-

Posts

1,620 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Montana, USA

Recent Profile Visitors

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

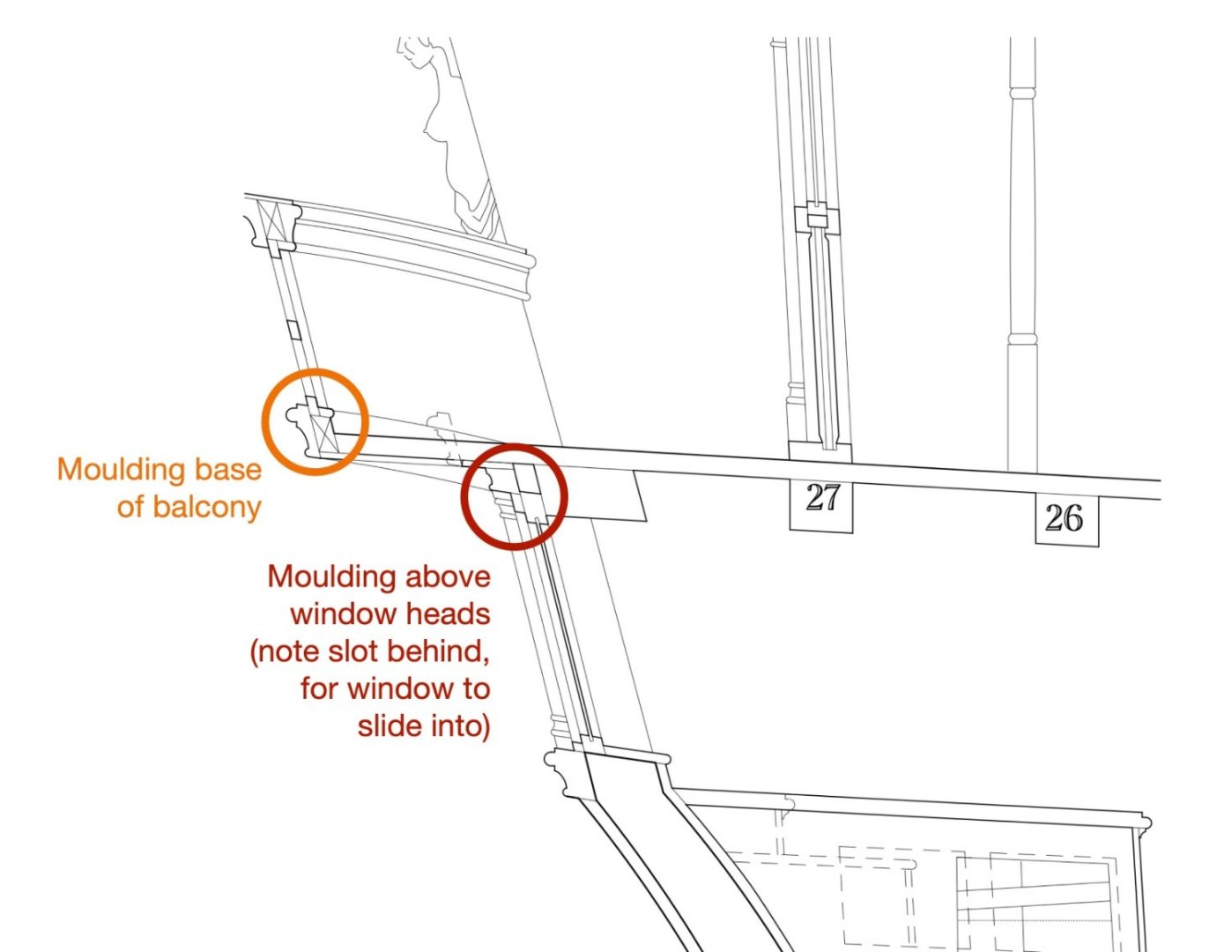

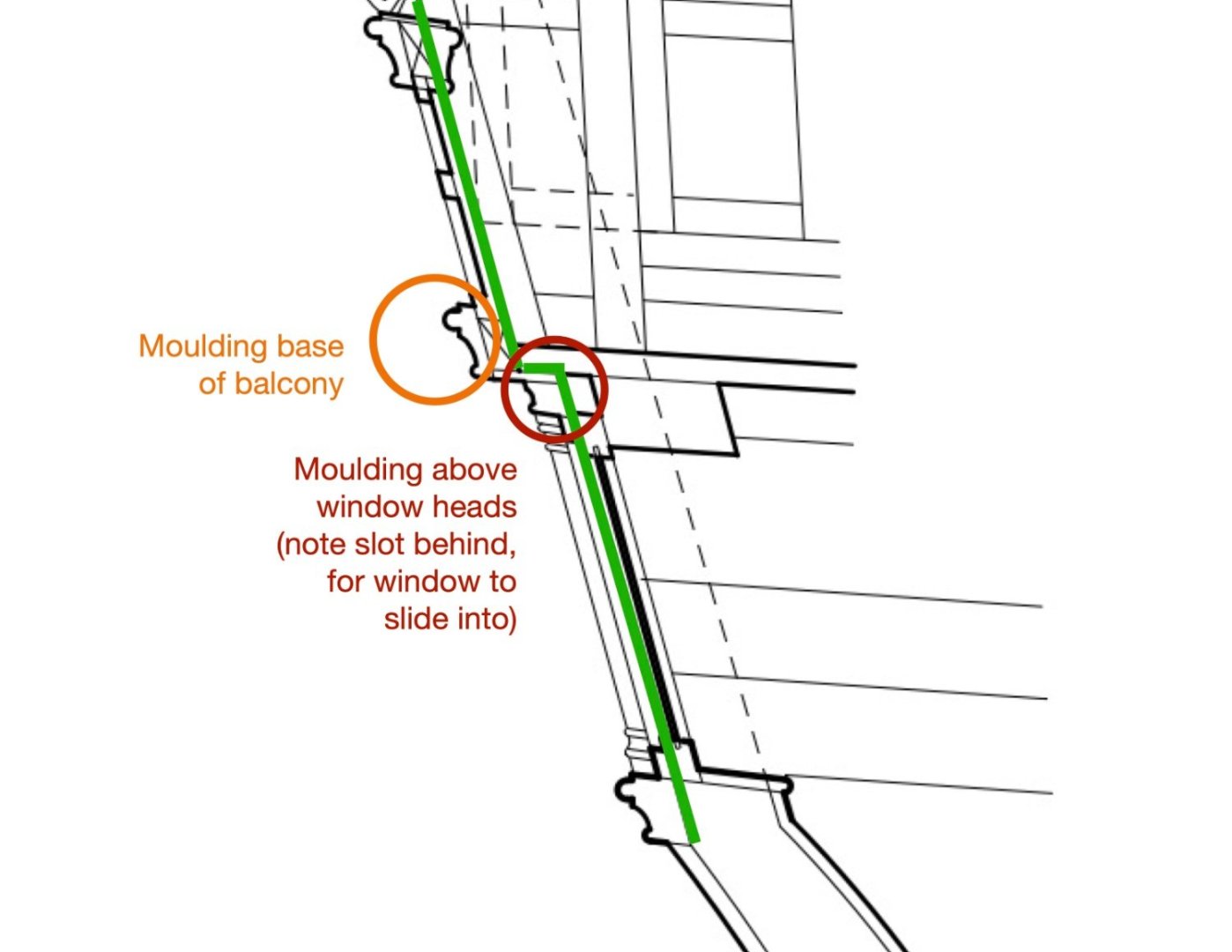

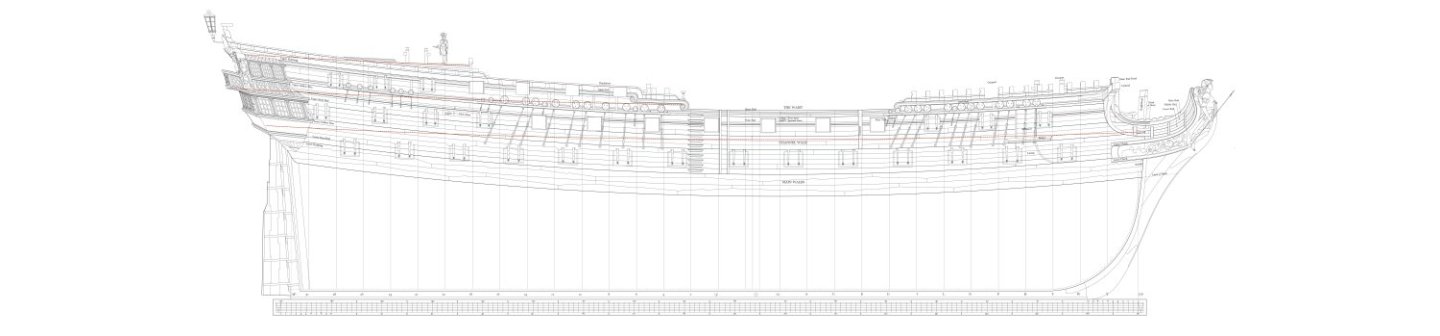

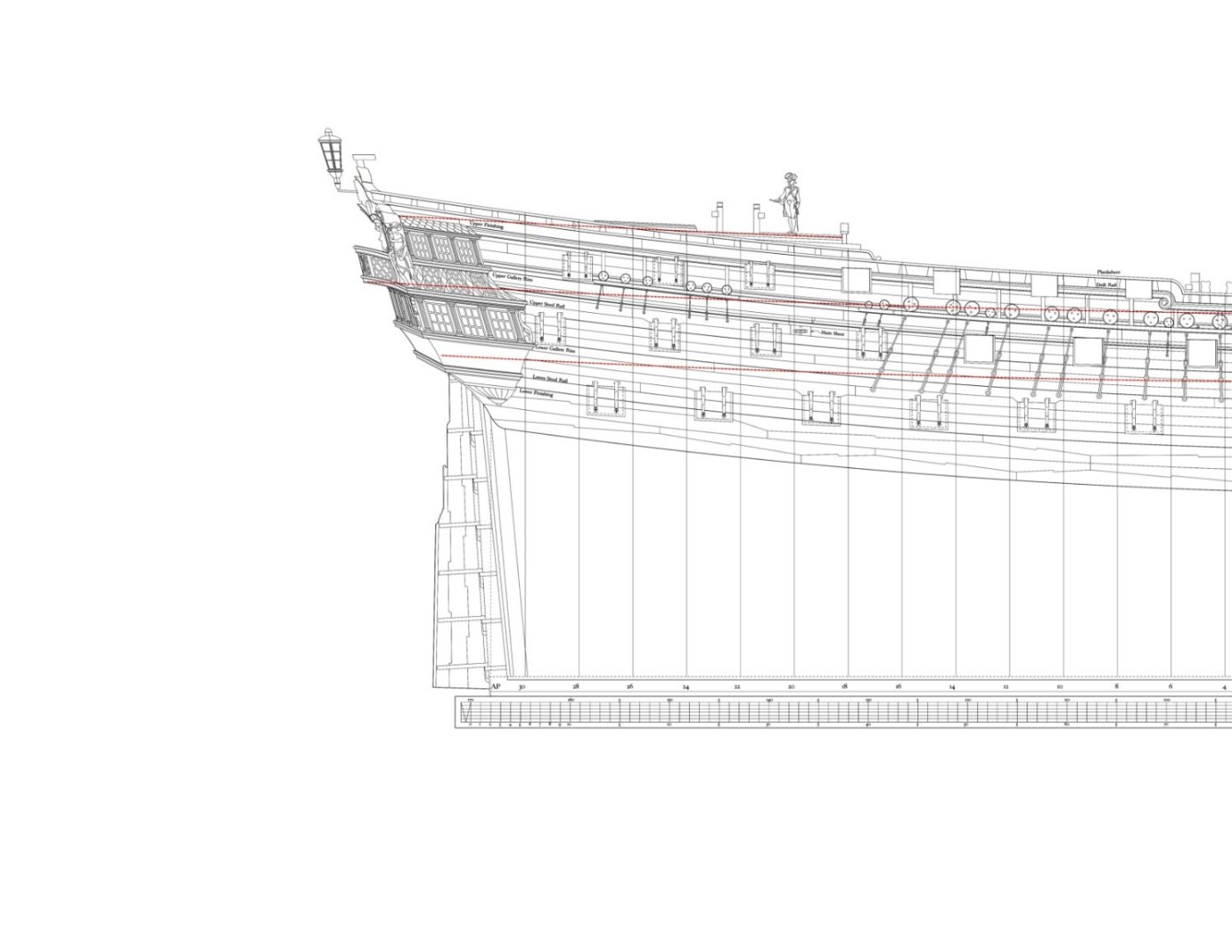

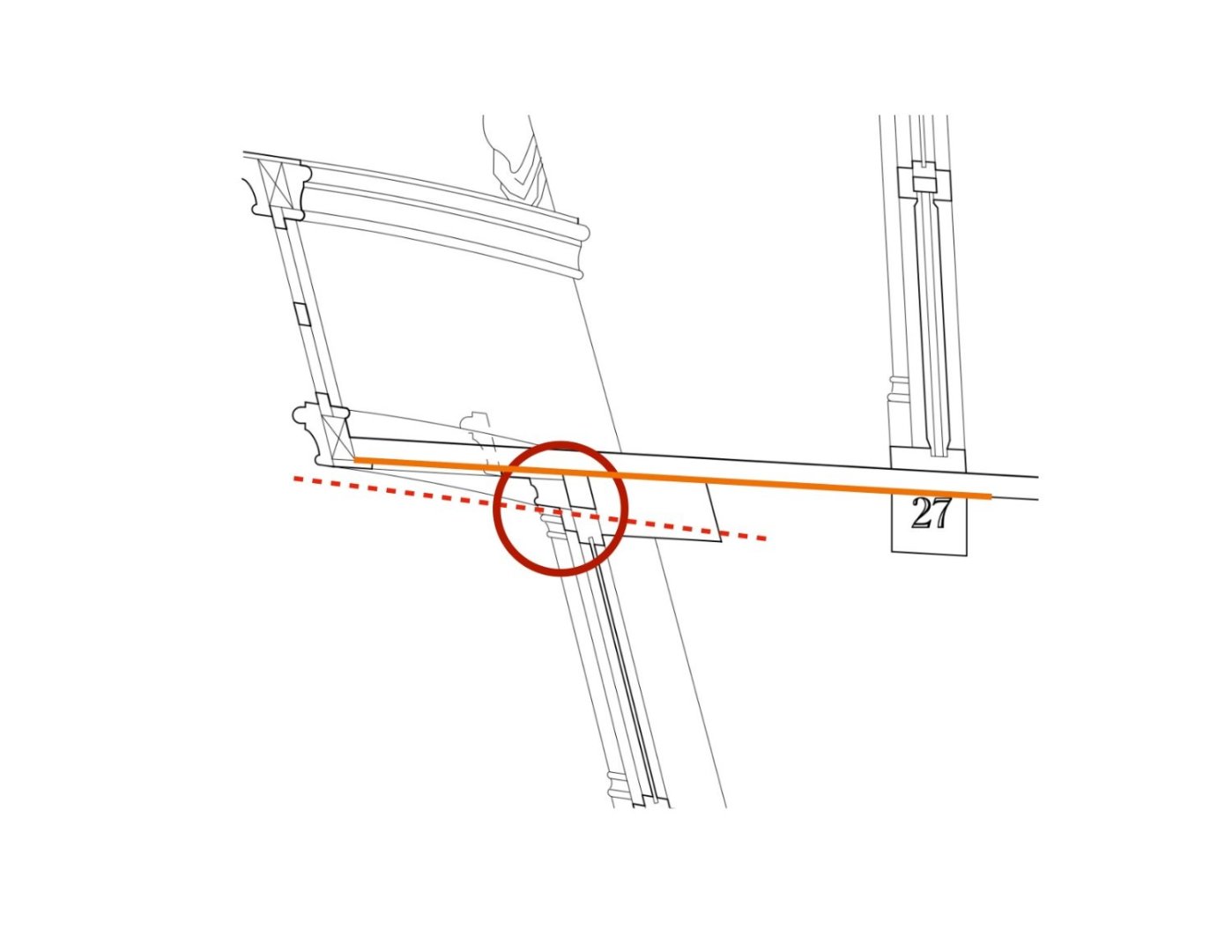

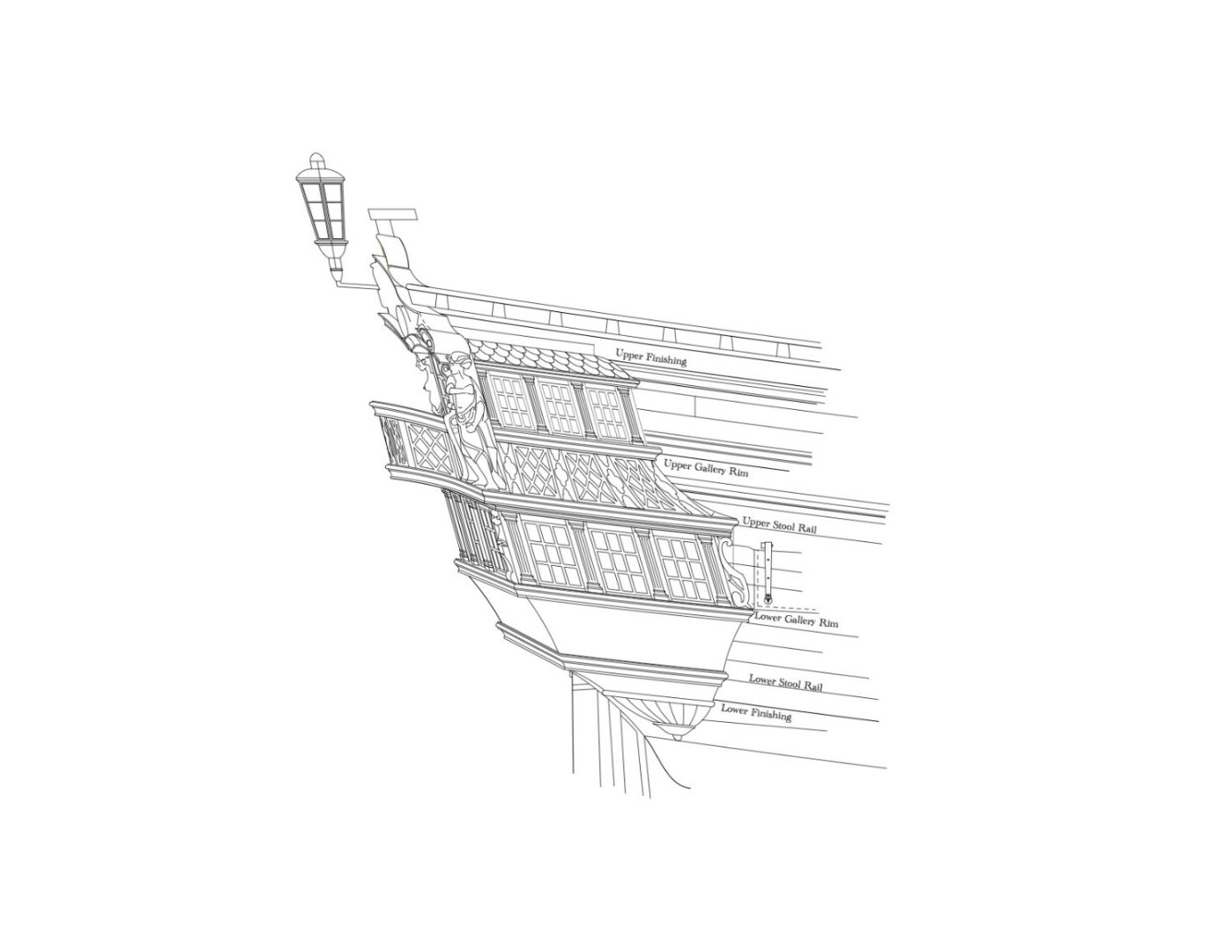

Now for some analysis of geometry and construction. Fifteen years ago, I built the stern frame based on my observation of the first Bellona model, and the Admiralty drawings. I did not understand what I was building at the time, I just followed what I saw. And now I understand as I get into the details. In the model, you can see a couple of strange things. first, the tops of counter timbers with the dovetail joints stand proud of the horizontal transom tying them together. This leaves a gap of about 2". I now realize that these gaps provide a space for the bank of sash windows to slide up into. It means that the windows can be opened at the bottom by about 9"; not a lot, but better than no opening! Second, the side counter timbers, effectively the end of the hull frame, project out from the bottom of the balcony upwards. that is, the bank of windows are recessed back relative to the balcony, creating a shadow line between the upper and lower parts of the stern. There is no functional reason I can see here; it is a visual trick to emphasize the sweeping serpentine curve of the balcony from one side of the composition to the other. That creates some complication in how this is constructed. The green line shows the aft most edge of the side counter timbers, or hull. There is one moulding along the tops of the window bank, just under the balcony, in red below. Another moulding runs along the base of the balcony, in orange below. when the balcony swings out from the stern, the two mouldings split from each other: The next item I did not fully appreciate until I started constructing the stern is how its design needs to reconcile two geometries working against each other; the upper sweep of the sheer, and the flatter sweep up of the decks (red lines below). The conflict shows a little where the gun ports cut into the sheer in odd places. But at the stern they really need to be resolved. One of the most important, I discovered, is that the moulding at the tops of the windows must align with the sheer of the deck at its upper edge (orange line below), since it sits flush under the deck itself; but its lower edge must conform to the sheer of the hull (dotted red line below), since it turns the corner and runs along the side of the quarter galleries that align with the hull's sheer. And then one more thing about the stern. In 2014, ten years ago, I posted a question about the stern geometry (posting #173). I noticed a discrepancy in the drawings relative to the roundup of the quarterdeck. If I continued the deck aft with its normal roundup, it was a couple of inches lower than the deck as it was shown coming out into the balcony. There was a lot of discussion around posting 173 as to whether this was a mistake in the drawing, or something else. I finally found in Steel that the quarterdeck does indeed increase its roundup as it approaches the stern balcony, to give a lighter, more springy feeling to the visual lines of the stern. So the drawing is correct, and this needs to be accounted for: So, construction next! Mark

-

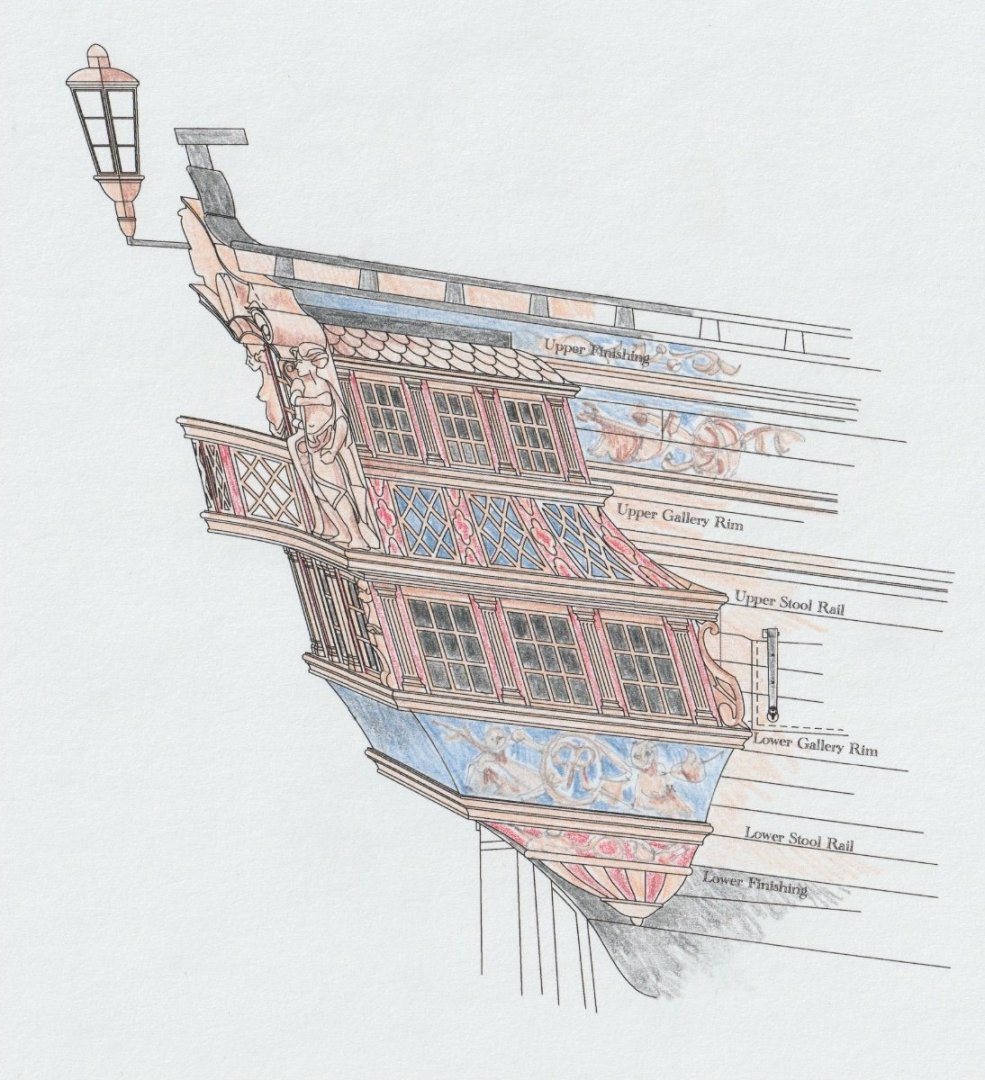

Yves, thanks for sharing your model. I was aware of a kit, but I have never seen it! It looks like you did a very nice job of it. scrubbyj, the history of the Bellona in Brian Lavery's Anatomy of a Ship has the ship paid off in 1762 after her initial service, turned into a guardship, briefly recommissioned, and laid up in ordinary in 1771. Then she was given a major repair in 1778, completed in 1780. this was now 20 years after her original launch. I can only assume that the first model represents her before the major repair, and the second one represents her afterwards. Adding that railing on the roundhouse bulwarks was very typical of designs of this later period, as best I can tell. Visiting my son in London last year, we visited the National Maritime Museum and toured around endlessly disappointed that they had removed most of the models. Then we walked into the room devoted to the Napoleonic Wars, and there were two representative models, the first and second Bellona models side by side! At last two decent models, and they were the Bellona! In this photo you can see that the second model is larger than the first, which I never realized until seeing them side by side. Busy day outside the shop, not as much done on the Bellona as I had wished... But I did get a chance to color the stern quarter galleries based on my reconstruction:

-

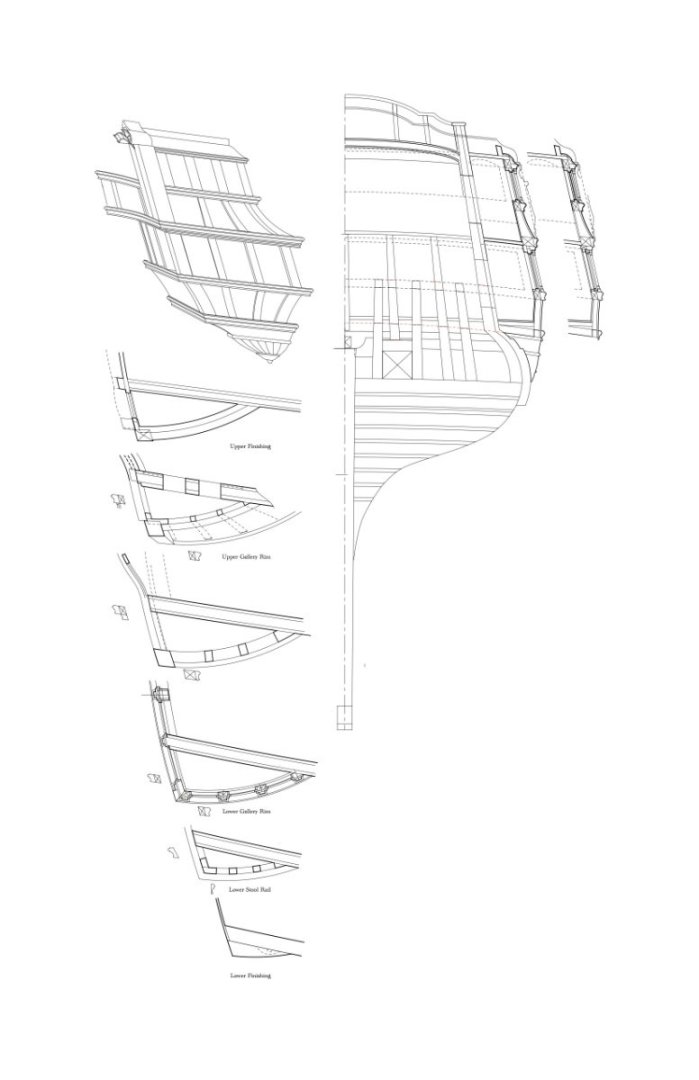

Thanks so much, Marc, Hakan, Allan, Mark and Dan. It really means a great deal to me to hear from all of you. I have a meeting with a pain specialist on Friday, and hopefully I will be able to get past this soon! In the meantime, I have been working away on what has been the biggest challenge for me so far, the stern. I plan to make a number of posts on this, starting today with an overview of the end goal; what will it look like? I have always aimed to base my model on the original design and the first model, shown here: Although this model shows mainly the framing system, it does have a hint of what the original design intended on the stern at least down to the bottom of the captain's balcony. Everything past this is speculation for a reconstruction! The second model, made twenty years later after a major refit of the ship itself, shows much more detail (see below). At first glance, this provides information on all of the detail not shown in the first model. But the second model changed the original design in ways I did not find pleasing. It added an ugly railing above the roundhouse (nice for the sailors, bad for the aesthetics). The balcony railing makes a sharp turn into the stern one bay inboard on each side, whereas the original model has a nice sweeping serpentine curve across the entire stern. The original model has nicely proportioned vertical supports (painted red) with nicely detailed fretwork, whereas the second model skinnies those down and punches crude holes for detail. The first model carries additional carving down to the bottom of the railing adjacent to the large corner post carvings of women, linking things together visually. The second model unsatisfyingly smashes the balcony into the corner sculpture. And in terms of color, the second model uses white for the balcony fretwork and the pilasters on the band of windows, which I find visually jarring relative to the rest of the ship. There are a few other examples of white windows, pilasters and fretwork on other roughly contemporary ships, most notably the Princess Royal in the Annapolis museum; but not many either in models or paintings of the period. This is not typical, in other words. I suspect this was the modeler's effort to give visual "punch" to his model, not a reflection of common practice in the actual ships. I suspect the Princess Royal model has white details like the Bellona second model because it was built by the same modeler; the friezes on both ships are identical in painting style and technique, and the models were likely built at the same time. It may be two different modelers used the same frieze painter, but given the rarity of this look in most other ships, I think we are seeing the personal signature of a modeler here. I would be very interested to hear if others have another view of this. So, how can I reconstruct the original model, from the incomplete information in the original model? Here, for better or worse, is my first shot at a reconstruction (see below). I reproduced the balcony geometry, the carvings, and the wider balcony vertical supports with the more elaborate fretwork. I picked up the little bust carvings below the balcony from another contemporary ship. I accepted the pilaster design from the second Bellona model, although in the spirit of visual harmony I continued the red down from the balcony into the boards behind the pilasters. In the same spirit of visual harmony, I propose to keep the pilasters and the window frames natural wood, along with the carvings and mouldings. The second model friezes and paintwork on the upper and lower counters are really quite delightful (just like on the Princess Royal). So why not use them, with no other sources to draw upon for this? I propose to reproduce those paintings in my model, including the tone and hue of the background blue paint. I would be very interested to hear any opinions as to whether I am on the right track on this reconstruction. Next posting will discuss the very complex geometry in this stern, and my efforts to bring it under control for construction. While I am working on that, I am also working with Chuck of Syren models, who is going to laser cut the window frames and balcony fretwork for me, using my drawing templates. I had long wanted to make everything on this model myself, but I finally had to face the reality that I did not have the skill to make window frames just .023" thick, or even worse, the pierced fretwork. And after a long and fascinating chat with Chuck at the Admiralty Models workshop on carving in Annapolis in October, I came to see that this is just using another tool to achieve my modeling needs, still based on my drawing. Thank you Chuck! By the way, Chuck also pointed out to me that the very fine details like window frames were made of ivory in original models, because it could hold the detail better than even boxwood. Most models seem to have colored this; the second Bellona model builder maybe put up the freshly cut window or fretwork and thought, "looks good as is!" Best wishes, Mark

-

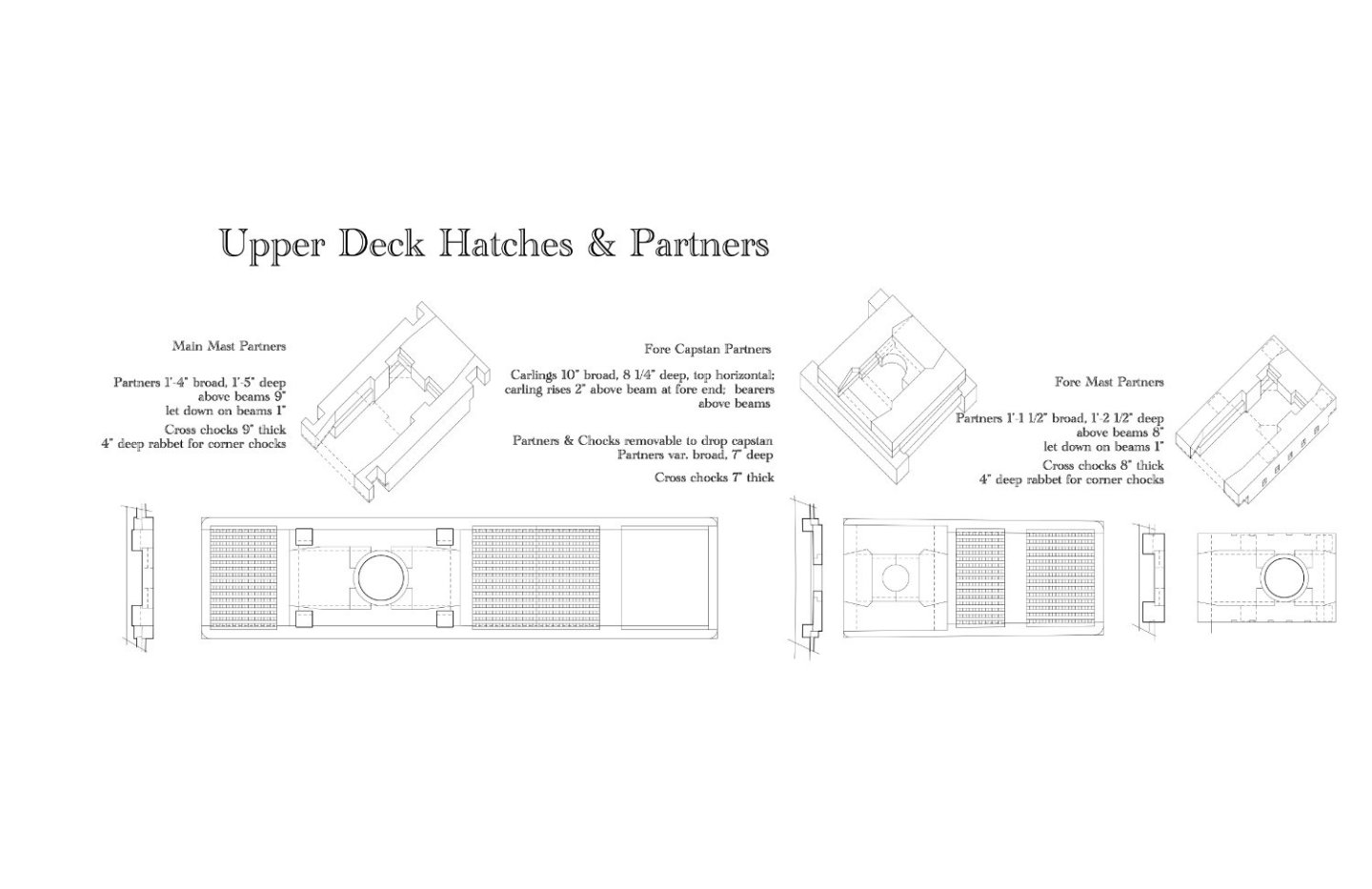

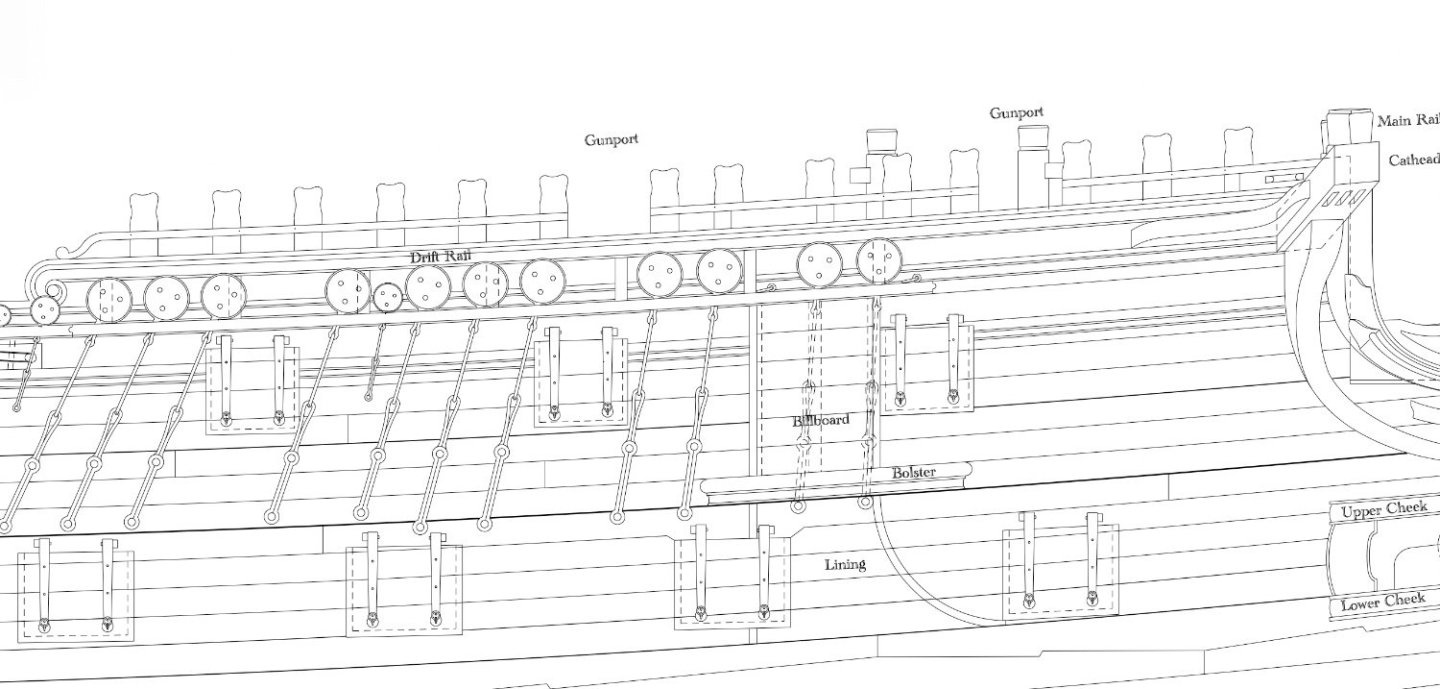

Pirate Adam, Dave, Druxey, JD and Amalio, thanks so much for your kind welcoming back comments. This really is a genuine community. JD, I did work for several months at my computer with it propped up on a stool on my desk. Unfortunately, my shop work surfaces are not moveable, and so I work for a bit, lie down a bit, then work again. More doctor visits coming up, hopefully we can get this finally resolved. Amalio, I have so far drawn the Bellona for my own modeling purposes, and also because I like to draw. I am not sure they are in a state where I could reliably say they are complete and consistent. I am also not sure what copyright issues would be involved in selling these, since they are derived from prints of the original Admiralty draughts I obtained from the National Maritime Museum many years ago. And I don't want to get into running a business now I am retired. But I do want to share, where appropriate, back to this community that has helped me so much over the years to develop many of the details I have now incorporated. Here are a few more examples, first, the stern framing I am now working on in the actual model. A note of interest is that I found it necessary to suggest a false floor in the quarter gallery of the upper deck (the lower of the two). If the floor of the gallery were down on top of the lower finishing, it would be a long step down from the door cut in the bulwarks, as measured on the original plans. I imagine it would be a continuation of the upper deck in height and roundup. This is an interesting case of where they needed to resolve the different sheers of the outer bulwarks and the inner decks at this point. Further below, I am showing some of the hatches and partners on the upper deck I will be building at some time in the future. Interesting construction issues in these! Best wishes, Mark

-

HI everyone, I have not posted in many months, and want to catch up now. In anticipation of carving the figurehead, I attended the excellent workshop on carving run by David Antscherl and Greg Herbert in Annapolis in early October. Fired up with my newly acquired skills, I flew back home to Montana ready to carve, only to discover that I had pinched the sciatica nerve in my leg on the flight. I was unable to sit at all for several months, taking me entirely out of the workshop. After several months of physical therapy, I am finally able to get into the shop again in small bursts of activity. During that down time, I put my computer on a stool at my desk so I could work on CAD drawings standing up. I was able to draw many more of the details still to come. I will show some of those in some following posts. Here is a taste: The unexpected and enforced downtime due to medical issues caused me to realize that I have to get my skates on and work more aggressively towards completion. I may not have the luxury of working for many more years at the same leisurely pace. At the Annapolis workshop, Chuck Passaro discussed with me a number of ideas for tackling the most challenging pieces that were putting me into a tizzy, like the frieze paintings and the fretwork stern decoration, and I am beginning to pursue some of these ideas with him further. Thanks, Chuck, huge help! I am starting with the stern, and here is a sample of what I will discuss in a later posting. The time off from cutting wood also gave me time to think more carefully about the decorative scheme I will want to follow as I get to this level of detail. I decided at the very beginning that I wanted to show the Bellona as originally designed and built, based on the original Admiralty drawings and on the first Bellona model of 1760 that shows her mainly in frame with little decorative detail other than the taffrail down to the floor of the stern balcony, with no quarter galleries. I did NOT want to portray her as she looked after a major refit 20 years later and shown in the second, fully detailed and colored Bellona model with the coppered bottom. Not only did the latter model show the later structural changes like the changed balcony geometry and the railings along the roundhouse that I do not like, but its overall decorative scheme felt like it was more extravagantly Rococo and showy than the real ship would have looked several decades earlier (like ivory details sprinkled around, and exuberant carvings). So I have been looking at other models contemporaneous with the first Bellona, like the Princess Royal and the first Victory, both designed by the Bellona's shipwright, Sir Thomas Slade. In some later postings, I will explore this further, as it might be of interest for others who are attempting to reconstruct a decorative scheme from indirect sources. So anyway, back into the land of the living! More posts to follow as I am able to put them together. Best wishes, Mark

-

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

SJSoane reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

SJSoane reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

SJSoane reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

-

SJSoane reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

SJSoane reacted to a post in a topic:

Soleil Royal by Hubac's Historian - Heller - An Extensive Modification and Partial Scratch-Build

-

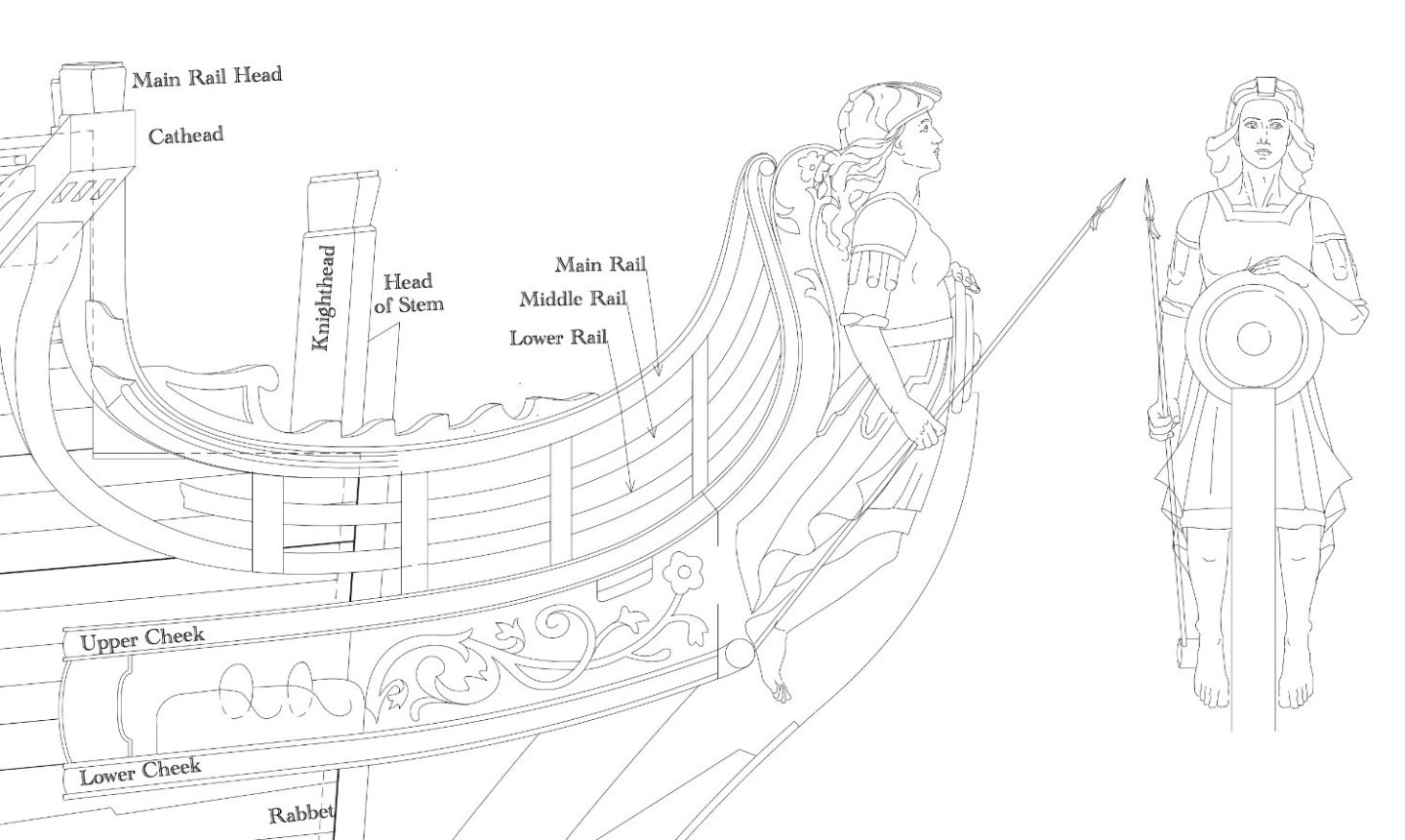

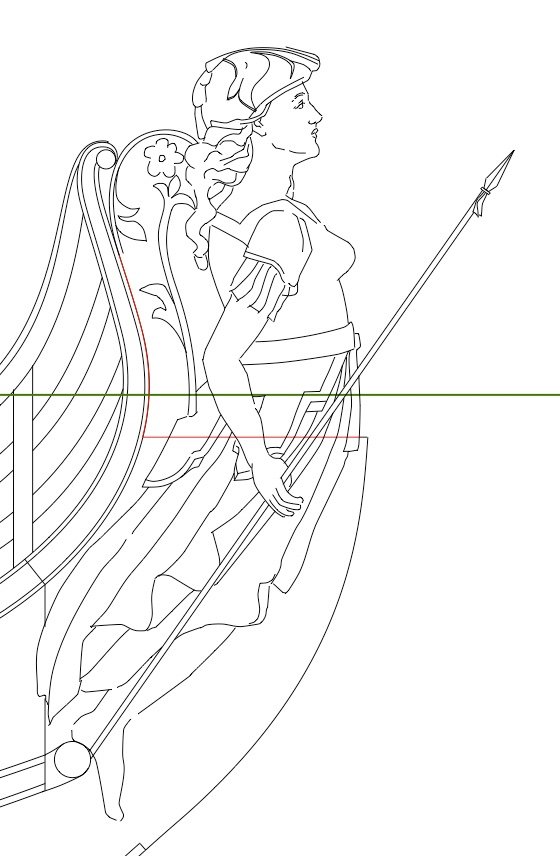

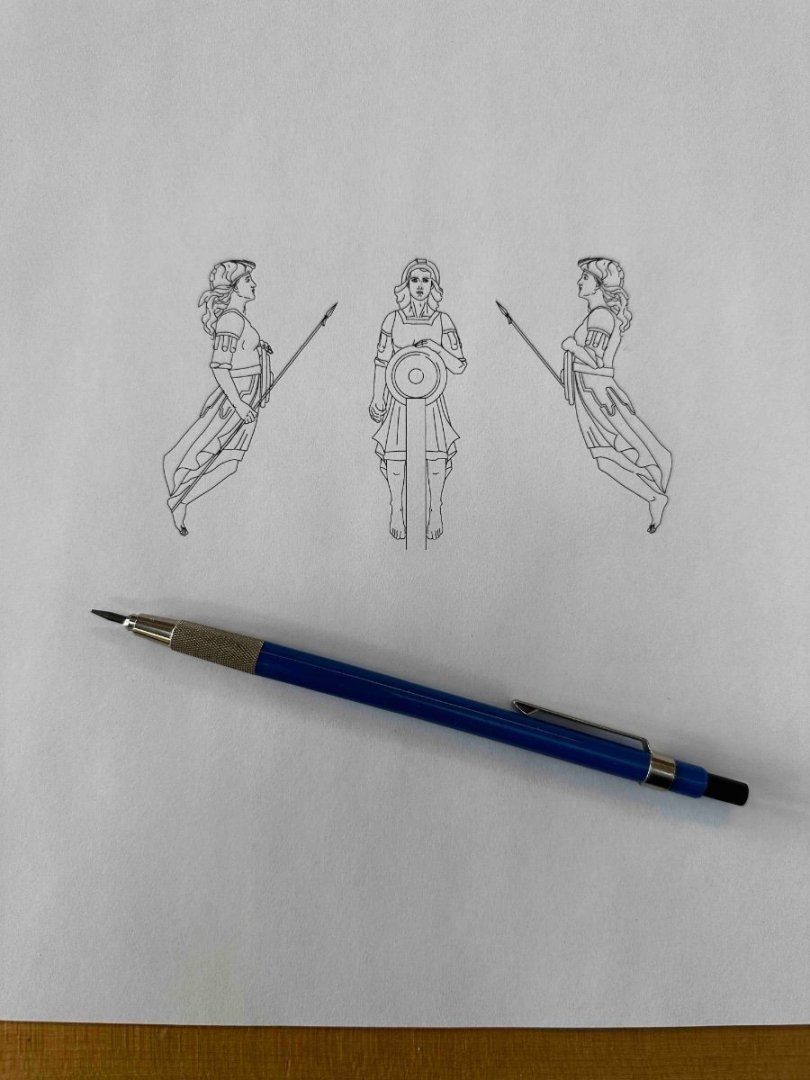

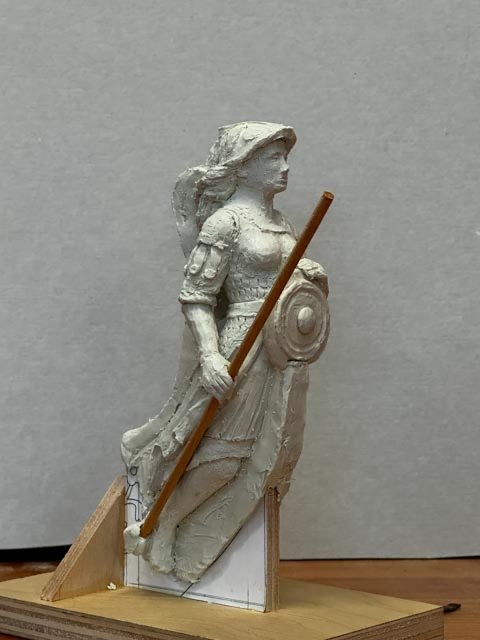

Thanks so much, Mark. I thought I would share my working process thoughts regarding the carving of the figurehead, for everyone including me who is daunted by the thought of this. After completing the double size maquette, I was ready to start carving. Then I realized that my original drawing of Bellona was a tracing over a photo of the Bellona figurehead on the first model. This is the one I discovered was much out of proportion, and with arms and hands that I kind of guessed at. This would not be a good drawing to work from on the actual wood. I knew I would have to redraw Bellona in light of what I learned in the maquette, to have a more accurate starting point for the carving. Here is the original drawing: Once I had a maquette, I took pictures of it, and then scanned these into my CAD drawing. This provided a better foundation for tracing a more accurate Bellona. Here is a photo of the maquette: And here is the revised drawing based on this. Comparing the two look in particular at the location of: the head (further back on neck; shoulder (further back on body), breast (lower and reshaped), width at waist and derriere (narrower, lower), arm location and proportion (hanging straighter, shorter lower arm), and the hand and feet. I struggled with drawing the hands and feet, until I hit on scanning images of hands and feet into CAD and tracing them. I took photos of my own hands, and found photos of feet online. Also notice in this drawing a new trailboard. This is many, many thanks to druxey, who drew this for me based on typical designs of the period. I know he has studied many models and drawings of this period, and he has provided me with an historically more accurate idea than I would have been able to do on my own. It was exceedingly kind of him to take the time to do this, and my model of the Bellona will benefit not only from his historical knowledge, but also his artistic eye. It is an honor to have this contribution from one of the key experts on this website. Thanks, druxey! Next step, starting to come to grips with laying out the wood blank. Here is the size of the figurehead I will be attempting: All for now, Mark

-

SJSoane reacted to a post in a topic:

74-gun ship by Gaetan Bordeleau - 1:24

SJSoane reacted to a post in a topic:

74-gun ship by Gaetan Bordeleau - 1:24

-

SJSoane reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

SJSoane reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

SJSoane reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

SJSoane reacted to a post in a topic:

HMS PEGASUS by giampieroricci - Scale 1:36 - Swan-Class Sloop from plans by David Antscherl & Greg Herbert

-

Thanks, Greg, I have been dreading it. Of course, I haven't yet tackled actually carving wood, which I am sure is a very different level of skill altogether in relation to shaping clay. I tried to keep track of the number of times I had to add clay to the form--lots of times--which of course I won't be able to do once I start cutting wood. It will be cut, cut, cut and it is still too short!

-

Thanks so much, Jason. This is my very first effort at sculpting the human form. The artist guides to human proportions helped enormously, then looking at examples of details like folds in clothing from other eighteenth century carvings. Yves, the Bellona has 28 guns on the gundeck, 28 on the upper deck, 14 on the quarterdeck, and 4 on the forecastle. At the time the Bellona was first launched in 1760, which is what I am trying to reproduce, there were no carronades. The four on the forecastle were long range nine pounders. They peek through short interruptions in the forecastle railing. I have labeled them below.

-

I just finished a clay maquette of the Bellona figurehead, at double scale, or 3/8" =1'-0". Here is a filler showing location and fit with the cheeks: Then taking the advice of David Antscherl's Fully Framed Models tutorial on carving, I used an artist's guide to dimensions of the female figure to get the right proportions of things, and initially modeled Bellona with no clothes yet: It is a good thing I did this, because I discovered that the original figurehead on the first Bellona model had lower legs way too short for the torso, minuscule feet, and a head pushed too far forward from the neck. To me, she also looks too cherubic to be the goddess of war: Since I had to add arms anyway, I looked at other artistic renderings of Bellona for a fiercer, more war-like look. I found a haunting image by Bertrand MacKennal of a sculpture in the Australian War Memorial https://es.m.wikipedia.org/wiki/Archivo:Mackennal_-_War.jpg. Mine is not as haunting, but as good as I can do, first go around: Next, reducing this by one half, and doing another maquette. I might try to do it in Sculpey so I can take measurements from it for the wood carving version after it is hardened. Does anyone know if Sculpey shrinks when baked in an oven? Mark

-

Thank, JD, Grant and Gaetan, I have looked into microscopes (pun intended), after your suggestions to kit up. It is a world entirely unknown to me (somehow, I managed to get through all my school including college with never taking a life science class, only physics; so I have never even looked through a microscope). I need a little more information about what I am actually looking for. Reading some back issues of the Nautical Research Journal, I came across several articles by William Sproul who discussed his microscope, an old Bausch and Lomb Stereozoom 3 or 4 with a 10X eyepiece. If I have this right--and please correct me if I don't--you need a stereo microscope to enable your depth perception. Not all microscopes are stereo? And you need one with enough working depth under the microscope to allow the workpiece and the tools. He says he works at 7X to 10X most of the time. My Optivisor #5 is 2X, so that would make a big difference. Is the 7X to 10X range for the eyepiece what determines how much working depth there is under the microscope? Since my vise is sitting out in front of my bench, I imagine I need a boom stand. Or are you all using another way to fasten the work down underneath the microscope? I thank you all in advance for help on looking for a microscope! Gaetan, my dentist once showed me her dental loupe, which must have been a chirurgical magnifying glass. It sits in front of her glasses. Do you have suggestions about which ones would work for model making, and is the main requirement that it has a working distance of 10-20 inches? The ones I see online only seem to go up to 3.5X. Best wishes, Mark

-

Hi JD, I am using an Optivisor with a 5 lenses. It is definitely pushing my limits. As I get closer to what I think is finished, I take macro photos with my iPhone to see more detail than I can see with my eyes alone. then I clean up some more. I probably should start looking into a microscope as I start ramping up the carving part of this project. What do you use? Best wishes, Mark

-

I finally made my first foray into miniature carving. I started with the lion heads on the outboard ends of the cat beams. 7.85 mm or 5/8 inch square, so tiny enough to keep me focused! I used my Russian chisels for the first time. They are as wonderful as everyone says. Super sharp, well balanced, controllable cuts. I glued 3000 grit paper to a hardwood block for sharpening. I have been able to sharpen freehand with success, using the fore and middle fingers to hold the chisel at the right angle to the block, and the fore finger to press slightly down on the cutting edge. It brings back the super sharp edge in only a few strokes. And it does have to be touched up regularly, like every 8-10 cuts. I haven't had to do the gouges yet. That looks more challenging, especially the .5 mm one. At first, I took chisels out and put them on my desk when switching to another chisel. I quickly found out that this does not work. First, they were all to easily starting to roll towards the front edge of my bench when I wasn't looking. Second, the cutting edges are so tiny that I would have to pick up each on on my bench to look very carefully to find the right one. I decided it was a better idea to keep them in their box whenever not in use. To facilitate finding them, I made a small chart and double sided taped it to the back of the box. Now it is very easy to find a chisel right away, and put it back safely between uses. I held these in my GRS vise. Its ability to pivot really helps get at the wood from the right direction. Since this vise mounts on the edge of the bench, I pulled out my sliding platform beneath the bench (that usually holds my cutting board), and built a small platform to sit on top the platform and around the wood block to be cut. This gives me something to rest my hands on as I try to control these very fine cuts. Gosh, a three dimensional figurehead doesn't look so scary after this!😏

-

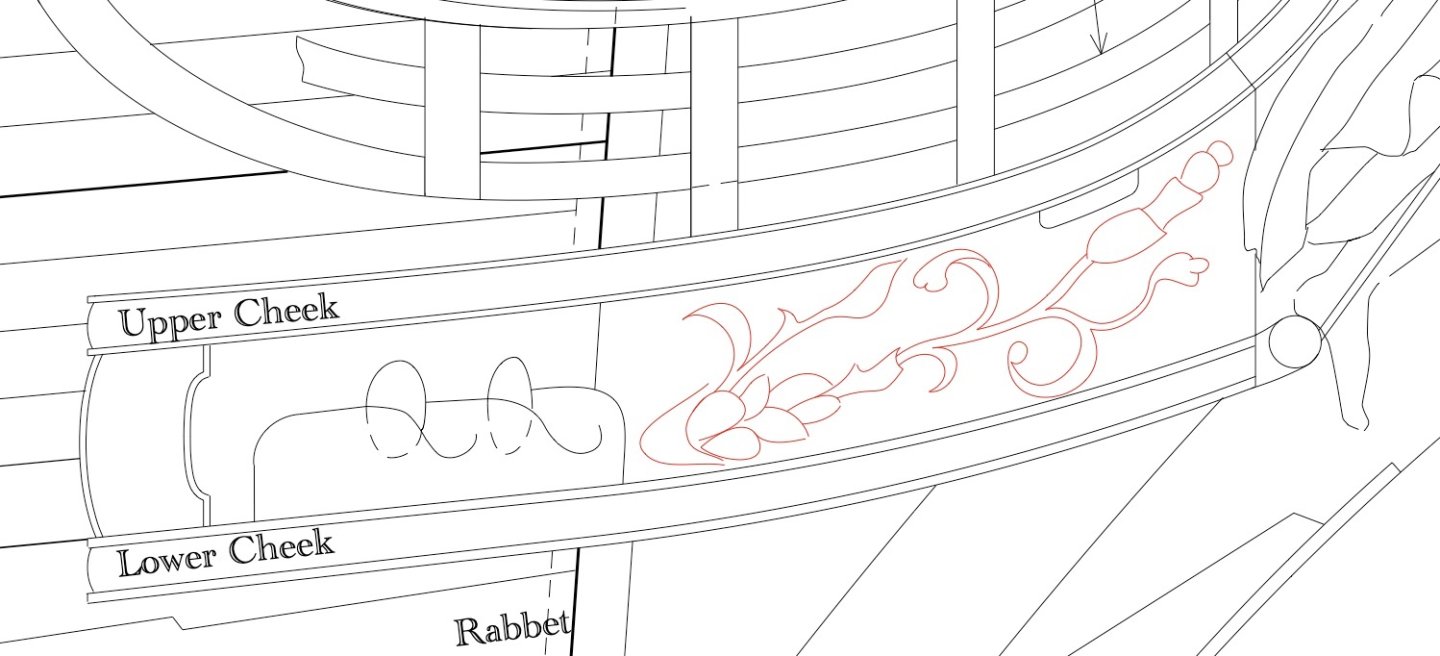

A small update on the traiboard question. In posting 2286 above, I showed the two different trailboards for the two different Bellona models. I wanted to follow the first model because it is closer to the original design (since it predates the second model by 20 years or so), but the only photo I have is frustratingly out of focus. I also looks like it lost parts in the center, and I could not imagine how to recreate the original design. Then I saw the trailboard for a contemporary ship, HMS Hercules or Thunderer, launched just one year before the Bellona, in 1759. This shows a floral scroll: So I traced what I could see of the remaining Bellona pieces, and speculated on how it might have been filled in in the spirit of the Hercules design. Too far down the road of speculation? At least it would be easier to make than the second Bellona model design, with its super thin spears, the George III cypher, etc.

-

Hi Noel, Others more experience than I may have a better answer, but so far, I have used this trick for temporarily holding other parts together (for example, to shape a port and starboard piece at the same time for perfect symmetry), and I have had no problems with distorting or discoloring the wood. Using 99% isopropyl means it is mostly alcohol, and it dries quickly when the piece is removed from the bath. My biggest mistake was using too much glue. Only a tiny drop or two will temporarily hold parts together, and this is much faster to release than a full coating of glue. Indeed, I have given up trying to separate pieces that were glued too thoroughly together. Best wishes, Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.