-

Posts

2,694 -

Joined

-

Last visited

About Gregory

- Birthday 01/15/1949

Profile Information

-

Gender

Male

-

Location

: Just past ' Resume Speed '

-

Canute reacted to a post in a topic:

Micro-Mark Desktop Dust Collection System

Canute reacted to a post in a topic:

Micro-Mark Desktop Dust Collection System

-

Gregory reacted to a post in a topic:

Cutty Sark by VitusBering - Revell - 1:96 - PLASTIC - Redux

Gregory reacted to a post in a topic:

Cutty Sark by VitusBering - Revell - 1:96 - PLASTIC - Redux

-

Gregory reacted to a post in a topic:

Micro-Mark Desktop Dust Collection System

Gregory reacted to a post in a topic:

Micro-Mark Desktop Dust Collection System

-

Gregory started following Need help with HMS Beagle bowsprit , Planking before or after transom install , Micro-Mark Desktop Dust Collection System and 7 others

-

Gregory reacted to a post in a topic:

18th Century Longboat 1750-1760 by davec - Model Shipways - 1/48

Gregory reacted to a post in a topic:

18th Century Longboat 1750-1760 by davec - Model Shipways - 1/48

-

Micro-Mark Desktop Dust Collection System

Gregory replied to eurekapaul's topic in Modeling tools and Workshop Equipment

Steve, I use a small USB fan for that purpose. The dust settles in a corner of my shop, and I vacuum it up. l was a little put off by the price of the MicroMark device, but really couldn’t comment from experience. Your information is very useful. -

Gregory reacted to a post in a topic:

Micro-Mark Desktop Dust Collection System

Gregory reacted to a post in a topic:

Micro-Mark Desktop Dust Collection System

-

Gregory reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

Gregory reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

Scottish Guy reacted to a post in a topic:

1:35 Viking Knarr - Dusek Ship Kits

Scottish Guy reacted to a post in a topic:

1:35 Viking Knarr - Dusek Ship Kits

-

Gregory reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

Gregory reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

-

Gregory reacted to a post in a topic:

San Juan by SighingDutchman (Seb) - OcCre - 1:70 - felucca

Gregory reacted to a post in a topic:

San Juan by SighingDutchman (Seb) - OcCre - 1:70 - felucca

-

Thukydides reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

Thukydides reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

-

Thukydides reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

Thukydides reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

-

Gregory reacted to a post in a topic:

Lady Nelson by mmotherw - Amati/Victory Models - Scale 1:64

Gregory reacted to a post in a topic:

Lady Nelson by mmotherw - Amati/Victory Models - Scale 1:64

-

Gregory reacted to a post in a topic:

Rattlesnake by CapnJack43 - Model Shipways - 1/64 - American Privateer

Gregory reacted to a post in a topic:

Rattlesnake by CapnJack43 - Model Shipways - 1/64 - American Privateer

-

Gregory reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

Gregory reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

-

Good work on the edge bending. It looks like the planks are laying flat on the bulkheads. are you foregoing tapering the planks at the bow for a reason? It’s not so important with the first layer, but will make a big difference with the 2nd layer..

- 8 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Scottish Guy reacted to a post in a topic:

Type of glue to use planking a hull

Scottish Guy reacted to a post in a topic:

Type of glue to use planking a hull

-

Scottish Guy reacted to a post in a topic:

Type of glue to use planking a hull

Scottish Guy reacted to a post in a topic:

Type of glue to use planking a hull

-

mtaylor reacted to a post in a topic:

11th century viking crew and freight in 1:25

mtaylor reacted to a post in a topic:

11th century viking crew and freight in 1:25

-

Canute reacted to a post in a topic:

semi-gloss varnish on veneer wooden deck choice?

Canute reacted to a post in a topic:

semi-gloss varnish on veneer wooden deck choice?

-

Scottish Guy reacted to a post in a topic:

11th century viking crew and freight in 1:25

Scottish Guy reacted to a post in a topic:

11th century viking crew and freight in 1:25

-

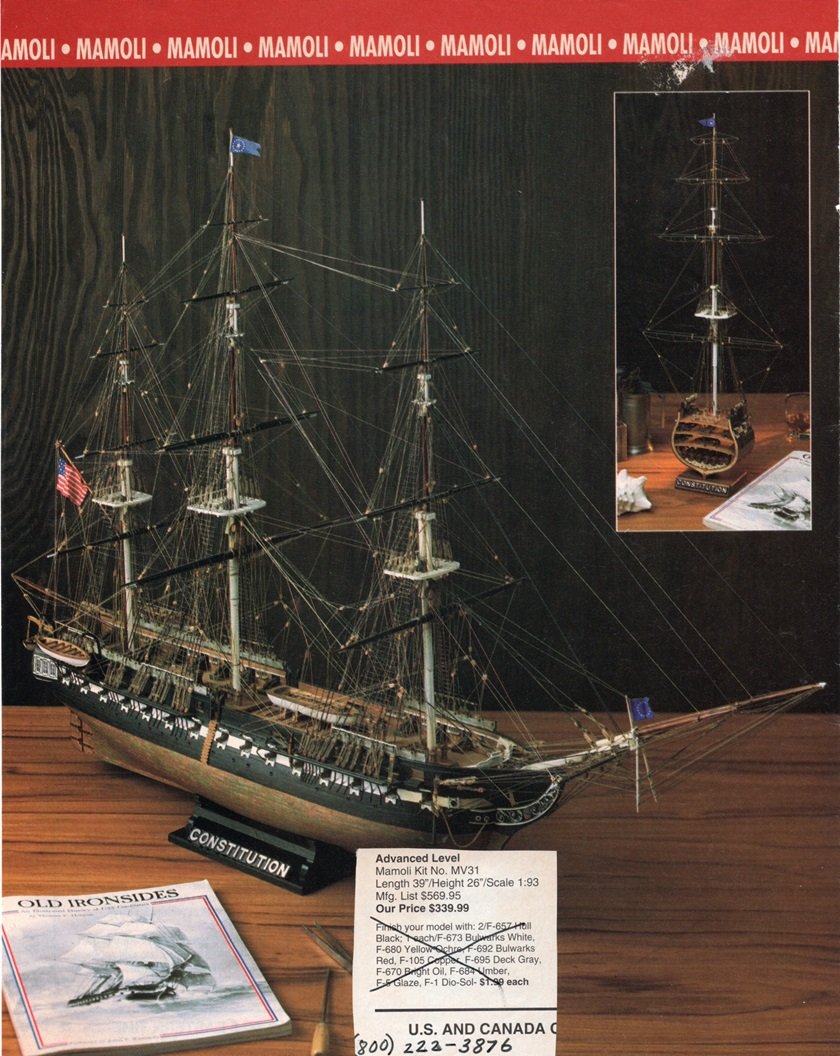

The Mamoli kit had little competition when it was released. Mamoli had a lot of the best kits available at the time . Check some of the drawings for a date. I would like to remember, because I had that kit back in the early 90's, but sold it because life got in the way. I believe the drawings are very good, but the kit itself may have it's detractors these days because kit quality in some areas has come a long way with laser cut parts and such. My recollection is that the Mamoli kits really have everything you need in the box to build it to match the drawings. That has been my experience with a few other Mamoli kits I have built. If I were going to go outside the box, I would consider a different coppering scheme than the little green wood chips they provide, other than that, I would be happy to build it as is. I look forward to following your progress.

-

Unfortunately, that color chart on the box is as good as it gets. There is such a wide variation in wood color, a third party chart will not be any better. If you are trying to identify the wood within the box, the amounts provided my be your best help to match it to the box chart. In this case the lighter wood should definitely be the maple.

-

A lot of builders put a layer of painters tape on stem etc.. It can save a lot of grief..

- 8 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

What’s great about MSW is we have a lot of logs and experienced builders here to help you with these ‘flawed’ kits.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.