-

Posts

230 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FreekS

-

Thanks for the Likes and good wishes! Oer the Xmas holidays I’ve printed all 43 „windowsills“, and started finishing the three that mount on the dome-shaped bow of the hull. Takes some sanding and a few coats of primer-finisher but looks OK. From some copper tube I sawed the thin rings, which were filled with clear 30 minute epoxy. These will be mounted in the 6mm holes after the bow assembly recovers its white final color. Then I will cast the conical windows in place. next is to finish the 40 windowsills that mount on the sides of the cylindrical hull. Ones done so far. freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

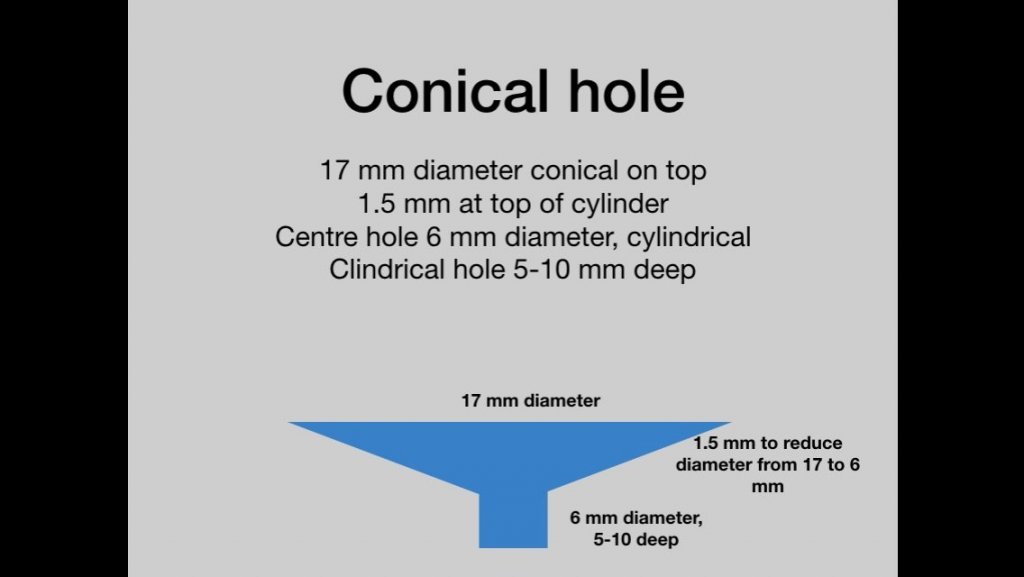

Hello all, as you may have noticed, I’ve had a long “dry” period. On the one hand I really could not figure out a way to create those 40 identical windows in the Auguste Piccard, and on the other hand I also took up another hobby - long distance running - which took up a lot of time. But the itch was often there - how do I solve this technical problem? so back to the windows. Up in this thread is a closeup picture of the windows, they are located somewhat below the heart line of the cylindrical hull, and are mounted vertically. That means there is a “structure” connecting the window to the hull which is different above and below the window. After much experimentation I’ve now come up with the following strategy - drill 6 mm holes in the hull - the actual windows - built a cutter to make this into a conical hole 17 mm round at the outside of the hull and 6 mm on the inside. I tried to make the cutter out of steel, could cut it in the right shape but could not drill two 0.8 mm holes through it to mount the cutter to a shaft. As I will use this cutter at 30000 rpm, i felt i meedeed the safety of two messing “rivets” to preventie the blade going airborn. So i toen Made the cutter from messing. Probably have to sharpen it after every few holes. - i used the cutter to drill some more holes in the “testhull” and it workshop, BUT, of course the holes are not circular due to me drieling with a circular cutter on a cylindrical part. Therefore that “connecting structure” I talked about needs to be made as well. And 40 times identical. - at this point I decided for a radical solution. I can 3D print these structures, which will give me a perfect round 19 mm windowsill connected to the hull. The conical hole will be closed with a 6 mm slice of copper tube, which is closed with transparent epoxy glue. Then I can pour the window from the outside. the 3D printer of course is not the problem, it’s the CAD that I will need to learn to design the parts. But eventually I found a free but sophisticated CAD program with huge numbers of online help videos (Autosketch Fusion 360), and after a few evenings had the part on the screen. The 3D Printer took 4 days to arrive from China, and the next day I printed my part. I’ve not poured a full window yet but at least I have a strategy and proof of concept. Pictures show some of the stages including the first two 3D designs and prints of the window strauctures (red), one double size of the other due to confusing radius with diameter !), the cutter, the finished bow of the sub and some of the holes for the windows Wish you all happy Xmas and much persistence and patience in 2018! Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

Hi Flip, you made a comment on my O-1 buildlog in 2014, indicaties you live in Vlissingen and might be able to fine Some images of het "dokje van Perry".

Ive built a stand and bought a transport case for the O-1, and now I'm interested in mounting a 40x70cm photo behind the model of the dockyard. Ideally it would be an early 1900s foto - I've seen many on internet but no high-resolution ones.

If if you happen to come across something like this or know where I could find it let me know! Appreciate it!

freek

-

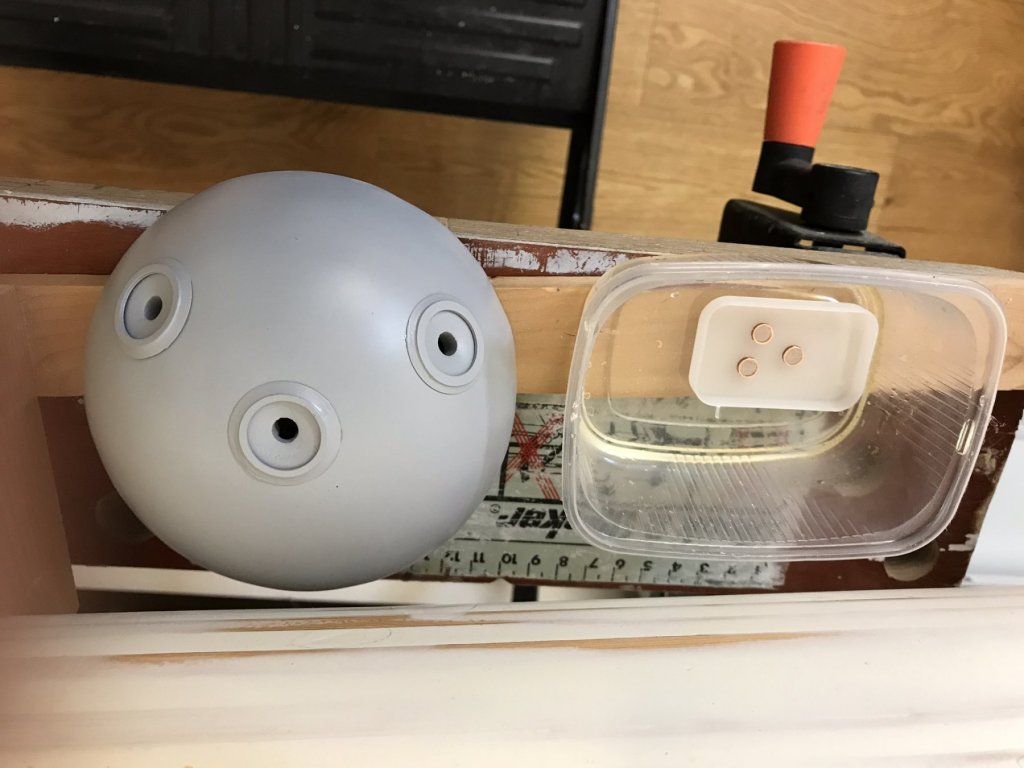

Hi all, Progress has been slow throughout the winter, I've been training for a first half marathon which is in three weeks, but recently I started feeling like experimenting again. One of the key elements will be the 40 viewing Windows in a waterproof hull. here is what those windows look like. My plan is to drill the holes for the Windows, conically sand then out, then treat the hull with glass fiber and epoxy resin, and then pour the Windows from transparent epoxy resin. Here is a test piece with on the left the drilled and sanded holes and on the right the first test. I'm not very satisfied, the structure of the glass fiber is somewhat visible and I need to think how to create the very thin metallic ring around the window. Comments and ideas very much appreciated. This has to be a robust process, as I have to repeat it 40 times and differences between the Windows would stand out! Greetings, Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

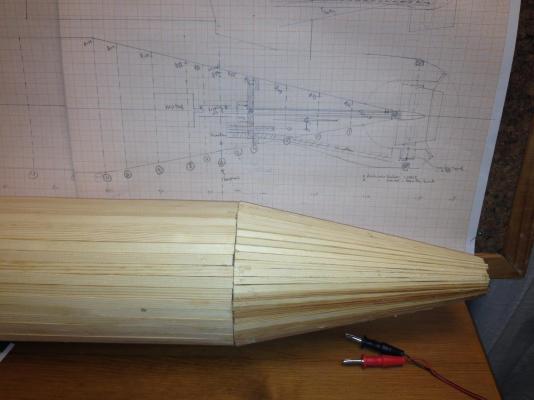

Another small update, basic planking of the pressure hull is finished, need to still make the domed bow but that can come later. I will start on rough sanding before impregnation with epoxy as part of the waterproofing. As part of the sanding the end cone on the stern with pre drilled hole for the prop shaft will be formed. The prop shaft will be made of a messing tube, in which are brass gliders placed, and a spring mounted shaft seal between the shaft and the housing. Exactly like I did for O-1, with the advantage that the whole thing is lubricated by water so no need to change grease. A propellor has been ordered from propshop (luckily it's a modification of an existing one and does not require a new mould), and also the first order for the dive system and bayonet has been placed with Norbert Brüggen Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

Like the O-1, the hull will be attacked with a saw and cut in two parts between which a bayonet closure will be installed! That's a ways down the line though.....I'm wearing a sports watch when I do that to monitor my heart rate...! Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

A small Update. The main hull is planked to a 75 cm cylinder and I started on the conical stern. The boat will get a hemispherical wooden bow, but I'll leave that open for now until the inside has been treated with epoxy and the Windows made. In front of the hull is a test piece for trying out ways to make the Windows. Greetings Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

Thanks again for the interest and the likes. I started building a week or so ago. The start is great, the frames of the boat are perfectly circular, and most are identical in size. There is no real keel, rather two identical ones with notches to hold the frames. Oh, and neither is the keel, as will rotate the boat 45 degrees so that these are not at the lowest point. I want to keep the bottom of the boat open to put in some sensors to detect accumulating water and alarm. Pictures of course are clearer (hopefully) In this third picture extra planks were fitted on either side of the "keels" between each set of frames. That enabled me to make the structure very stiff and totally straight, without the need for mounting the boat on a building plank. I guess that only works with symmetrical hulls like subs! Also visible in this last picture is the half-franc from 1963 glued to the keel. I shipbuilding tradition going back centuries and supposed to bring luck - always welcome in submarines. Planking the frames is usually where the skill of the builder becomes visible. Not here! It's a real beginners-hull, no stresses, no bending of the planks, no shaping of them. Easiest hull in the universe (and that's good as it's only the second plank of frame I ever did) So far today's update, we're basically in real time now so I'll be slowing down some (and the Xmas holiday is over). The advantage of that is that any suggestions from all of you can be acted upon! Happy New Year, Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

Thanks for the encouragement! Any project start with drawings. I found some sketches on the Internet in addition to the photo of the drawing in the museum. Then I made lots of photos of the boat itself in the Museum in Luzern. Based on that I have made basic drawings and rib plans on old fashioned millimeter paper (unbelievably still for sale!) Does that last picture say "Vancouver"? Yes after some years of tourist dives in the Lake of Geneva, the boat was sold, refitted for oil exploration type duties in the Caribean, and ultimately found somewhere in North America and brought back to Switserland. The basics of the build will be similar to HR Ms O-1, I.e. a plank on frame design, fitted with a bayonet ring to pull out the tech rack on which all electronics, pumps, motors and servos will be mounted. New for me will be the inclusion of lights, each window had a floodlight mounted in the saddle tank, then there were internal lights of course, and even the prop is illuminated by its own light - should be pretty in an evening event, but also LOTS of possibilities for leaks and shorts where wires go though the pressure hull. Below some of the sketches made from above materials! While doing this you also start to think of the sequence of the build, what to do first? What will be the most challenging (I think making the 40 windows in a way that they are clear AND leakproof! As well as the lights)? Also the rudder is integrated in the "jet-shroud" witted around the prop. I.e. Where the prop is fixed, it's shroud turns around the prop. And the pictures suggest the prop fits VERY snug inside the shroud...... I've made kind of a checklist of build items that I can continue to refine re-sort and add to.

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

A few months ago I started on my new project, it will be my third radio controlled submarine. "Auguste Piccard" was built in 1963 by the famous inventor family of the same name, who also built the bathyscaphe "Trieste 2", which reached the deepest point on earth. Auguste Piccard was a electrically powered submarine able to carry 40 passengers to the bottom of Lake Geneva, where the World Fair was held in 1964. The boat is reported to have made over a 1000 dives, transported over 33000 passengers and was recently completely restored and is now displayed in the "Verkehrshaus" in Luzern. A 30 meter long submarine in a landlocked country! I took a lot of pictures of the sub in that museum during two visits (one before and one after the restoration). I was lucky to also be able to make some photos of a book on display with a schematic drawing. I've not found any real drawings, though there is an actual model sailing around in Germany - I'm not the first to build her. The model will be 1:25, making the model 1.10 meter and 10 kg. Here are some pictures. Freek

- 55 replies

-

- auguste piccard

- submarine

-

(and 2 more)

Tagged with:

-

Thanks for the compliments! The torpedoes have an elastic band, made out of flight rubber and oiled somewhat. With that I can apply 300 windings before the elastic band breaks. The prop is only 9 mm diameter and has a cm or so pitch - theoretically I could get 3 meter-ish, but as the Torpedo starts to counter rotate and has slip I'm getting between 1 and 2 meters or so. Amazingly the speed is very high and I calculate that the prop reaches 18000 rpm or so. Piet, your father was serving on some of the most modern subs of his time! But those deck tubes were rarely used! Freek

-

OK, this is my other boat, hr ms K-XVIII, or the predecessor to Piets O-19. I finally had an opportunity to test the torpedoes. These are rubber motor driven - have a great speed but not much range! But it looked great!

-

Ter lering ende vermaak! http://www.dutchfleet.net/showthread.php/16630-Proefvaart-en-overdracht-Hr-Ms-O-19?p=108753&viewfull=1#post108753 Fantastic how your boat looks. Freek

-

Piet, Your O-19 is really beautiful! Fantastic detail! I'm sure you've considered mounting the boat on the kind of blocks that she would rest on in a drydock. I've seen several models mounted this way and it adds nicely to the real circumstance. Of course, then you'd have to explain why a perfectly looking boat would enter Drydock...... Alternatively, how good are you building a reef? Freek

-

The model is 28 cm (or 11-odd inches) long. It's a 1:350 scale model of a adapted British destroyer design built in the Netherlands in 1929 to 1931. Modern in its time, they were completely outclassed by 1942. As to knowledge of this naval event in history, the battle of the Java Sea (in which two of the eight of these took part) was the largest surfac gun engagement since the battle of Jutland - not that is impressive. 10 allied (American, British, Australian and Dutch) cruisers and destroyers were lost trying to interdict the main invasion fleet heading to Java, mainly by the superiority of Japanese gun calipers, their superb long lance torpedoes, and their almost total air superiority. It was a very tragic battle lost in the 1930s military budgets, costing over 2100 lives and delaying the invasion of Java by exactly 1 day. Other destroyers of this class faced even more insurmountable odds, one was the escorting a merchant ship and became the sole focus of hours of air attacks from a Japanese fleet carrier, and another faced German Stuka divebombers trying to displace German paratroopers in Rotterdam. I think very few Dutch people know this part of history, except for the famous last words of Admiral Karel Doorman Leading the Allied ships into the Battle of the Java Sea: " ik val aan, volg mij". (I attack, all ships follow me). Our newest, largest ever and soon to be commissioned Navy ship was named after him. Freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

the model is finished. I've decided on the name Hr Ms Banckert. this destroyer was in dry dock in Soerabaya when the Japanese invaded Java, and was sunk (including drydock) by my other model Hr Ms K-XVIII (herself then destroyed by her crew). All 8 of the class were sunk in WW2, one by the Germans in Rotterdam and the others by the Japanese in the Dutch East Indies. The first time working with PE and with airbrush has not been a disappointment. With a lot of patience it was well doable and the overall level of detail that Boris built into this model is very nice. pacific Crossroads has a set of models of many other Dutch warships that fought in the pacific, and I can certainly recommend then to anyone interested. freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Last dast day of the holidays Further work towards the stern, starting to look like a real "jager"! Freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Another day work - a few hand wheels lost and mother few errors but on the whole it's starting to look like a nice destroyer. Freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

The Admiralen class destroyers were a series of eight destroyers built between 1928 and 1931 for the Dutch Navy. All were lost in WW2, one in Rotterdam and seven in the Dutch East Indies. The kit is from Pacific Crossroads, designed by Boris Mulenko, who is Russian and has built models of many of the Dutch ships that fought in the Pacific. The kit is a mix of resin parts and PE, and I have never used either. Here are some of my pictures of the start of the project Started with my (also new) airbrush. I practiced a bit on a small helo project (still visible!) but now started using it in earnest. Waterline is nice and straight and painting the PE before use seems to work. I put the resin parts onto double sided tape. The hull after painting on the box from Boris. First experience with PE - I bought one of those bending tools and read a bit on Internet. Main tool seems to be patience and it's still holiday... The nearly completed bridge, I count only 7 errors (all of them thinking errors - wrong parts on wrong places etc) ! And a start on the 75 mm gun platform between the funnels. All for now - so far I like the work and I very impressed with the extreme detail in the kit. freek

- 7 replies

-

- admiralen class destroyer

- pacific crossroads

-

(and 2 more)

Tagged with:

-

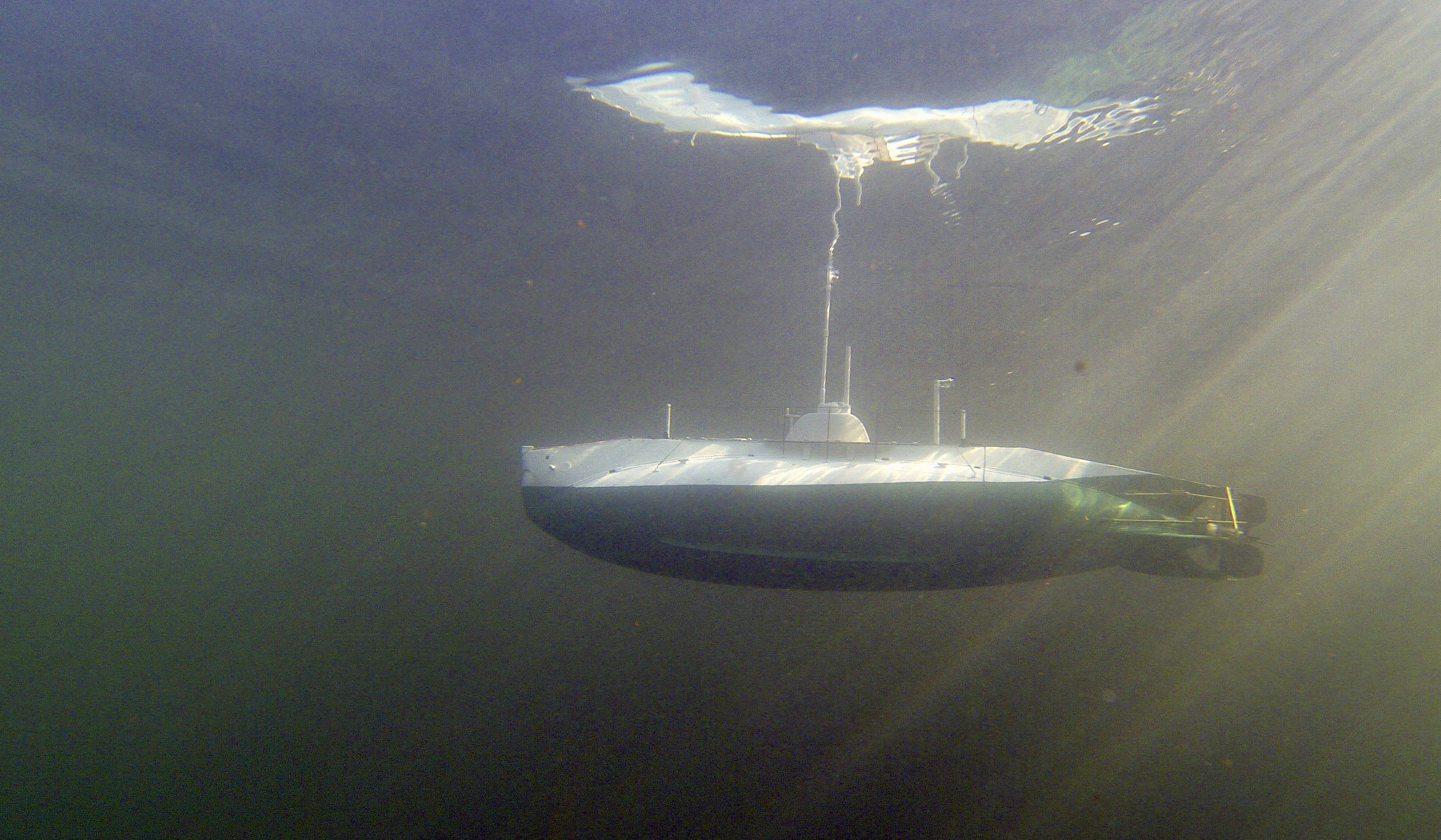

Hi all November 23rd, 12 degrees C outside and sunny! Today I went back to the cologne rowing club waters, my sub was followed under water by an ROV taking pictures. I must say, model subs look fabulous in their own element! Still some work planned, I want to replace the wires to the mast (they stretch too much), install turnbuckles, decals, and a few other things Freek

-

Hello all, Slowly this thread is turning into a sailing rather than a building log! Last weekends trip to a nice clear lake in Cologne, home of the oldest German model sub club. Note slight damage due to underwater collision Also note the even older sub encountered in the last few seconds... Freek

-

After the "shakedown cruise", as Piet called it, some more details were added to the boat. I redid the waterline, though still not as good as I want it. Added supports for the deck, a forward guide bar for the anchor chain, cables on the mast and a flag in top. Also copied one of Piets additions, the "pikhaak". Which was stored under the deck. A flag was used by these boats on exercises so the "enemy" Could keep track of the subs movement and prevent collisions. In the 1909 and 1910 Dutch Navy exercises the boat sank the armoured cruisers of the surface fleet! the boat has now hads its second voyage, in de Vinkeveense plassen, nice and clear water in the centre of holland where this picture was taken. Again unfortunately the photographer did not capture the dozens of other models of Dutch Navy ships that were sailing around!

-

Piet, see here how Paul Burghorn has made the plans for his sloep http://www.modelbouwforum.nl/forums/bouwverslagen-schepen/139613-mijnenlegger-hr-ms-nautilus-1930-1941-a-13.html Freek

-

Boris there is nice model of the O-1 and two of KXVIII in Den Helder. I agree Piets model competes well with them, but musea are not that keen on static model displays anymore, nowadays it has to have buttons, a screen and a theme! Freek

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.