-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FreekS

-

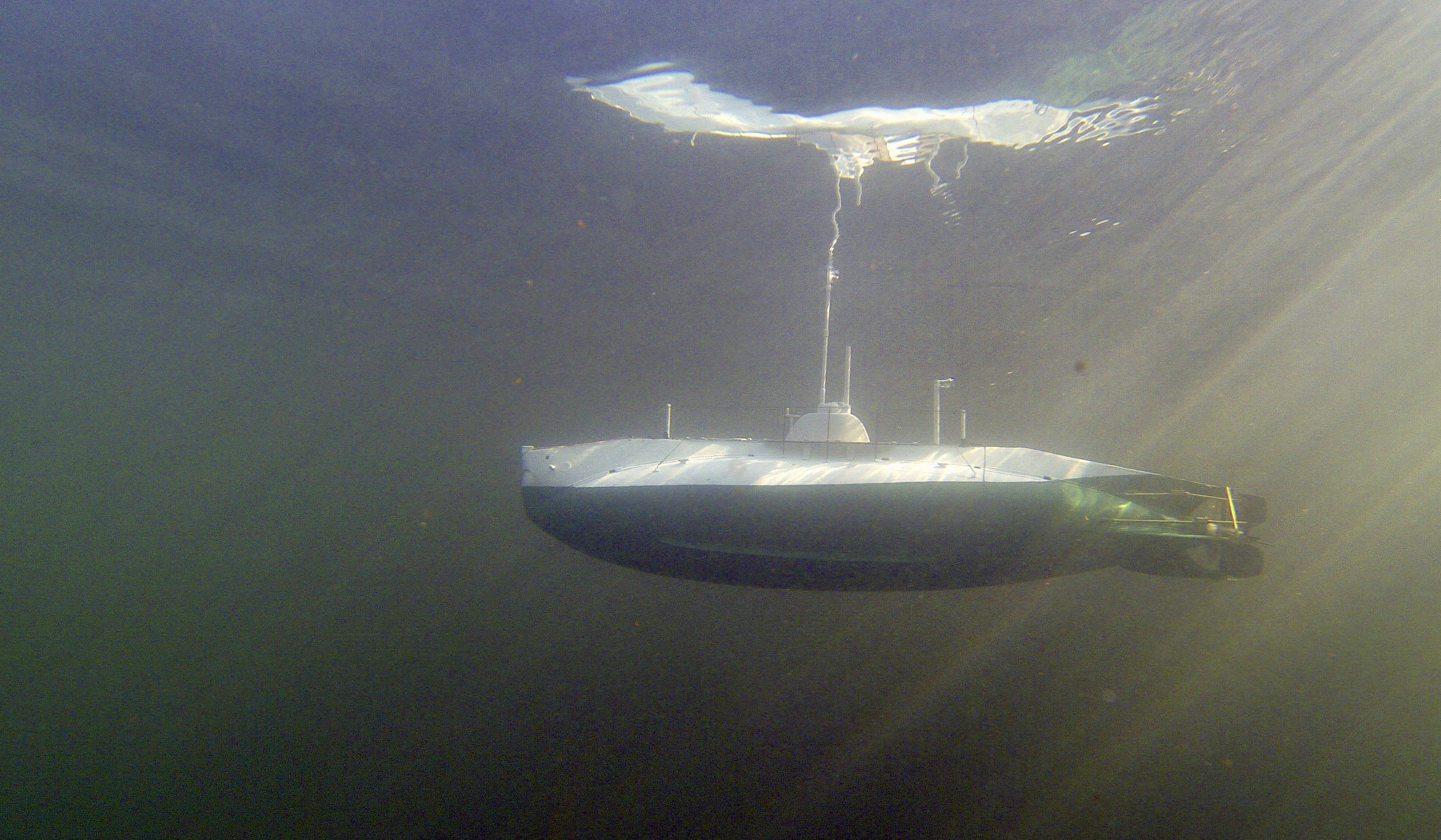

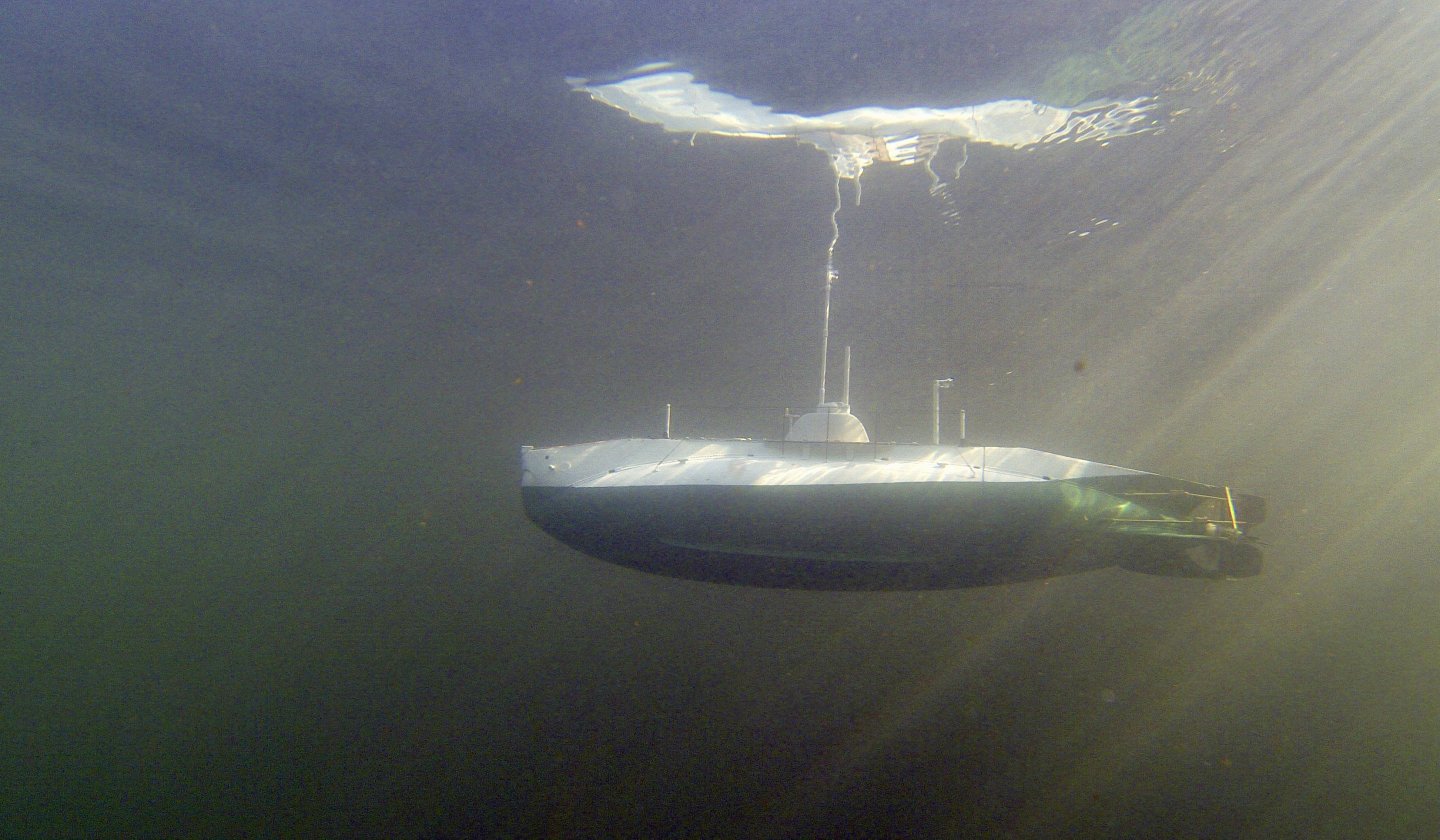

The “leak” turned out to be an “error in thinking”, water dripped out of the flood zones, not the watertight compartment! Decals replaced and in clear coated with a brush (instead of airbrush) hopefully has a thicker protective coating. The boat was a bit heavy after so put a bit of floating foam under the deck. then today we went with a small group to my model sailing club. Sunny weather, about 1-3 feet of pretty clear water, could not be better. amd the boat sailed - a bit too fast, very easy to dive and surface and a huge turning radius. Still work to be done, but the boat is fully under control and I’m very happy!

-

Yes it is difficult, frequently I have to reach and change a component worked on months ago that is no longer so accessible. Now that the cranes and net cutter are mounted on the deck, I needed to make a rig to safely work on the components under the deck section, for fear of damage. But pre-thinking those things is also part of the fun…

-

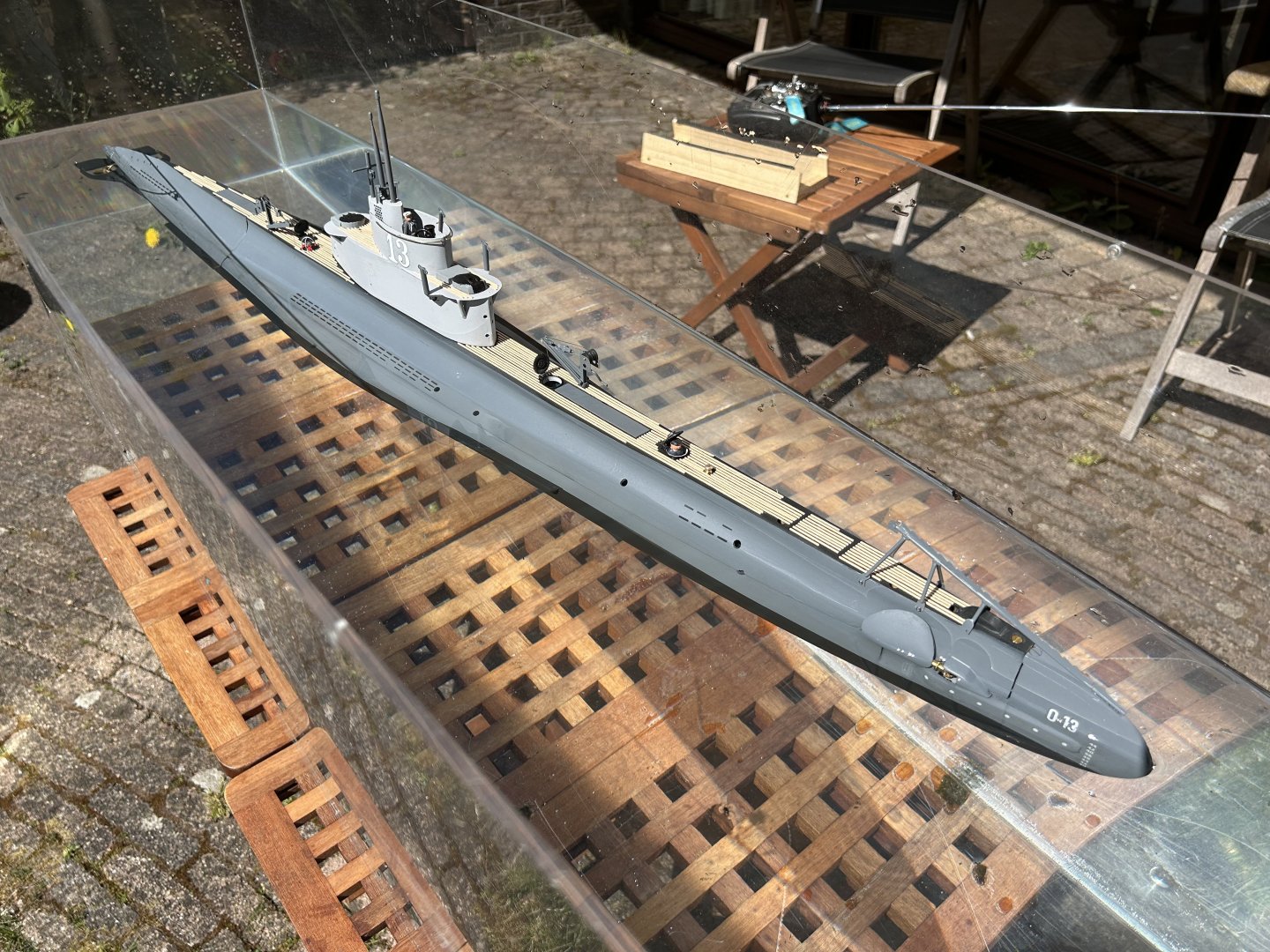

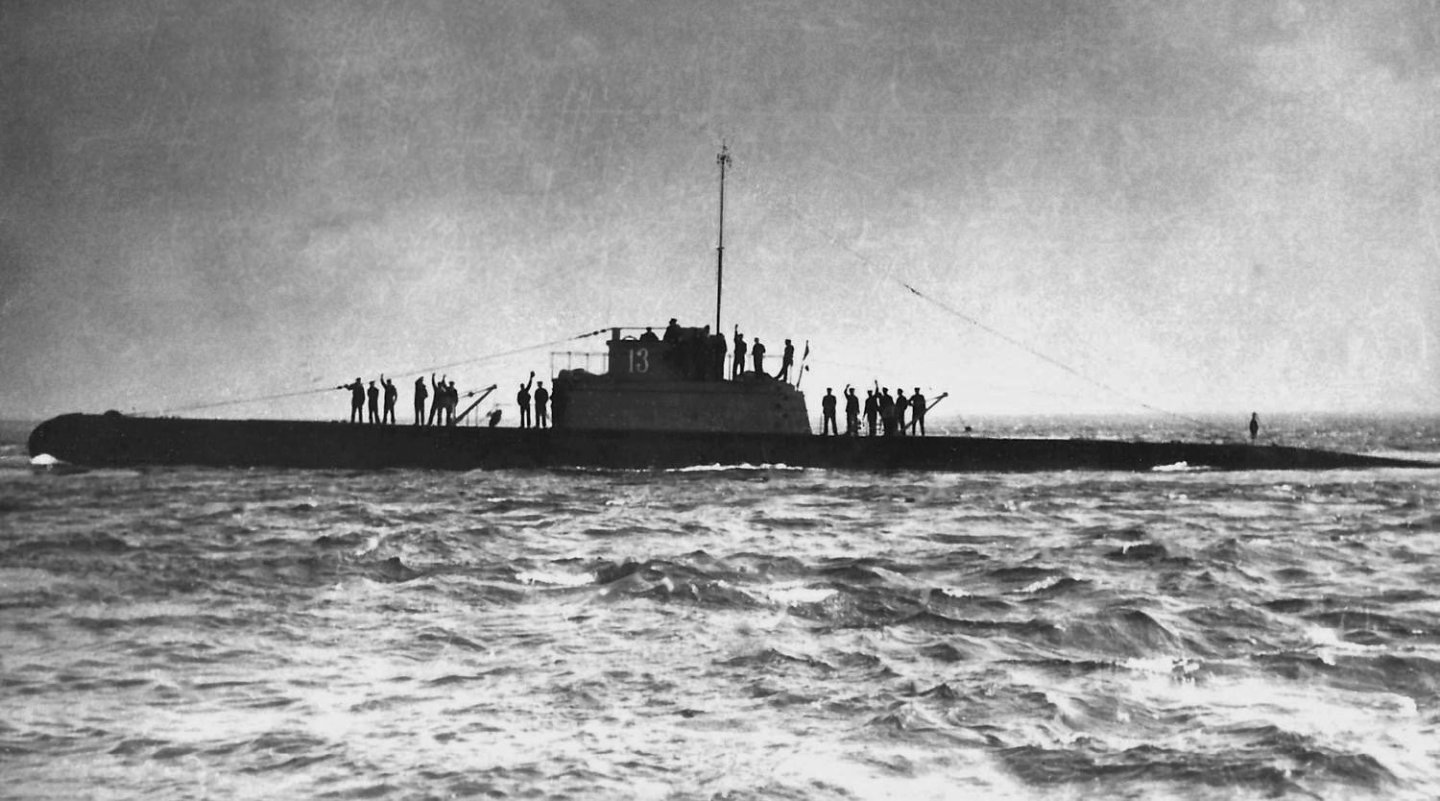

The past weeks were about making everything ready for balance tests in water following the rough trimming I had done in my bath and the one night sailing. For that I needed the weight (distribution) to be close to final. Ive painted and mounted the net cutter, turned two periscopes on my mini-lathe, made an aft mast that will double as the air exit from the tank, made the floats to close all 4 hatches when the boat dives, and mounted the bridge equipment (radio direction finder, compass and helm). Still some smaller details to do but the boat looks great! In my plexiglass test tank the boat lies level on the waterline. I would prefer a slightly higher nose-up attitude. Then started the pump to fill the tank. The pump is programmed to stop after 27seconds, which was enough to fill the tank in earlier “partial” tests. Now it brought the boat to “decks awash” but not to neutral buoyancy. Took the boat out, weighed it on a kitchen scale (3,9kg) and then emptied the tank (now 3,4kg). As the tank volume is 600ml the tank was clearly not full. Maybe the air exiting through the mast is giving some back pressure. On repeating this twice the boat came lower in the water (and more nose heavy). Now the boat with full tank was 4,1kg. Do I have a leak or did I fill the tank more? Took the boat out, there was a small amount of water in the water tight compartment (may 10-20ml), not enough to trigger to water sensors. Ok, it’s clear that I need to change the tank filling procedure (fill longer and end with a slow top up fill?) to try to get the tank totally full always. 100 gram more or less has a huge effect on the stability underwater. There is no point in adding or moving weights until the tank is always full. I have a list of other issues (find the leak, one decal came off for example), so my task list for the coming weeks is set - and that was what the testing was for! Thanks for your attention - this phase of fine tuning subs is always time consuming (and fun), and I’m very happy with the overall look of O-13!

-

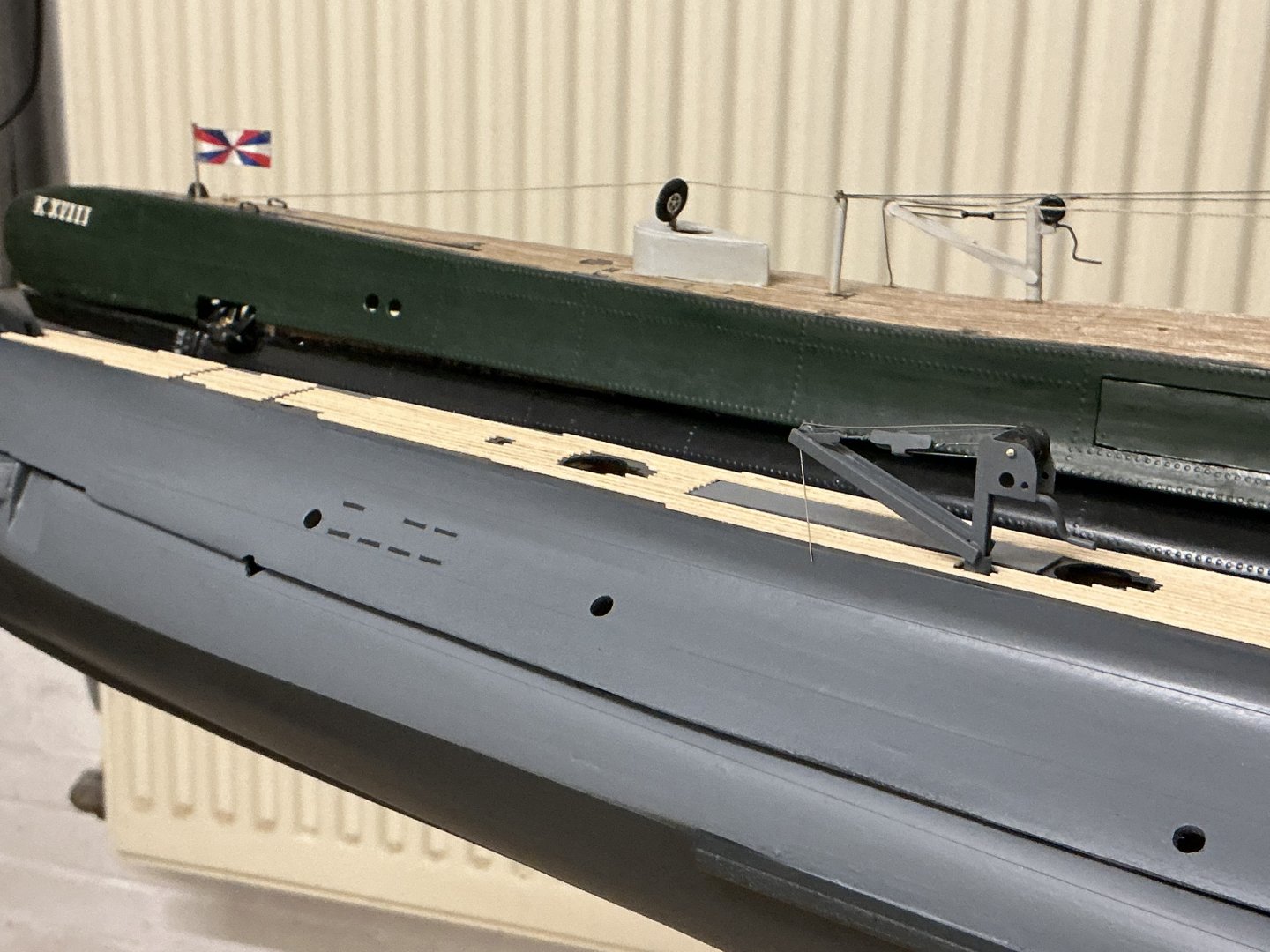

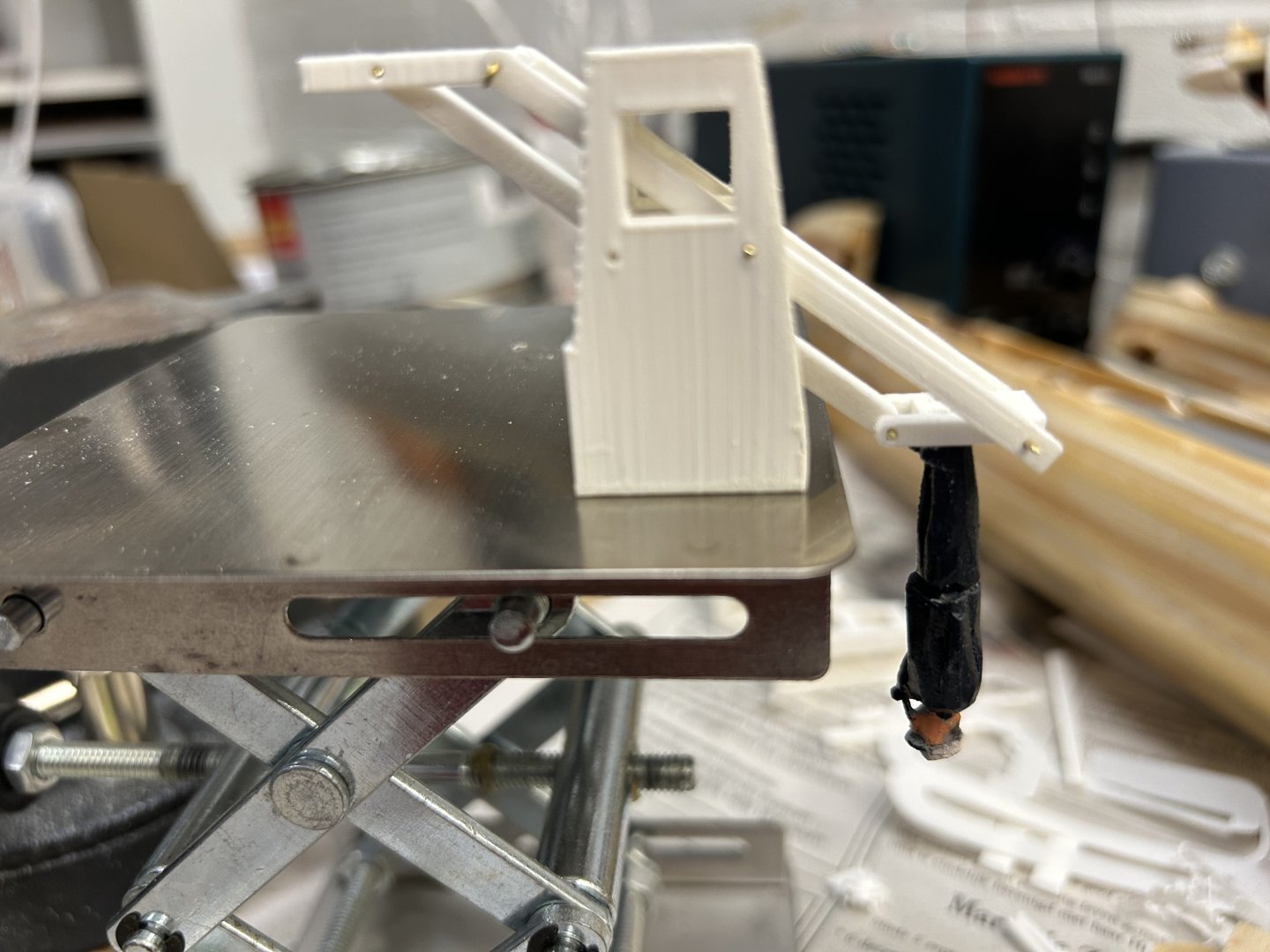

The cranes have been completed, the main cables are 0,3mm stainless steel which hopefully stays nicely straight over time. In the background the same cranes as I built them from wood twelve years ago on my K-XVIII model (after sailing 78times these still look good!). Also the wooden deck has been constructed from 1x1 mm wood bought at a rare model shop. A bit thick at this scale, but I don’t think I can sand it down nicely enough, so I’ll leave as is. For the moment covered by two layers of clearcoat, will add some more once the decals are mounted.

-

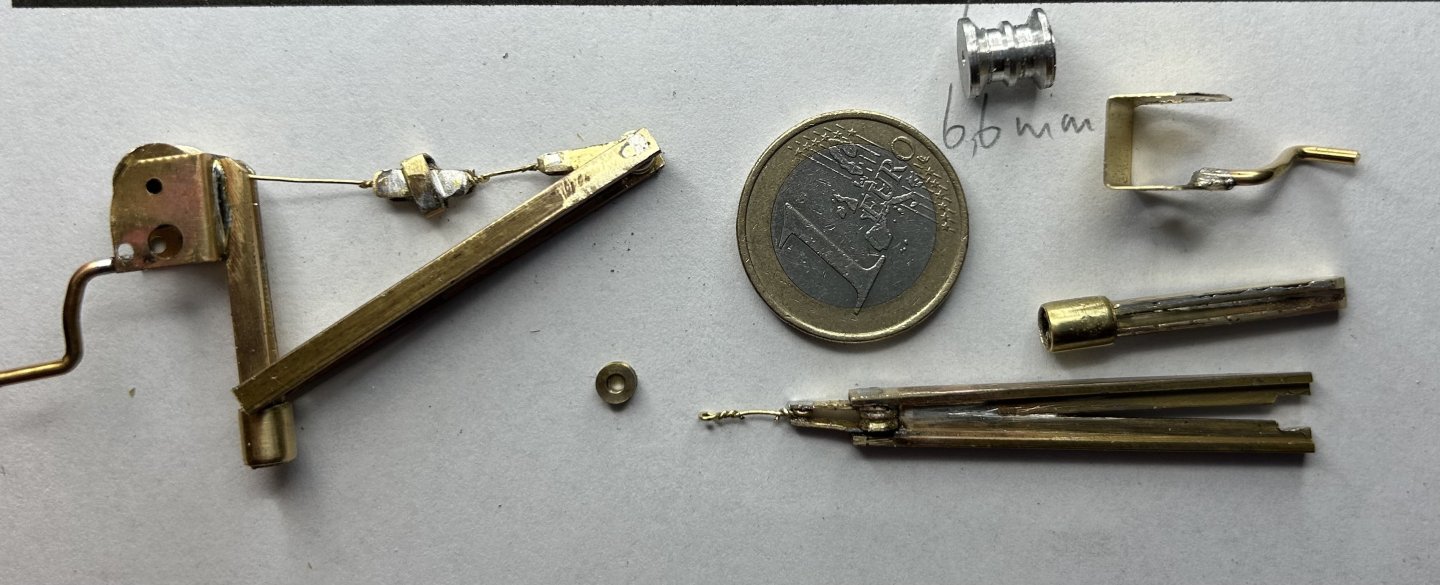

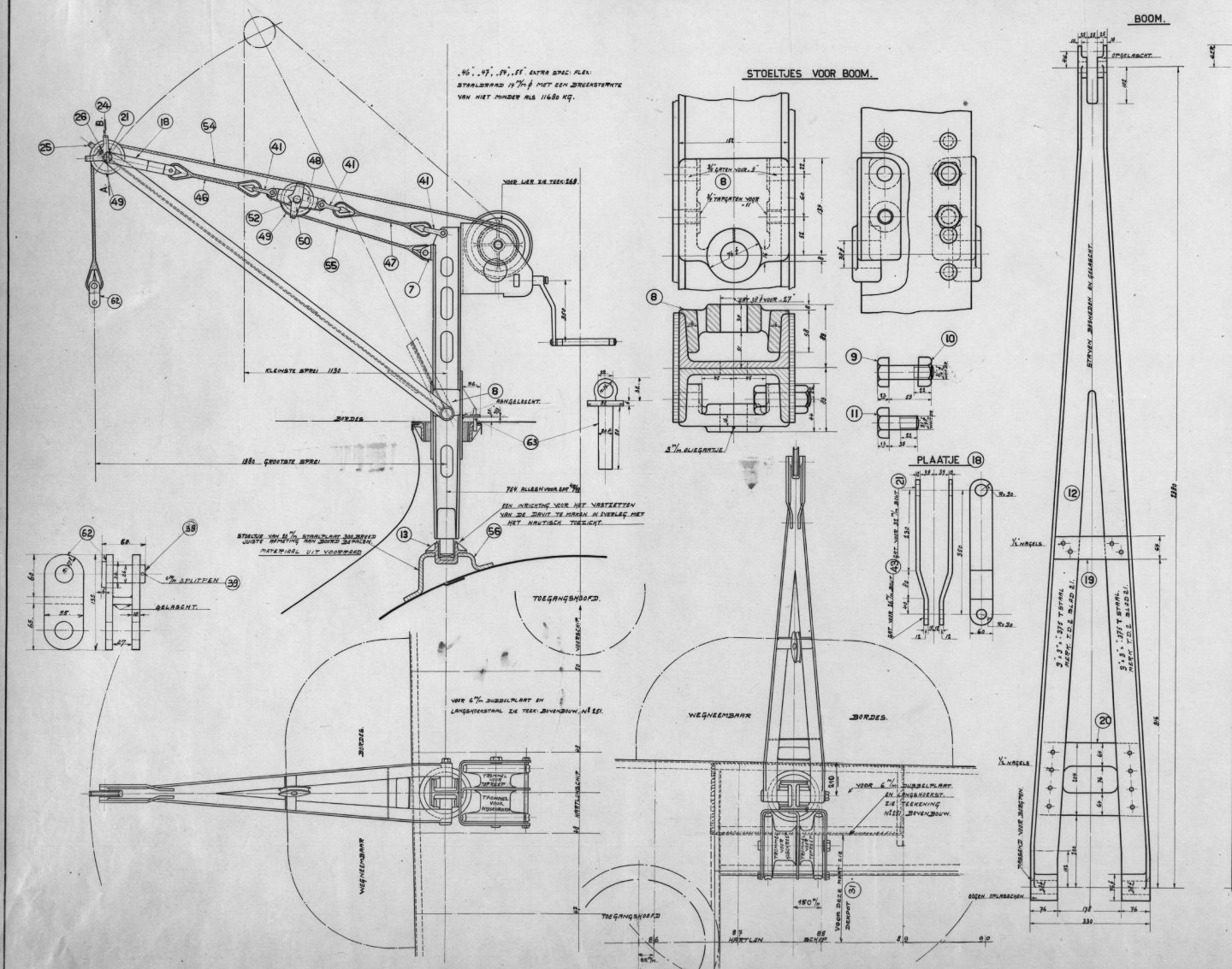

Today was a soldering day, I made the parts for the two cranes on deck. These were used to load torpedos and are permanent on deck. The drawing showed the main beams to be made of H-beams (for strength of course), and these were made at 3x3mm, seated in a 5mm brass tube that will anchor the crane in the deck. The torpedos weigh several tons, and the 14mm cable was rated for 11 tons. At 1:50 that was made from a 0,3mm brass wire. The double cabledrum was turned from 8mm brass and aluminium (brass was easier) and two blocks with 4mm wheels were made for each crane. Here is first loose assembly before painting and including the two actual cables (one for raising the crane and one for raising the torpedo).

-

My model boat club organised a beginner airbrush course in February. I bought a starmax about 10 years ago but kept using brush mostly. For this boat I’ve been practicing… The sail was already painted with rattlecan , but I used the airbrush for primer and grey coats of the hull. Some of the horizontal deck plates are very visible on photos, so I tried to mimick those by marking them with tape and applying some paint with a brush about 4 mm above the tape. Then tape was removed and after another couple of airbrushed layers the plate was nicely visible. I also tried some rows 3Dprinted rivets (0,2mm on decal) on a testplate, but after airbrushing they were no longer visible. Photos do show rivets but I need some more testing to see if I can make them visible (and hide the decal film). dis make a stencil for the flood holes, that worked OK but needed some touchup.

-

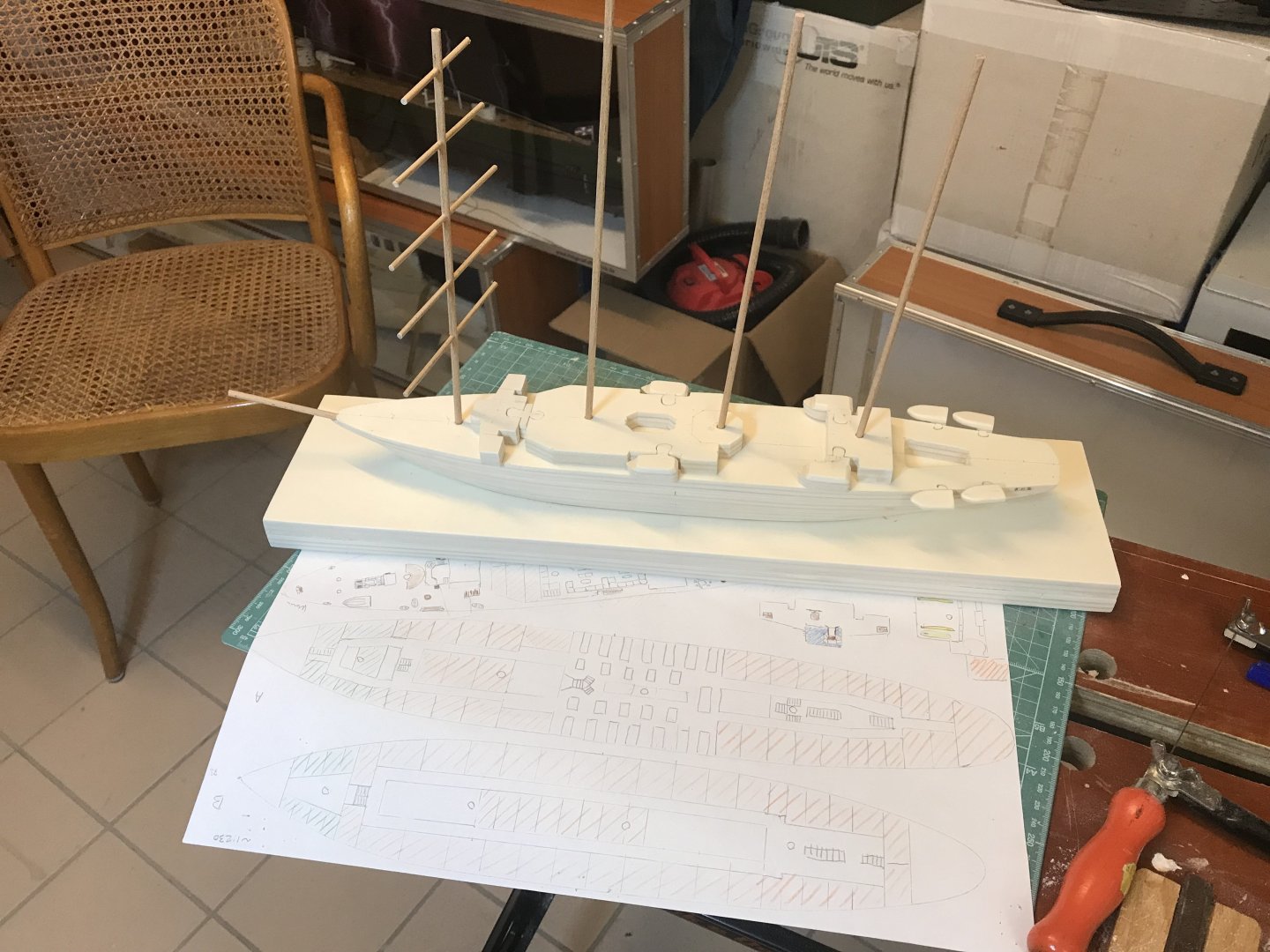

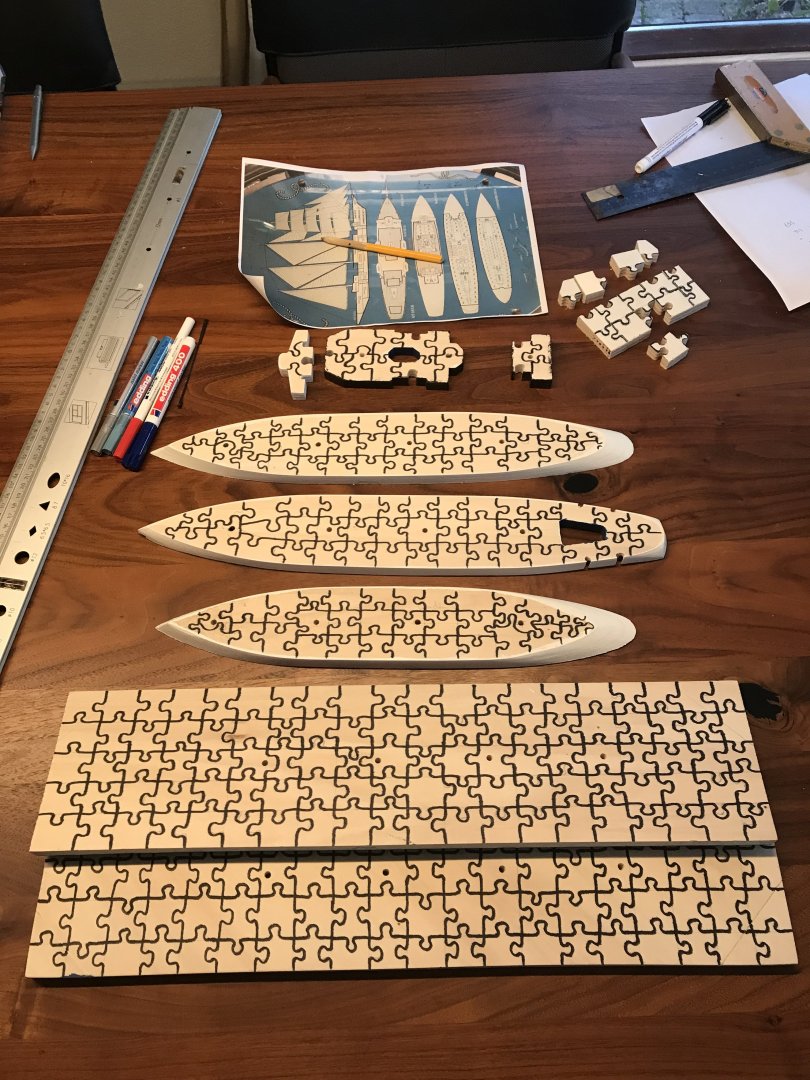

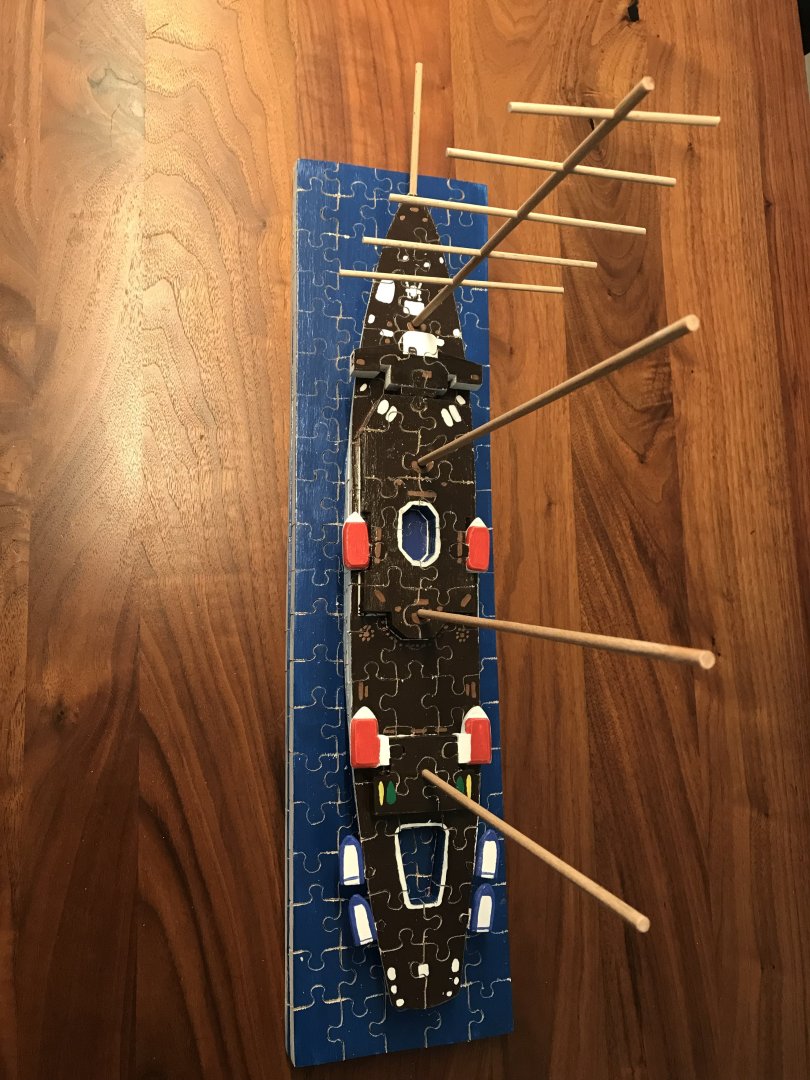

I think I had this idea after an episode of “The repair shop”, a UK TV program. Someone brought in a model of a ship, cut into puzzle pieces. Having done a trip on one of the nicer sailing cruise ships, I thought it would be nice to have a puzzle of the ship. “Star Clipper” is a 115m 4-master sailing ship (with engine, note smoke coming from the mizzen mast) from 1992. It can carry up to 170 passengers and has the first mast square-rigged and the others “Latin” (is that barquantine?). It’s a wonderful holiday opportunity, sailing in the Mediterranean or Caribbean depending on the season. The basic idea was to construct a “bread without butter” model of the ship, with each board representing a deck of the ship. Each board/deck would have its actual layout painted on it, and then the boards were cut up into puzzle pieces. I happened to have in my vacation photos a picture of the safety poster showing deck layouts (and sail layout). I did not have any plans and thus I’m warning the community that this is fun-quality rather than museum-quality! Here the first three boards (and the deck layouts prints of my photos below the). These represent the ship above the waterline. They will sit on two additional boards that contain the sea and the below waterline hull. The 5 layers will be held together by the 4 masts only, for which holes have been drilled under the appropriate angle. The hull was shaped by hand with the boards in a vice using a plane and sandpaper. next, the deckhouses, tenders and masts were added. I made a simplified deck planes, with color coded spaces (white-common spaces, red-passenger cabins, green-crew spaces) now turned all boards over and drew the puzzle pieces. A couple of days on my dremel jigsaw and numerous saw blades later I had around 300 puzzle pieces, still neatly arranged by deck. off the starboard bow is even an orca in the sea. Assembled: and then came the main test: it took about three hours to revert from the puzzle pieces to the model again. The normal strategy of finding the corners and edges first does not work, as there are so many of them….the motorised jigsaw was critical, as each puzzle piece must be cut perfectly vertical or the puzzle won’t fit. finally (and a few years) I added 16 more pieces in the form of 3D printed sails. She looks great and the puzzle has been completed several times! thanks for reading!

-

yesterday at my model boat club O-13 made her maiden test. Water was perfectly clear and just still liquid. The evening hours made it a great test for the LEDs (but somewhat scary for everything else). Made two small rounds, one on the surface and one semi submerged - the ballast is “on the safe side” and she does not want to dive at low speed yet. Filming was a challenge too but a friend at the club recorded the event. https://youtu.be/nnN6TKy9Hg0?si=mhxLVOyGmUrWRlAB

-

Recent focus has been on testing the boat. Based on the last bath test, I glued about 40 grams lead in the bow, and fixed with a small bolt 3 plates of 5 gram lead each inside the water tight compartment all the way in the bow. This for future trimming (as still a lot of small details need to be built and mounted). The stern was already heavy enough. Now, most photos of O-13 show her trimmed on the surface with bow high and the deck sloping down towards the stern. To achieve that and still keep the boat horizontal when dived, I glued a 30ml piece of building insulation foam in the stern, but above the waterline. I then placed 30 grams of lead under the foam and beneath the waterline. This cancels each other out when submerged, but pulls the stern down when on the surface. In the bath it looks “good enough” for now. In the bath the pump took 25 seconds to fill the tank and submerge the boat. That’s about the same as a WW2 sub could achieve. The pump actually works faster than its spec! The water sensor on the arduino now switches the pump off just when the mast, through which the air from the tank is pumped overboard, becomes filled with water. So it seems the tank fills completely (hopefully leaving no air bubble that can move fore and aft). The arduino also correctly measures the battery voltage and alarms when too low. The fore planes deploy but there is too much play in them. The crew goes below just before the dive but “forget” to close the hatches behind them. Oops. When the tank is full, the boat is trimmed to “decks awash” the props and diveplanes can then submerge the boat under very low speed. But that is for the next test. so the work on the technology is nearing completion, but much work remains. These pre-WW2 subs had a wooden deck, I want to build the “net cutters” on the bow, handrails, periscopes, radio antennas and bridge equipment, and of course get to painting. O-13 was deployed in 1937 during the Spanish Civil War to escort ships into the Mediterranean, and had clearly visible Dutch flags painted on the conning tower. That’s what I’m aiming for. its almost a year to the day since I started this build , I’m sure 2025 will see a lot more work on O-13 but also some nice sailings.

-

Happy holidays everyone! Captain below working as intended! https://youtube.com/shorts/58Pdq6fnKrM?feature=shared

-

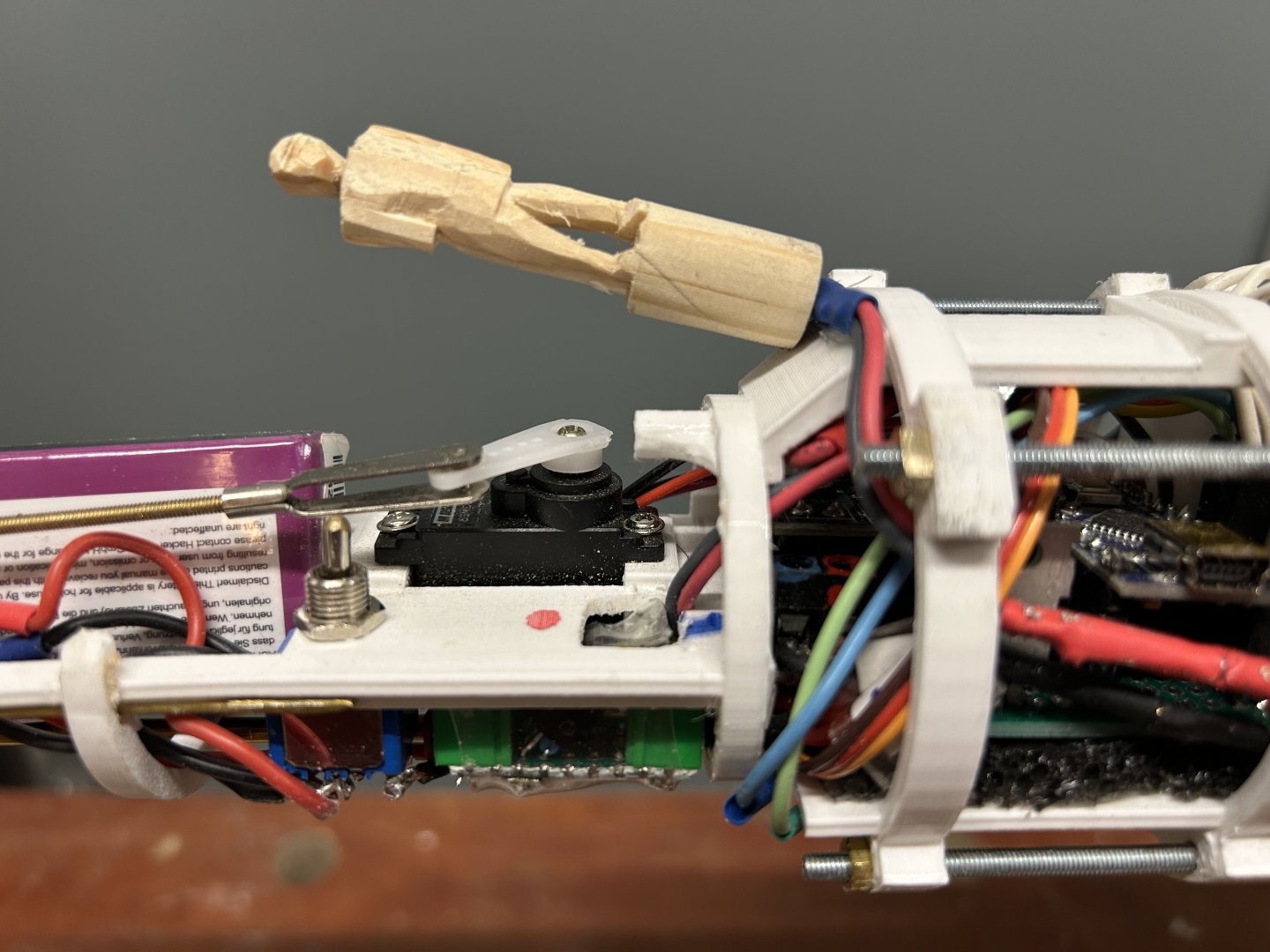

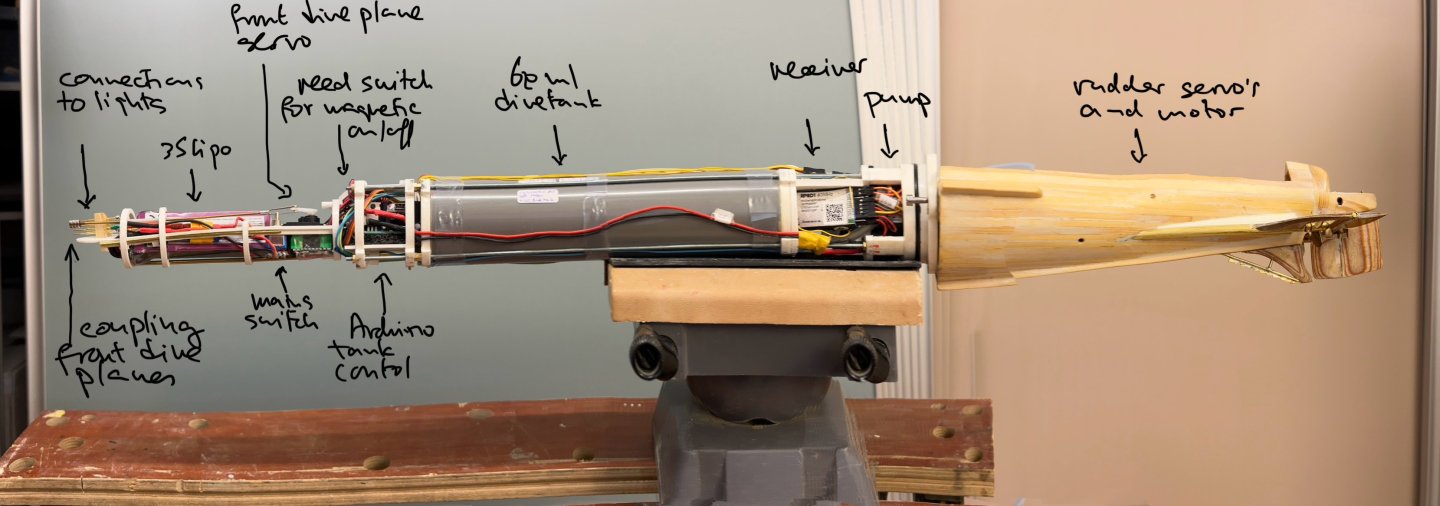

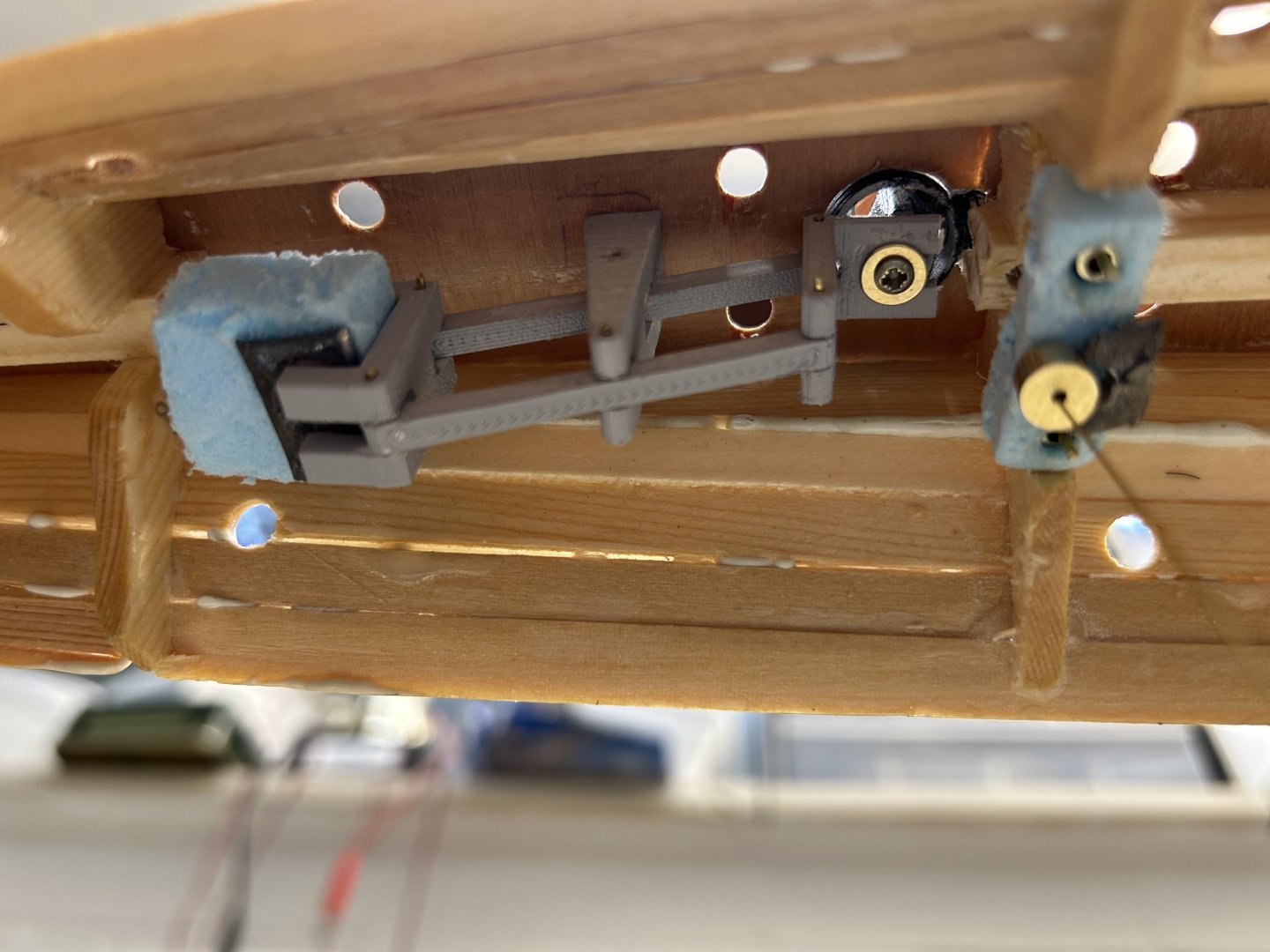

As usual, the first wetting of the boat has revealed some work. First, I glued 500 grams of lead in the bottom of the ship, below the WTC. Also the techrack has too much friction, so I straightened out the M3 wires and adjusted the nuts. Sanded all contact points with the PVC tubes. It now runs better. Also, I wanted a magnetic switch so the whole boat can be switched on and off without opening the bajonet, using a magnet. The normal units use relais, and I did not have the space for them. Instead I made a small circuit with one MOSFET, one resistor and a reed–switch. I’ve tested it switching up to 2.2A, and when the reed is open there is no measurable current use. Seems to work! The reedswitch is located inside the water tight compartment, underneath a hatch. I put a magnet inside a wooden crew member, and when I place this in the hatch, the boat is switched off. On removal before sailing, the boat is switched on. It just fits between the existing main switch inside the WTC and the Arduino controller. I think the techrack is now complete, and next step is to test the boat in the bath, further balancing, filling and emptying the temp to dive and raise the boat and unfolding of the planes.

-

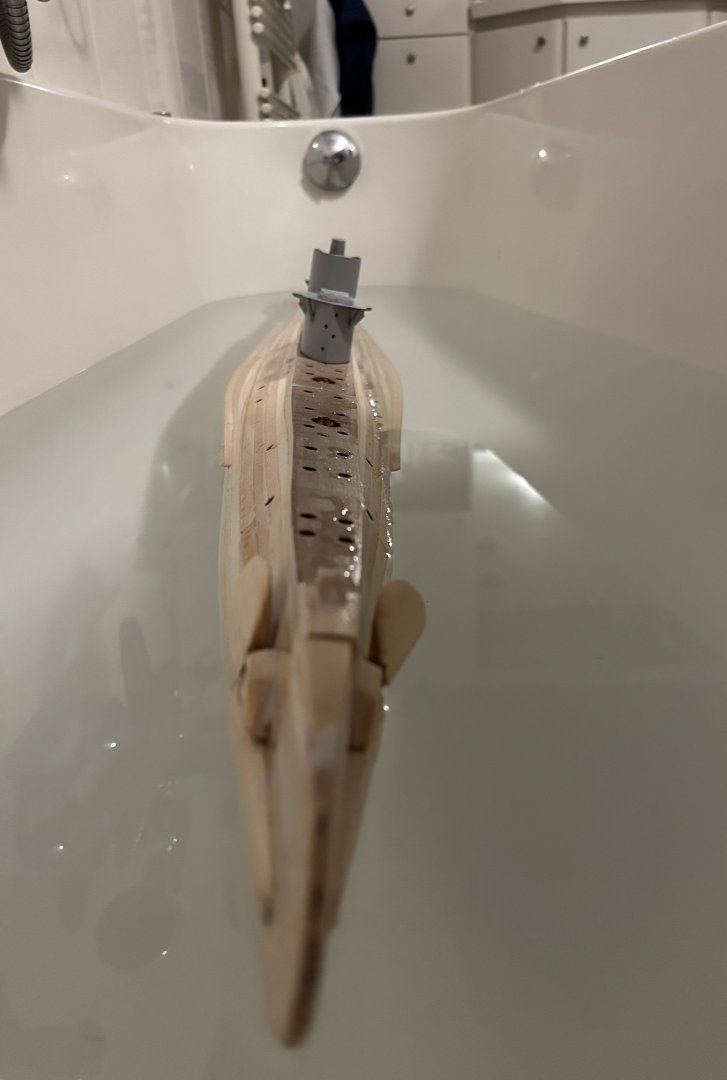

I tried the dome cap - but it did not solve the issue. So I looked for modifications to the double hinged balance - while maximising the vertical hight the (tall) Dutch captain can rise out of the hatch. I came up with a double hinged balance, with side by side pivot points. That seems to do it. I also tried to replace the blue foam floats for 3D printed hollow shapes which can be fitted more precise in the sail. On the top of the picture is the printed float. The three arms keep the float and the captains platform level. The two half-cylinder shapes left and right are connected and are the float to open and close the hatch still not sure if this will work in water with minimal differences in gravity force and archimedes’ buoyancy. Only a practical test will tell… but first I did a basic balance test, to see how much lead the boat needs. the WTC endcaps were glued, and replied until airtight (I blow in a tube as a waterproof test). Then the boat was “launched” in the bath. it needs about 800g plus 620g that simulates a full dive tank to “hover”. And when then removing the 620g the boat was reasonably on waterline. Needs trimming though very happy with this!! I have some more work to do to test the props and pump for the dive tank. And I need to review the front dive plane mechanism, the plane looks like it was hit by a depth charge.

-

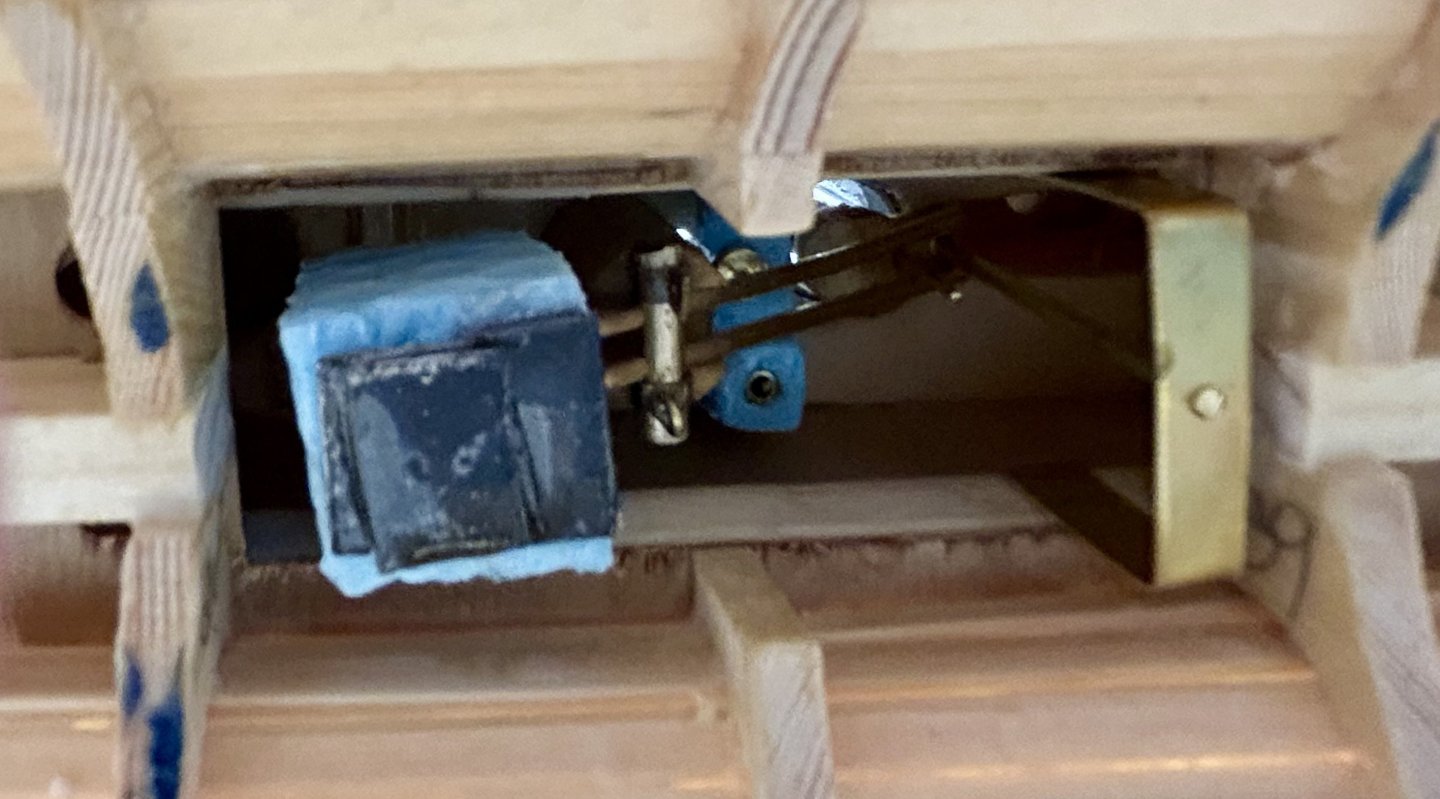

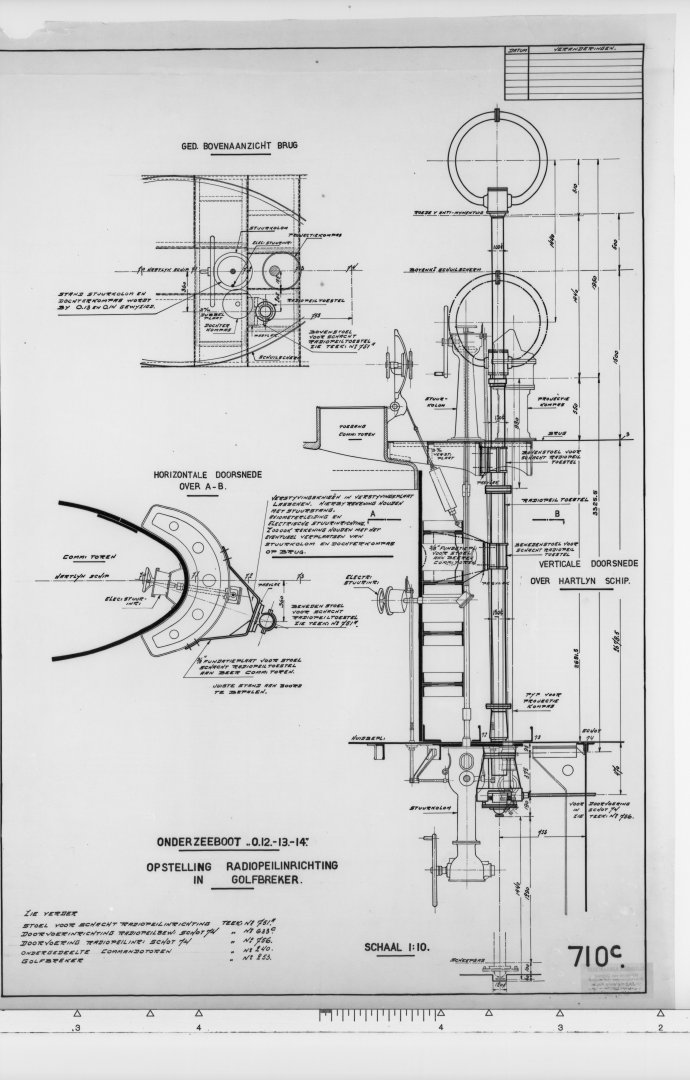

Working on the “captain below” feature. O-13 has 4 hatches. I’ve made those from wood before, but to have low friction hinges I decided to print these. All hatches should open when the boat surfaces, and close before submerging. The hatch to the forward torpedo room has just enough space below it for half a crewman to stock his torso out of the hatch. by the way; the 1:50 winch holds the mechanism below and is the first part made with my first ever, very old Unimat-3 Lathe! I’ve mounted him on a printed double-arm balance, so he comes vertically up. On the other side of the balance are a 4ml blue foam-float weighted with 2 gram lead. So a “driving force” of 2 gram to either raise the float when the deck floods or to lower it when the deck drains on surfacing. The hatch is driven by the 2ml float weighted with 1 gram of brass on the right of the pic. It all seems to work dry…. although there is more space underneath the bridge, the officer emerging from the hatch there has to rise full length, to be visible over the bridge rim. The double-arm balance did not fit there, so the officer is pushed up by a simple counterweight and is guided by a brass wire. It’s a little more iffy - likely needing optimisation. The nut will be replaced by a compass stand made on my lathe.

-

That’s exactly what I’m thinking of, plus I will try to also close the hatch mechanically once the captain is down. The drawing of the actual boat gave me some idea how to do that; the hatch can also be operated by a float below the deck

-

Now that the “insides” of the sub are more or less done ( still need to make the connection from the power inside the water tight compartment to lighting on the bridge and hull), I’ve worked more on the wooden boat itself. Next major step is a wet test - so the wood needs to be impregnated. I wanted most of the remaining work on the hull finished so I don’t compromise the epoxy impregnating with future sanding and sawing. Thus I’ve made the holes to flood the hull, and the holes to let the air escape as that happens. The front dive planes are hidden behind a structured that I read was actually a set of hydrophones along the hull (in the 1930s). The bow needed a face lift. O-14 had a single stern tube, firing over a teakwood “deck” located over the stern rudders. Presumably to protect the torpedo from bumping into the steel hull. the weather was great for a photo shoot of O-13, together with her now 12 years old younger sister K-18, built to defend the Dutch East Indies from the Japanese. Both models are 1:50, O-13 was smaller as it “only” needed to cover the North Sea and the Carabean - while the K-boats defended an area as large as Europe. the bajonet especially needs more tweaking to fit the parts better together and I’ve started on the mechanism to make the captain go below on diving.

-

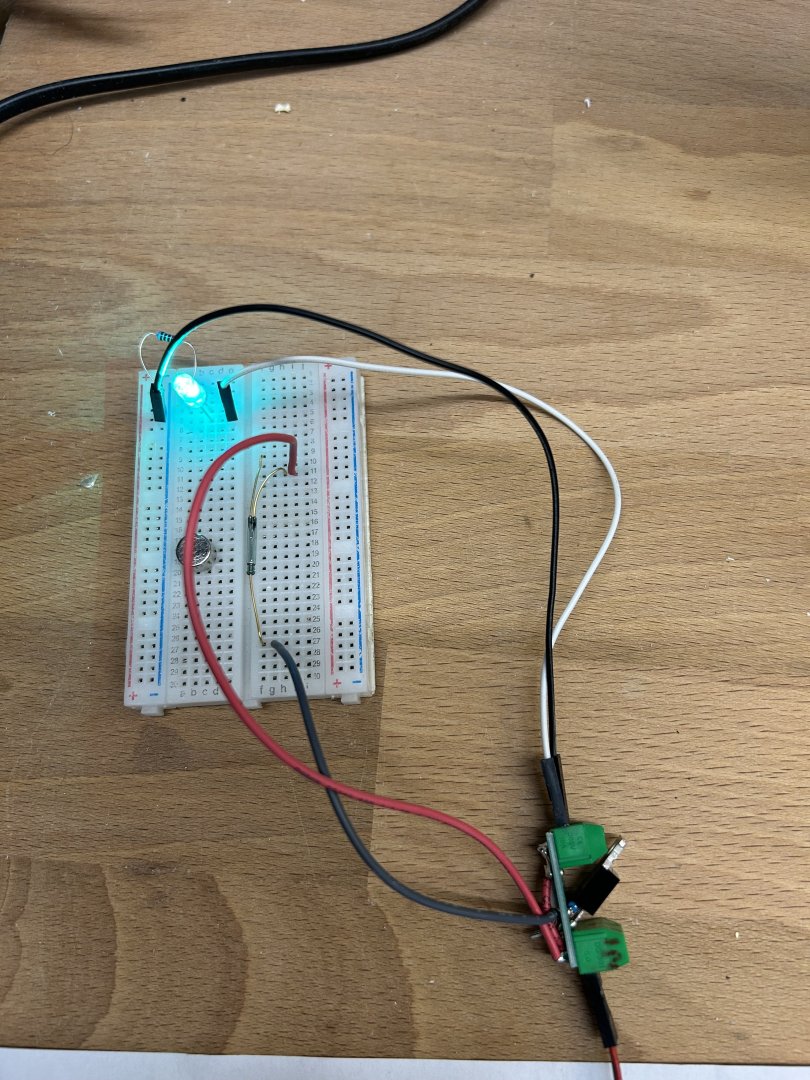

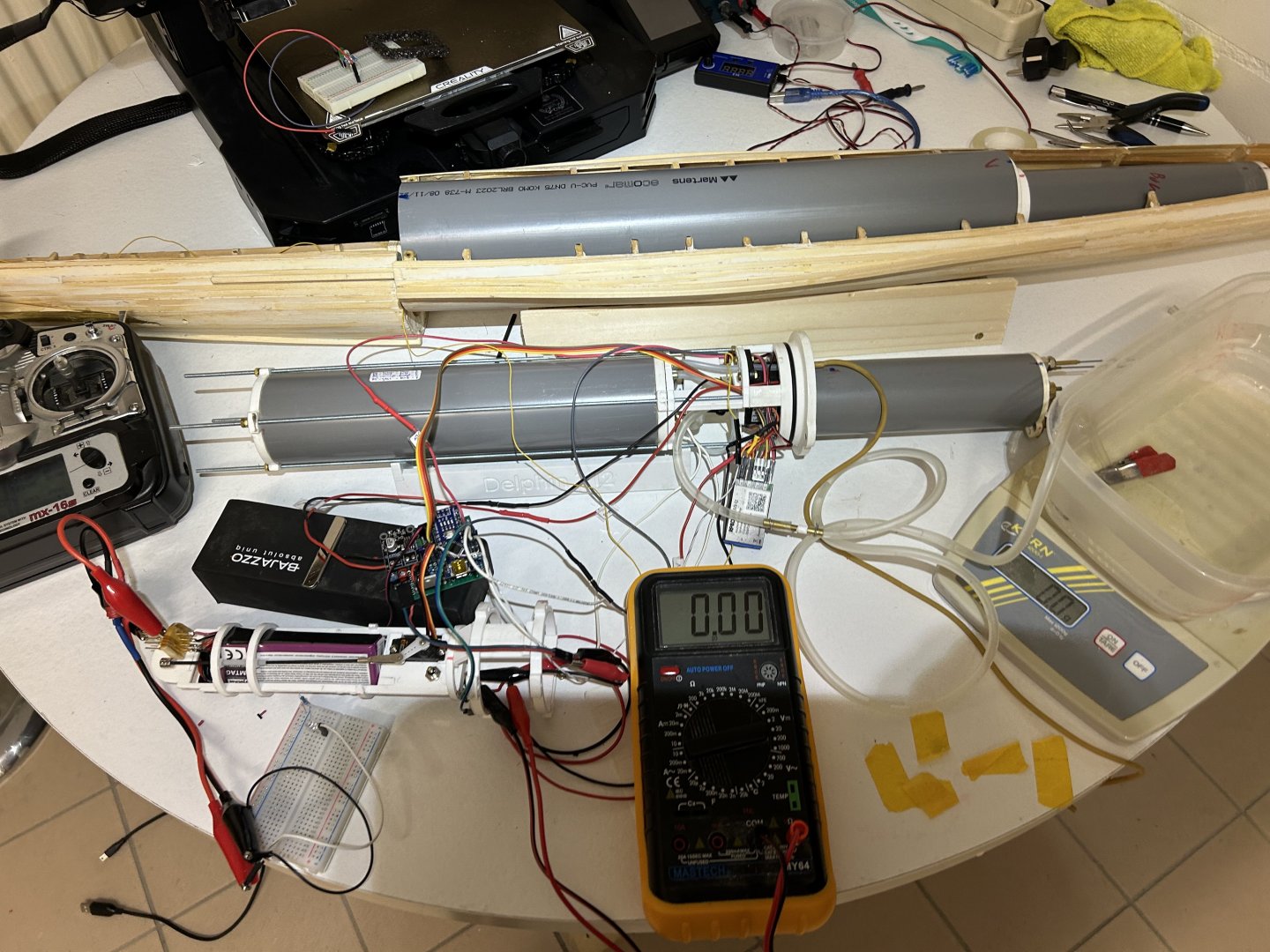

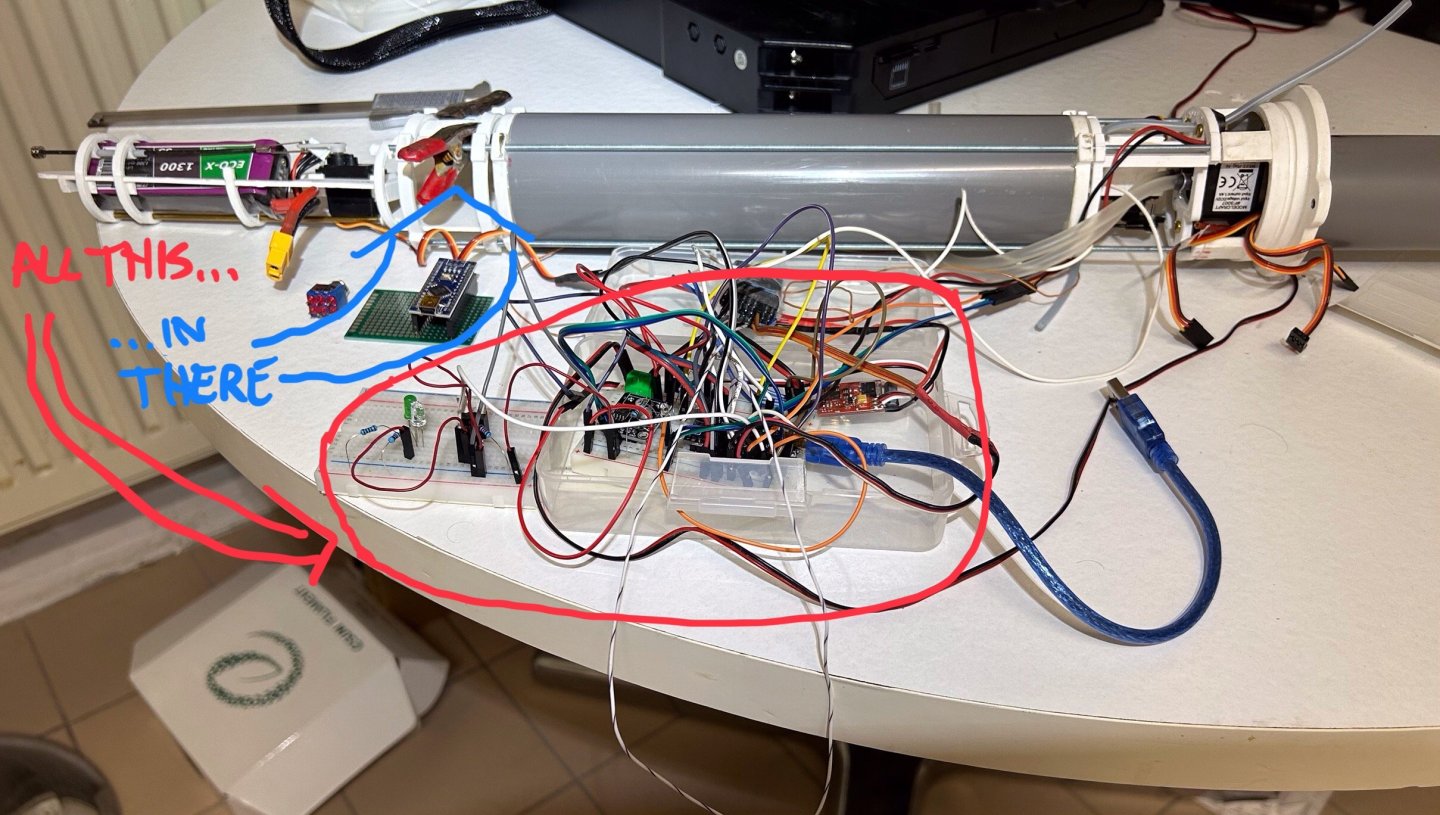

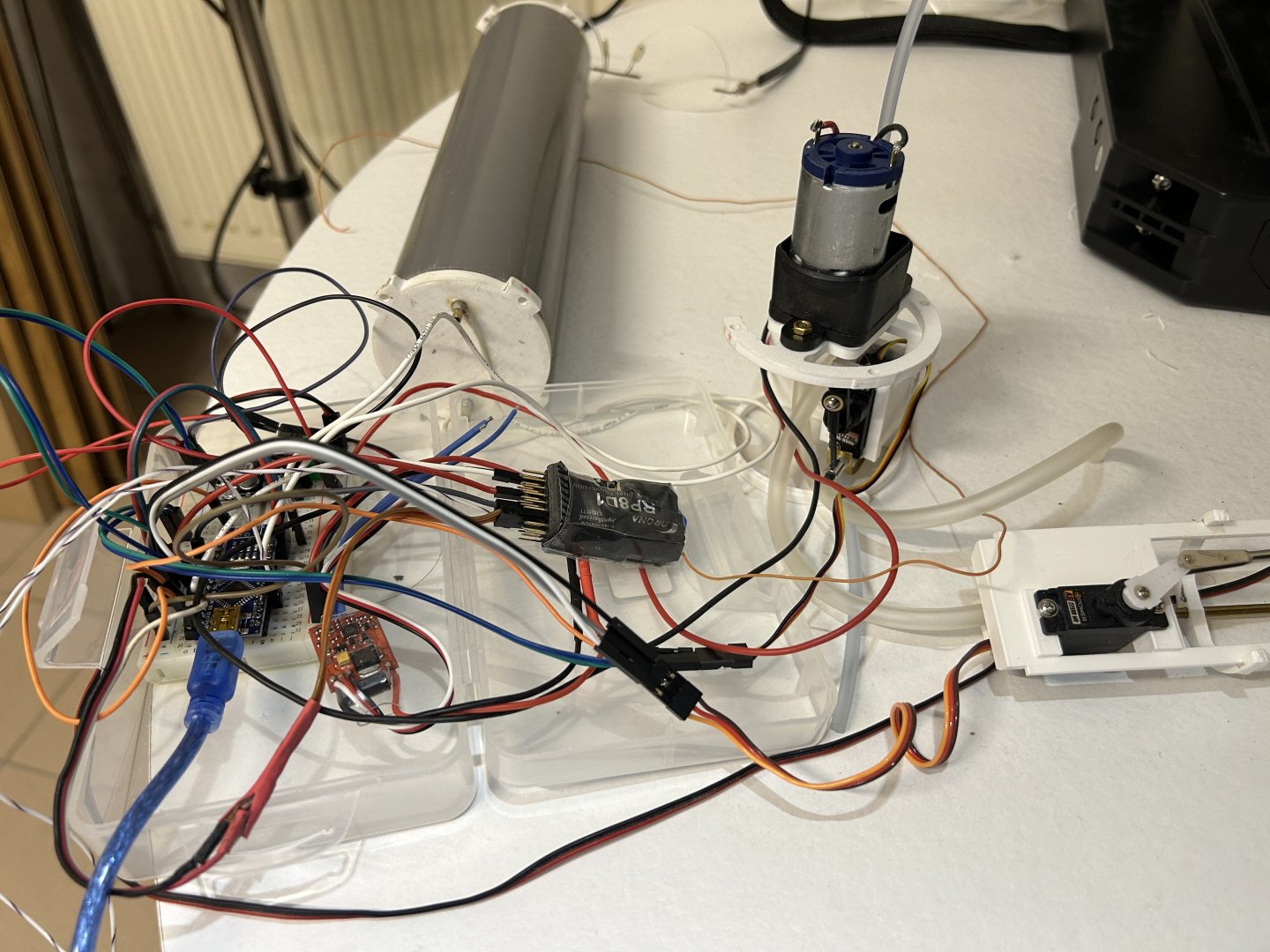

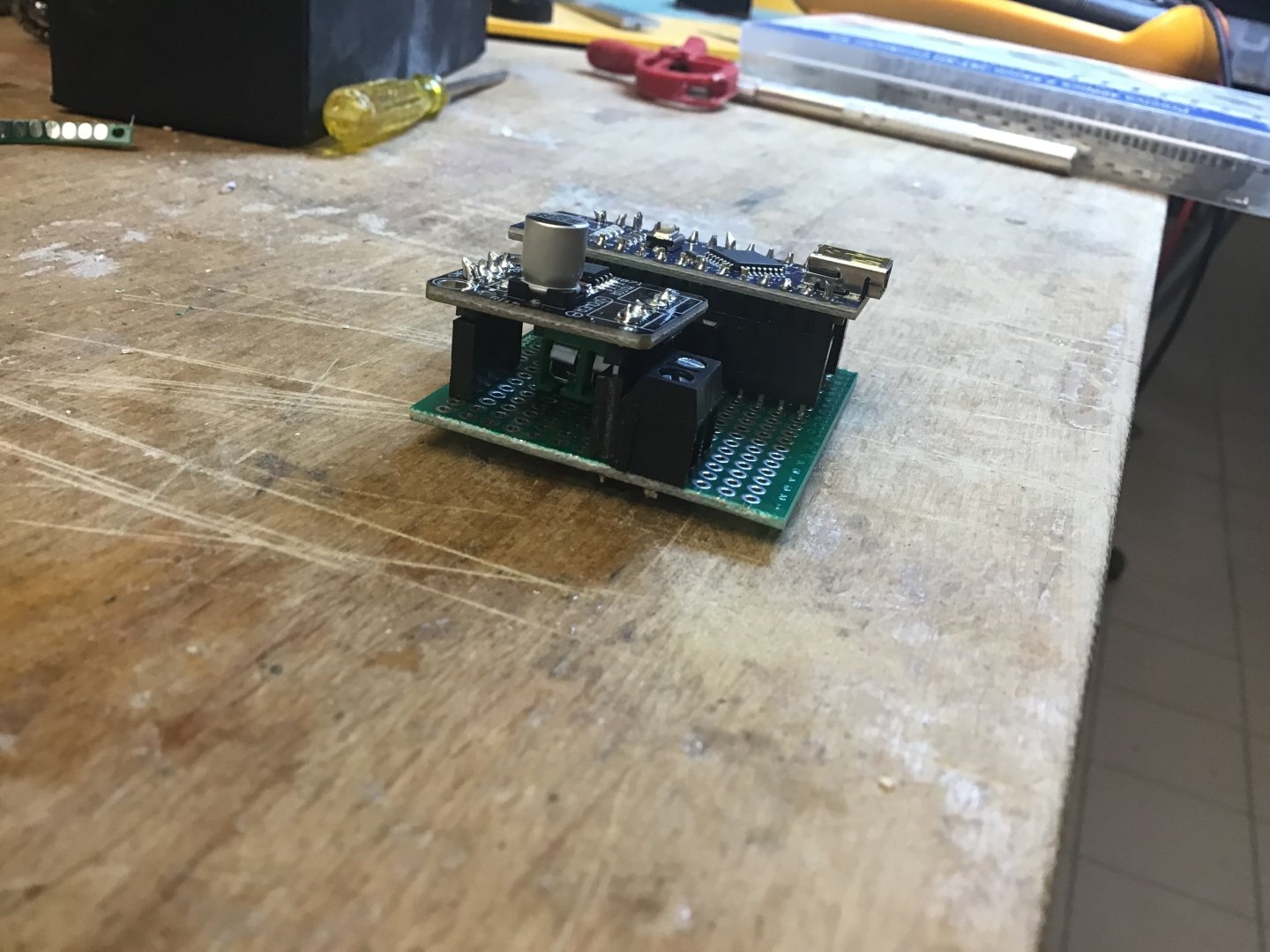

Last month or so has been the development of the arduino to control: 1. the pump pumping water in- and out of the ballast tank 2. The servo that folds/unfolds and operates the front diving planes 3. A low battery alarm and a water in the boat alarm, both resulting in surfacing the boat by emptying the ballast tank. 4. the navigation lights and alarm lights on the bridge it could get very geeky if I explain the details, but basically I’ve built a circuitboard first on a breadboard, with loose wiring to and from all components. realising all the “mess” needs to go into a small compartment next, I’ve soldered the components on a 4x6 cm circuit board (the max space available)and spent days finding soldering errors at the same time I wrote the sketch or software program and tested it dry. finally today I actually filled the tank with 570ml water before the pump shut off when the water sensors said it should, and emptied the tank again! Success! also did a first attempt to tidy things up so the whole assembly can slide into the waterproof PVC tube.

-

Mirabel, Great question shedding light on the post-build trimming! control at periscope depth typically depends on two things; - near perfect trim. Once the boat is watertight I will trim it in a tank with lead ballast (and sometimes with pieces of foam too). One must also make sure that if the boat has a ballast tank filled with water when dived, that there is no air bubble in it that may move around. Then trim during sailing, as the shape of the hull may impart some preference for the boat to rise or sink at some speed. the position of the ballast tank relative to the center of mass, the distribution of weight must be optimized to sometimes grams. That optimization can take months after the maiden…(at least with me). -a leveler like Norbert Bruggen’ Lageregler LR3. This is a piece of electronics between receiver and diveplanes. In the absence of up/down commands, it will operate the diveplanes to maintain the boat on an even keel. Commands from the transmitter are mixed with these. Levelers (or gyros) tend to work well for faster subs (like the 1:12 Delphin in the pic above). There are also subs with trim tanks fore and aft that automatically pump water around (just like real subs do) but I’ve not gone there yet… The most impressive boats tend to be the ones that can sail at periscope depth with very low speeds, when the leveler and diveplanes done do much any more. finally, as boats inevitably will go out of control or get lost from view, failsafes for loss of signal, low battery and water detected in the boat are used to force boats to rise (the 40mHz frequency used does not allow comms back to the transmitter). PS, I still always have eyes on the boat and two fingers nervously on the up/down control!

-

@Mirabell61 yes, that is exactly the problem. Skippers of surface models don’t spot a submerged submarine! Sub skippers always keep their eye on the tip of the periscope, the periscope wave, or slight decolorations where the boat is under water. That’s why sub skippers never remember who they were talking to at the waters edge! Generally, you sail as deep as you can just keep track of it. In a lake that is usually at periscope depth, or with clear water and little water reflection somewhat deeper. once or twice per year some outdoor pools offer the chance to sail subs on the day before that start or end of the season. Then you can sail just above the bottom and sail all sorts of maneuvers. I can really recommend it as a hobby, but you need to educate the other skippers in your club…..

-

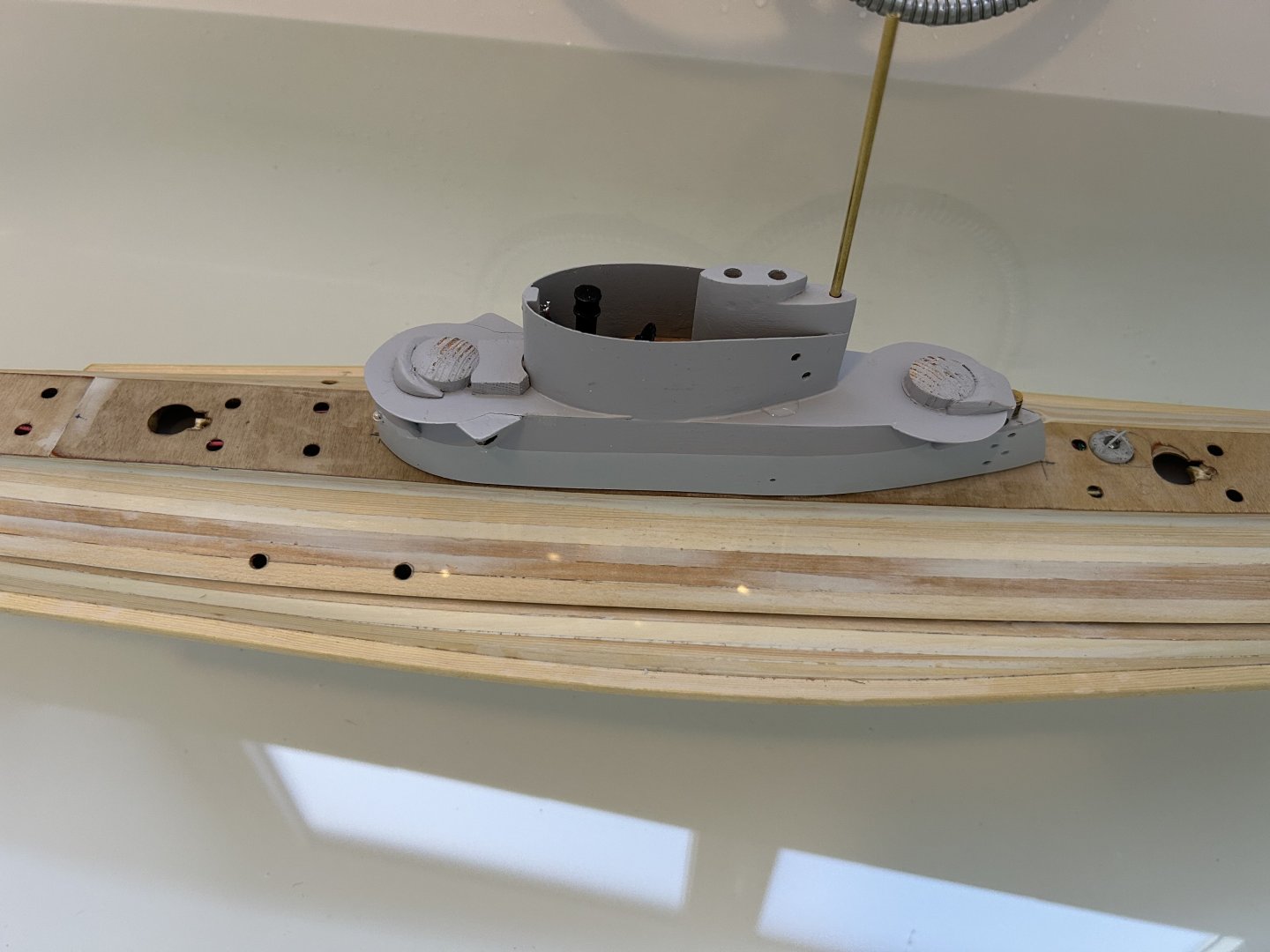

Been a while since the last update. Much time has gone into repair of other subs post sailing - either by being rammed by unobserving skippers of (surface) models, or by time causing small leaks. found time to continue work on O-13 too. The joint problem seems to result from the PVC pipe not being exactly centred on the bajonet. A few wedges have improved the situation a lot! The sail has been roughly built of wood - with some thoughts as to make moving periscopes, a captain on the bridge that disappears below when the boat dives, and room for LEDs. I might include one of the 40mm guns that sit in waterproof buns. I think the boat carries only one (and no deck gun) as it had chronic stability issues! Not sure about the movable persicopes, the WTC directly under the sail means they would only rise 5 or so cm, seems not worth the trouble to construct pushrods to a servo inside. the front of the boat now has the covers for the front dive planes and spaces for the anchors constructed. Needs quite a bit of fine tuning too.

-

Hi Keith, that workmate is 37 years old! But I only started modelling in 2009 so maybe it’s had an easier life than yours! yes that model is a 1:32 Holland class; its O-1, the first Dutch submarine built in 1905. It’s about 10 years old and sails well! Like O-13, it’s made of wood with a dive tank inside.

-

The diveplanes, rudder and propshafts have been finished - meaning they are functional and firmly attached, but removable for further sanding and coating. one very big risk is that I lack a flexible connection between motor and shafts - the prop - shaft - gearbox - motor turns easily but I’ll have to see if vibrations don’t cause problems. I’ve assembled the main control components, they slide onto 4 M3 wires to form the “techrack”. This assembly slides nicely into the PVC pipes that keep the water out. The home made bajonet needs some more thought - having only two bolts to connect the two halves of the boat means it rotates a bit too easily. ive now started on the sail - which will be built of 1mm boxwood on a frame - has some acute curves through.

-

Thanks Ron! I will watch that! I’ve been mounting and remounting the propshafts dozens of times to correct the alignement ! I’ll be mounting the gears on the shafts today I hope!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.