-

Posts

1,915 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by cdrusn89

-

-

Quick look through Wikipedia and the 1934 Rainbow hull was made of bronze plates on an iron frame so the cleats were probably something other than wood.

I am going to use the provided cleats "as is" after I clean the mold marks off the bottom so they will sit flat on the deck.

-

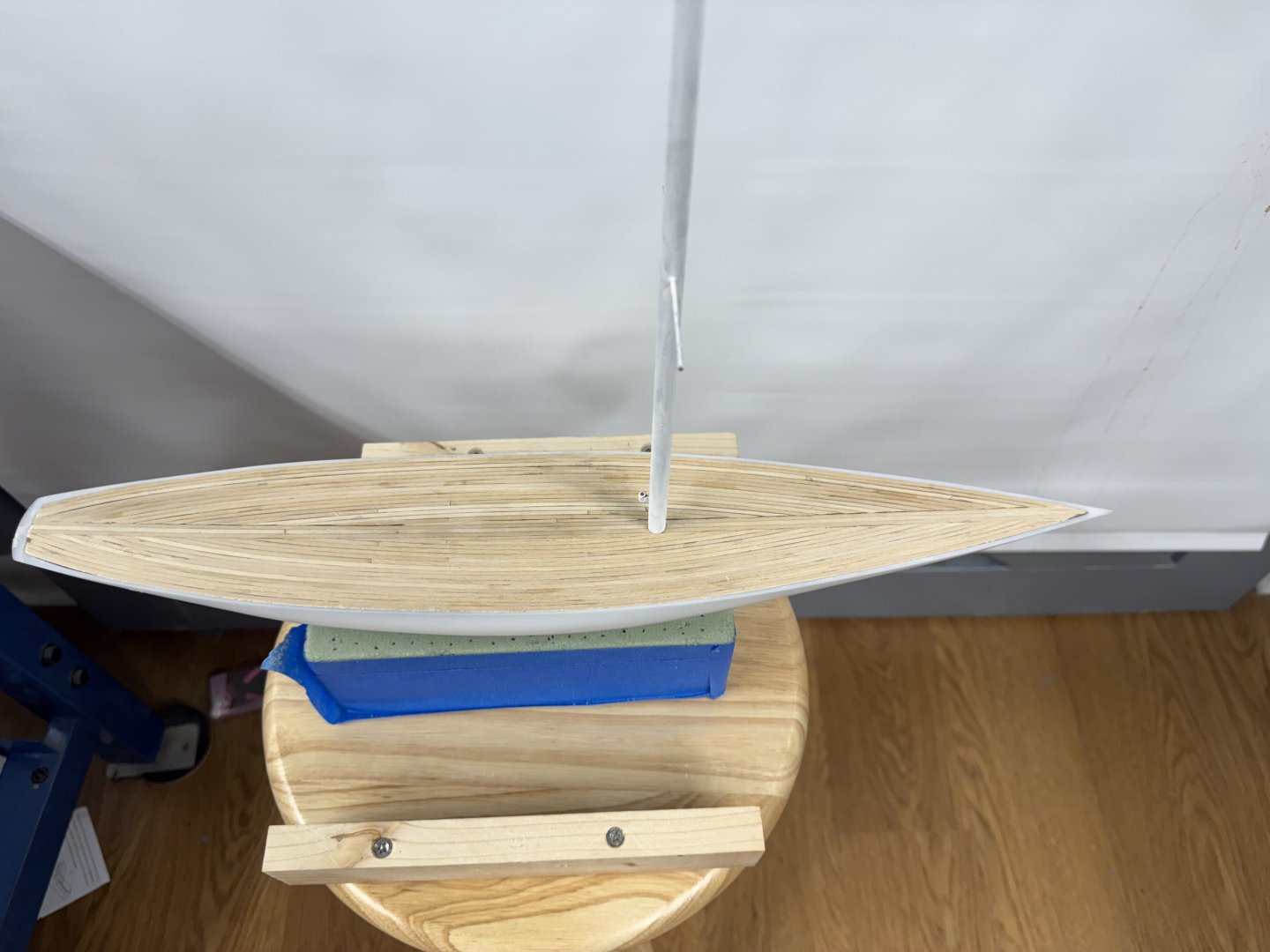

Deck planking is completed. Exactly one full length piece of planking material extra plus half a dozen much shorter pieces. Be careful with the planking, there is not much to spare.

No sanding or finish on the deck yet. Plan of a 220 and 320 sanding and at least three coats of Wipe-on-Poly to protect the deck hen my masking prowess proves to be less than satisfactory. The pictures of the finished model at the end of the instructions shows that the area on top of the hull at the bow and stern is painted the same as the hull so the deck needs to be masked off very well as I will have to spray the top of the hull at least at the bow and stern.

I also have the second coat of white on the mast. It needs one more. Boom has three coats and just needs some touch up and it is ready .

Tamiya primer spray paint arrived today so once the deck finish is applied and masked it will be time to start painting the hull.

While the hull is drying between coats I will work on the sails and figuring out what to do about cleats. Syren boxwood ones are still not here. Will at least prime the Britannia metal ones from the kit. Not sure what material was used for them on the real boat. If the hull is aluminum as I seem to remember reading somewhere than I suspect the cleats were also aluminum so maybe leaving them as is would work too.

- king derelict and gsdpic

-

2

2

-

I started planking the deck. As I said above I started with three planks down the centerline then moved to the outboard edge and working inward per the instructions.

Before I started the starboard side I divided the planking strips up evenly to see how much "loss" was permitted.

I got the starboard side completed but had to resort to cutting planks when it became obvious that there were not enough full length planks to cover the entire deck. No mention of this in the instructions nor in the drawings (there are NO pictures of the model under construction in the instructions only somewhat stylized drawing )showing the planked deck.

Here is what I had left over. with the starboard side completed.

None of these are over 6" long so you need to be "thrifty" with the planks or you will run out.

Here is the starboard side with the deck planked.

One potential problem for later is that the deck planks are not flush with the hull sides at the bow and stern. Amidships the top of the hull and deck planks are pretty much at the same level but as you move forward and aft the deck rises above the hull sides.

When I sand the deck after all the planking is done i will try and whittle the difference down but I think the will be some deck "sticking up" unless I can figure out a way to add the missing bulwarks.

Something to think about while I plank the port side.

- king derelict, eatcrow2 and catopower

-

3

3

-

Thanks Clare - here is the link to my notman build log:

-

I got the second coat of clear flat on deck furniture and assembled and primed the winch grinder. A note that the nails provided in the kit to link the arms to the center body and become the handles are way, way too thin. I used a piece of .7mm brass rod and that worked more or less perfectly.

The window maker has not come completely clear (sort of a fog) in four of the windows but I am hoping it is just taking more time where the material is heaviest. It is difficult (for me) to get a consistent thickness across all the area.

I broke out the laser to get a good centerline on the deck as I have decided to plank the deck before painting the hull. My spray primer is still 6 days out according to UPS. My plan is to lay a single plank down the centerline and then add one additional plate on either side before shifting to planking from the edges inward. The instructions say to have two planks down the centerline but I find that somewhat difficult (for me) to accomplish. I find it easier to lay one plank as I find it easier to line it up on centerline rather than just a bit to one side.No mention in the instructions about caulking between the planks but I am going to do it anyway. It probably was not used on the real Rainbow as I believe both the 1934 boats were built of aluminum so the wood decking was just there to provide a better gripping surface than just the aluminum - could be wrong but...

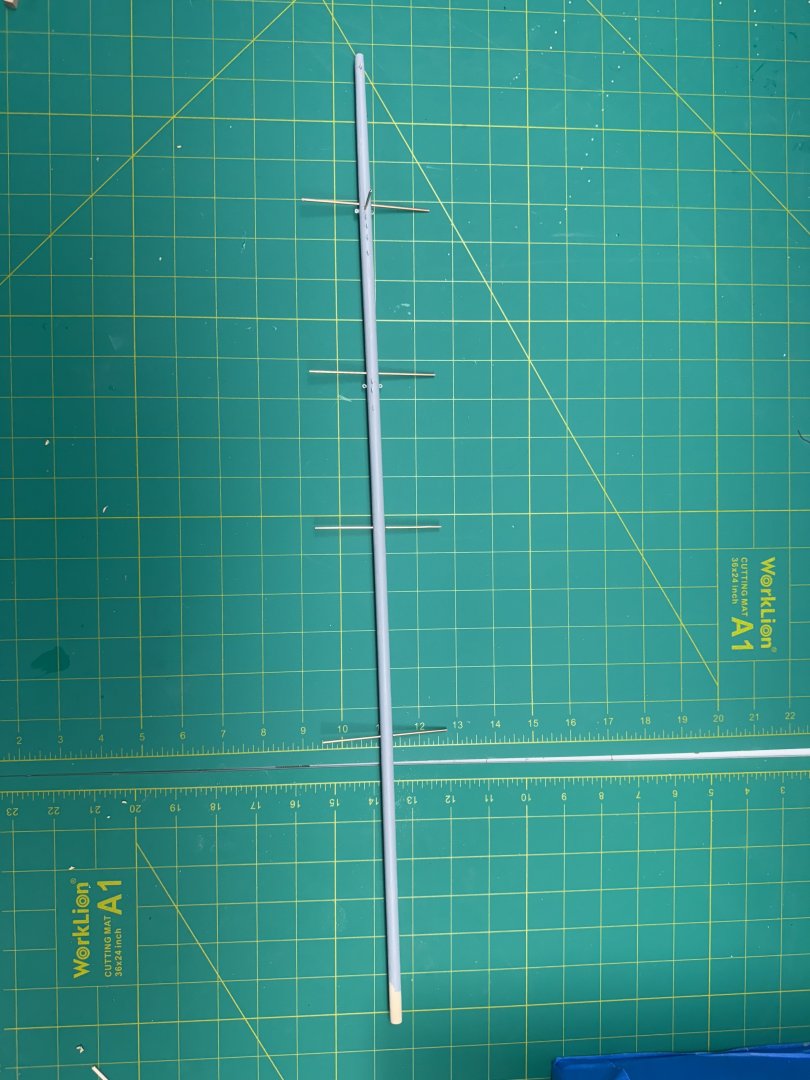

I got all the spreaders and eyebolts installed on the mast. Still have to add the eyebolts to the ends of the spreaders but that wil come after I am sure all the spreaders are properly allined.

More deck to plank while I adjust the spreaders and paint the boom.

- Ronald-V, eatcrow2, MAGIC's Craig and 3 others

-

6

6

-

-

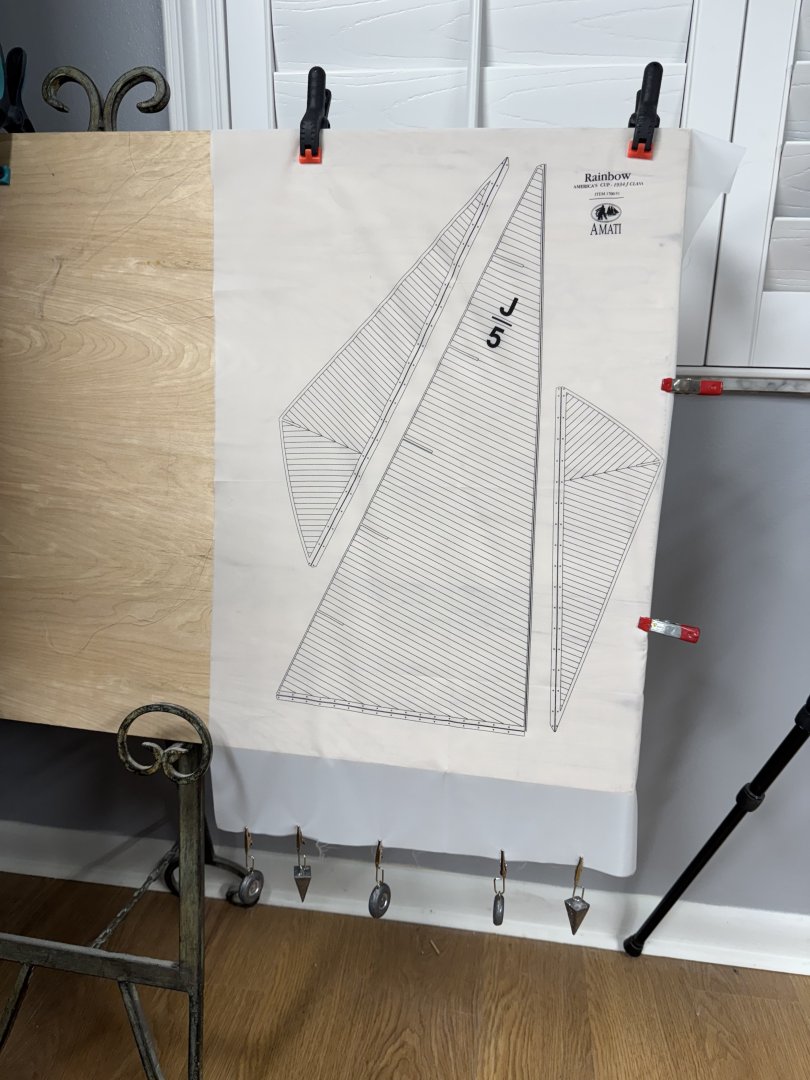

I took out the sails and decided maybe it would be a good idea to hang them up to at least reduce the creases from being folded in the box for who knows how long.

Seeing the fuzz at the bottom of the sheet makes me want to use fabric glue along the line when they are cut out. Don't ask me how I know but once the fraying starts it is hard to stop.

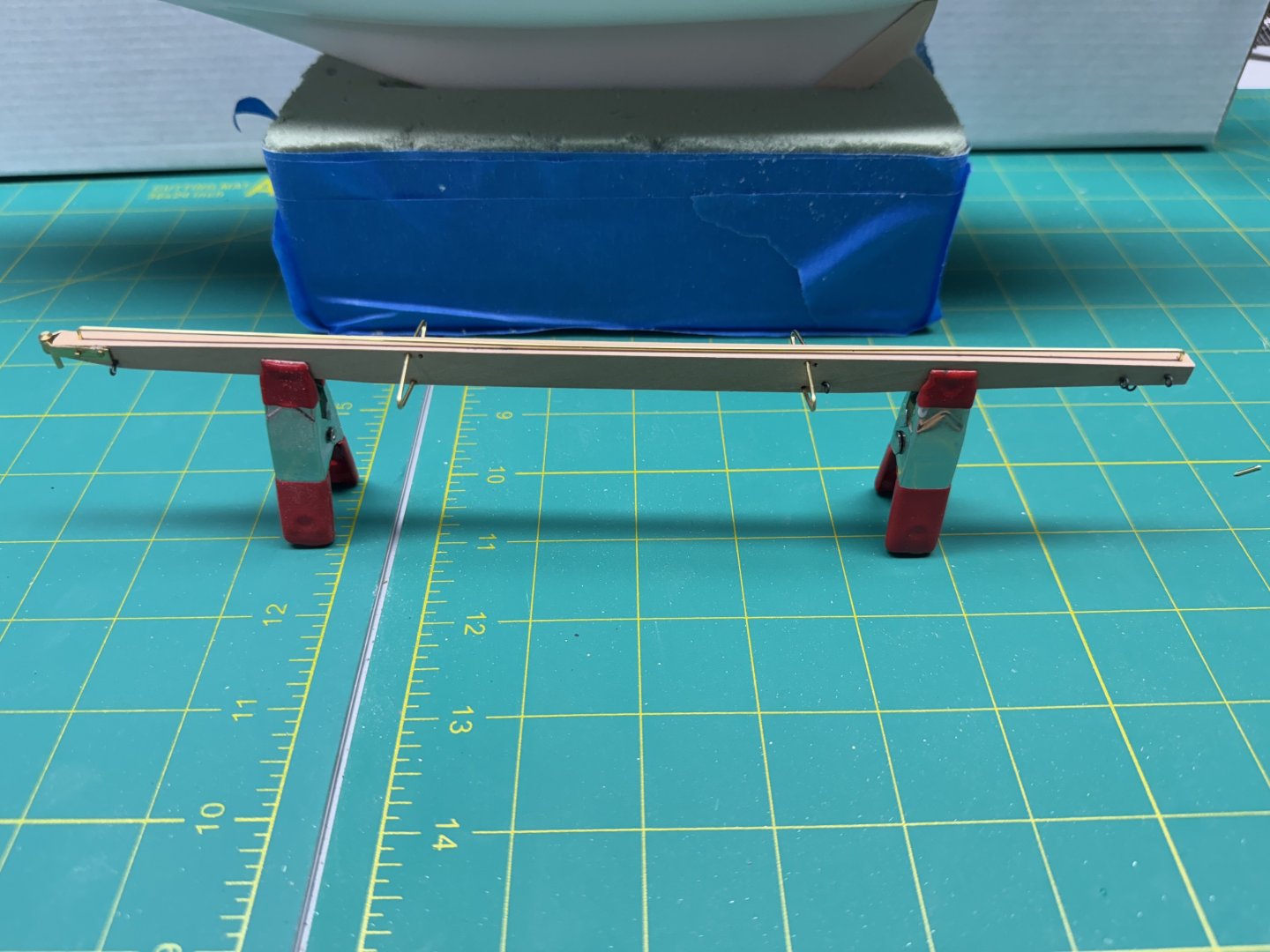

I finished the boom and its hardware. Instead of the supplied eye bolts I made my own from 24 gauge wire with an .047 "hole" which is close to what would been obtained using the ones supplied. A word of caution for anyone else who builds this - there is one 24" brass rod (1mm) supplied for all the brass needed for the boom. That is not enough to make more than a mistake or two cutting the pieces for the four arms and "arch" (the rod across the top of the boom where the mainsail attaches). Also the nails supplied with the "gooseneck" (where boom attaches to mast) are way too long. I had to cut the nails to less than half the delivered length. I am thinking about putting some primer on the brass as I neglected to clean it before but I had to handle it enough that I doubt a prior cleaning would be good enough.

I also got the nav equipment painted and a first coat of clear flat on the deck furniture.

I am going to suspend work on Rainbow and shift focus to taking pictures of a previous build for the NRG Photo Contest. I should be back to Rainbow in a day or two.

-

While I let the deck furniture dry overnight before applying the clear coat I started working some of the other items not the hull.

I got out the navigation items which are all cast in brass. I had to clean up the areas where the material ran into the mold and the bottoms needed a good deal of filing to get flat. I plan to paint the portions that do not remain brass with a surface primer before trying to add the brown and red/green as I have little faith the the acrylic paint will stick to the brass. As further insurance I have cleaned all three pieces with 99% isopropyl alcohol - another item left to dry overnight

I cut the tapers in the boom as shown in the drawing then decided that given all the "things" that get attached to the boom, all of which are painted white I should get the wooden part ready for painting before adding the other "stuff" so I sanded it with 220 paper and then applied a sanding sealer. Will sand again in the morning then start adding the holes and such.

The cleats (for the boom and deck) present a quandary. were the cleats on the real rainbow made of metal and thus do not have to be painted? Or were they something else (wood) that would be better represented by some wooden cleats that would be procured (like from Syren where both3.5mm and 5mm cleats in boxwood are available). I will look at my build log for the 1/35 scale Endeavour I built a few years back and see what I did there. I would go look at the model but need a step ladder to see it atop one of the ship model dsplay cases. It is so big it would overpower any room where it sat. Plus since I do not have a case for it (it is almost 5' tall) I do not see the dust building up.

Anyway here is the boom with the sanding sealer drying. I have not cut the boom to it final length yet to have easy placxes to hold it.

I tapered the mast and added the fittings at the top. I could not get the supplied eye bolt to engage because there is very little room behind the filler piece so i used a home made eye bolt. It is all going to be painted white anyway so all I need is a place to hold the bitter end of the main halyard tackle (the other end gets glued into the opening above the eye bolt).

The mast also has a coat of sanding sealer and will be treated the same as the boom getting all the "extras" added on before painting.

- catopower, gsdpic, SiriusVoyager and 2 others

-

5

5

-

My test run of the window maker was a success (IMHO)

So I went ahead and assembled and painted the deck furniture. I added some flat red to the Vallejo flat brown to try and approximate mahogany but it still looks mostly brown to me. Oh well, the deck furniture is not the focus on this model (hopefully).

I will wait until the clear coat(s) are on the deck furniture before I "fill in" the windows. No sense making applying the clear coat difficult by having to keep it off the windows.

On to the mast and boom while I let the paint dry thoroughly.

- gsdpic, Knocklouder, catopower and 1 other

-

4

4

-

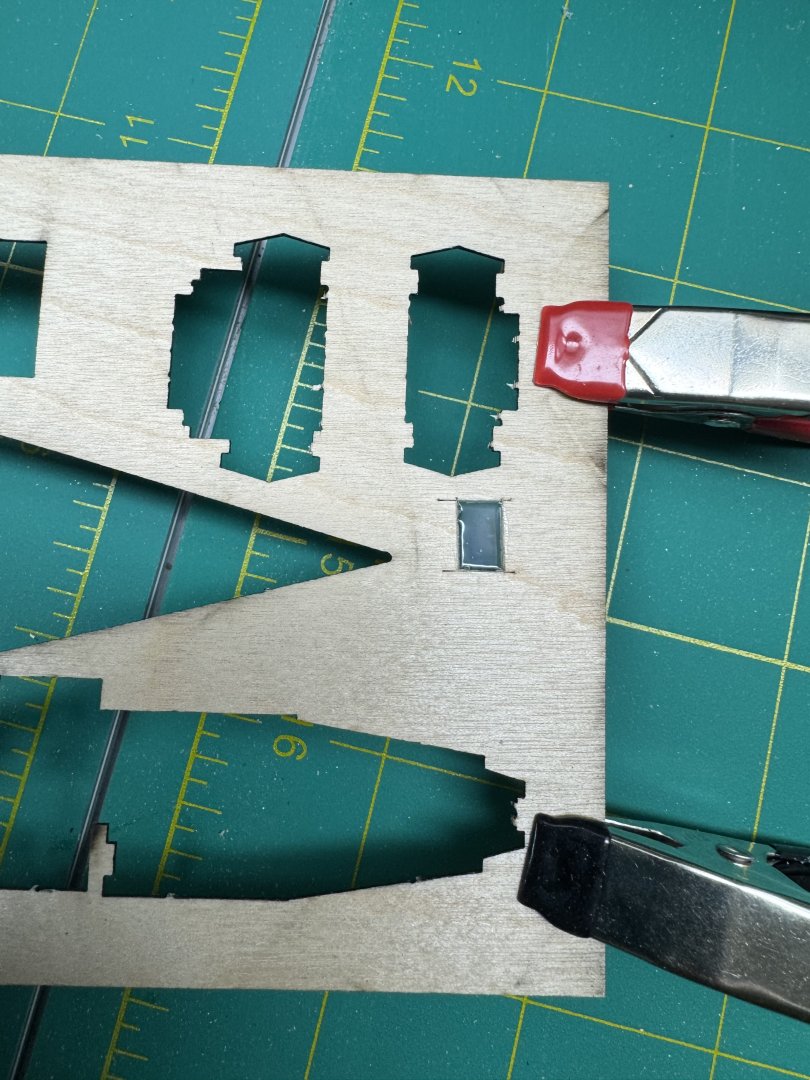

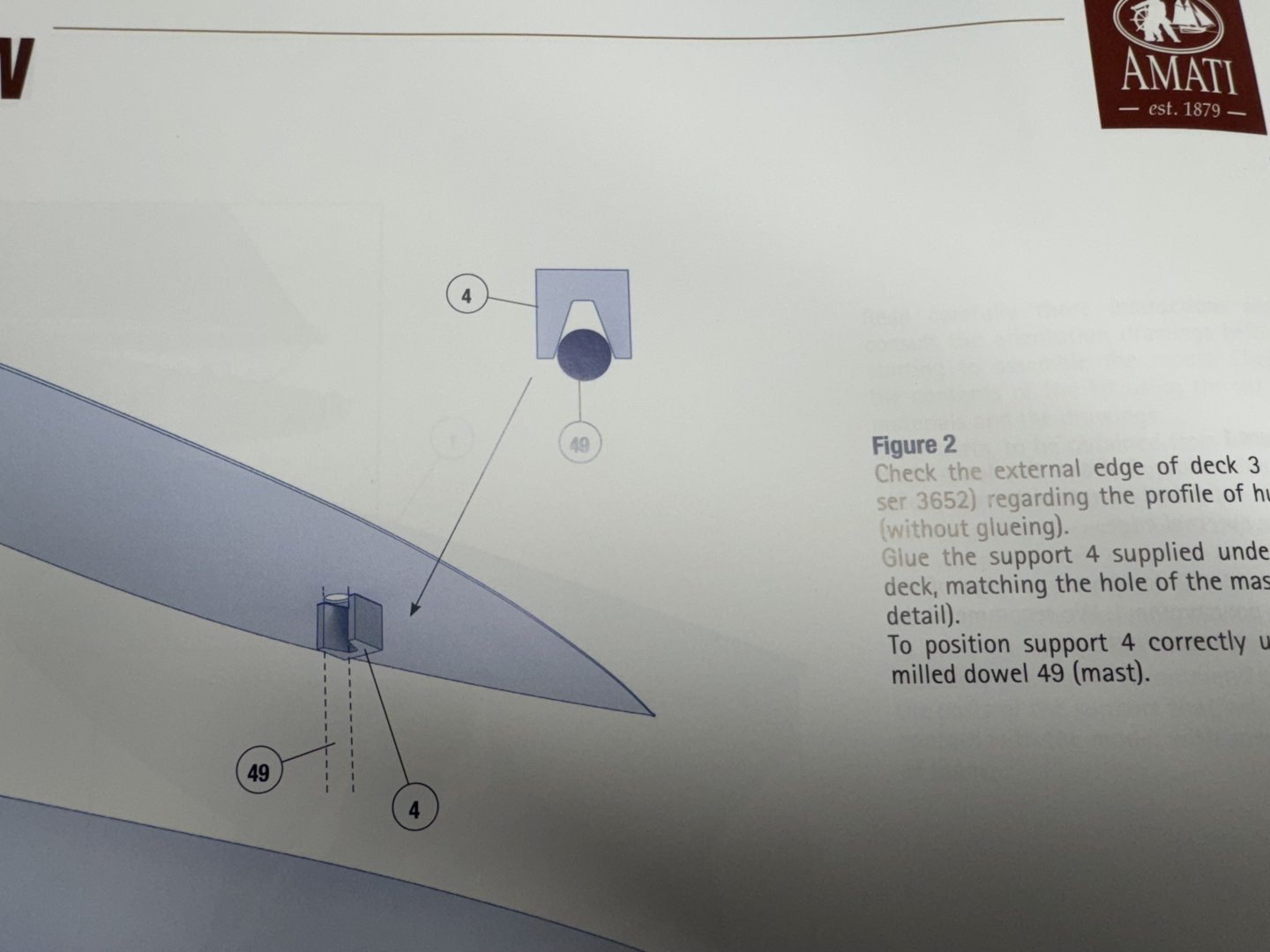

First mistake.

I was so focused on getting the deck to fit inside the hull that when I finally got it to fit I immediately glued it in place.

I forgot the mast support that is glued to the underside of the decking.

After what seemed like gallons (but was actually a few dozen drops) of de-bonder I got the deck up without major damage, installed the mast support and got the deck glued back down. Whew! Another bullet mostly dodged.

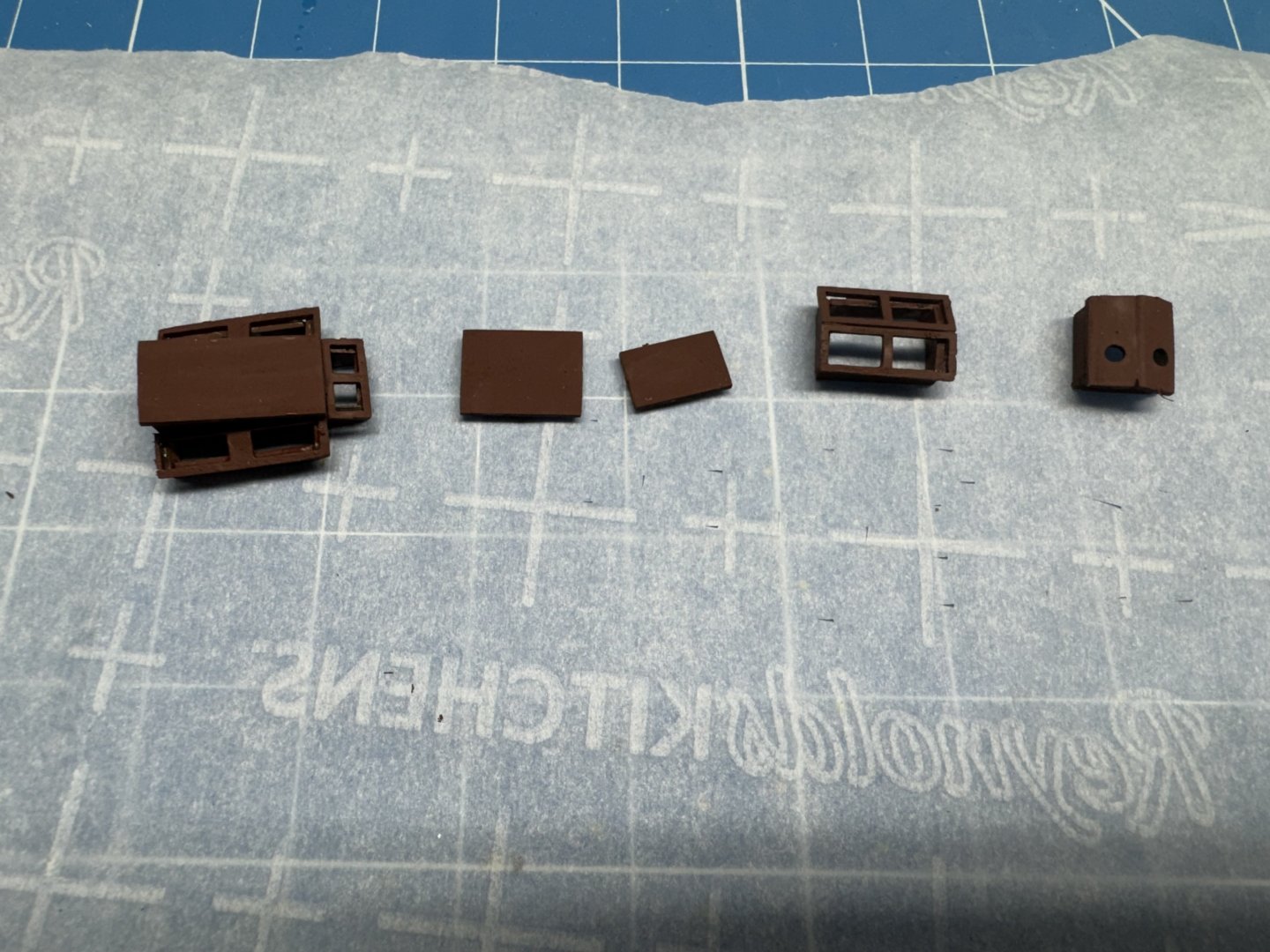

I am waiting for delivery of the recommended Tamiya primer spray paint so I moved on to the deck furniture.

These are really small pieces and getting them assembled and evenly spaced is quite a challenge (for me).

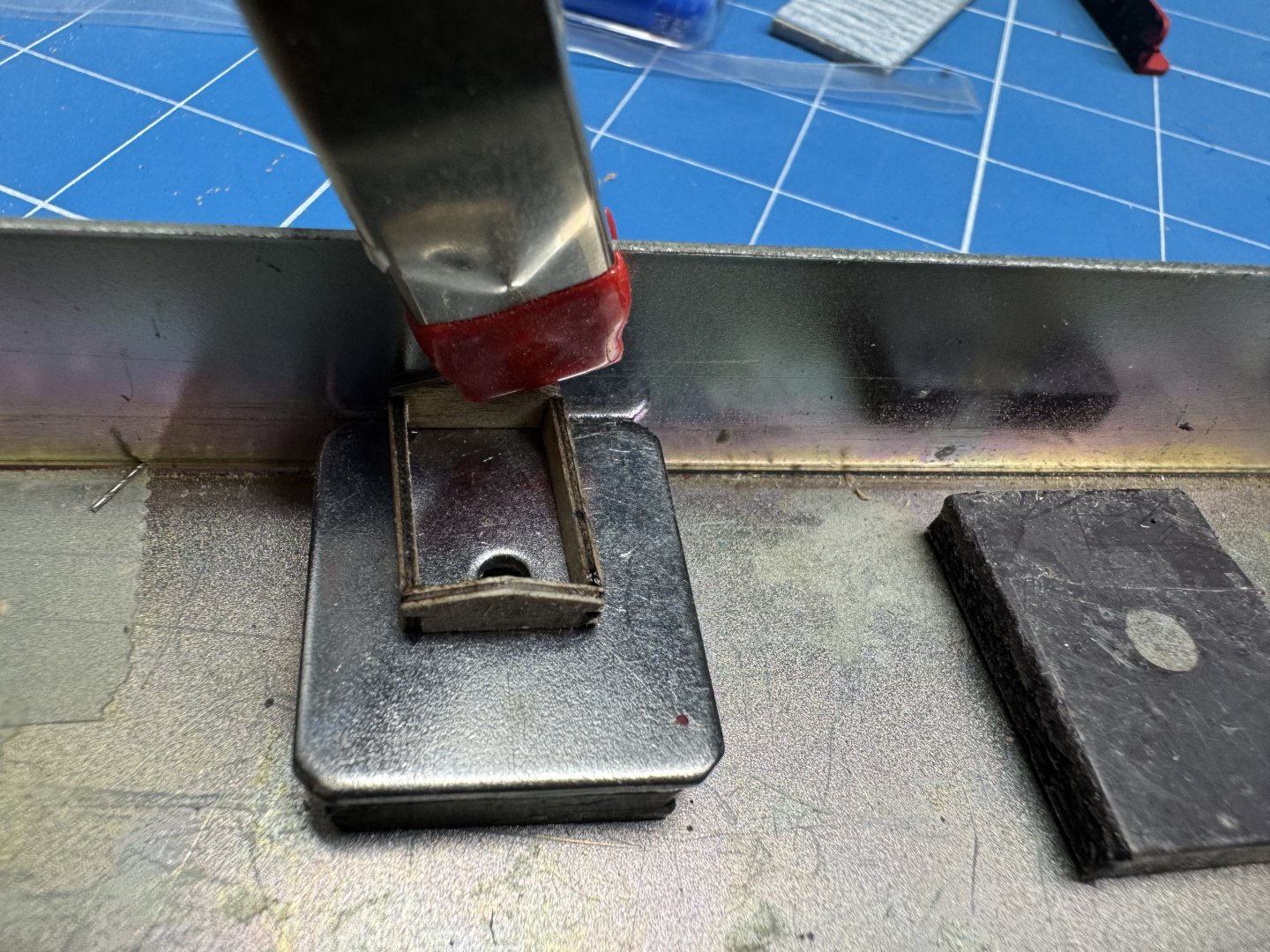

I used my magnetic furniture building board to help but still after the rectangular base is together getting the top pieces on and evenly spaced in both dimensions took more than a couple of tries.

I had to build on top on the spacer so the clamp would reach the top of the side piece.

I am generally not a fan of acrylic windows, especially when they are provided as a single piece and you have to cut the pieces out yourself which is the case here. I have used two different "window maker" products and while they never make a completely clear window they do make a reasonable approximation especially if there is really nothing to see on the other side which is the case here.

To see what they might do with the windows here I cut out a "window" of approximately the same size as are on the deck furniture and used Micro Krystal Klear to "fill it in". It will be a few more hours before I can see what it will look like but based on past experience I think this is the way I will go.

-

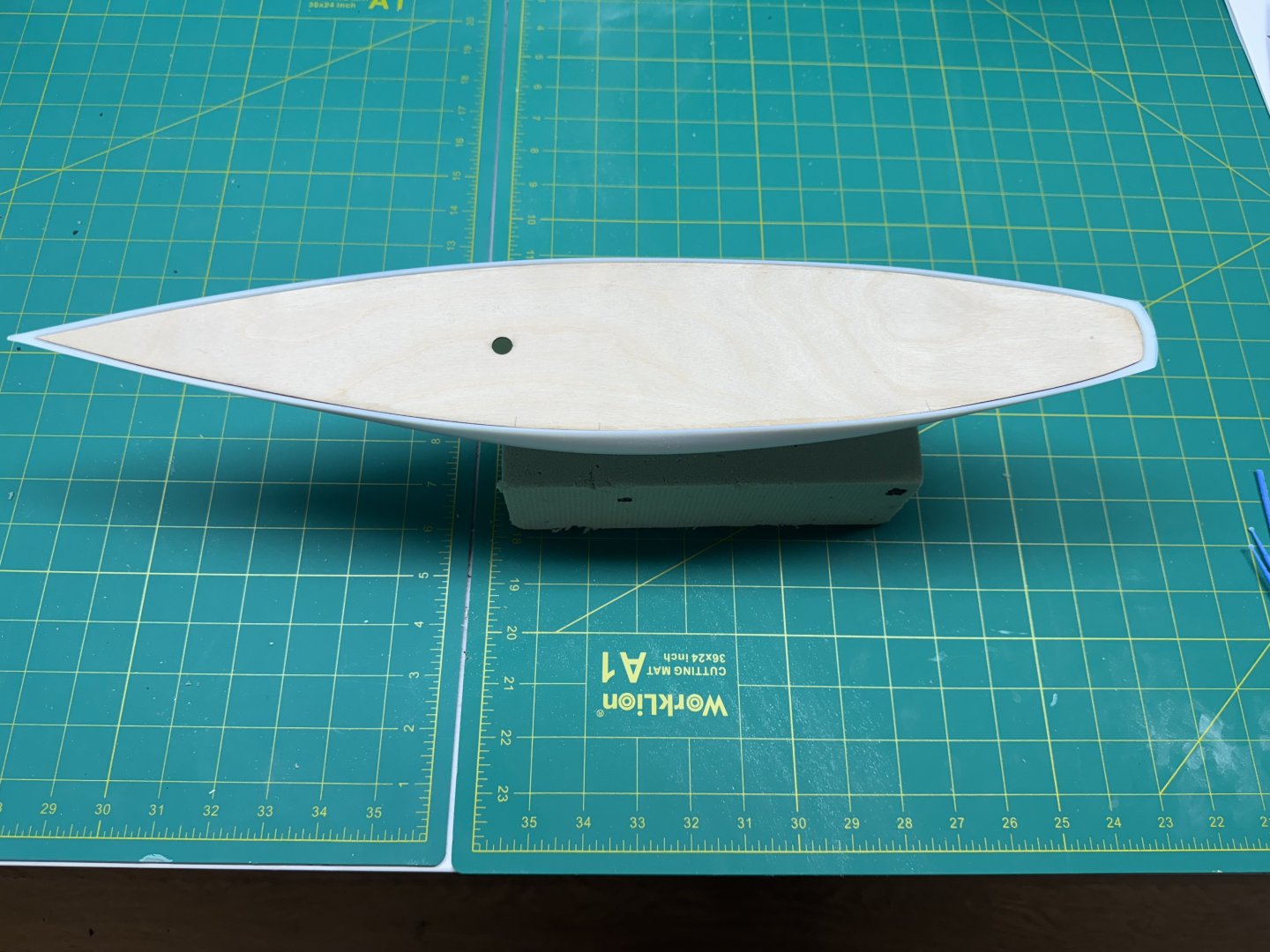

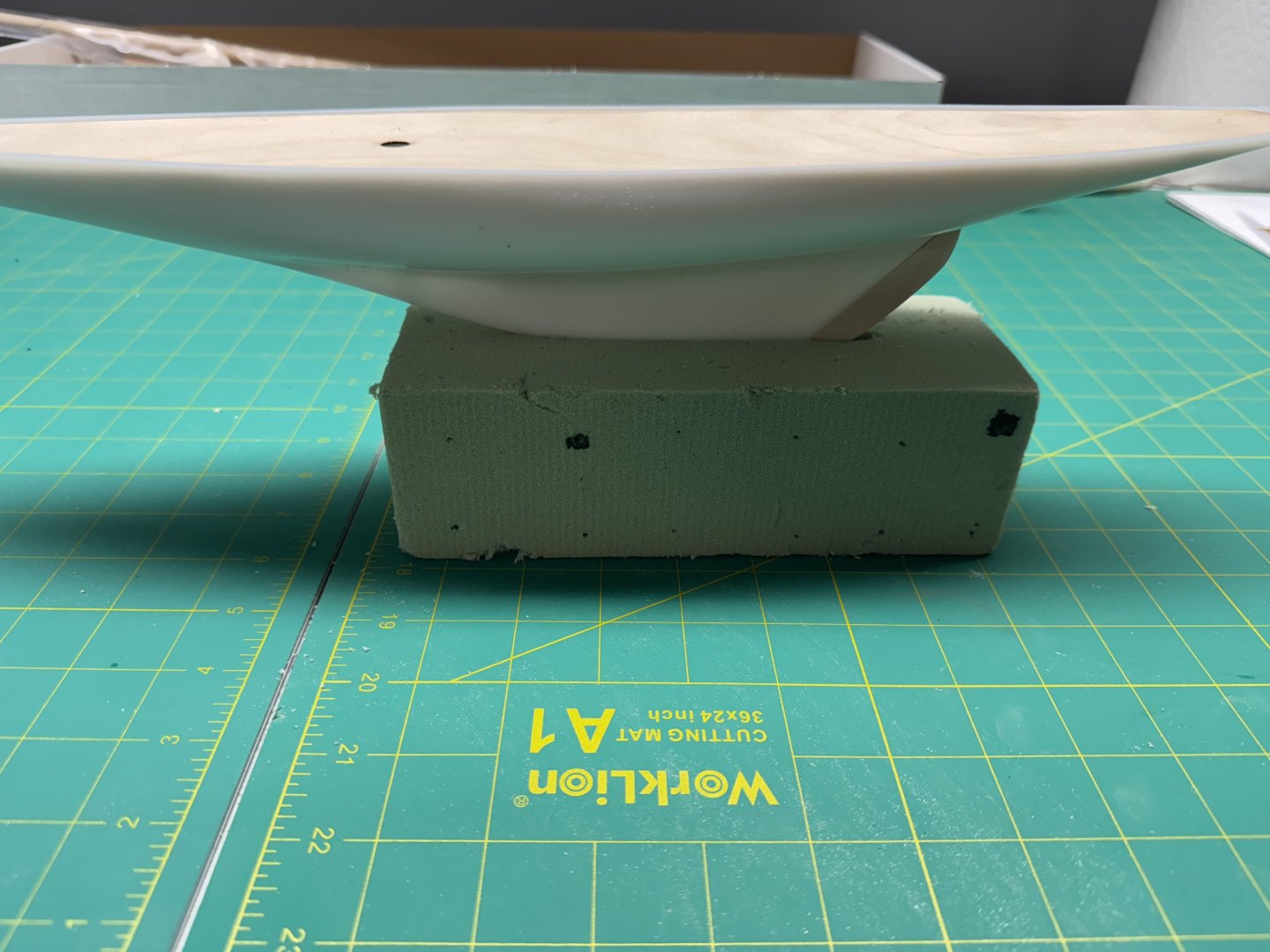

I started gluing the deck down at the bow using medium CA since I knew it wanted to raise up there.

After a few minutes I snapped the rest of the decking into the hull and ran thin CA around the rest of the hull. It should soak into the wood and bond (more or less) with the plastic hull. I have not had great success with CA and plastic in the past but there is not a great deal of stress at the joint and hopefully the deck will stay in place.

I also found a way to hold the hull - I stole a floral arrangement block from the flower arranger in the house and cut a slot in the top to accommodate the keel. It works for now and I think is gentle enough on the hull paint as it may be useful throughout the build - if I can put up with the green "fuzz" that seems to pour of fthe block whenever I touch it. Maybe I should paint the sides that are not touching the hull.

- catopower, gsdpic and king derelict

-

3

3

-

I am building the latest version of Amati's Rainbow (winner of he 1934 America's Cup Challenge) kit - the one with the plastic hull. I also have the same version of the Endeavour (and I am hard pressed to see any difference in the hull but...).

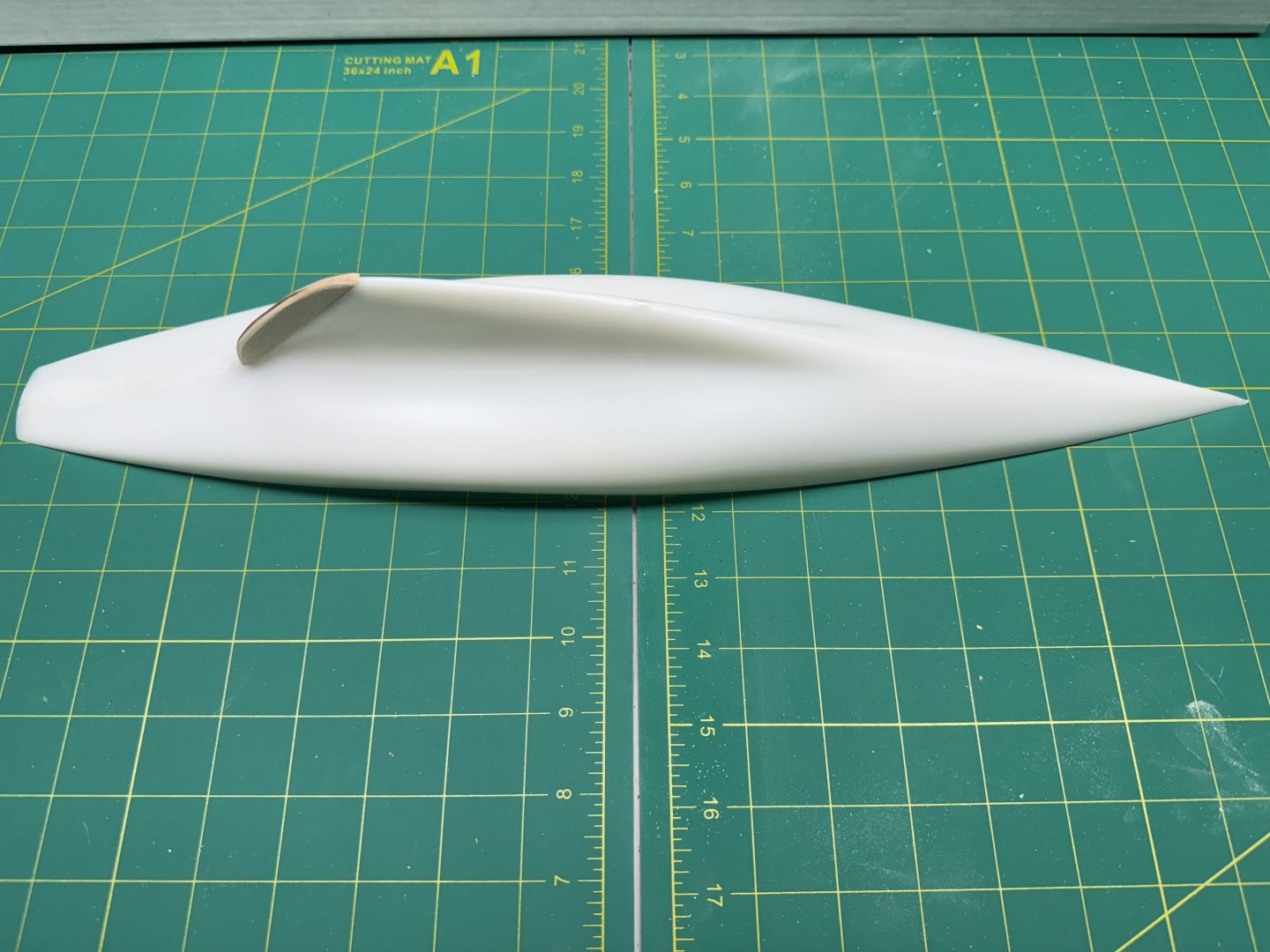

The first step is to lightly sand off the mold marks on the hull centerline and taper and add the rudder (which is made of wood - dah).

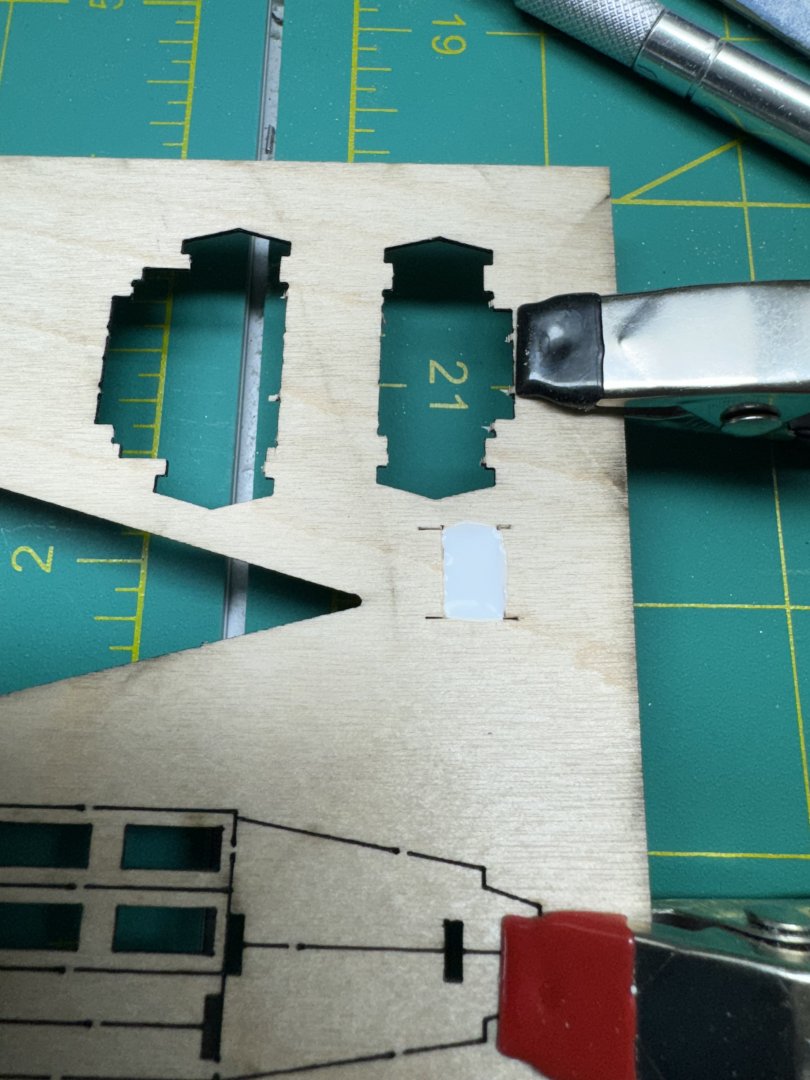

Step 2 is to glue in the "false deck" (which will be planked shortly. It took a bit of fiddling to get the laser cut false deck to fit inside the plastic hull. I would get it seated about 3/4 of the way around, mark where it was too large sand that area, rinse and repeat. You can see some of the pencil marks showing the areas being sanded.

Here is the deck dry fit. It apparently has a bit of "warp" as the bow will not sit down without some gentle pressure (rubber bands). The instructions say to glue the deck in with CA and then plank it with the provided planking material.

I am not sure why I would plank the deck before painting the hull as that seems to be asking for trouble.

Perhaps it is to minimize handling the hull after it painted but I think I will paint it first then plank.

I also need to find a way to hold the hull as none of my availble jigs will fit a hull this shape.

- catopower, gsdpic and king derelict

-

3

3

-

-

-

I my haste to get the top masts in place I forgot that there are mast hoops for the topsails on the main and mizzen masts.

I had some 5/16" and 1/4" wooden mast hoops that are laser cut and thought MAYBE I could cut them open and TWIST them around the top masts and live with the small "crack" in the hoop. Not in my lifetime, the hoops are so fragile there was no may I could get them around the top mast in less than two pieces.

I rummaged through my "parts bin" and found some plastic mast hoops in black.

They are about .095" thick and have a ring for connection to the sail.

I cut them right next to the attachment ring and they could slide around both top masts. I used some liquid plastic glue to attempt to glue them back together but was unwilling to hold the end together by hand for the glue set time which seemed like hours. The liquid glue did restore more or less the black finish that cutting them had disturbed.

Here is what the main top mast looked like.

Compared to the mast hoops on the lower masts they are much thicker and the ring attachment stands out.

So, since I had enough of the plastic hoops to make another set I started by sanding the hoops down to approx .05". Still thicker than the lower mast hoops but about as thin as I could go without risk of them getting "crooked" with one side/end noticeably thicker/thinner than the other. Don't ask me how I know this.

I cut the ring off and used the plastic glue to restore the finish playing particular attention to the outer edges as that is really all that can be easily seen.

Here is the mizzen mast with the new, smaller hoops without the ring. They are still black but not nearly as noticeable as the larger ones.

Short of painting them brown this is the best I can do. I looked at the other schooner i have built and all have mast hoops on the top masts, that carried topsails.

And here is the main - looks much more "in scale" than before (IMHO).

- schooner, JacquesCousteau, ccoyle and 1 other

-

4

4

-

Thanks ccoyle!

The stern name board looks a little "off-center although this is what the drawing shows. Please do not notice the "hole" under the stern rail at the extreme port side.

I should touch up (very carefully) the edge of the cap rail back here.

The anchors are attached to the chains and lashed down.

The last items to be installed are the two forward name boards (I screwed up the first two tries) and the two flags which are still "being processed".

After that it is on to "picture taking" for the NRG photo contest.

- schooner, Paul Le Wol, SiriusVoyager and 1 other

-

4

4

-

Thanks Schooner - I have the Syren kit (must be five years old now) sitting under the work bench but am not ready to get in "cannon making mode" again just yet so it will have to wait as it is not yet "next".

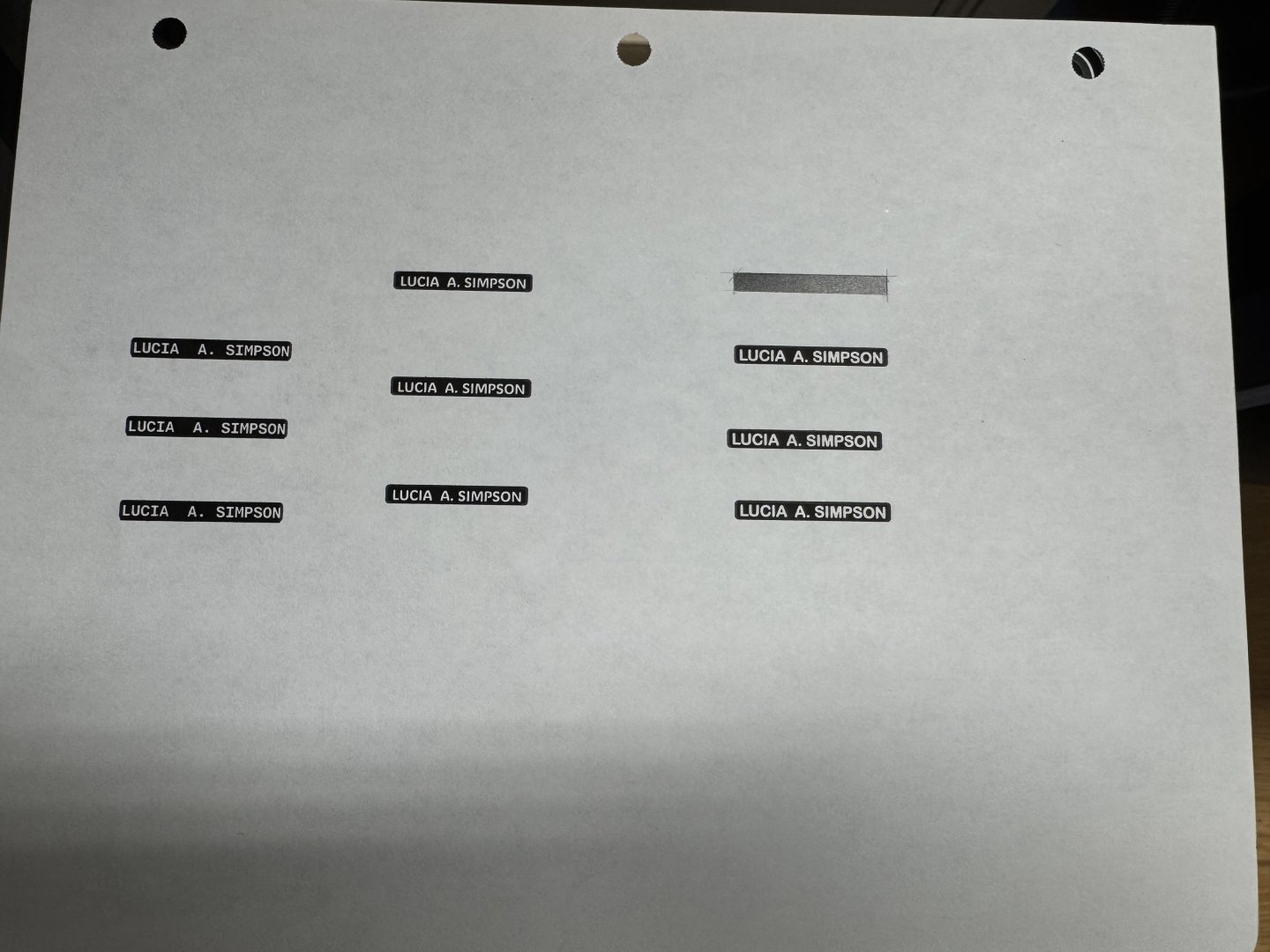

The name boards. Although the instructions say the name boards are white letters on a black background I did consider doing it the other way as the label maker I have did a pretty nice job and the small size letters were "just right". But as best I can tell there is no label maker (or decal maker for that matter) that will do white on black.

So I fell back on what I initially thought was the next best and bought several sets of white dry transfer lettering from Woodland Scenic. I measured the gap between the cap rail and the lower trim and cut some basswood stock to the measured 3/16". I started with some 3/64" thick because that was what it was already. Painted it black, two coats with 220 grit between to get it smoother and then got the letters out and...

- Either I have forgotten or never tried to do this many letters in a row but this was definitely not easy. After three tries this is the best one

Not good enough by a long shot. It was really, really hard to get things lined up one letter at a time while looking through the other letters on the sheet and being very, very careful not to press too hard elsewhere as it does not take much pressure to transfer a letter you don't want.

So I thought about other alternatives and remembered the friezes that were part of the Winchelsea build. These were printed on fairly thin standard copy paper with my ink jet printer (Canon 6820), cut out and then glued onto the ship sides with dilute PVA. They looked "great" if I do say so myself.

So I thought I would try that here.

I used PowerPoint to get the text and a rounded rectangle as the background. It took some fiddling around with fonts and font sizes but I finally got what I thought would work.

I printer them out on a heavier weight paper and here are several versions. The ones on the far right are the "good" ones (one is already cut out).

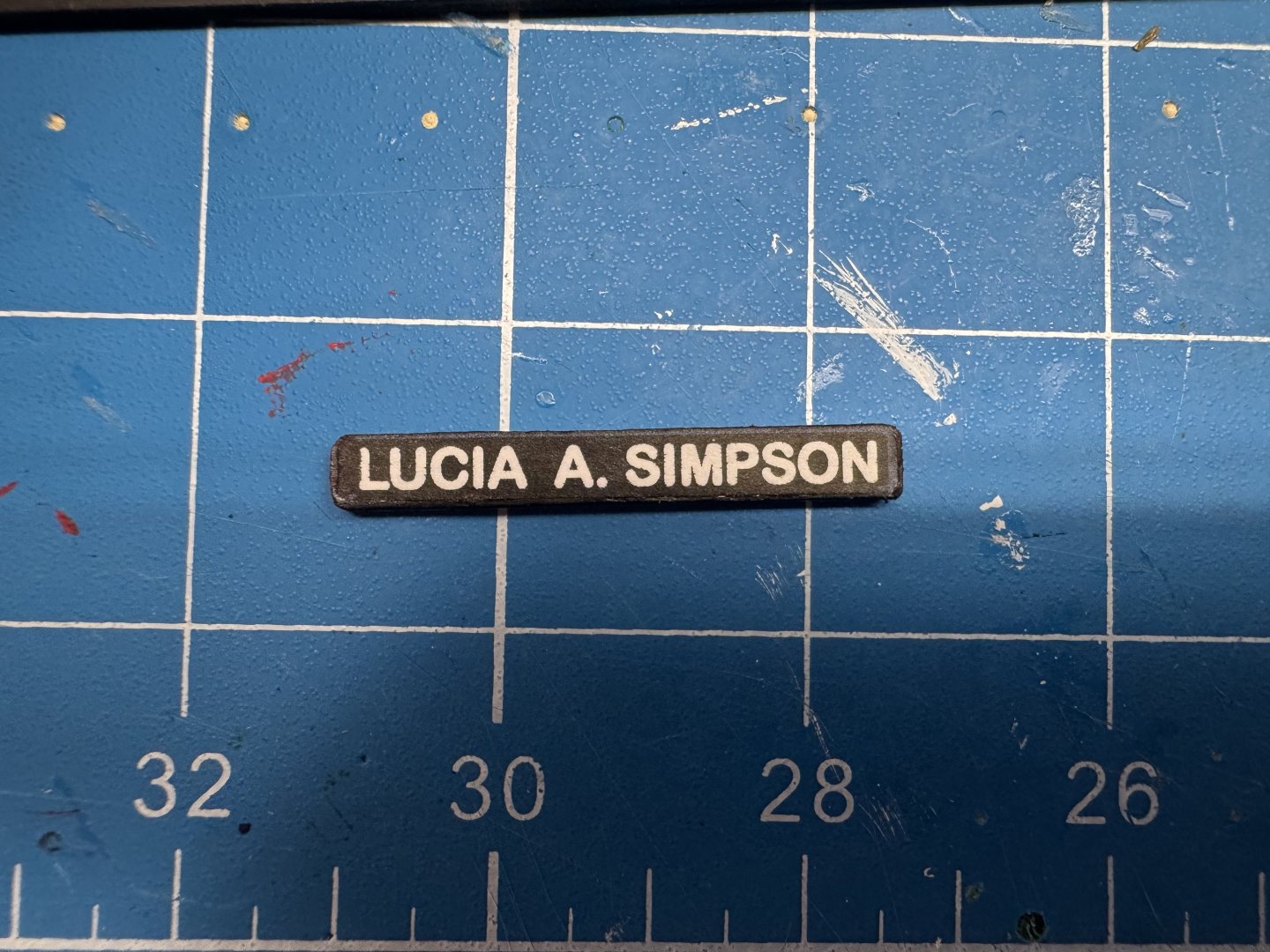

I carefully cut out the name with a new #11 Xacto blade and glued it onto the per-painted basswood strip. A sanding stick rounded the ends and reduced the length to just past the paper. I used a Sharpie (wide tip) to blacked the wood where I sanded and to cover up the white line that is the end of the paper.

Here is the first (of four) required.

And here it is installed on the stern

For the bow I had to thin down the basswood as the 3/64" did not want to bend around the bow and wood is cheap so I will use 1/32" (or maybe a little thinner) for the two name boards at the bow.

The stern has both the name and home port so I need to go back to PowerPoint and make up that one but I think this 'problem" is "solved".

-

Almost done.

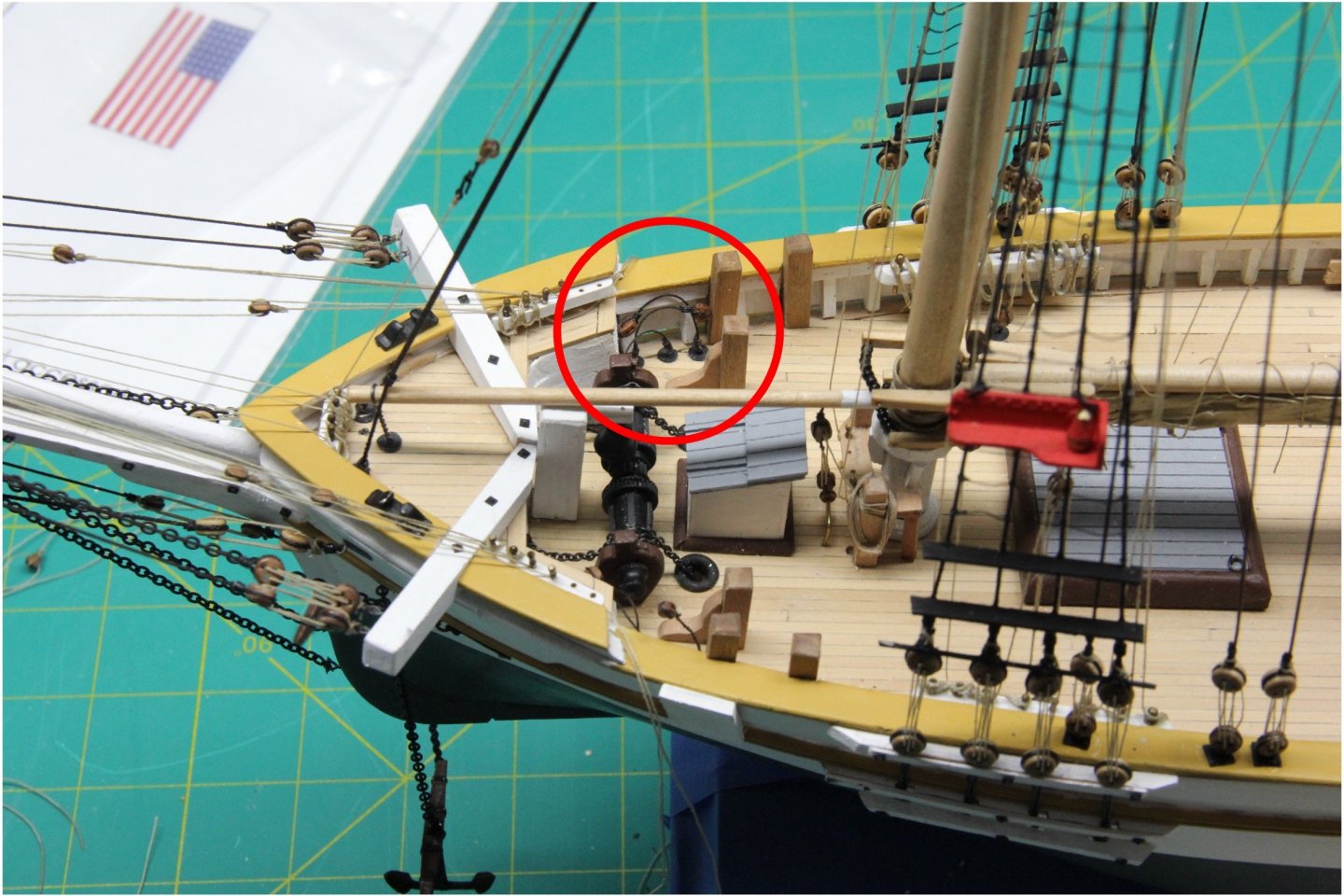

When it became to add the jib sheet lines things got a little complicated. I had added three 3.5mm single blocks on each side just behind the raised forecastle deck because that is where I thought the "turning block" of the jib sheet tackle went based on the rigging plan. Red circle below:

When it came time to actually rig the sheets lines using these blocks produced somewhat unrealistic (IMHO) leads and runs for the tackle.

Further review of the rigging plan revealed that each sheet line was allocated four belay points, two on each side (dah). That accounts for the six pins on each of the two forward pin racks.

So I decided that one pin was for a pendant holding the turning block and the other the bitter end of the hauling line. You can see some of the standing jib tackle in place in the photo above.

So I revised the plan and now need to either remove the "extra" blocks or just leave well enough alone. Jury is still out.

I probably mentioned this before but I got the running lights back in place in the correct orientation but here is a better picture of the port side light (and it is actually on the port side showing the red light from dead ahead to 112.5 degrees relative.

And I have the fore yard arm rigged and in the "stowed" position.

Cleaning up odds and ends and completing the re-rigging of the jib sheet lines.

Once they are done there is a bit of paint to touch up and add the name boards which is a story for the next post.

- ccoyle, Paul Le Wol, JacquesCousteau and 1 other

-

4

4

-

Phil,

I know from experience onboard the Pride of Baltimore II that their upper yard arm on the fore mast (Royal I guess) is rigged on deck and raised on the halyard.

The picture of the Denis Sullivan clearly shows (if you expand the image) that the raffee is furled against the fore topmast.

-

- schooner and JacquesCousteau

-

2

2

-

After further consideration and a more careful viewing of the picture above I think the answer to how is the raffee furled is that is furled against the fore top mast on the forward side, not on the yard arm. Since I did not make the other topsails and do not have the time, materials or inclination to do so now I will dispense with the raffee and leave all the topsails off. I think it would look strange to have just the one upper sail in place. In fact I think that the raffee was probably only set when running more or less down wind while the other topsails would have been more useful at other points of sail. How someone gets up to near the top of the fore topmast to furl the raffee is a mystery to me - bosun's chair?

So now to secure all the back stay and topmast shroud deadeyes and proceed with rigging the inter-mast stays.a

-

Everything I know about the Great Lakes schooners I learned at the Tall Ships Erie in 2019. Below is the Denis Sullivan which at the time was the "official tall ship of Milwaukee" (or maybe Wisconsin). She is now some sort of "school ship" in St. Croix according to the internet.

Anyway the thing I found interesting was the single yard arm on the fore mast and that it was rotated out of the way when not in use, or presumably it might be tilted with the raffee sail (aka topsail) furled on the yard. The only rationale that comes to (my) mind for allowing the yard to rotate would be to allow the ship to moor to a pier where buildings (like warehouses) were very close to the pier for ease of loading/unloading. However, since two of five stay running forward from the fore mast pass through a cut-out in the sail the sail would have to be furled sort of "around" these stays. As you can see in the picture the yard is bare so no help here. And of the tall ships I have seen in the US no other one carries a rig like this so...

I have the yard in place on the model and able to rotate. I originally furled to raffee sail on the yard but I have since unfurled it and am letting it dry now.

Plan is to tie the sail on the yard - sail plan shows it tied on at lower corners and at the edges of the cut-out for the stays - attach the halyard and raise the sail - then spray a little water on the sail and see what can be done about furling it.

I have an idea how the sail would be rigged on the real ship. If the yard was tilted to one side you could reach the sail attachment points on one side from the ratlines, then tilt the yard the other way and do the other side - then level the yard, attach the halyard and haul away. Probably not too difficult unless the weather is not cooperating which on the Great Lakes can be much of the time.

- JacquesCousteau and ccoyle

-

2

2

-

The mizzen mast turned out to be a bit more problematic than the main/fore. In addition to tightening one side and lossening the other back stay/topmast shrouds I had to rerigged the lower shroud deadeyes on the starboard side as they the lower shrouds had become noticeably loose after the back stays/upper shrouds were tightened.

In any event i managed to get the mizzen mast straight.

It was much easier to get the laser on the hull centerline at the stern as there are obvious reference points (rudder et al)

By the seaman's eye all three masts appear to be in alignment.

I am not sure how I will deal with the list of the model on the display stand. I can correct for the photos and then crop the base out of the photos) but when "on display" the list would detract from the overall appearance - maybe a discreet wedge or two under the baseboard would work - I am not sure redoing the screws in the solid hull can be done by me) is such a way as to guarantee the model is perpendicular to the base.

- JacquesCousteau, ccoyle, Paul Le Wol and 1 other

-

4

4

-

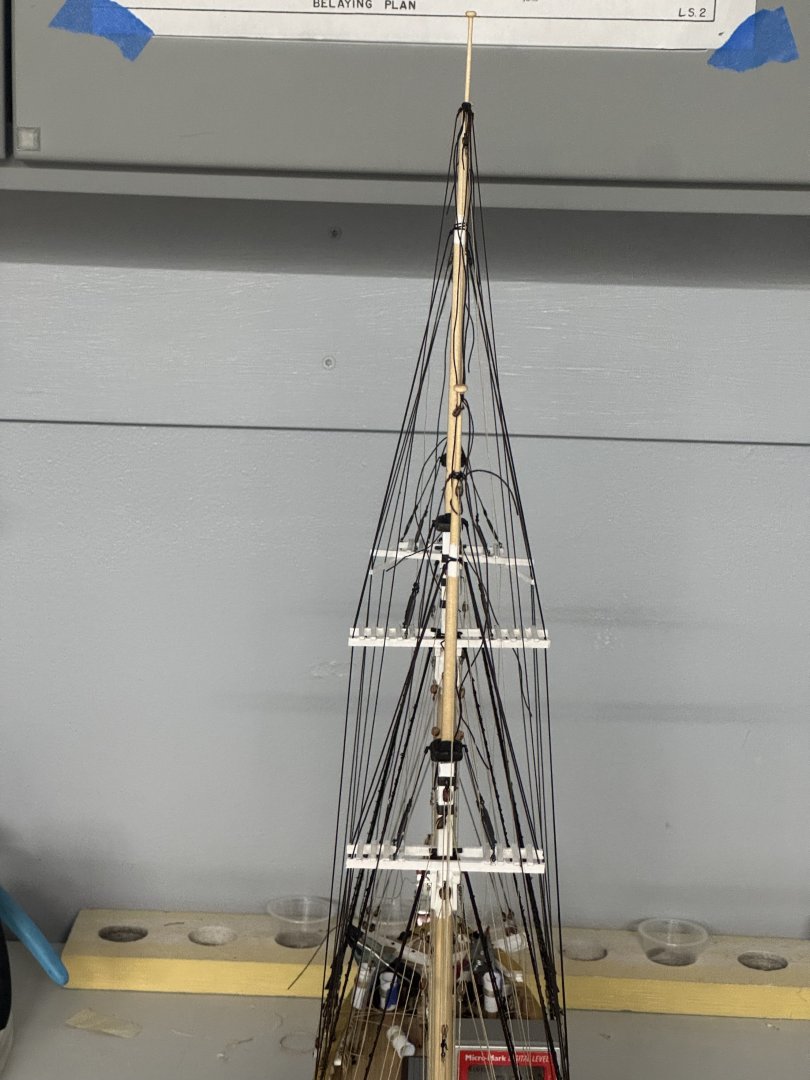

I got all the back stays and topmast shrouds installed and lanyards revered but not yet secured (good thing).

I cleaned off the workbench (more or less) and took the model off the turntable which makes switching sides while rigging much easier. It does however present challenges to keeping everything clear of the "swing radius", especially of the bowsprit/jib boom.

First order of business was to get the model level. As at least an approximation of this I used a thick plastic ruler across the cap rail amidships and stuck thin pieces of wood under the baseboard until I got an indication of level.

For those interested the model was 2.5 degrees out of level.

I turned out the workbench lights and set up the laser level to see if the masts are straight.

I fiddled with the back stays and topmast shrouds on the fore mast until I got the laser light on the entire mast. Disregard that toothpick I got the fore mast straight without it.

The bowsprit (jib boom actually) is just a bit over to port - you can just see the laser light on the down haul block just behind the first two stays. Need to tighten up the starboard side guys on the jib boom.

Since the fore mast blocks most of the light from getting to the main mast I had to use the "seaman's eye" to adjust the main mast back stays/shrouds to get it in line. I could not get the light to hit the very top of the mainmast but it is "really close".

So now I have to go secure the main and fore mast back stays and top mast shrouds in these positions before everything "springs back" out of shape.

Once I have the main/fore "squared away" I will turn the model around and see how the mizzen masts looks. Hopefully the main mast will now be the "gold standard" and I can adjust the mizzen to line up with the main.

Once all the stays/shrouds are secured I can get the yardarm/raffee in place. Given that three of the fore mast stays pass through the raffee I will have to unfurl at least part of the raffee to pass the stays through.

Should be an interesting evolution.

Rainbow 1934 by cdrusn89 - Amati - 1/80

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Deck is planked and has two coats of Wipe-on-Poly (water based) applied. Will have to do one or two more. After the first coat the grain in the wood (basswood presumably) was raised up considerably. A good sanding with 320 grit was applied and I am waiting for the second coat to dry to see what the deck looks/feels like.

I cleaned up all the Britannia metal cleats and will add them to the boom once the last coat of paint is dry.

The mast also has another coat of paint on it and I added the eyebolts to the ends of the spreaders. I am considering painting some of the provided line gray as I am pretty sure these boats had wire rope standing rigging, not hemp.

I laid out the sails on a sheet of parchment paper (don't want to glue the sails to the work surface) and added some weights to keep it stretched out (more or less).

Then I went over all the edges of the sails with fabric cement. Hopefully the fabric cement will keep the material from unraveling once the sail is cut out. The objective it to get the fabric cement on just the least little bit of the line outlining the sail and very little on the sail material. Easier said than done. The wrinkles shown below will be substantially reduced (I hope) one the fabric cement has dried.

Once I get the deck WoP completed I can mask off the deck and take the hull to the spray booth.