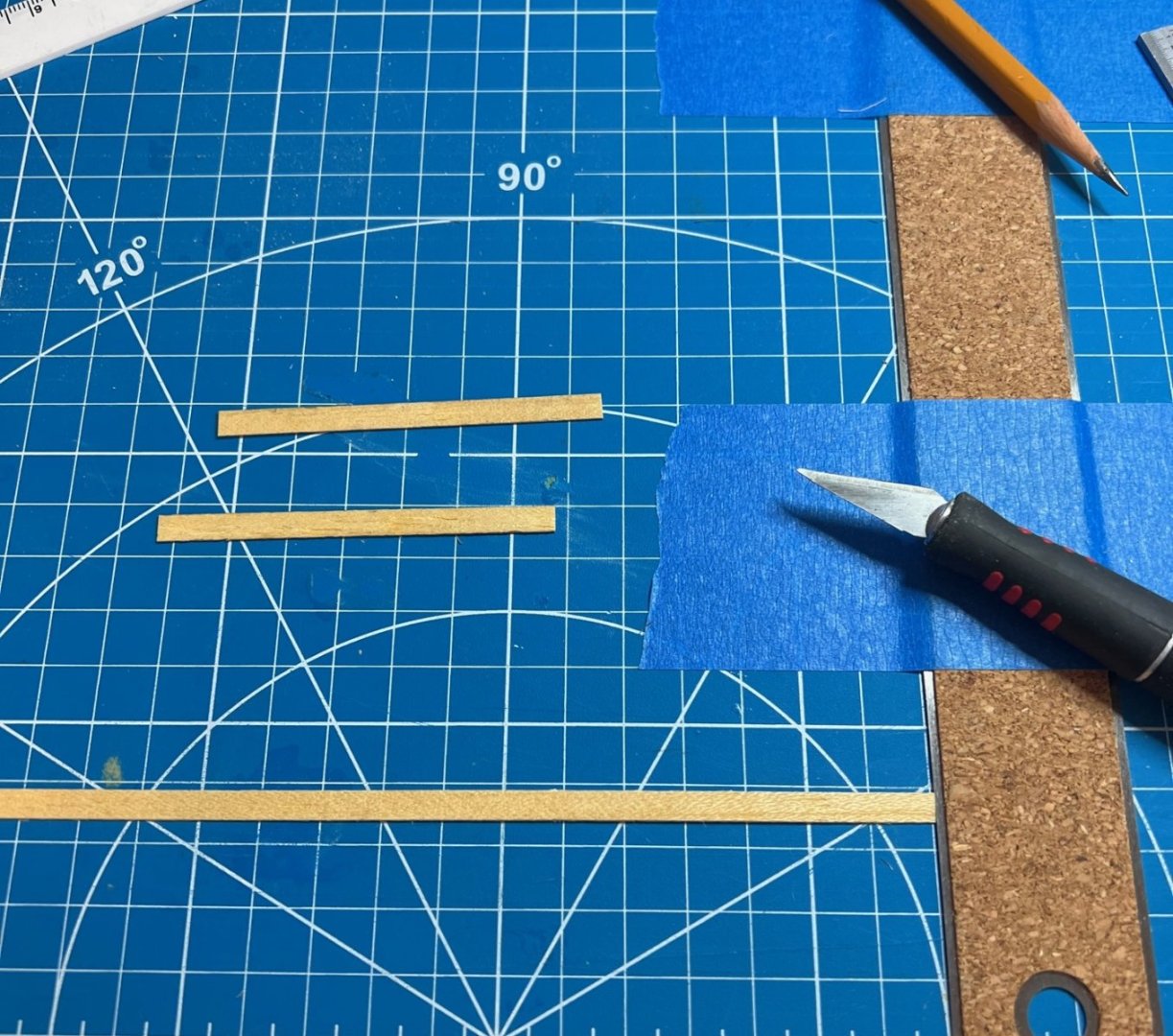

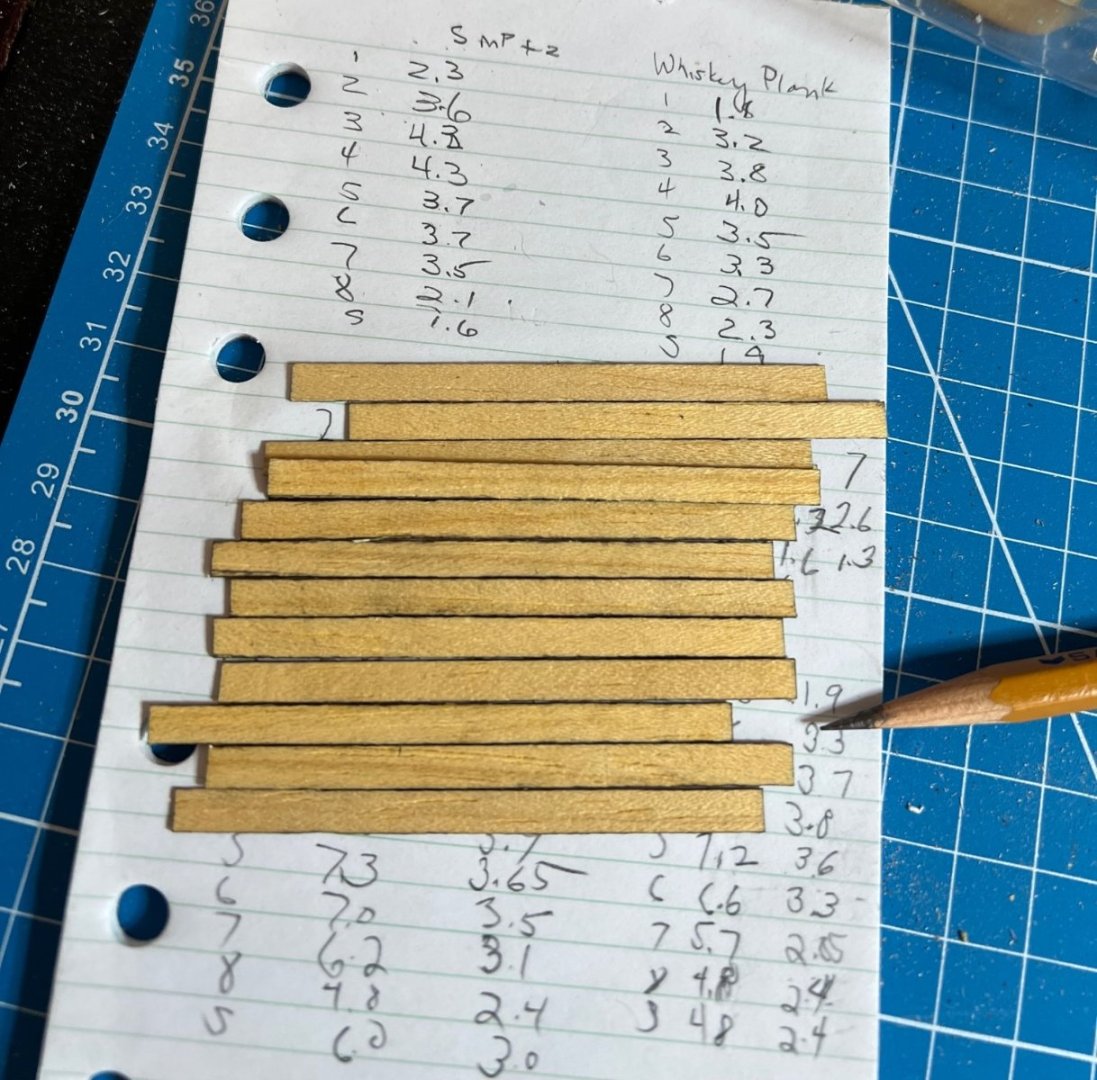

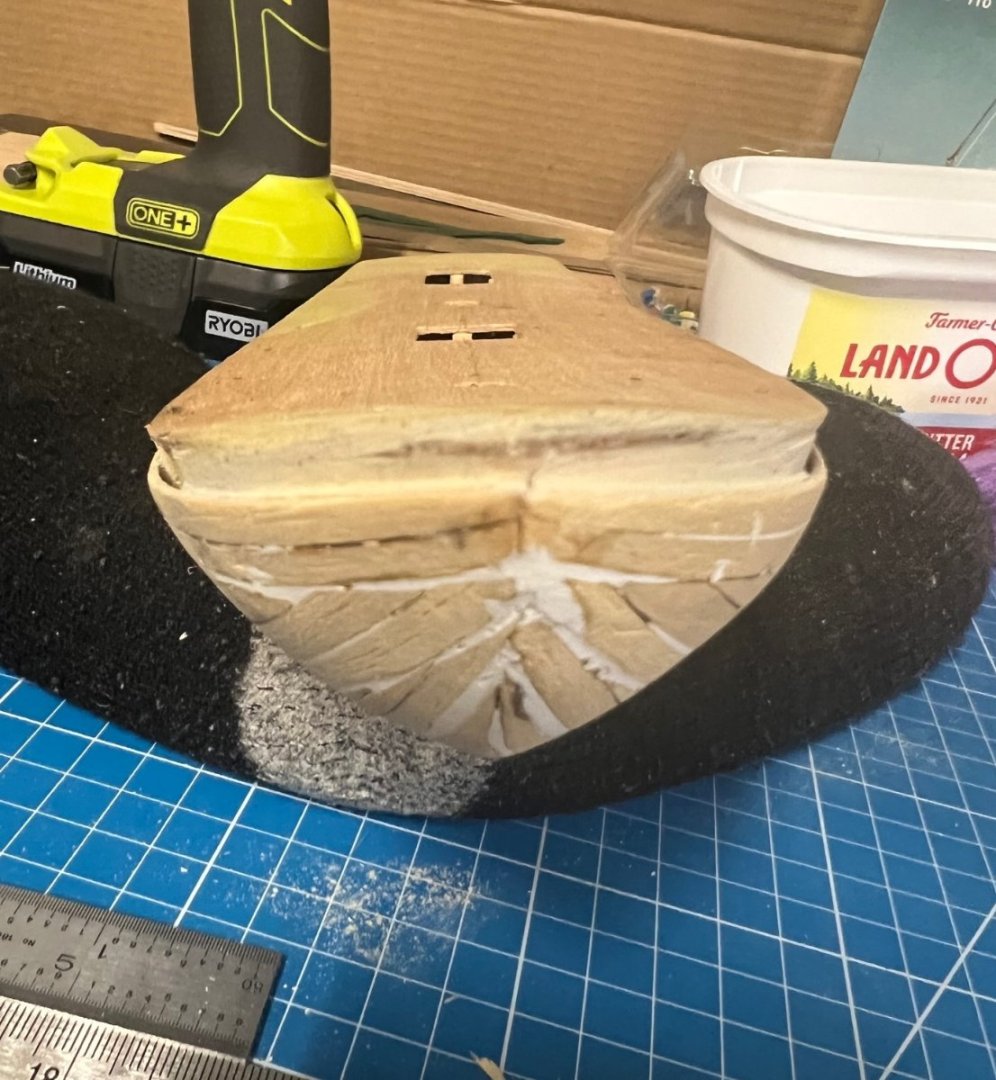

Planking, the point of no return. After watching countless videos and reading volumes on planking, I acquired a couple of tools before proceeding. I got one of those plank bending crimps and realized quickly it wasn’t for me and got myself a soldering iron, bending jig and a flower vase to soak the planks in. I also picked up a micro wood plane and a mini-mitre box. I already had a set of mini mitre saws but didn’t realize they wouldn’t reach the bottom of the box due to the flange on top of the blades, duh. I solved that later with a Japanese pull saw that would fit and reach. Most cuts were done free hand on my board anyway. I went to the extent of buying extra planking that was slightly different size to practice bending and planning to shape before I started wasting the 40 year-old lime-wood 2x5mm planking that came with the kit. I was expecting more detailed instructions but realized quickly on it was up to me to provide the detailed instructions from their general guidelines which got worse as the instructions progressed. I began as they suggested with the first plank 3mm below the deck line and then moved down, bending, tapering and beveling each plank to fit. I broke traditional protocol with my joints and just went to pointed ended planks to simplify on this layer. I respected those protocols on the second layer of planking as you’ll see when I didn’t have to bend the super thin walnut planking to get to fit the curves before gluing. I proceeded one plank at a time on each side trying to match my work on each side as closely as possible. When I got to the garboard plank, I had to stop and research more since it was so important to get it right. I still didn’t get it right but wood filler had me covered at this stage as you’ll see in the photos. I used various clamps and pins depending on where I was on the planking but finally got it done. It was at this point that I knew I had to finish this thing. I still don't know why the photos are changing orientation during posting but whatever... The "Whiskey Plank" was my favorite as you'll see below. Used a little plane to taper the planks. Worked great! Bending station. The Whiskey Plank is ready to install. And Christened with a few drops of good Rye. The rest for the ship builder. Steelers? I was an Oilers fan. Done. Now some filler for those ugly joints. Ever see a worse bow than this? It'll be covered, no worries.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I gave this kit to my aging Dad back in 1984. Bought it new from Model Expo for $39.99 and still have the receipt! He had been an avid plastic modeler when I was a child in the 1960’s and from whom I gained much of my knowledge and skills building plastic models. The last model I completed was a big scale SR-71 Blackbird in 1995 or so. I haven’t touched one since, until now. While moving some boxes from a closet last spring, I came across the kit, still in the box it was shipped to me in 1984. I’m retired from disability with neuropathy in my hands and have turned 65. I can’t imagine what I was thinking when I made the idiotic and expensive decision to attempt to build my first ever timber ship model but it has been extremely rewarding and frustrating at times. I had a lot of tools to begin with from my plastic modeling days but knew I would need many more to tackle this project. While it was a kit, I feel it was closer to scratch build given the shaping of each and every part and the need to make scratch parts when some got broken or damaged thanks to my clumsiness. Although its Feb 2023 now and I am now making the masts, spars, boom, bowsprit and flag mast, I’ll start where I started in June of 2022 and work up to the present. If you something I did that was a rookie mistake, please feel free to offer better ways for the next time I try this. I already have noted dozens of things I would have done differently from experience and lots of YouTube videos and reading here. I find sometimes there are just too damn many ways to do something and I have to find the one that works best for me. I’ll never build museum quality models but my friends and fam are already wanting me to leave this ship to them when I go! The Frame: I only thought to start photo journalizing this build after I’d completed the first step of getting the ribs together but took an abundance of pics after that to create a time lapse movie of at some point for my YouTube channel. I read the instructions ahead thoroughly and noticed they get less detailed as you go as though the author got tired and really wanted to finish. That and the translation from Spanish was lacking in places. Nonetheless I trudged forward not noticing the last stern rib was misaligned top to bottom. We’ll deal with that soon enough. I should have used squares to line up my ribs instead of my eye but puddy and sanding will cover those tracks since it will be covered. It was at this point that I realized I had to look way ahead to see what pitfalls I was setting myself up for and the journey began. I would miss the parts of the build that would be covered soon enough. The instructions had me install the false deck on at this point too, not sure if that was the right move but was afraid of cracks in the deck planking if I planked it before bending the false deck over the ribs. I measured where the ribs would be so I’d know where to put the nails and marked them on the deck. So far, I felt ok with how it was going together but was just dipping my toe in. Frame, balsa inserts and false deck complete. Next, the first planking. Oh joy. . Pre-nailing the false plywood deck for installation.

- 59 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

My name is Scotty and I've started building the Artesania Latina 1805 Virginia Pilot Boat Swift. I purchased this kit for my father to build in 1984. He never tried and is long gone now. During our last move in 2021, I came across the kit which I still had and finally decided to give it a try in May of 2022. Countless hours of research got me past the planking which came out lovely. I got all the deck furniture built and have begun the masts. Spars went well but got to the boom crab-jaw which was a 3mm wide strip of brass that has to be bent around the mast and attached to the sides of the boom. Metal fatigue got to it after bending with needle nose pliers and it broke. I managed to get it installed in two pieces. When bending the first of two double crab-jaws that holds the flag mast to the main mast, I broke another one and doubt I can make it work. Now I must locate 1/8 x 1/64 brass strips and the proper tools to bend the curves and sharp angles without breaking them. That's where I'm stuck and also not sure how to drill tiny holes straight through the tiny round boom through the brass without an expensive mini drill press. Want to get to the scary blocks and rigging but stuck on bending brass strips to shape without breaking. Sigh. Thanks for having me!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.